Leaderboard

Popular Content

Showing content with the highest reputation on 09/29/21 in all areas

-

I do think I already answered the question just didn't spell out the details like below. Complete with photographs. now I just had to figure out where mine went to I never use it. I found lurking on the mess on the coffee table yes I know a strange place for it to be but that's where I found it. then a classic green plastic holder for movement recycled by Bulova. Although typically today the holders are all clear in plastic. Nicely spray-painted to protect the inside from prying eyes. For some reason I kept thinking it was bigger like 470 but looks like 100 at 6 V. That should smooth out the pulsations on the meter and give you a better average.2 points

-

2 points

-

I was going to object to looking prettier than DIY. But I do like the way the unit looks but does DIY really look that bad? although I definitely would not build it the way that I did originally. Now you can buy digital panel meter displays already made and you don't have to build it from integrated circuits and all the associated components like you once did which is largely what is filling up the box.1 point

-

I was thinking of building a low voltage PSU for testing Accutrons, then I came across this in in AliExpress. SG$ 19.48 50%OFF | Analog 0-5V 0-10V 4-20mA Signal Generator Rechargeable Battery Pocket Adjustable Voltage Current Simulator Calibrator SG-002 https://a.aliexpress.com/_mrkj9Pc I think it should work and should look prettier than a DIY one.1 point

-

1 point

-

yes that weird unknown metal thing I think I have three of them in my bench at work who knows how many are lurking around the house here. then things get really interesting if you throw in all the other ones for the other movements. Plus you'll need to collect all the tools.1 point

-

1 point

-

Not Patek, could be AP or LeCoultre (which if AP would still be LeCoultre haha). Sometimes this kind of oxidation flees in a normal cleaning. The parts are likely german silver, or nickel plated brass. If they don't come clean in normal watch cleaning solutions the best thing I know of is blanc de meudon or calcium carbonate. It's a white powder, related to chalk, you wet it and rub on the parts with your fingers. It removes the oxidation without introducing scratches or removing plating. When it works it's like magic, when it doesn't, no harm done. It's very easily obtained in this part of the world, as it's commonly mixed with water and swept over shop windows during renovation or whatever. It's not some special thing. From what I've gathered it's essentially French chalk, which comes up in numerous horological texts. It's also the base for gesso. I have 500g I bought for a few bucks 20 years ago and still have probably 450g and I use it once every 3 or 4 months.1 point

-

Hello Bodo! Welcome, you are in the right place for any questions you have about watch repair, from beginner's level to the most respected professionals, all are represented on this forum and are ready and willing to help.1 point

-

Welcome to this friendly forum. Lots of discussions about these movements, most often just a basic search reveals a wealth of information not available elsewhere.1 point

-

Welcome to WRT forum. If the picture was clea,r someone might see what part in the keyless has jumped out of place. Have you googled for NH36 datasheet? Regs1 point

-

FYI, we have a dedicated section where it's considered polite for new members to introduce themselves.1 point

-

Tear down the keyless works, and see what's out of place. Reassemble correctly. I don't know about the NH36 movement (I don't think it's one of them, but I've never pulled one out without tearing it all the way down), but some movements are designed such that the crown must be in some position or another before you remove it lest you find yourself in this exact situation.1 point

-

The easiest answer is simply to quote the opening paragraphs of the preface to volume 2 (Loomes), which state; "This book is written as a supplement to the late G. H. Baillie's Watchmakers and Clockmakers of the World. Its function is to complement it, not replace it. The reader searching for facts on a maker should first of all turn to Baillie, since I have not replaced in this present book any maker already detailed in Volume one, unless new facts have since come to light. This book contains entries of three distinct types: Firstly, makers from about 1820 to about 1875 (later in some instances) - Baillie did not attempt to extend his list beyond about 1825; Secondly, I have included any makers of any period who were men not known to Baillie; Thirdly, I have included some makers listed by Baillie where further information has since come to light that either extends the working period of the maker or occasionally corrects an error." As you can see volume two (Loomes) extends and adds to volume one (Baillie) rather than replacing it, so you really need both. Have a look at Watchmender, I hope you you find it useful, although I haven't updated it for sometime due to a whole load of issues including Covid and a family bereavement. I am getting back into my watchmaking though and hope to be updating Watchmender again soon.1 point

-

So you have these books. Very good. What is the difference between the two volumes, I understand that the Baillie version was reviewed by Loomes, but the information in the Loomes is an addition or a correction? It seems that my James Burton is one of them from London: I have not seen you page so far, I am going to check it out watchmender.1 point

-

G. H. Baillie, Watchmaker & Clockmakers of the World Vol.1. lists; James Burton. Whitehaven. 1795. Watchmaker. James Burton. London (Carey St.) 1805-19. Watchmaker. James Burton. London (Bethnal Green). 1805-08. Watchmaker. Brian Loomes, Watchmaker & Clockmakers of the World Vol.2. lists; James Burton. London, Lincolns Inn Gate. 1811. Watchmaker. James Burton. Norwich. Late 18c.1 point

