Leaderboard

Popular Content

Showing content with the highest reputation on 09/19/21 in all areas

-

1 point

-

1 point

-

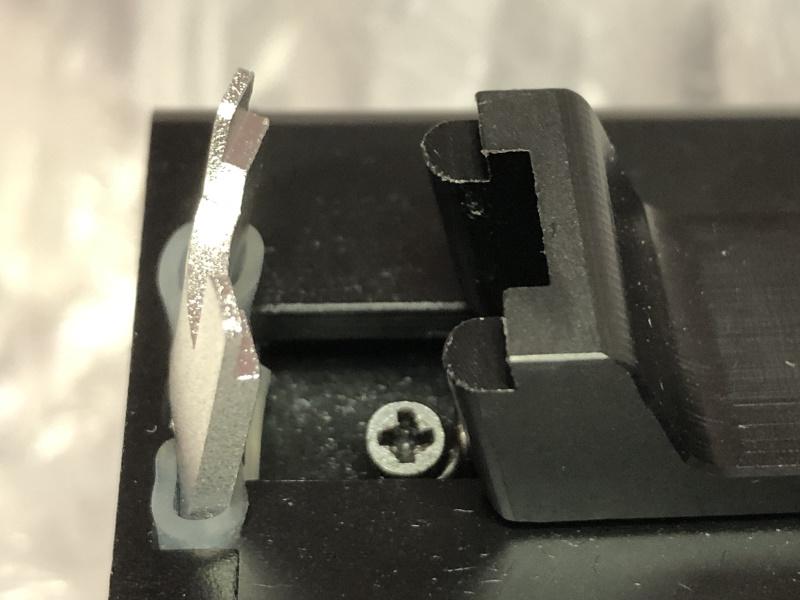

If you push the up down keys on the 1000 machine the only thing you change is the contrast of the display. It does not have any way to adjust the gain. If you look at the display of the 1900 the top right it displays the beats per hour the machine is set to. Alternating with the gain adjustment. No such display appears on the 1000. Another reason why the 1900 is a much better purchase than the 1000 is not just a pretty color display that makes it different. On the other hand having any timing machine in the hand of anyone working on a watch is better than no timing machine like we used to have when people are trying to diagnose their watch looking at a crystal ball or whatever they were using. Or worse than a crystal ball using a phone app. To understand the problem of the microphone I'm attaching a picture. The Chinese didn't quite Clone the microphone correctly. Just a little additional machining on the outer jaws and the problem would've been solved but they didn't. Which is unfortunately bad because This is how you're supposed to hold the watch if you want the best signal quality. Not so much noise just not getting a good signal. This is also a common problem with some watches in their chase if the casing material insulates the movement from the outside world you have inconsistent results. In other words big heavy cases tend to be bad cases with plastic movement rings Also can be a problem. Then it doesn't matter whether this is a Chinese machine or Swiss machine some Watches in their case are just hard to pick up. It's also important that the crown face outs as that cans to help get a better signal but not always. Do you have a preferred way to hold the movement holder in the timing machine Pick up? If you look at the picture way up at the top he's holding the movement holder sideways is this the way that you hold the watch or do you have the knob of the holder facing out? WeiShi Timegrapher 1900.PDF1 point

-

Hello Klasskier, Thank you for the information, I apologise for not replying sooner, ill heath. Hello jdm, I did try and make an introductory post, but I'm not very good at them. After 15-20 minutes of indecision about what to say, I gave up. No offence intended. Best regards, Ed.1 point

-

Dear KarlvonKoln, thank you very much for your thoughts and reply. As you stated, the core of the problem is professionalism, I think. Because, again as you said, a good business, no matter what business they are in, should not leave any questions in the customer's mind. I was residing in Japan for quite a while and was nagging about the prices, even a simple battery replacement you will be charged around 1000¥-1500¥ (roughly $10-$15), and this was until I learn more about the process. An old watchmaker let me watch the process. It was a Citizen digital watch from my childhood and my goodness, even the battery cover lock hold by an extremely fragile lock. After carefully taking out the dead battery and replacing it with the new fresh one, he touched the watch back (electronic board) with his tweezers and asked him what he did. He said that he shortcut the board. Cleaned it properly, re-lube the gasket, and put it together. So it was not like replacing a triple-A remote control battery. There are lots of small details and never felt bad about paying what he asked for. My latest experience though was a disaster (of course there was a language barrier too). I cannot agree with what you wrote more. The purpose of this topic is also the reason for his lack of professionalism. I learned my lesson, you really get what you pay for. Again thank you for your precious time and reply KarlvonKoln. Have a great weekend ahead.1 point

