Leaderboard

Popular Content

Showing content with the highest reputation on 02/08/22 in all areas

-

Recently while scrolling through eBay, this watch caught my eye. It's a dead ringer for the one my father wore for most of my childhood (band not withstanding). I'm not sure what ever happened to his but this "as-is" "does not run" watch that shipped from only miles away from my home town, ment something to someone. For all I know, it could actually be his. It's a all stainless steel, Kaltron, 17 jewel, selfwinding watch with a Felsa 4007N movement. Not overly expensive in its day but very smart looking and dependable. It's failure to run resulted from the second hand arbor being seized within it's bore. A few nerveracking hours of chasing three small springs around my bench last weekend and it's up and ticking again. Thanks for all of your support. Yes, I know the date is wrong. Shane4 points

-

Remove mov.t, dry up the inside of the case with an hairdrier, inspect for cleanliness, inspect and replace as necessary crown and caseback gaskets, lubricate these with a bit of silicon grease before reassembling. Then do a condensation test which is warming the whole watch just a bit then let a couple of very cold water drops on the crystal, that does nor replace a pressure waterproofing test but at least tells you right away if all moisture has left.4 points

-

2 points

-

With an hairdrier as mentioned above. The standard test is described below https://en.wikipedia.org/wiki/Water_Resistant_mark2 points

-

Leave the watch face down under sun light for several hours to get rid of any moisture inside it. Moisture rusts the base metal that parts of the movement are made of. Keep the watch away from water moisture, which I presume has ingressed through the case tube due to worn crown seal.2 points

-

To the workshop, today I have received this fine old cleaning machine from Germany. The machine is manufactured by VEB Elektromeschanik in Glashütte. The machine is a type of AUII and is fully automated. It is about 30 cm. In diameter and 52 cm. high. Weight approx. 30 kilos. The machine is from 1979 and the gray paint is intact everywhere. In addition to the complete holder and basket on the machine, 8 other curves included. Two of them also with holder. Although DHL and Post Norden have given it a massive transport, everything is all right and it seems like it's going to be! These machines are often sold at ebay.de. It also exists in a version that is not automatic!1 point

-

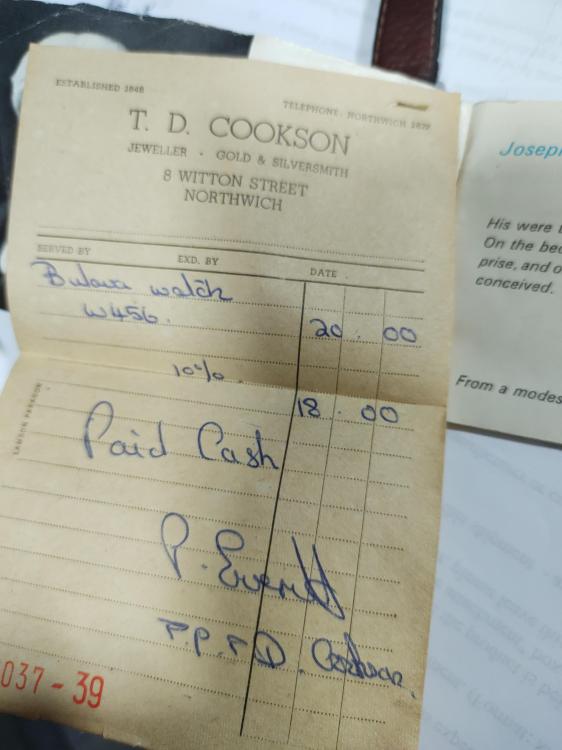

Just a quickie When my dad died 7 years ago my mum gave me his old Riquartz watch that she gave him for their 25th wedding anniversary in 1981. It was in a sorry state. Dad had worn it solidly from that day to the day he died. The case and case were badly scratched, the original strap lost, the day date mechanism jammed (broken as it turned out). It had been left neglected for the last 7 years. With a bit of patience and good fortune I located new-old stock movements and crystals. For a well worn 41 year old watch I think it's come up rather well after a strip down, polish and careful rebuild and new movement. I think it's good for a few more years. Before and after photos below. I can't wait to show my mum. James.1 point

