Leaderboard

Popular Content

Showing content with the highest reputation on 09/21/21 in all areas

-

I have recently used a jacot tool to successfully re-polish a badly worn pivot in a pocket watch the first time in my life. I have watched Richard's videos about it and I also went to a book printed in the same year I was born in 1976. This book is written in Hungarian and was one of the book used by the state sponsored and only one watchmaker school as far as I understand. (To my knowledge you cannot learn watchmaking any longer in Hungary as of now.) I scanned the corresponding pages as how to re-finish a pivot including the usage of a jacot tool. It was a great help to me so I thought I share these pages with you. After scanning the pages i sent the pdf through a pdf to txt engine then sentence by sentence I translated the Hungarian text to English. I learnt watchmaking in English and it might sound strange but the Hungarian name of the parts and methods were unknown to me. This added some more difficulty on top of the fact that my English is far from perfect. I am writing this because I am not sure how good the end result is. If anyone feels that could correct the text so it would be more readable or would make better sense please do so. Enjoy if you can. jacot_tool.pdf jacot_tool_Kopasok_javitasa_magyar.txt jacot_tool_repairing_wear.txt2 points

-

Which is also why the so called hollow shape in the picture by OH is not superior. The blade will contact evenly only if it's wide exactly as the slot. Whilst the wedge profile will be in full length contact with slots of different width, as long there is no interference to the bottom.2 points

-

No. A small discrepancy in width is not that important, what it is instead is that a regular wedge shaped driver blade will not touch the bottom of the slot. If it does, it will easily cam out. We don't say that the driver is sharpened, we say it's dressed, I find that the latter term better reflects the care one exercises. Now, since there are screws of the same head diameter but different width slots, that can mean you have to keep two drivers, one with a wider tips and one with a narrower one. Check and further discuss this subject in the topic below2 points

-

Yes Steffen Pahlow is at the top of his tree when it comes to watchmaking. He has a wonderful workshop and his set up is out of this world. You should watch all his videos he is the master.2 points

-

Most damage is caused by bad fitting screwdrivers. This is what I used to do with clock screws. Remove all the burr using various needle files, re-cut the slot using a slotting file. Polish the head in my lathe using various enemy sticks then burnish. If the screw needs bluing than that is carried out. Also with clocks if the bottom of the screw is showing that is also polished and burnished. You can do the same with watch screws the only difference is the scale.2 points

-

For a flat polished screw, I prefer to see them with whatever is left of the original finish; when you start filing on them that itself raises burrs so it's all or nothing. I get really irritated when I see a buffstick job on formerly flat screws. That's just my opinion though.1 point

-

That is a good way to start. You will soon get the hang of things. Going back to black polishing you don't do that with clock screws as stated most are domed.1 point

-

The above is important stuff, but I'd just like to revisit the original couple responses for a second. Currently I don't have a lathe, but I have files and emery paper. My immediate objective is not to achieve a high level of finish, but simply to clean up the most unsightly and damaged screws. From my reading of the above, my guess at a procedure would be: 1) remove burrs using needle file or other small file. 2) re-cut screw slot using slotting file. 3) give the screw a light polish with emery paper. Does anyone want to weigh in on this? I realize it's not ideal, but I feel like I need to start small here.1 point

-

The reason being, you want the downward pressure from your index finger to result in a wedging action on both sides of the slot along the whole width of the screwdriver blade. This inhibits the blade from slipping sideways out of the slot, and distributes the turning force evenly, so the slot isn't damaged.1 point

-

Oh yes! Here are some more: https://www.enstock2e.top/products.aspx?cname=hublot+classic+fusion+ultra+thin+skeleton Picture of the back of one too from this page. Very convincing for $82. The fact the OP didn't post a link to the selling site; that the obvious question on selling price has been ignored; and there are clearly fakes out there all screams alarm bells. @Rishah- did you get your watch? how much was it? is it $???? well spent? is it ticking nicely along at 28,800bph etc?1 point

-

There is an excellent explanation at this link: https://watchesbysjx.com/2015/01/explained-the-fine-art-of-black-polishing-aka-speculaire.html This pretty much exactly as I do it, including the slots and bevel around the head. I have a Lorch screw polishing lathe like Steffen's, and have done may hundreds of screws on it, but I find the tripod is faster and you can very easily adjust it to match the plane of the screw head rather than needing to grind away a possibly significant amount of metal to get it initially flat. Polishing with hand held abrasives in a lathe will always give a slightly domed surface. On many old pieces, especially clocks, this is desired. On most high grade watches the screws are polished dead flat, and to get that requires a little more work- either a screw head lathe or a tripod. With the tripod you can also flat polish any flat part, simply glue them to a brass block that can be held in the tripod (I use superglue, a few minutes in acetone and they unglue).1 point

-

1 point

-

A fair handfull, nice to see the TIMEX is well represented and not treated with scorn, they were in their time innovative and ahead of their time well worth keeping the name alive.1 point

