Leaderboard

Popular Content

Showing content with the highest reputation on 03/07/22 in all areas

-

I bought an anonymous 4-sided wristwatch movement vise on ebay over 10 years ago. "GERMANY" stamp on the thumbscrew and "GH" awkwardly engraved on both dies. I like it a lot better than most of my other movement holders, so, I threw together a 3d printed version in hopes that others might find it useful. The main innovation vs. most others is that the dies are slightly undercut where they grip the main plate, which seems to greatly improve their ability to hold on. https://www.thingiverse.com/thing:52753672 points

-

I'm going to be very biased here. I went to school and worked as a watch and clock maker in Axminster town. I even know the people that started Axminster Tools and some of the staff. When they first came to Axminster I think it was around the late 70's, I would go and look around there shop and talk to some of the staff while I had a watch cleaning in the machine, the machine was an auto type so when I returned all I had to do was put the thing together. So you have to go with the Axminster SC22 points

-

Sorry to pile on, but there are advantages and disadvantages to both plain and rolling bearings. With a plain bearing, "runout" can be brought to levels where specialized equipment and temp control etc. are necessary to detect it. Since the spindle itself is the moving part of its bearing, and it will invariably be finish ground internally in its own stationary bearings, the precision is incredible. There does always have to be some freedom, a space for the oil. In use, when well adjusted, the oil forms a film around the spindle that is effectively immoveable, while eliminating metal to metal contact. Plain bearing machines with 100s of thousands of hours of use out of watch factories are often in surprisingly good and accurate condition. Some very sought after precision grinding machine use plain bearings, usually bronze and hand scraped to fit, because of the superior surface finish they can achieve. But, a plain bearing machine won't hit peak performance until up to a certain temperature. Derek Pratt used to use stick-on thermometers on the heads of certain plain bearing machines so that he could use them at a consistent temp when doing really tricky work. A ball bearing machine is always ready to go, will have zero spindle play at any temperature or speed, don't necessarily need daily lubrication (often they are lubricated to run for at least 5 years without being touched, and don't tend to sling an oil film down the front of your shirt, which is one of the nicest features! I do love my ball bearing watchmaker lathe, but have used many plain bearing machines and they were also fantastic. Just wanted to point out that plain bearing doesn't equal lower precision; it is in fact the opposite.2 points

-

That is a very good Watchmakers lathe with loads of accessories and worth a lot of money. Do you have the motor for it or is it missing. No worries if the motor is missing. A motor can easily be bought.2 points

-

The Timex Weekender is a contemporary quartz model that our guy JM most likely despise. No codes on dial either I'm afraid. All what has to be done is to measure the stem and tube dia to order a compatible crown.1 point

-

The other thing really important you have to think about is? Even though you weren't planning on doing watch work a lot of what you're doing is watch work. So when you look at the various tools you have to think about how are you going to hold your components. Like a watchmakers bezel Chuck for instance? Some lathes have adapters so you could use a bezel Chuck on a bigger lathe. I know for instance I have an adapter to hold watchmakers collets on 11 inch Logan lathe. Yes it's a really big lathe but it still has an adapter and I can hold watchmakers collets. But it didn't come with one of those I inherited the lathes from my father who made The adapter. Which brings up the other thing if you have a lathe and you know how to use it you can make your own adapters. It just depends on how far you want to go as to what you want to make all your own tooling or pick a lathe that possibly has all of these things that you need to do what you want to do1 point

-

Angry Bear, If you live in the USA take a look at Grizzly Tools and Harbor Freight. Grizzly machines are fairly consistent in their quality while Harbor Freight has some good quality and lesser quality offerings. It depends on the machine and the quality can vary from batch to batch. Grizzly has a quality control and inspection department and is able to offer more consistent quality. Their machines also cost more. I have purchased some very nice machine tools from both companies. Some of the Harbor Freight tools had to be taken apart and reworked in certain areas; but in the end, ended up as a nice machine. As long as the machine is made out of steel it can be machined back into specs. If it is aluminum with anodized ways, it is essentially a disposable item. david1 point

