Leaderboard

Popular Content

Showing content with the highest reputation on 01/23/22 in all areas

-

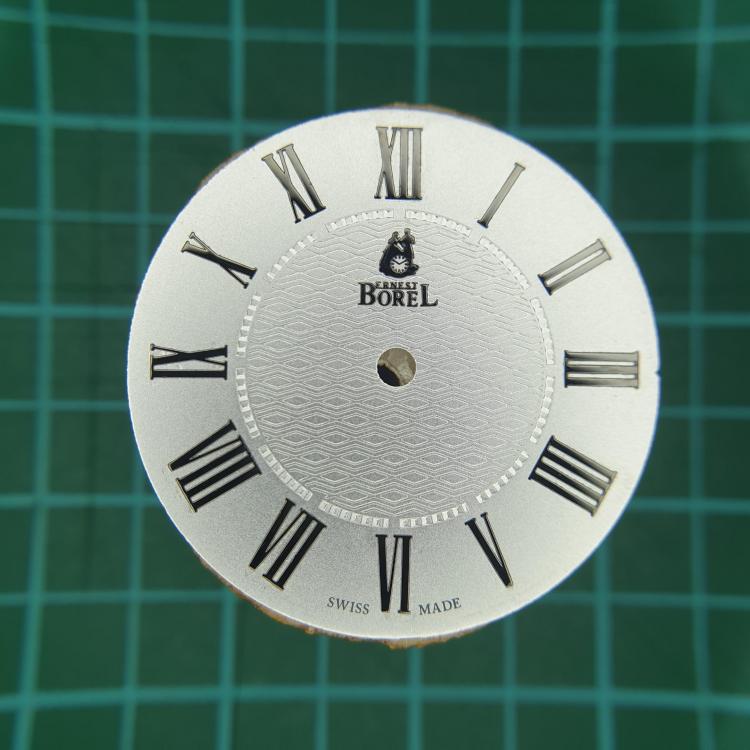

I got them out of the case. The indices look like they're made of some kind of titanium alloy. There are glue remnants still on the dial, so it looks like they were just glued on. I mixed up a batch of slow setting epoxy and carefully worked at gluing them back on till after midnight. This morning I cleaned up the excess glue and I do say it came out better than expected. It's not perfect but you can only see the excess glue if you stare real hard.4 points

-

Updating to THIRD Vulcain Cricket (Sensilarm) done except for the sweep second hand. To bring this one to life I had to: 1) new staff 2) turned a new pusher 3) replaced keyless works (clutch and winding pinion, crown gear, setting lever and setting lever screw) 4) sweep second pinion I am now in the hunt for a sweep second hand. I put a lot of money into this thing...I think...it has been going on for about nine months. Bought parts on ebay, NOS material houses, donor watch, and I made the pusher.2 points

-

Personally I use GS hypocement for that, as I think epoxy is orders of magnitudo stronger than needed. I like like it because beside is mostly friendly, easy to apply and remove and doesn't smell bad.2 points

-

Update! I found a partial Cricket case that had the button. Bought it and installed it on this watch. With the hood open, I fixed an issue with the alarm that had been bugging me. Ended up replacing the alram on/off spring with one from the donor I have. I also replaced the wig-wag in the keyless works. For some reason, it would not seat properly and the winding pinion would skip...strange. Anyway, it works now.2 points

-

It is without a doubt a front loader, there's no way that you're going to get that nice big round dial out the back through the rather smaller rectangular shaped hole in the case unless you're a magician!! Also if you think about the way that the case screws that you have removed interact with the case, they hold the movement back against coming out the front; if the movement were intended to come out the back then the way those screws work would serve no purpose at all. You will need to remove the crystal, and probably the bezel as well (I say probably because it's not quite clear from your side on photo if the watch has a separate bezel) and then everything should come out the front.1 point

-

Hey, I am blessed that you got to use what I recently discovered!! If you have a Samsumg flat panel TV that wont turn on, I can help with that too!! These switch-mode power supplies sprinkled about this consumer electronics are really finicky about ESR and ESR is a function of aging. Sadly, lots of stuff ends up in the land fill that just needs a few caps replaced.1 point

-

Ideally you have the correct size winders, with the winder arbor smalll enough for the mainspring. This isn't always possible - I only have a small set of winders. You have to improvise. The winder I use most is the 10.5 mm but the arbor is often too big for the inner coil of the spring. I use a bit of brass tube in the winder body, so that I can use the arbor from one of the smaller winders. If the spring does get distorted, use some round nose pliers to gently reduce the diameter of the inner coil. Once in the barrel, it's hard to do without scratching the barrel. DO NOT just squeeze the outside of the inner coil - it will kink and wreck the spring. Put something inside the inner coil to stop it bending too far.1 point