-

Not [i]every[/i], but practically every. As for a top cover gasket, it depends on the case design. There are some that [i]only[/i] have a top cover gasket (these often won't have back covers, and sometimes deceptively so), some that only have a back cover gasket. Tough to say from the photos, but it's not unlikely. @Nucejoe, Yeah. I bought it NOS. IIRC, it was 6 years old when I got it, so already due a service. I've been trying to get to the point where I'm comfortable tearing into it. It's a 2824-2, and ETA parts limitations for randos like me, so I don't want to risk screwing it up too badly. I did some major office rejiggering yesterday, and while I still have a bit to go, I'm hopeful that I'll be digging into a number of movements very soon! My office was the dining room pre-pandemic-two-people-working-from-home-and-also-we-had-a-baby-and-my-office-became-a-bedroom paradigm, and we finally realized that under quarantine, no one is coming to have dinner any time soon. Additionally, I finally found someone who could sell me a semi-temporary sturdy shelving unit in a safe and economical way, so I now have full run of the dining room table as a work surface rather than a junk repository. Just need to finish clearing a few things out of the way... Coming soon!1 point

-

You are likely to have got away with zero damage to the movement itself, I don't know about lubricants though. If you are obssesive like me, a goog clean and lube is in the order.1 point

-

Ha! Yeah. That's a bummer. Sounds like you did well for your first, but the horlogy gods will not allow success on the first attempt. Your fate was sealed before time began.1 point

-

Clever. My daily driver has very little in the way of water resistance (pilots' watch), and it's managed to have water ingress on two occasions. Both of which were when a slight stream of water ran over it; once water running off a tarp that had been rained on, and the second was something work related and tap water spillage or something. Both times, I just opened it up, put it under my tray cover with the corner raised to keep any dust out, and I just let the dry mountain air do it's thing for a few hours. I didn't think to add heat or test anything. I resealed the main gasket with silicon the first time, and the secondary (probably too much) the second time. Both times, I noticed the moisture inside the crystal immediately, and acted within minutes, so I'm hoping I staved off any significant corrosion damage. Next time (should there be a next time), I'll definitely apply heat and test. Yet another example of the dichotomy of watchmaking where high meets low. You don't have a pressure tester (high tech), so a decent proxy is to just warm it up and put a drop of cold water on it (low tech). Fascinating art/science...1 point

-

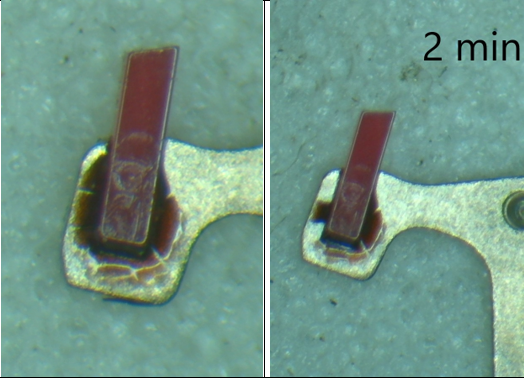

As a follow up, I thought I'd repeat my original experiment (because we all like an experiment ), as my new ultrasonic is twice the power (60W) and is heated (the test below was done at 40C). The only scrap part I could find was an old wristwatch pallet. The shellac was already badly cracked (you can't really see all the cracks in the first image) As you can see, after 2 mins, the loose shellac has been stripped - I wasn't surprised given the cracking. At 4 mins more of the loose shellac has come lose, but the remaining shellac is not noticeably smaller. At 6 mins it looks no different than at 4 min. The jewels are still firmly mounted. BUT ..... As I couldn't find a part with uncracked shellac, I took an old pocket watch pallet and added some big blobs of shellac. After 2 mins there was serious loss of shellac. So, Conclusions. Don't put parts with 'fresh' shellac in IPA in the ultrasonic. For more 'seasoned' parts, expect the ultrasonic to remove cracked bits of shellac - though I suspect it would be the same in any cleaning fluid - more vibrations than IPA doing the damage. From my test, it seems that, once the cracked bits are gone, the remaining shellac does not readily dissolve in IPA. As I mentioned, I rinse most parts for about 1 min in IPA, but parts with shellac - only about 30 secs.1 point