-

I spoke to Warco on the prospective of buying a bigger lathe and their answers were timely and complete. I like the fact that they normally include more important accessories in the delivery, these may not be useful for working on watch cases except for a 4 jaws chuck, but never say never, you may need them for making tools and other general stuff. You gain a lot of points with local business owners for being able to make parts for them. These are the same machine from the same factory. I bought my SC0 from Axminster and they have been impeccable in the purchase and sending a replacement crossslide nut which had worn out way too quickly. My other advice is to buy an ER16 colletts chuck, a QCTP, and if possible at all, a milling machine from the get go. If not possibile, a Z- axis slide attachment.1 point

-

Wow, I wasn’t expecting that! Thanks all for your comprehensive if sometimes opposed views. There is a lot to digest here. Give me a couple of days to go through it all very carefully and I’ll let you know what I decide to purchase. since reading this I have now written off the proxxon and I’m fairly certain I have it down to either the Warco WM180, the Seig SC2 or the Axminster SC2. Any further personal preference on these companies in particular is very welcome.1 point

-

Don't bother with the post office. How about using someone such as Yodel. If you are thinking of selling you could try ebay or take it to an auction house, if you do that find out the fees and better still take it to around 3 places for prices it should go for. If there is one that specialise in all things horology that would be the one to go for.1 point

-

Do they look like they're blocked? Then how about a picture of the offending watch so we can see what it looks like?1 point

-

A watchmaker's lathe. A mini-lathe will not have collets like the ones you see along the bottom row.1 point

-

1 point

-

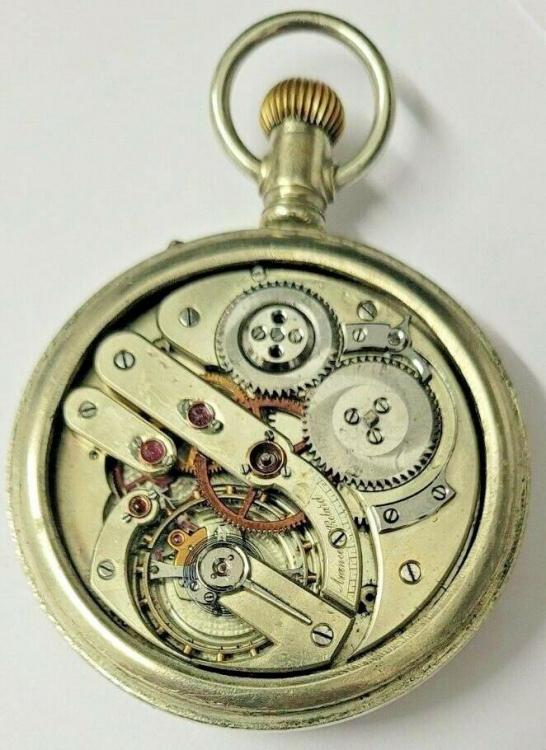

Some more Le Coultre history here. -> https://curatedition.com/watches-and-jewellery/jaeger-lecoultre-the-manufacture-of-makers/ Patek, IWC, Vasheron Constantin. Somewhat more exalted company than perhaps the 404 club is used to, but hey, we take anybody as a member, regardless. This is interesting as it may be that our mystery pocket watch calibre was made by Le Coultre & Cie for one of these other companies. To put that in to context, a micron or μm is a thousandth of a millimetre, or about 0.000039 inch for those still measuring in firkins and flagons . A micron is roughly a tenth of the diameter of a red blood cell, and also roughly the size of a single bacterium. A human hair (the bane of the watchmaker's bench) is somewhere between 20 and 100 μm1 point

-

That is a nice tool with all the accesories, Burnerd chuck, faceplate etc a real quality Item1 point

-

No, he didn't. I'm sure he could have, and I'm not sure why he didn't, but in fact he goes on to make an interesting series of videos detailing all the faults he found, and how he went about correcting them. We can all watch videos on YouTube, but what you make of them is a subjective thing. It depends for example on your own skills and confidence, and how much time and effort you'd be prepared to put in to repairing faults which should never have left the factory. The monetary cost of the repairs was low, so for some people, even this might be a good deal. To just dismiss an entire swathe of different products as "a waste of money" or "a pile of crap" simply because they are made in China is just wrong and doesn't add anything valuable to the thread, in my opinion. The videos were good though, very informative, so thanks for the link.1 point