-

Speaking of streaming (something that can't easily or reliably be done on my internet connection), I used to do a fair bit of it. These days (owing in part to the aforementioned lack of communications infrastructure), my music is 100% vinyl. 6-8 hours a day playing in the background, just rolling through my entire collection. I'm also a software engineer, and spend too much time in front of a computer screen for my eyes, and glasses are a fact of life. I've found that the ~20 minute/side is the perfect interval to get up from whatever eye intensive thing I'm doing to give myself a break. I know the topic is re: music, but the form factor plays a part as well. Also, hi-fi audio has a lot of mental overlap with horology, and I've got a tube pre-amp project on the back burner... Well, it's been a bit more in the front over the last few days, but it's a relatively low priority due to the same desk hog project that's keeping the watches in the drawer.1 point

-

Yes, and it also completely flies in the face of: Also, while it looks like a good idea for simplifying the process, the reality is to install those caps you will need to: -not only remove all traces of the original pivots, but also some of the length of the arbor, equal to the wall thickness behind the pivot on the cap. This will require measuring that thickness, and some precision lathe work on the end of a likely long and spindly shaft. Not simple. -turning a precision diameter, concentrically, to accept the pivot cap. Ideally for a friction fit. Again on the end of a long, thin, possibly quite hard shaft. Not simple. In my opinion it would be simpler and better workmanship all around to drill and fit a new pivot than use those caps. The technique could be useful in the event the arbor splits when fitting a new pivot (it does happen) or some other situation where planting a pivot is simply not possible. Otherwise they just look like the panacea to folks who aren't yet comfortable drilling and fitting pivots.1 point

-

1- I personally prefer always to make a new staff, the exception being something like a marine chronometer where the staff is very large (and usually very beautiful). Pros of making new: very easy to make sure it's all concentric, takes about the same time as repivoting. Cons- none. Pros of repivoting: can retain some originality for historically important pieces, on complex staffs could save time. Cons: real risk of problems drilling, like drill wandering excentric, drill breaking, drill drilling oversize. Difficult to blend the conical portion and making an invisible job. As always, a risk of splitting the original part when fitting the plug. Time consuming to do a proper job. 2- If you repivot you should make every effort to make the job invisible and original. This is basic good workmanship and applies equally to professionals and hobbiests. 3- This is absolutely a job for the lathe or turns (also a lathe), and yes you should remove the roller table.1 point

-

Hiya, dadistic! The one I found is, 'Classical WETA.' (90.9 FM. Washington based) Brilliant programme. Due to the 5 hour time zone difference between here, in the UK and the USA, there are some parts of WETA that I cannot listen to. (Gotta get me zzzzzzzzzz's!) They have a sister channel called, VivaLaVoce. That one is dedicated to opera, but I prefer the classical music on Classical WETA. Regards. Len.1 point

-

I would agree this looks like a standard stem release screw and the stem should come out. Then you didn't give us some movement number that would be really helpful but my guess is it's probably this one Then it be nice to have a picture of the case back both the outside and the inside. http://www.ranfft.de/cgi-bin/bidfun-db.cgi?10&ranfft&0&2uswk&Omega_3001 point

-

It is just a normal rack strike your clock doesn't chime. Check the wear to the gathering pallet and the wear of the teeth to the rack. Make sure the snail is in its correct position. The best way is at 12 the rack should drop on the snail leaving a good gap before the next hour which will be one. Do you need me to explain about the worning and the position of the wheels with pins where they should be before striking or are you OK with that part.1 point

-

The Jorvik Viking museum is always worth a visit. You can easily spend a couple of days in there. Fly presses turn up on ebay quite a lot, and they are pretty useful, but heavy and often pricey. You can also use a car jack and some steel or wooden framing if you want to crush or press stuff. Crude but effective. More controllable than a 4lb sledge hammer or a mashie nibblick. I'm not sure if HM Customs and Revenue would really appreciate me minting my own coins, although maybe I could whack out a few new Scottish 2022 bawbees without ending up in the tower of London. Nemo me impune lacessit and all that.1 point