-

1 point

-

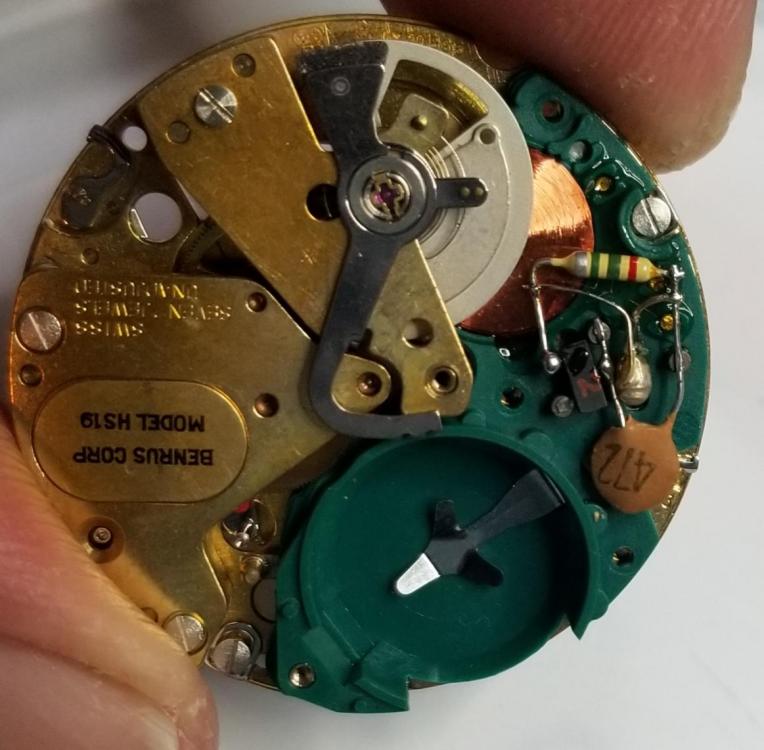

I've been busy...rebuilt 25 or so Timex Electric and Electronic watches in the last month or two. 32 more in the que. I heard there's some guy around here that likes to shoot the movement with contact cleaner and call it good. That's a shame. I can fully rebuild one of these, including wet sanding and polishing the crystal, in about 3 hours. No need for cutting corners I am the Timex whisperer Some...1 point

-

Thanks oldhippy will check that out, it does drop into the slot will check if it lines up with wheel and pin if i can i will post a video of it if need be1 point

-

Even with freshly sharpened screw driver heads I can sometimes still bruise the screw head. Does this mean you need to make sure the screw head is always the correct width size for each screw head slot? Meaning you may have to grind each screw driver head before use? I find that there is some variation in slot width thickness even amongst screws of the same head size (length).1 point

-

That's not difficult really. Cut and glue your favorite (some are better than others) waterproof emery paper on ice-cream wood sticks.1 point

-

Thanks guys that's helpful. Yet another reason for me to start saving for a lathe. @watchweasol that video is nuts. I hope to have that kind of equipment by the time I'm 95.1 point

-

I've been thinking about a safer method too. I was thinking of getting a sheet of Perspex and drilling a snug fitting hole, then insert the barrel into hole. This way, all the teeth will be supported and the force will be distributed.1 point

-

As correctly noted above the connector looks familiar but it's not what you're thinking it is. This is the one you want it fits perfectly.. https://www.ebay.com/itm/221445284681 I purchased the connectors for an unfinished project that would be helpful. The Chinese machines lack audio and the ability to listen to the watch especially if you're having problems is really important.. The ability to listen to the watch and see if it actually is an audio problem or something else. The easiest way to get audio from the timing machines is to hack the microphone.. Using a pair of the connectors you can make a pass through I would put it in a Metal box though so it shielded.. This way the microphone and continue to function like it's supposed to and you have access to everything you need to have audio. In other words it should be relatively easy if you have the time which I seem to be lacking to put an audio device on your timing machine and then listen to the watch and be unhappy with how horrible it can sound. Then I'm not joking about how horrible it can sound I have a horrible sounding watch currently at work I have to deal with it sounds very very bad... But at least in the audio I know why the timing machines unhappy with the watch. With the audio you take away a lot of the mysteries that you see on the timing machine. For testing purposes the watch should run just fine without lubricants. You might actually find the reality is a watch runs better without lubricants because all lubricants tend to have a dampening effect. On the other hand try to run your watch over long periods of time with out lubricant and see what effect that has it's usually not good. But there can be an issue with the lubrication of the escapement.. They get carried away with the 9415 then that's definitely an issue and will cause Amplitude loss as it tends to be sticky if it's applied way too heavily. The lubrication aspect is interesting because George Daniels was very very unhappy with Omega.. Look at the tech sheet for the coaxial escapement and you find lubrication but my understanding is it's not used as lubrication.. It's used to dampen the impact of the escapement but it still required. Defeating the whole purpose this escapement of not requiring a lubrication..1 point

