Leaderboard

Popular Content

Showing content with the highest reputation on 03/16/22 in all areas

-

A list of watches to avoid? I suppose it all depends on *what* aspect you're trying to avoid. I could offer my two cents here, but that's all it is, so have your grain of salt ready. As quality goes, I'd certainly avoid any of the cheap "replica" watches (i.e. fake). The Chinese movements they tend to have in them are often unreliable and very fragile; some have no markings anywhere on the movement and that makes finding replacement parts extremely difficult. As ease of maintenance goes, I've heard and seen that the antique "dollar watches" are not for beginners, to say the least. Certain aspects of their construction can make them difficult to work upon until you get used to them. But there are many who collect them, and have learned how best to maintain them. I can no longer say that I would avoid Timex though. They are a bit different, even quirky, what with the mechanical ones being mostly pin levers. But they are simple and plenty of parts are available, and they have much to teach. I've seen some brilliant innovation in some of them. If you want experience with pin levers but you don't want to worry about scarce parts, putter about on an old Timex. This last bit I'd reserve for beginners. If you're looking for a watch to practice with, or one to own but also maintain yourself, I would avoid "complications". In other words, mechanical watches with a lot of extra functions, sub dials with calendars, alarms, etc. If, on the other hand, you have that level of experience or are not easily intimidated, no reason not to get one. But I'm prepared to admit, I was privileged to work on an antique minute repeater recently, and I was apprehensive to the point of questioning my self-worth. I was filling my phone up with pictures of the works. I was giving myself headaches trying to keep track of exactly how each part of the chiming train interacted. I got it sorted in the end, and with great care and a little trial and error, and I learned loads about them, but I do hope it will be a long while before I ever have to work on another repeater. I need to catch my breath after something like that. I think, really, one should mostly consider one's preference. What do you value in a watch? What do you do with them? When you look for a watch, what are you hoping to find? If you can answer those questions, we can point at the watches that meet those elements.3 points

-

2 points

-

KvK nailed it. Depends on what it is you're trying to avoid. There's an ass for every seat. I tend to avoid Japanese movements because they're typically very plainly finished, and I like the French/Swiss flair. I avoid Russian watches, because they're almost universally in plated cases. I also avoid anything with less than 15 jewels because it's more likely to have wear requiring the sourcing of parts that no one cared enough about to hold onto. Finally, I avoid anything too expensive (the current bar is $5). This is because I'm not trying to impress anyone (and trust me, it's working), I'm still learning, and this is not a job for me, it's a hobby. It's meant to be fun and relaxing. If my 2 year old runs in and bumps my elbow, and I manage to break something or cast it into the aether, it's not fun for anyone. If it's barely a fancy coffee to me, who cares? It goes into the parts pail, and I move on.2 points

-

You want it easy? Bring work chest high. Rest forearm on the bench. Grab the hand near to the tube, at an agle. Look where you place it, going down from the above. With the mov.t running it will be in place, and start moving as soon the pinion is in the tube. Press down with the tip of the tweezers. People which is able can get away skipping one or more of these details. But a beginner can't afford to not go by the book.2 points

-

Threads are bit of a can of worms. The old Martin threads, the most common screwplates, are by and large pretty close to modern metric threads. But the U.S. companies generally had their own threads- each company had its own threads.2 points

-

My mentor conducts watch repair classes using Seagull movements. Somehow, he seems to have an endless supply of all the parts students are likely to damage/lose, like hairsprings, balance wheels, pallet forks, shock springs, click springs, etc. I'll ask him where he gets his supply from.2 points

-

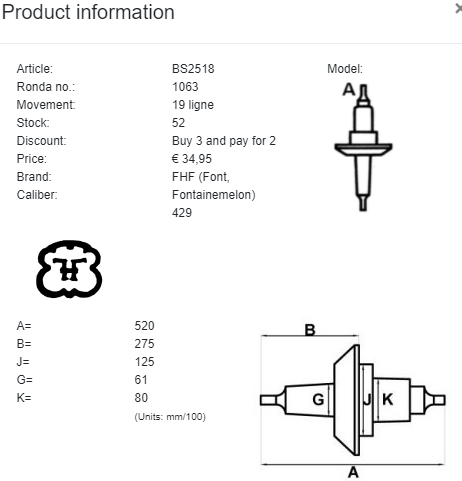

I still have not abandoned hope to restore this beauty and continued my search. Based on what I was able to look up for balance staff measurements (1063?) , it looks like the only fitting movement is FHF429, which would be in line with the earlier idea from Randy55. The bridges look very similar. Does anyone have any information on the 429 caliber? I am awaiting deliver of the staff now, but the roller is cracked, so I need to source that as well.1 point

