Leaderboard

Popular Content

Showing content with the highest reputation on 11/05/21 in all areas

-

Interesting... Millionendorf. Leave it to ze chermanz to come up with a word like that. Wittgenstein and all that; language and vocabulary opening new avenues of thought. I used to live in Dallas (pop ca. 9MM), and moved to Denver (pop ca. 1.5MM) a decade or so ago. The destination aspect may have something to do with it (people just want to be here rather than resigning to living here due to a job or something), but I haven't found anything in terms of amenities, commercial opportunities, etc. lacking. Meanwhile, in Dallas it took a good hour to get from pretty much any point A to any point B due to traffic, whereas here we live up in the mountains to the west without any distractions from the city (aside from tourists driving/biking through), but can be anywhere in only 45 minutes with a good 20-25 of that just being getting from the mountains down to the flats. I'm sure there are other manifestations of this, but I haven't finished my coffee yet.3 points

-

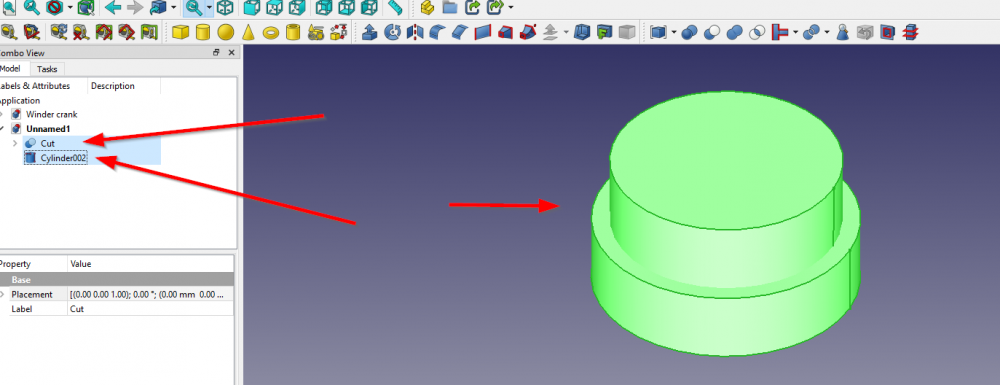

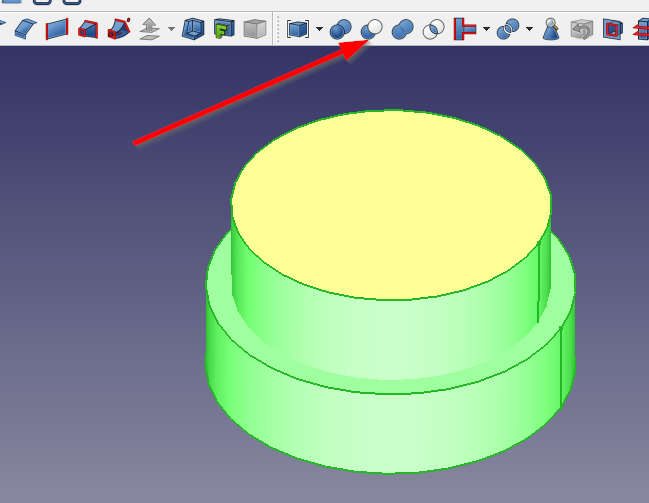

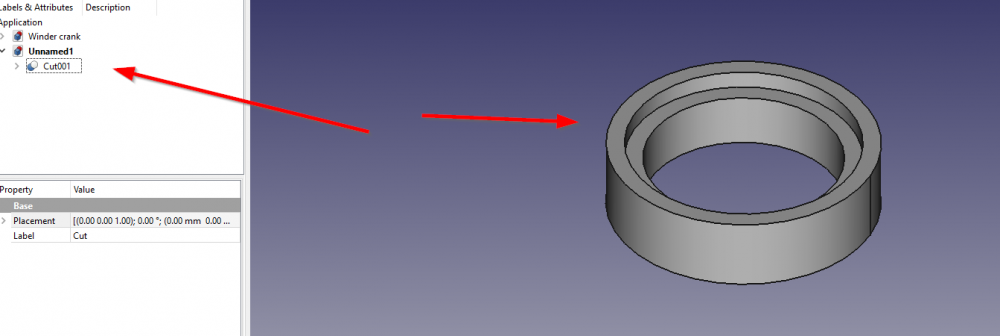

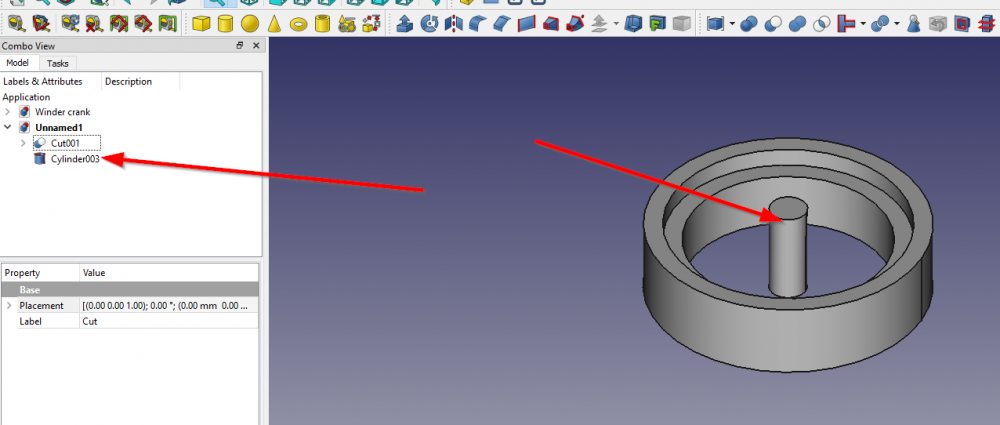

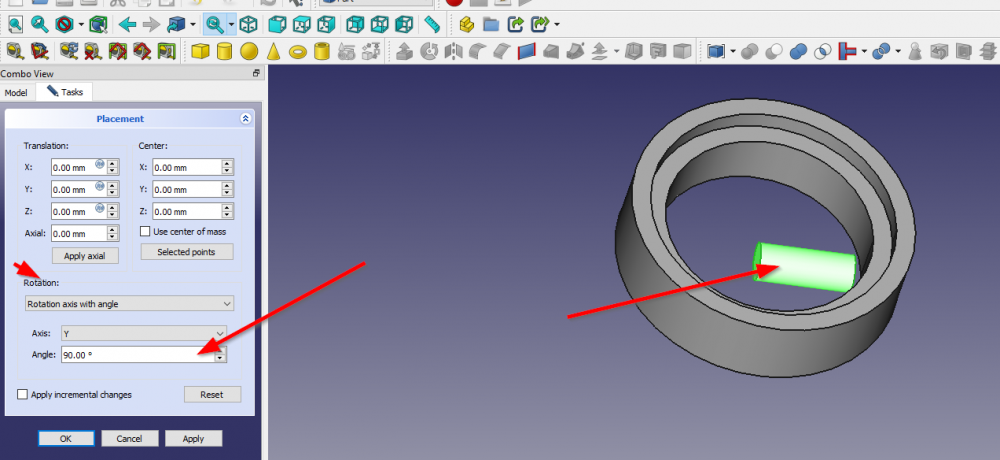

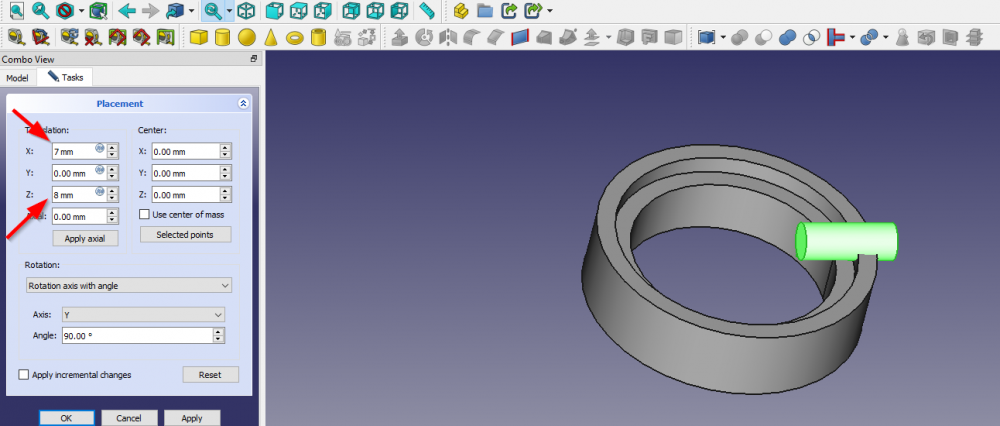

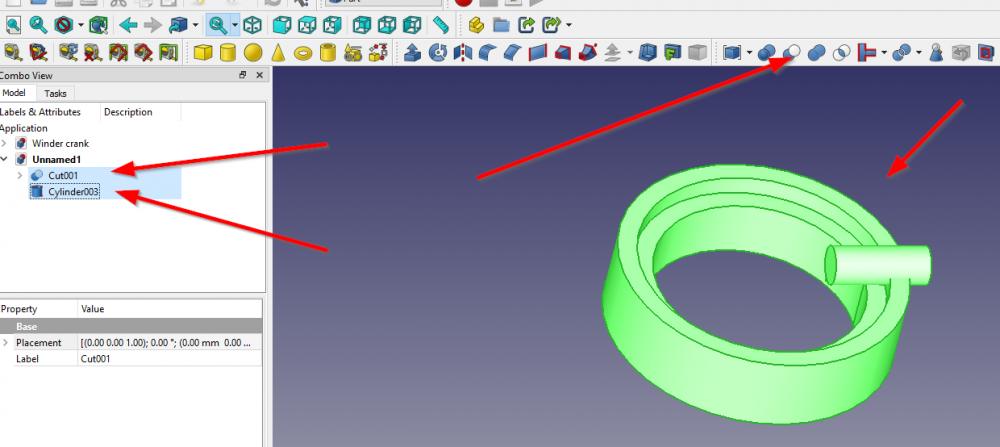

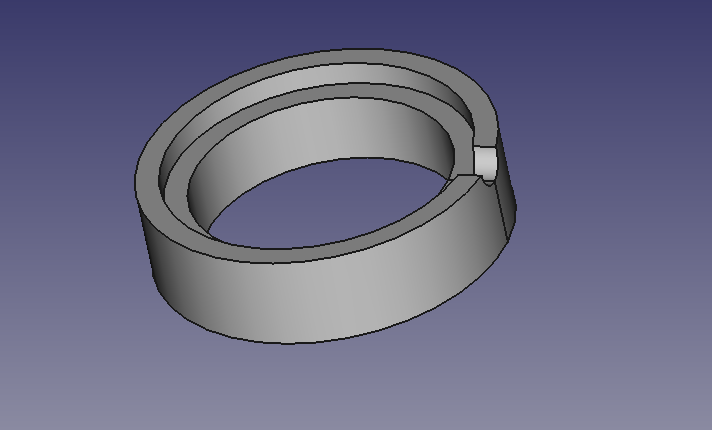

My first keyway cut I didn't really needed these spacers for the lathe changewheels, but I was curious to see if the 'alternative' way to cut a keyway is really doable. Answer: yes and no. Typically that is done pushing a cutter ground for the task into the work with the carriage and advance the cross-slide a bit each time. The chuck is jammed steady with a wood wedge or the like. Here's my findings in case anyone wants to try doing it without watching any YouTube video first (both propositions would denote some weirdness). Grinding the cutter (5mm keyway in my case) on small motor like mine can takes quite a bit of time and wheel diameter. Do drill a slightly undersized hole for the keyway, before drilling the hole for the arbor. I did not, and regretted that all the way through. Set aside some time (forever should suffice) for the work. I used "free machining" leaded mild steel for these, and it has been very slow anyway, at least I did cut two at once and then parted them off. Material and cutter couldn't agree to an optimal depth of cut and suffered much stopping where I had to back off the tool. Anyway, my objective was reached 100%. Original spacer in the middle.2 points

-

I don't know about the numbers, but you can calculate the length with this calculator https://theindex.nawcc.org/CalcPendulumLength.php Weight is far less of an issue than length (effective length is what gives its frequency); what you'll find that's in the ballpark for length will almost certainly be OK for weight.2 points