-

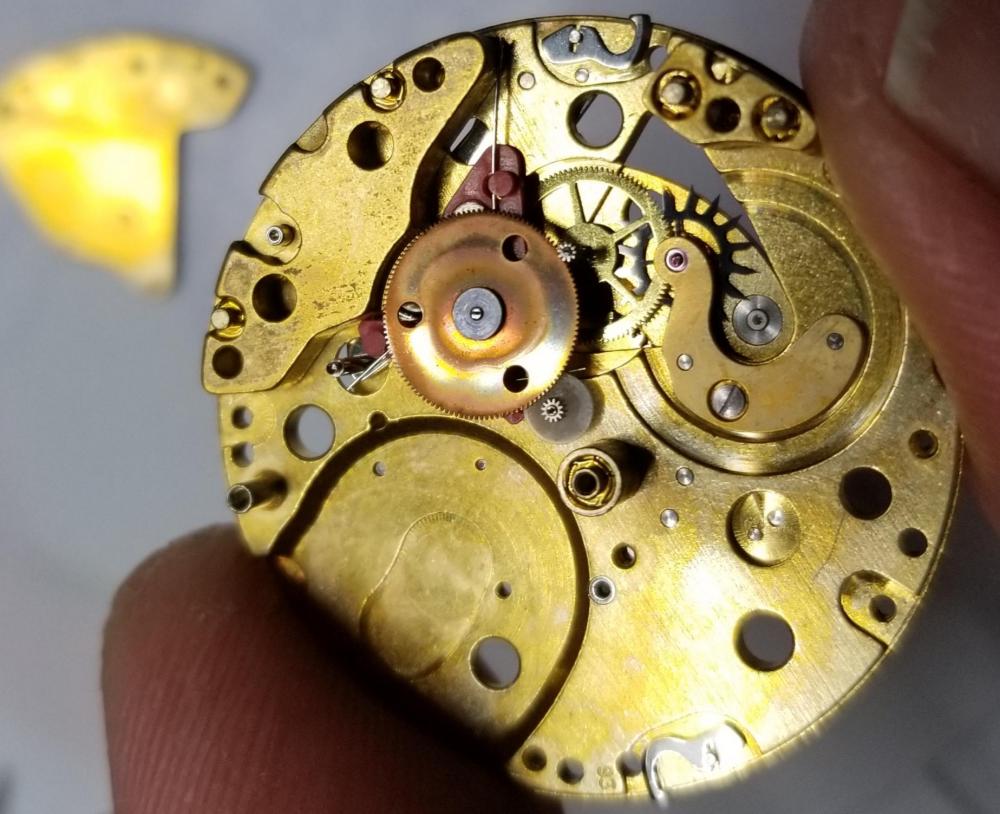

Winding wheel is missing a few teeth. Is the seller selling you this as genuine? Does he accept return?1 point

-

It's still tripping so check the lever and the pin in the wheel and make sure the lever holds the wheel and pin. As it's a count wheel strike are you sure the lever that drops into the count drops right down in the slots and lines up with the wheel with the pin.1 point

-

1 point

-

Hi This guy has all the answers, and the tools. https://www.youtube.com/watch?v=nYamLPIrvr81 point

-

Hi thats a shame its such a historical piece, but understand if there is no room. Prices seem to be between £750 and £1200 on the net so I would say around the £1000- mark. would be interested to know what it goes for and hopefully to some one who will use it.1 point

-

1 point

-

Unless you suspect it is causing an issue then no. Removing involves removing the friction fitted parts and replacing back to the correct depth.1 point

-

you really need to elaborate on this? As most commercial watch cleaning machines use ultrasonic and I've never heard of watchmakers talking about vibration destroying their pivots or doing almost anything else bad to the watch. then there other commercial machines that vibrate when they rotate around. There are exceptions to this? If you leave the watch too long in some commercial watch cleaning solutions like way past the recommended time you'll start to see chemical etching. But as far as pivots mysteriously disappear in the cleaning machine that's news to me? I'm finding the story doesn't make sense to me? You had a winding problem then at some point in time you totally disassembled and cleaned everything? Did you take the balance jewels out and clean those? Then I'm assuming you moved the regulator trying to regulate what about the beat adjustment? Here's what's bothering me timing machine you need to understand how to interpret it. It shows you're running really slow and the beat is perfect but I doubt that? ideally will be nice if you let the power off and visually verified the watch really was in beat? Because I don't think your watches in beat at all I'm attaching an image from the eta website of your movement. when you have a watch that has a floating beat adjustment it becomes really easy to get that out of alignment and if you go too far like to the extreme your timing machine may have an issue and not give you the correct information.is supposed to have the ability to adjust in either direction but yours is at the extreme there is no room for adjustment so I think it is at the extreme and it's a problem amongst other things. as an experiment you collided push the stud holder away from where it is and move the regulator so that more corresponds to the picture that I have and see what that does for you. Also of course you want to pay attention they hairspring that the regulating pins aren't too tight of the etachron system. Sometimes people adjust those two tight. Then leave the micrometer screw alone it's not that I get you anything right now. then this is an interesting statement because the final rinse in our cleaning machine is isopropyl alcohol. It was recommended by the manufacturer of the commercial watch cleaning machine.1 point

-

1 point