Leaderboard

Popular Content

Showing content with the highest reputation on 03/08/22 in all areas

-

There are no parts (except for the stem perhaps) or technical documentation available for Chinese watches. In addition, in most cases they are fragile, and easily break while working on them. However it can be that the keyless went dislodged because the stem was extracted from the wrong position. In that case you need to access and inspect with knowledge of the matter.2 points

-

2 points

-

Many watchmakers have their own code when it comes to repairs. Apart from knowing who did the work you might never know what it is or says.2 points

-

Looks Greek. (Not just "Greek to me", but literally Greek.)2 points

-

Your spring visually looks fine. At one time they made a special winder just for the short little inset part because it can be a pain to get in some time it's really stiff. Yes it has to go in the right direction so it slips properly. You also need breaking grease on the outer wall. Then I think your diagram looks right I'm just trying to figure out the wording you using? Basically put the bridle in the first the outer part with its breaking grease on the outer wall you may find that the ends actually overlap sometimes they do. Then you can just insert the spring like you would any other spring of that type and it will hook on its protruding hook on the bridle. Otherwise you can find a replacement which should be all one piece1 point

-

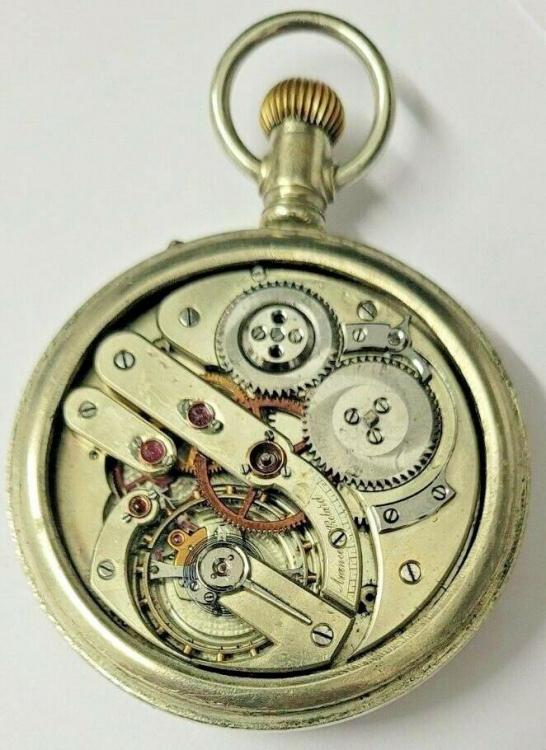

It looks like a skeleton watch can't you see the problem? It depends on the watch some watches you can only remove the stem or only should remove the stem in the setting position typically others they can be in the winding position. It's good that this is a practice watch because now you get the practice taking movement out of the case. Then practice of taking the dial off if you can't see the setting components which of course means you have to take the hands off all good practice. Then you can see why the setting parts are not where there supposed to be. Then one of the problems watch repair that we continuously Are pointing out to newbies not everything has technical documentation. So always get lots of pictures because that's the only documentation you're going to have.1 point

-

I agree, these were/ are good workhorse and undervalued as you say. I think some Famous brands did make high grade Peseux movements. This crystal looks undamaged you can polish it, check this vid. Saves you a few bucks.1 point

-

From the pictures it seems you've lost the stem also, not just the crown. Timex does not make stem or any other part available, they want people to buy another watch. But (maybe) if you reinsert the battery at 4:55, you can still use it.1 point

-

It certainly was. Also pretty amazing was the ability to resolve detail optically at those scales. The single-chip microscope invented by Leeuwenhoek ((1632-1723) born in the Dutch city of Delft) and produced around around sixty years earlier than LeCoultres Millionomètre could resolve details down to around 1/700mm so pretty close to the 1 µm mark. By 1878 Chase/Abbe (Zeiss) et al. had created the first oil immersion objective lenses, which were able to resolve things at pretty close to the limits of optical microscopy (approximately 250 nm). So by 1884 you could argue that we could pretty much see and measure the entire (optically) observable world i.e. everything resolvable with visible wavelengths of light.1 point

-

Many brands used Peseux movements, they are easy to work on and mostly outlasted the case, real good pinion leaves specially. Dr ranfft lists the family Peseux 320 belongs to, which should help in case your watch needs a new part.1 point

-

I saw a code the other day. Was able to suss out the shop. Contacted the owner, to whom I recently got acquainted, and he told me the history of the watch. The code, in this case, was just a number recorded in their database. Blindingly simple for modern times1 point

-

1 point

-

yes, my interest in Timex is only with the mechanicals or early electrics.1 point

-

Hi again @LeCorbusier Avia seems to have been a popular make in the 50s/60s. Do a google Images search on avia watch for instance. Actually more specifically for your watch do an Images search for avia de luxe! There were numerous watch companies before the 'quartz crisis' of the 1970s put a lot of them out of business. Such companies bought in movements from movement manufacturers; presumably whatever manufacturer gave them a competitive deal for any next planned batch of watches at the time. It's therefore quite typical to see movements from different manufactures in watches from the same watch company.1 point

-

Depends how much time you want to spend on cleaning. If it is already peeling then I would personally strip it and re-lacquer . I haven't had petrol peel lacquer off.1 point