-

I recommend this. You can hacksaw to size, easy to put a small taper on by using a fine needle file. The poor devil has been through the wars, nasty repair to the crutch and a very bad bush to the pallets that has been filed down. The ones in red are causing the trouble as you point out with the red mark, I ones in red are ones that have been repaired and are not in my option good repairs, the one in blue also looks as if it need to be looked at, or it might be the photo. https://www.etsy.com/uk/listing/876146296/clocks-bushing-wire-8x-hollow-brass?gpla=1&gao=1&&utm_source=google&utm_medium=cpc&utm_campaign=shopping_uk_en_gb_a-craft_supplies_and_tools-other&utm_custom1=_k_Cj0KCQiAxoiQBhCRARIsAPsvo-z3JTiNCS7-tDJkO_dMHZHGkRnHZOGqkDXXxv-udYjTyHwvGHyVK_waApRGEALw_wcB_k_&utm_content=go_6479444532_72974637810_380837596062_aud-371913912633:pla-295462056907_c__876146296engb_142203909&utm_custom2=6479444532&gclid=Cj0KCQiAxoiQBhCRARIsAPsvo-z3JTiNCS7-tDJkO_dMHZHGkRnHZOGqkDXXxv-udYjTyHwvGHyVK_waApRGEALw_wcB1 point

-

Interesting test. Question , How do you warm the watch and how much in terms of degrees?1 point

-

Do check out Cousins catalog. They do have some bushes for longcase clocks. But they are more for very large holes like those for the mainspring arbors.1 point

-

Hi there Micheal, https://blog.watchdoctor.biz/2019/03/23/what-is-a-split-stem/ This will help you understand. Cheers Graziano1 point

-

Welcome to the forum @timekeeper. Keep trying to upload the pictures. Hopefully it will work.1 point

-

Welcome to the forum. You can take your hat off for those two tools. Look very nicely made. No better feeling than doing it yourself.1 point

-

That makes sense. I put about 200ml in a jar and have cleaned some 6498 parts in it. First a main plate, train bridge, and train of wheels - the wheels in one of the brass and steel cleaning capsules and the lot of it in one of the baskets i formed out of zinc chromate coated ultra-fine aluminum mesh -- and then later the train wheels from a pair of 6497 movements in just the brass/steel mesh capsule. first time it was as blue as moebius 9010, second time as blue as windex. I would also like to suggest that people who think it is especially smelly perhaps did not live through the 70's/80's era of ammoniated household cleaning products, pine-sol, and pine tar shampoo. It's not Chanel #5 but it isn't exactly an all-out assault on my senses either. As a guy who wrenches on cars i would say it isn't 10% as bad as hypoid gear oil or 5% as bad as wet-clutch transmission fluid.1 point