-

Don't get me wrong, I have nothing but sympathy and admiration for Vincent Calabrese, a self taught independant master watchmaker. I was pleased to meet this affable gentleman and buy his signed book at the Hong Kong Watch and Clock fair in the past. There we have his latest, an attempt to get away with the hairspring. Basically two springy bars make a third rigid one to bounce in between. An (energy hungry) rack and pinion mechanism then mediates to a conventional balance wheel and lever escapement. My immediate feeling is that the elastic deformation of the bars is so small to not have enough isochronism properties. even if they look like one, they vibrate much too slow to resonate like a tuning fork does. https://monochrome-watches.com/vincent-calabrese-presents-calasys-a-new-concept-to-replace-the-hairspring-independent-watchmaking/ Have you ever wondered why the hairspring is a long and thin string as opposed to a short one, because it needs to be to provide both elasticity and isochronism with the smallest energy used. Further to this fundamental defect, I see even some more, as in the large energy absorbed by the impacting between bars, the lack of self-starting, and the difficulty of regulating an "inertial balance", that is with screws. No matter what will be of this, my praise and best of luck to Mr. Calabrese for his invention.1 point

-

I have no Ph.D, in fact I dropped out of high school. So it must have not been because of studying that myself either has never been afraid of tackling the unknown. No crowing and that's right, but let me say it has worked for me too.1 point

-

1 point

-

1 point

-

It may be worth looking hard at a machine that's capable of ABS even if you intend to primarily use PLA. I believe the only difference is temperature. ABS is generally a better materially mechanically. SLA printers may be worth a look-see. The resolution is phenomenal, and I recall the mechanical properties being pretty excellent. Been a long time since I've been around one, but the price has come WAY down. The google ad that comes up first when I search it is only $399. I'm sure it's pretty small format, but for watchmaking, there's really nothing all that big anyway.1 point

-

I can’t quite make it out from your pic but the one that is I think 4.11. If so your pendulum should be 133mm. This taken from the top of the suspension spring to the centre of the Bob.1 point

-

Hey Thanks everyone. After reading all your comments I think I will go along with jdm. Reason I am not great with new software (cad) and as jdm says it can take up a lot of time. So thanks everyone much appreciated. Cheers Gary1 point

-

On the back plate of most french clocks there is a series of numbers of which in part give the length of the pendulum required. See link below: https://www.m-p.co.uk/formulae/frpend.htm1 point

-

As @HectorLooi suggests , a crystal lift tool like this: https://www.cousinsuk.com/product/round-shaped-glasses-bergeon-6400 They crop up for sale used on eBay often. They aren't guaranteed to work in safely removing the crystal though, especially with tension rings.1 point

-

I think you will find it's a Howard Miller. I have looked on the internet and some of there movements start of with U W before the number. They are made in China, Asia or SE Asia. watchweasol was very close.1 point

-

It looks like a crystal lift was needed for that watch. Sometimes I just put one of those rubber movement holders on the inside and give a sharp tap with a hammer while holding the case in the other hand. Crystals do break occasionally, even with the utmost care. So don't remove it unless absolutely necessary.1 point

-

If you use brass shavings, make sure they are relatively clean as well, since if there is oil then it can evaporate and condense onto the work. Sometimes it can be a bit like scrambling eggs and the part will carry on bluing after you’ve removed the heat. practice, practice, practice1 point

-

Good news guys! I remembered where I have seen these things before: On some chronographs the pushers are held in place by these little clips. So I took an old worthless chronograph and voila! Exactly the same. I removed one and it actually fits! so case closed, thanks to all who replied. This is the watch by the way: Have a nice day!1 point

-

I wouldn't want to sand a gold case. Only polish. I'm not used to working with solid gold cases, hopefully someone else can advise?1 point

-

1 point

-

1 point

-

Agree with OH I watch all of his vids really high end top quality workmanship. How I would I would love to own some of his machinery or have even have a workshop.1 point

-

Tommy Jobson I watched this the other day. It's a good video. It shows you how much preparation and skill that is needed.1 point

-

1 point

-

1 point

-

yes its a shame when it happens, I'm not on here as much i would like to be as my work takes me away etc etc, although from a humble and small curiosity in horology I'm now neck deep in parts, tools, website addresses and a couple of lathes, not to mention a few clocks, which by the way the wife would like rid of but I'm keeping. As for the OP question I'm saying its in need of a good service, so apart it comes I'm afraid.1 point