-

For the 101 the manufacturer I do them for simply states "cyclotest" and they check the time visually at 24h intervals; for other calibers they are quite specific about delta, number of positions, amplitude, at full wind and 24h, etc. haha. With some effort you can get them within 60s or so over 6 positions, sometimes you get lucky and it's even better. The big issue on small calibers is it's just not possible to scale down the tolerances to the size, so 0.005mm sideshake of the balance or fork on a 13"' watch with 0.09mm pivots is terrific, on a 6"' watch with 0.07 pivots it's a lot- and the pivot size is big for the balance, and the hairspring collet is oversize for the balance and spring (this makes a huge effect), and on and on. But JLC get it right on some small pieces. The caliber 168, 8 lignes, is usually a very good runner. I've made a number of staffs for them (at least 3 different versions over the years of manufacture), and often can get a 6 position timing of 20s or so. The 838, more modern ultrathin, is also often within about that range, which is really surprising. And to the other discussion above- yes, LeCoultre and later JLC were/are a major supplier of movements to many high end brands, as well as lesser known or prestigious brands, with corresponding quality levels. Sometimes you have to completely dismantle the watch and you'll find a tiny "lecoultre"stamped under the barrel bridge or something, sometimes no mark. They were like the Swatch group of the late 19th/early 20th century, haha.1 point

-

Man is it ever! I've had a couple that, once they were cleaned and oiled, their accuracy was all over the place. Regulating them was no picnic. And getting parts can be a challenge too. One that I worked on a while back (I'll post a pic if I can find it) had a broken mainspring and back then I could not get a replacement anywhere. I remember also wondering if my winder could even put a tiny spring into a barrel that small.1 point

-

Just take the GR 5995 without the TR, the TR is with a hole. While the hook in your barrel may work with a hole, the function of the tongue end (the standard end on springs without suffix) is far better. They have plenty of them at Cousins.1 point

-

Those Excalibur expanding bracelets are very good because it is so easy to remove links or add. As some one has already said open ended lather strap normally size would be 18mm some are 16 or even 20 the most popular is 18mm. This tells you how to go about fitting one. https://www.watchbattery.co.uk/Open-End-Watch-Strap.shtml1 point

-

I would fit a leather strap as a metal one would eat into the gold. There are leather straps designed for non removable springbars which have metal hidden in the leather at the ends which you fold over the spring bars. There are also some with some metal prongs that you fold over to retain the folded leather piece. The choice is limited compared to normal straps but at least they are available! Lovely watch and all the more valuable because of the family history! Anilv1 point

-

What a coincidence. I have only recently serviced an Avia watch pretty much identical to this! This too had fixed bars on a 9ct case. It is hallmarked on the inside of the case if you want to pinpoint a year. The one I dealt with was dated to 1959 (but had a FHF movement). Owner has had the watch since new and it has always had a strap; dark brown. Search for open ended strap if you want to follow that route.1 point

-

The Timex Weekender is a contemporary quartz model that our guy JM most likely despise. No codes on dial either I'm afraid. All what has to be done is to measure the stem and tube dia to order a compatible crown.1 point

-

1 point

-

Hello and welcome to the forum a close up picture of the dial and movement would aid menbers to help you. there is a series of numbers under the 6 O'clock position de coding them will give you the year of manufacture and the modle http://www.woodlandtechnical.co.uk/ this guy greg wood in th uk Is one of many Timex repair persons1 point

-

I did some digging on that cal. 101, and at least some were adjusted to multiple positions. Based on @nickelsilver's owning of the "most difficult thing I've done in watchmaking" thread (or whatever the actual title was), that seems like an absolute nightmare.1 point

-

1 point

-

1 point

-

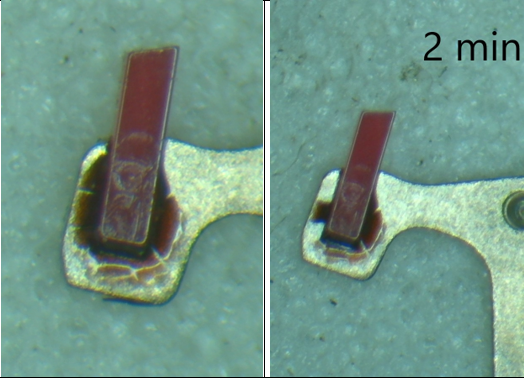

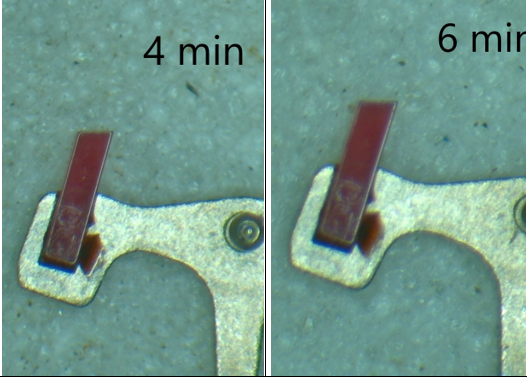

As a follow up, I thought I'd repeat my original experiment (because we all like an experiment ), as my new ultrasonic is twice the power (60W) and is heated (the test below was done at 40C). The only scrap part I could find was an old wristwatch pallet. The shellac was already badly cracked (you can't really see all the cracks in the first image) As you can see, after 2 mins, the loose shellac has been stripped - I wasn't surprised given the cracking. At 4 mins more of the loose shellac has come lose, but the remaining shellac is not noticeably smaller. At 6 mins it looks no different than at 4 min. The jewels are still firmly mounted. BUT ..... As I couldn't find a part with uncracked shellac, I took an old pocket watch pallet and added some big blobs of shellac. After 2 mins there was serious loss of shellac. So, Conclusions. Don't put parts with 'fresh' shellac in IPA in the ultrasonic. For more 'seasoned' parts, expect the ultrasonic to remove cracked bits of shellac - though I suspect it would be the same in any cleaning fluid - more vibrations than IPA doing the damage. From my test, it seems that, once the cracked bits are gone, the remaining shellac does not readily dissolve in IPA. As I mentioned, I rinse most parts for about 1 min in IPA, but parts with shellac - only about 30 secs.1 point