-

https://www.britishmuseum.org/collection/term/BIOG66495 http://southlow.co.uk/documents/The Burton Family of Clockmakers.pdf I found these for you have a look if I dig up any more on him I will post the links.1 point

-

My mentor gave me a small bag of it. It's dark brown, in the form of flakes.1 point

-

Shellac has many purposes, from furniture polish, to chocolate glaze, to pallet stone mounting, to jeweller's dop stick mounting, to dental shellac. Each purpose would require different physical properties and would probably have different additives to produce the desired properties. If you look at Cousin's catalog, they have several types of shellac. They have some supposedly for "fixing jewels". But I think this is for jewellery work, like for fixing a jewel to a dop stick for faceting and polishing the stone. So this shellac would have a higher softening temperature to prevent the heat from polishing to melt the shellac. I have some of this type and it hardly melts on a pallet warmer over a an alcohol lamp. In Cousin's catalog, there is also another type of shellac in the form of a semi clear stick. This is the correct type for fixing pallet stones.1 point

-

I think shellac from different sources can be quite different since it is obtained from insects, such that the conditions under which the insects were living, as well as the exact family of insects obtained from, will have an effect on the properties of the shellac. After all, different breeds of cows, how the cows lived, and even if the cows are massaged, all have an effect on the taste of the beef!1 point

-

the problem appears to be the word shellac probably does have an exact meaning but in watch repair it appears to be a lot of stuff. A lot of somehow different stuff over time. Even if it is supposed all be identical. The flake shellac that I have complements of the lecture I was once asked. The person at the buy I can't remember how many pounds of the stuff so they gave it away to everybody it works really nice. Then I can't read Roy mentioned it way back before but I still remember the instructor had at school said there was a difference between the various shellac with the old being better. I've noticed that at work as various bottles will end up on my bench acquired from wherever it's acquired from. With some of it not really melting very well just from memory I just didn't like it so I tend to just use the flakes as it does melts really nice and it's nice and shiny and hard.1 point

-

I tried this today but I'm afraid the result was disheartening. I tried with two types of shellac bought from Cousins. This and this. The clear shellac is very brittle. The dark brown shellac is more tough and doughy in its texture and a bit reminiscent of gingerbread dough in color. Anyway, after having rinsed a piece of each kind in IPA (about 23 degrees Celcius) for about a minute and a half, they were still "wet" and soft after several hours. Then also, I remembered a re-shellacked fork I had rinsed in IPA several month ago but never got around to use, and when I poked the shellac (the clear type) today if felt as soft and doughy as did the day I rinsed it and it disintegrated. I doubt it would be any different with shellac flakes? So, for the time being I'll keep cleaning pallets manually with Horosolv degreaser.1 point

-

1 point

-

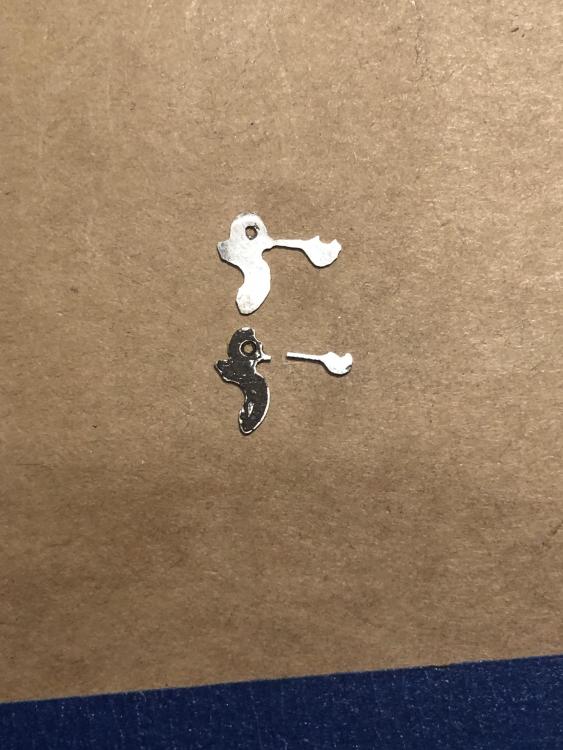

Many thanks again for the help on this one! In the spirit of learning I'll keep going in both directions, trying to source a part while I make a replacement. The references above are great - clearly I need to keep working on identification and cross-referencing skills with the catalogs and various other sources. Looks like a chance to revive the old army identification skills with those decks of cards that showed silhouettes of planes and tanks (now adapted to watch parts). A rough-in of the replacement is shown below. I've filed and shaped it a bit more but may start over to give it another try. Quick summary of the process: Started with metal from a feeler gauge Punched the screw hole Attached the broken part to the steel with Shoo Goo Roughed in the shape (very slowly) using a cutoff wheel on a Dremel Shifted over to various files for the final shaping Will keep everyone posted on the outcome!1 point

-

1 point