-

Yes not bad I take it its a runner It has the magic finger drive on the auto wind quite ingenious.1 point

-

The whole TZ article on the motion works is worth a read*: https://www.timezone.com/2002/09/16/the-motion-works/ (* anything by Walt Odets is worth a read)1 point

-

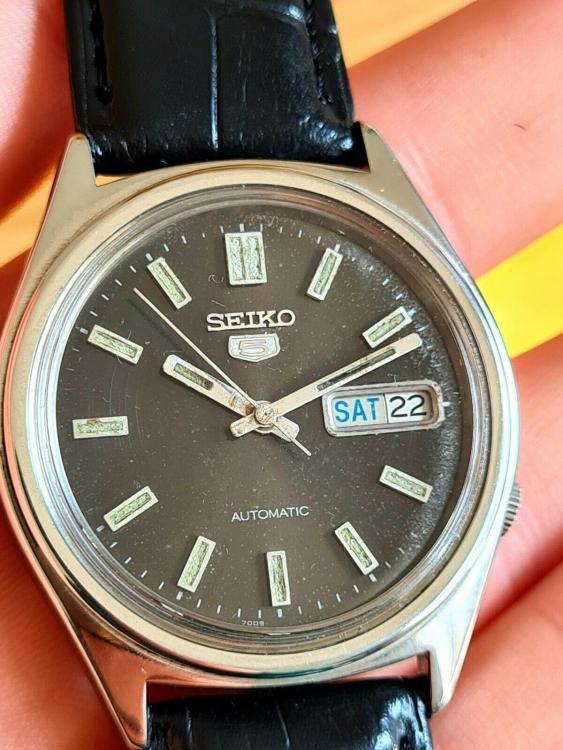

7009 automatic sound workhorse movements clean and tidy. Tech sheet attached, this is what it looks like with no clothes on cheers 277_Seiko7009A (6).pdf1 point

-

Fashion watches are just that nice to look at but many have dissapointing movements but others may not be too bad. Ideally get to open them up and have alook. or get a picture on the movement. Spectre6000 has it right. cheers1 point

-

1 point

-

Thanks guys I have learned today that I should probably avoid watches made by fashion houses.1 point

-

I think the tie has come to establish a few facts, So the problem still exist where the hand setting involves the gear train. So lets go back to basics, remove the balance, fork and gear train then with the center wheel with canon pinion fitted hour wheel and min wheel. Now when tried does it still act the same way with just the minimum of components fitted. when pulled out to the set position the clutch moves and disengeges the wind and engages the handset,which is now still hard to turn (CW) if so remove hour wheel and canon pinion and try now, turns ok /still stiff if ok the canon pinion is too tight if still stiff the problem lies elsewhere. If the canon pinion is too tight it will need broaching to free it off somewhat, (jdm has just come back with the same answer mid post) so for now we will leave it there and await further developments.1 point

-

I trust all is well all thanks to watchweasol. My sister has been with me all day so not able to spend much time on my PC . She has gone home now.1 point

-

Not strange. OP wrote I can't actually set the time because I'm limited to moving at whatever rate/direction the escapement lets me. If we replace 'direction' with 'clockwise' that describes perfectly what an hard stuck cannon pinion causes. Then, we know that on a mov.t that doesn't hack, setting time counterclockwise is not recommended, but personally I still have to see escapement damage caused by that.1 point

-

The warning wheel next to the fly should be in the position around 10 o'clock, if it is in the correct position no hammers lift when the warning has been triggered.1 point