-

As you're finding out American balance jewels fall into a different category of problem. If you look at balance jewel hole sizes you tend to have limited choices sort of? in the case of your watch the upper jewel is 453. The lower jewel is either 453 or4806 it depends on serial number. Elgin for 12 size watches only had three different types of balance hole jewels and conceivably you could be using two of them. They will come in pivot holes sizes and I have an image below of what you're supposed to have. Then companies like Illinois is not that simple. There jewels basically fit all the different size watches and is quite a few choices as a result lots of variations. So you have to know exactly which one you're supposed to have it's not good enough to have a balance hole jewel for a X size watch. Then there is the other problem creativity? Creativity is that you have a bad hole jewel you need to replace it so went the replace it with? That's another reason you'll find all sorts of unknowns and things that don't look right because other people of replaced it with whatever they had. I had a Hamilton 99 to come in a couple weeks ago looked beautiful is running nice visually at least and I was puzzled by why are we having it serviced? When been serviced two years ago by another local watchmaker it was having timing issues. After evaluating the watch it was discovered that the upper hole jewel the entire setting was loose. So for dial up and dial down it was fine but in one of the crown positions the amplitude just crashed and burned and that was fully wound up I suspect at the end of 24 hours a be lucky to run. Another reason why it's important to evaluate your watches on the timing machine in more than one position. Yes this is the another problem variations. Depending upon how long it made there could be lots of minor changes. The final all sorts of strange and interesting things mainsprings changed even the end of the mainspring changed the barrel but the mainspring went in changes for the different end of the mainspring. Typically most mainsprings come in different thicknesses or strength depending upon which watch they go in. The simplistic comes down to it's really good if you tried not to start swapping parts on an American pocket watch as you introduce interesting a new problems that you never even dreamed could exist probably none of them are going to be good.1 point

-

I don't see a reason why it has to be a two-piece stem, release 1 and 1/2 turn the small screw closer to the edge, and remove the stem the normal way.1 point

-

We mix it with a precise amount of a silver alloy so that when mixed with the mercury, it amalgamates completely leaving hardly any unreacted mercury behind. Out in the Old West, your travelling medicine man ( snake oil peddler ) would fill teeth with amalgam made with mercury and filings from a silver dollar.1 point

-

You could try your dentist. Especially old ones. I recently gave 2 bottles of it to my supplier as I haven't used them in over twenty years. He says that he still has customers using that stuff.1 point

-

1 point

-

1 point

-

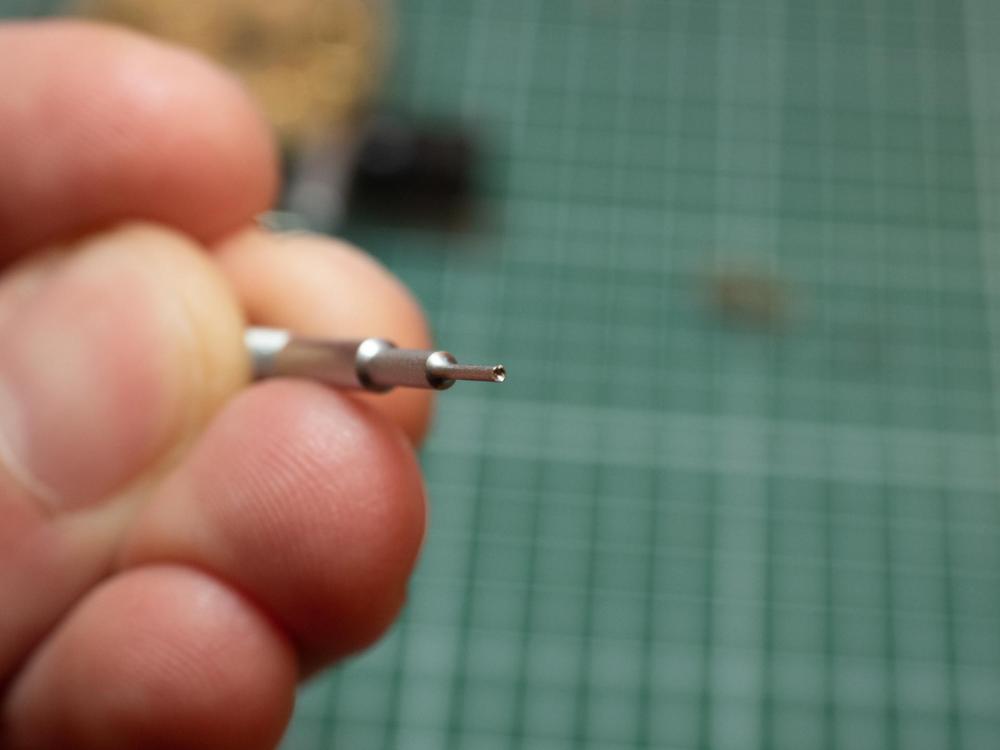

Thank you so much watchweasol ! I didn't have the brass rod and tube to make a proper sliding punch but I've ordered the materials for next time. I ended up using the pin part of a Bergeon 6767 tool that was a good fit. I've added photos for reference although I would definitely recommend making a sliding punch for safety.1 point

-

Hi Harmines apparently the fault you describe is due to the stepper motor being faulty the parts are hard to come by (1342-9400).completer movements seem expensive if you can get them but note that the Tissot 2044 movement is the same but again finding the parts or a donor may be a trial. I have enclosed some PDF's relating to the 1342 for your interest. 1342_complet_4216.pdf 1342_complet_2302.pdf Omega 1342 test.PDF1 point

-

0 points