-

I would recommend searching for your yoke spring. Get a bar magnet and a good flashlight and do a systematic search of the last known location. then widen your search area. It might take awhile but runaway parts are usually found eventually. I not aware of any replacement parts available for Chinese movements. But I might be wrong as the ST3600 is a very popular beginner's watch movement. There are generic springs assortments available from good material houses like Cousins. They may not be a perfect fit but some minor modification will usually solve the problem. Good luck and keep us posted of your progress.1 point

-

Nothing aside from the fact that I'd never seen one like it. If they are common, it may just be that I don't get out much, i.e., haven't worked on that many wrist-watches. And yes, that jewel "kit" is indeed on the escape wheel, and does have a cap jewel. Many thanks, all. Cheers.1 point

-

Just noticed this. Please read the first post of the topic below. Note, the plus sign in the thumbnail may be 'Insert' instead.1 point

-

To put a price tag on all that I made a spreadsheet with prices. https://docs.google.com/spreadsheets/d/e/2PACX-1vSWfhOjlAfpI_c1EWF8MPSKnbIVIPoIH6mxCC1nVYQPQ8cJbiwBhLc1v597F9Z_AZteVKsfJ1lZDOOe/pubhtml Like everything else these have likely increased enow. Few more considerations in the original thread below.1 point

-

If you purchase a mill or lathe, match it to the work you plan to do on it. If you plan to do larger work, you need a larger machine with more power. If you plan to do single point threading, you will need an engine lathe with a leadscrew and change gears. Larger engine lathes work better than smaller engine lathes. A smaller machine like a watchmaker lathe isn't more precise than a precision machine that is larger. That said, it is far more suited to make tiny watch parts requiring smaller tools and less cutting pressure. I would avoid any lathes or milling machines with aluminum ways. Aluminum is a softer material than steel and is more sensitive to dimensional changes due to changes in temperature. Also it offers less resistance to warping due to clamping and cutter pressure than steel. Adding a hard anodized finish doesn't solve the warpage issues. An aluminum mill or lathe will never perform better than a desktop hobby tool.1 point

-

That only happens in an ideal world. The guy went for the lowest price, and was served accordingly. But evidently not all the Chinese lathes have been sent back, otherwise the importers and resellers would have gave up on them a long time ago. You may not like the notion, but in most cases they perform from good to very good. Here's another link from very British "Model Engineer". They (and I) are the kind of people that don't buy for collecting, but to do things and report on them without prejudice https://www.model-engineer.co.uk/forums/postings.asp?th=137849 Then if you like video better here a 2 yr after review, randomly chosen. No one but two comments up on this page alone, then as many you want on YouTube and any machining forum.1 point

-

I for one don't like plastic on machinery. Luckily my lathe change gears are cast iron, and I do spend a lot of time in re-making plastic parts in steel, bronze, or brass. That being said, the truth is, change gears need to carry little torque on a small machine. If exceeding stress is given to these during power advance turning or screwcutting, you are doing something very wrong. So plastic (nylon actually) is perfectly suited for the task, and if it enables someone to learn and do as opposes to not do , I'm happy they do make like that. All it takes is to read few comments on this type of videos to learn the informed feedback from machining hobbyists, they are all saying the same: there can be a big difference in buying China made at lowest price (Vevor is an example), or from reputable importers, e.g. Optimum, Warco, Axminister, Precision Matthews, Sieg factory.. I could add another 10 names here easily. Unfortunately some people has difficulty coming to terms with the fact is that the good old times of UK/EU/US made small machinery are gone (exception: Wabeco Germany, nice products and direct sale) and won't come back, and even that back at the time a small setup was easily 2 months average salary, nowadays you can be productive with a quarter of that.1 point