-

The warning wheel is being arrested by the auto correct cam not the locking lever. The warning wheel should be arrested by the lever when the lever drops into the slot. when locked the pin should be resting on the face of the lever in the approx 12 Oc position1 point

-

Thats the chime warning wheel, when the strike is initiated the warning lever releases the wheel 1/4 to 1/2 a turn wherei it is arrested by the locking lever and released at the chime point. the cam turns during the strike depending on the profile and is locked again when the lever drops in to the slot, at this position the warning wheel is arrested again to await its next release. Books Laurie Penman The clock repairers Hand book Mike Watters The Clock repairers Manual1 point

-

While it seems very Logical and I would agree with that there is a minor problem? We really need access to Omega current documentation but that can be problematic. Cousins has a slightly newer parts list and sometimes somebody will handwrite notes on these So I have snipped out a image out of the PDF. Looks like logic flies out the window and metal is preferred? At least for one of the parts The problem with the watch companies are they make revisions and then there can be revision documents but trying to get newer documentation especially out of Omega can be very not easy at all. Even if you have Swatch group access you might not have the right level of access and getting technical documentation then can be impossible. That means we get stuck working with older documentation. You might bill find a clue from the parts list below but they're probably still working with all documentation also may be perhaps http://cgi.julesborel.com/cgi-bin/matcgi2?ref=OME_1022 214_Omega1010,1011,1012,1020,1021,1022NEWS-1 cousins.pdf1 point

-

I suppose the confusion has to do with trying to figure out the standards? Darn somebody beat me to the answer? Yes everyone assumes their standards for screws sizes used in everything on the planet. But all the American watch companies had their own sizes. I think only Elgin and Waltham ever published their sizes everyone else it's a mystery. It's why you can have a whole bunch of boxes of screws and try to replace one find that none of them will fit.1 point

-

Just google collectable watches. Hard to tell genuine apart from fake if you have never seen a genuine piece and don't have a image of whats inside, though there are so many makes of caliber 7750 that some non-genuine ones have as good of quality as genuines. As said show pix here for help, thats what I do. Regs1 point

-

Looking at your last picture of the canon pinion there is a dent in the tube this is for it to friction fit on to the center shaft from whence it gets its drive. Too little friction means no hand drive or loose hands too much friction makes the hand setting very stiff. so when adjusting the canon pinon you have to reach the happy mediun between hand setting and hand drive. What I meant regarding the free running is the t the center post is rivited to the plate and the canon slips over the post being driven by another wheel/pinion, not free to rotate loosely as that would be totaly useless.and impractical.1 point

-

I need to see all of that cam can you photo the other side of it and does it screw onto the wheel or is it just friction tight. Do not move try to move E as that is in line with the pin. Do you know if this movement puts it self right with the chimes if they are out of line with the hands?1 point

-

1 point

-

A good start is to read https://watchguy.co.uk/a-new-era/ and https://watchguy.co.uk/cnc-update/ Then search online for one of the hundreds of machines: 3 or 4 axes, kit or assembled, working material. I started with a 3-axes Chinese kit (eBay) intended for work on plastics, aluminium and brass. Then swapped the motor for a pre-owned 15,000 rpm 36V servo motor (also eBay - rip out the control gear and just use as drive for the milling tool). Then some home-made setting up accessories. Total expenditure was $450. For that I have 0.1mm precision and can cut small parts in steel, brass or CuBe. Another cost is the fairly large number of Kyocera end mills. Grblcontrol and Carbide Create software for an easy life, plus gcode from Christian.1 point

-

Oddly enough, I had the same with an ETA 28xx one time. I think it was a relatively high beat model. What came off the pallets and escape wheel was pitch black and I was inclined to believe it was actually worn steel from the escape wheel.1 point

-

Is that your first screw? That looks great! Looks like you tapped with a screwplate, Martin L? The thread pitch will be different to Elgin, but doesn't mean it won't work. Work it in with a little oil. Which reminds me, how do mathematicians deal with constipation? They work it out with a pencil.1 point

-

A sad tale indeed, but there is still hope! If you post good-quality close-ups of the back, from above and from the side, together with some measurements (glass diameter and thickness) I expect we can help. You will not find any spares from the manufacturer, but I expect the glass will be a simple standardised form and size, and fitting a new one should not be too difficult.1 point