-

1 point

-

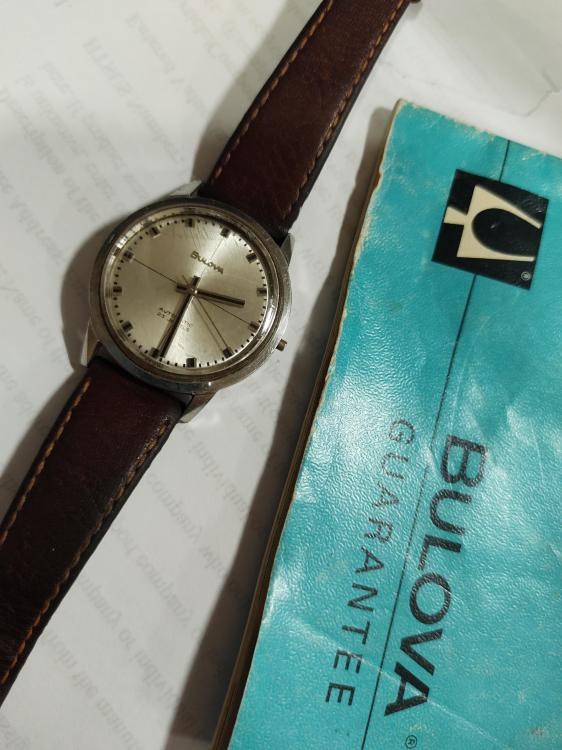

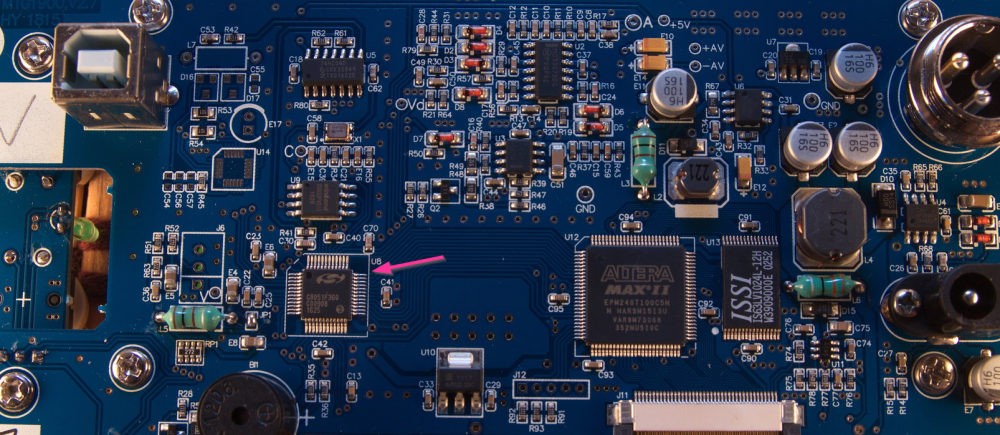

A fairy early Swiss quartz (the late 1970s or early eighties artwork in the included instruction booklet state it runs at 32768 Hz, so that kind of dates it). Generally I wouldn't pay much attention to a quartz watch, but this is Swiss made, has the original box, warranty and instruction leaflet, and of course an irresistible blue dial. Limit International, in one form or another have been around since around 1912.1 point

-

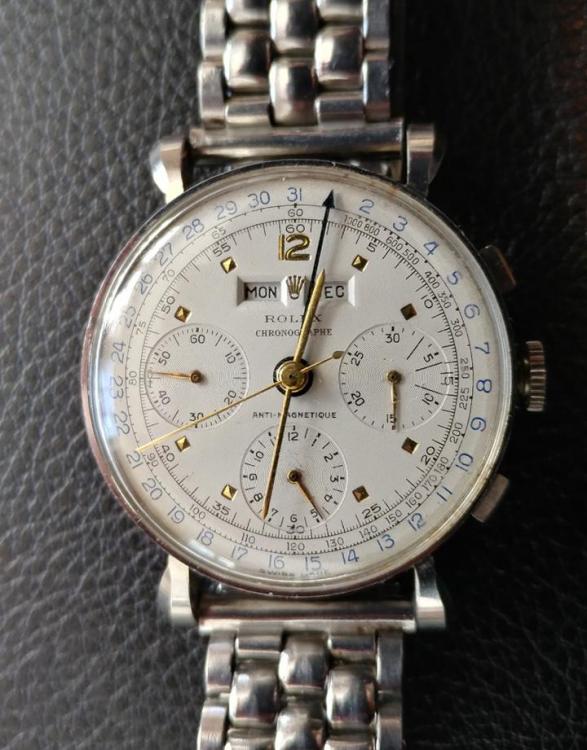

Right. But when owning a Rolex dato-compax 4768 with upright 8 - 23 days, which is difficult to estimate but possibly worth north of $40,000, probably more considerations are made beside liking and wearing it. No matter when and where, it was a very generous gift to receive.1 point

-

1 point

-

1 point

-

Also had trouble with that issue in the past. Especially a very flat mainspring (0.63) nearly drove me mad. Finally I designed a little tool and a friend with a 3D-printer produced it for me. Once screwed down it holds the spring and its ring tight on the barrel. Then I can just push it down with a brass screwdriver. No „flipping out“-danger anymore.1 point

-

Are the copper disks some kind of eletro-magnetic brake or speed regulator. Are those blocks next to them magnets or electomagnets? They appear to control the chimes somehow. They remind me somewhat of a mechanical electricity meter, but on a much smaller scale.1 point

-

1 point

-

I haven't done one of these for a while..... My latest acquisition with a Record 107 movement, and on my first attempt at making a strap (no apologies for the dodgy stitching). Came in as a non-runner, turned out to be a broken M/S so easily sorted. I was tempted to have a go at re-plating the case but I think it carries off the brassing rather well.1 point

-

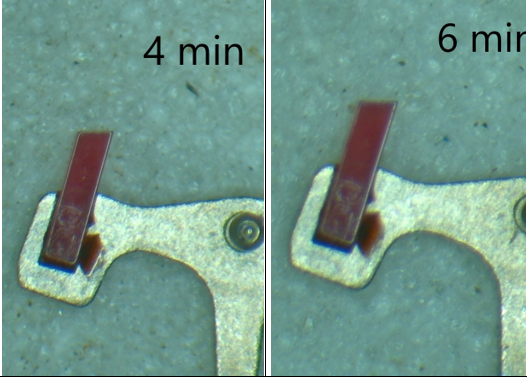

Bulova Seaking Automatic from 1975 I believe. Just restored and serviced this for my next door neighbour. It's 'on test' for the next day. He told me he got it for his tenth wedding anniversary and has been in a drawer for 25 years or so. Going to give it back to him tomorrow evening. I hope he will be pleased to wear it again.1 point

-

1 point