-

Yes he did seem to have some minor problems with quality control didn't ? It's back to the problem of the quality of Chinese tools ranges from very bad to very good. Just have to be really careful when you're making your purchase as to you getting the good one. For instance I have some links there is one first link and you notice the reviews for the most part a pretty good some people don't like plastic gears. https://www.grizzly.com/products/grizzly-7-x-12-mini-metal-lathe/g8688 Then here's an example of an improvement notice there's no longer plastic gears https://littlemachineshop.com/products/product_view.php?ProductID=5100 Then I was pretty sure I remember this group existing or this website all about the mini lathe. It really is a very popular lathe. http://www.mini-lathe.com/Mini_lathe/Modifications/modifications.htm1 point

-

Personally what I always find interesting is what people can do with tools that other people perhaps feel are less than desirable. Of course you have to have skills to use these tools. But still you find all kinds a interesting examples of wonderfully made stuff with tools that are wonderfully made. Although it would be easier if you made stuff with better tools the first place but still it's not usually the tool lets the problem. Then as the original posting price of what was wanted to be spent was pounds Sterling here's a thought? Looks like a trade fair and they have people selling tools. https://www.thebirminghamclockandwatchfair.com/traders For instance this is a vendor that snap the fair the last time this fair came up somebody in the group said they had purchased tools from this company. Looks like they have a variety of lathes but a lot of them up and sold and it would be really nice if they enlisted the selling price for not seeing that but still even an idea they might have something of interest. The other thing is you go talk to somebody like this a bit I can find you something https://pennyfarthingtools.co.uk/ Haven't heard of her but the video did look interesting. Then she definitely understands how to use it which is why she's getting wonderful results.1 point

-

If you still like this kind of work, even after losing a tiny part and seeing a broken balance pivot, then surely it was meant to be. May I ask for pictures of the movement and especially the balance and its pivot? We can help much when we see them. The best and clearest pictures you can make. You will see a lot of broken balance pivots in this line of work. It is good you are learning about them now. Let us see pictures and learn more and we will help how we can.1 point

-

1 point

-

1 point

-

This tool is wonderful. Like many, I'm new to watch repair, and reluctant to spend big $s on specialized tools. I was intrigued by this winder design, so I decided to purchase an inexpensive 3D printer and make it. I figured I'd be ahead of the deal even with the cost and learning curve of a printer. The files printed beautifully, and the winder performed flawlessly -- I think perhaps even better than the traditional brass tool. Also, I now have a 3D printer to play with! :))) Thank you Zero so very much for creating and offering this tool.1 point

-

I actually agree with David basically. In the last 20-25 years the price of "exclusive" watches has taken a hyperbolic leap. Maybe not literally, but it's far from linear from years before. There was an excellent article on this in a major watch mag a few years ago but I haven't been able to dig it up. Essentially the price of "high end" watches has exceeded the price of inflation by x percent and as Ben Franklin would agree that sh!t compounds and is a force to reckon with. As for brands trying to f*ck people on repair of vintage pieces: I do repair/restoration for a Big Brand. I regularly make balance staffs and stems, less often vibrate hairsprings, sometimes make pinions, winding pinions, fill in the blank. They don't pay me to make these because they have a secret stock of parts that are worth more than my time- they don't have the parts. Some of these are from the 60s (most much older- my point is lower production number 'rare" movements means fewer spare parts) and there are simply no parts available. So a dude makes them, and if anything they take a hit so the customer is happy with a reasonable repair price.1 point

-

I'm not sure I agree with that assessment. He's essentially putting everyone on an even footing, but allowing for exceptions to the specific example. Said another way, one pad printed dial is no better than another because one name is carved on the pad vs another. There exceptions where dials are hand engraved, or printed on meteorite slices or whatever other special thing, but exceptions aside, a dial remains a dial. Does a Patek dial deserve any special consideration because the letters "a", "e", "k", "p", and "t" (alpha order) are on it in some particular order? No. It's still a little disc of brass with paint on it applied in a particular way. If a dial is actually somehow different (per noted exceptions and others), then it warrants different consideration, and likely a different price.1 point