-

You can get a used king Seiko for that kinda money, its got a Chronograde movement and some are officially certified or a used Universal, perhaps even a JLC.1 point

-

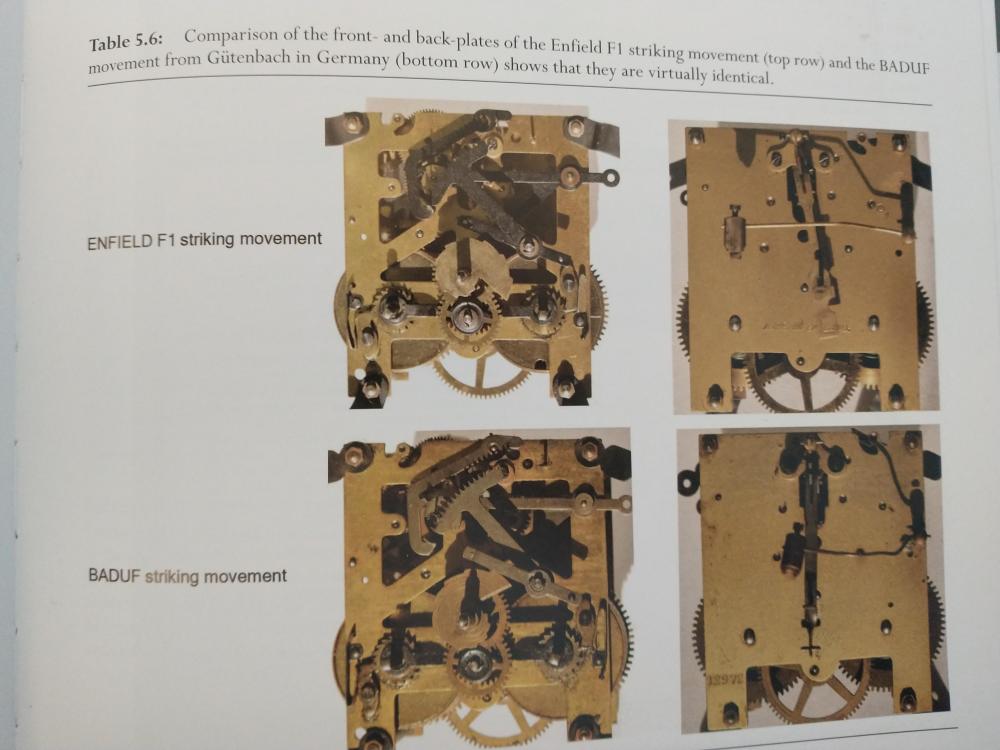

Hi all i know from the book is Enfield purchased the German production line for the BADUF striking clock and installed it at Edmonton. The clocks produced were sold as the Enfield 14-day striking clock and were the F1 one model. As you can see in the photo they are near enough identical. This time oldhippy i did post the photo1 point

-

1 point

-

Hi Dmitry, I feel your pain, my friend. In 2020 I found two Services Despatch Riders, both with complete movements and bought from eBay as non-runners, intending to cannibalize at least one of them for my Transport. In the event, I decided that they should be restored, which still left me searching. By this time, I was now only looking for a balance cock and regulator and bought a mixed job lot of 150 regulators, none of which fitted the Divina. Then in 2021 I was lucky enough to find, also on eBay, an un-named German watch with a 13''' Divina, and also non-running, but with the balance cock and regulator that I needed (see image). It was the equivalent of about CAD $55. I found the only answer was to be patient, and to frequently trawl eBay from where all of my missing parts were sourced. Best of luck.1 point

-

1 point

-

Blacklab, It was indeed a setting lever screw and I confirmed it by finding the technical manual on line. It is minute and I had to hone my smallest driver down to just about a knife edge. No more than 2.5 turns or you damage the train wheel bridge As you can see it is not much bigger than the end of the stem ! I will post the info I found in case it helps someone else. Thanks to all ! Now I have to get some really bad scratches out of the glass and buff out a ding on the case - such fun Cheers, Vich1 point