-

Only $45? That's less than I charge, and I am told I charge very little. After reading what was written above, I can understand why you are concerned, Khang. Learning to be a watchmaker will teach a person to repair watches. But one must also learn to be a good business owner also. A watchmaker can be a good businessman by explaining how he can repair a watch, and what his prices are for standard things, and what he charges for a complex problem. And he will do this before fixing. It is important to put the customer at ease, to show the customer that you are a professional, and that the customer will know how much they may need to spend before the work is done. I always examine a watch closely, then communicate with the customer. I make sure I know what work will need to be done so I can tell them, and explain what I will do and what I will charge. And when they agree to that, then I begin the work. If it is a simple cleaning I will tell them the cost up front, but if I see something that needs to be addressed as I prepare to clean (as sometimes happens) I always tell the customer. It should always be their choice. I believe good communication is very important. And I always place one of my business cards in the package with their finished watch or clock, so that they may contact me again, even if only to complain if something I did was not satisfactory. This is important too, because if it happens that the repair work I have done has not fixed the problem completely, then the customer must have the means to tell me. (This is also why it is important to understand the watch's problem as thoroughly as possible.) Another mark of a true professional is being prepared to face a shortcoming with grace and diplomacy. If one can make a displeased customer happy again, and willing to return, that is very good business. I have had to do this in other work in the past, and even though it is hard to face an angry customer, I believe it is something all business people should do. It is a good thing to learn, and can teach you how to do better. From what you have written, this watchmaker you visited told you nothing of what he would do or how he worked, nor gave you means to contact him. It is no wonder you are apprehensive, he has not shown you any measure of professionalism. In short, if he is a very good business person as well as a good watchmaker, you should not have to wonder if he has serviced your watches. You will either find yourself pleased with how well they run and how he has cleaned and polished them up, or he will explain why he could not repair them - and is not charging you - and will refer you to someone who specializes in your brand of watch and would fix it for you.1 point

-

You do this test dial-down. Firstly, you get a feel for how far the balance rim will move. But remember that slight side-shake will also allow it to tilt. You will be able to see the pivot move upwards into the jewel hole in the balance cock. If a chaton has been pushed outwards (increasing end shake) then you may sometimes actually find that the cap jewel spring does not appear secure against the cap jewel. It doesn’t prove which end has moved. That requires further investigation such as inspecting balance rim clearance against the plate and the interface between the roller and pallet fork.1 point

-

Just curious... did you lubricate the pallet jewels or the escape wheel teeth?1 point

-

yes you are supposed to place the watch directly in the timing machine microphone if you want the best pickup. fter all that split the microphone holder was designed for is designed to hold watches movements in particular. There is a minor problem for the Chinese isn't designed the best but still that's what it's designed for. Sometimes it doesn't matter who's movement holder Chinese are Swiss if you hold a complete watch that sometimes is problematic. Because the jaws are specifically designed to grab the edge of the movement the dial side in particular. A complete watch like a pocket watch for instance has rounded edges in the case and sometimes that doesn't work well. and no matter what you do want to be careful that it actually is in the microphone and not at some weird angle are on the edge or something else then it could pop out.1 point

-

I agree with @jdm (lo and behold! )! Try to increase or decrease the gain. I think you might find this post (or the entire thread) informative. Let us know if it helped!1 point

-

1 point

-

as it was a new old stock movement did you put it on the timing machine before you service? then why did you replace the mainspring barrel? Then it appears to be your holding the watch in the timing machine in the movement holder why are you not holding the watch in the timing machines holder directly?1 point

-

Purchased a new one from Cousins. There is however an issue while on test overnight it stopped. After a lot of fiddling I stripped down again and found a tooth broken off the barrel. I normally check all of the wheels and pivots when I strip with my microscope but it’s light ring had broken and so I did not inspect closely. My mistake and since found the fault re microscope it’s light source is via fibre optics cable and the units projector lamp had failed. The new lamp and barrel are on order. what fun1 point

-

Hello all. It’s been a while since I logged in here to chat. I discovered Facebook and found Mark’s Facebook forum which is keeping me occupied. I do feel compelled to return however to check out one of my all time favourite threads, “Lew & Me”. Well since last logging in, I have gained another stray. My wife and I discovered this little tabby fellow soaking wet, shivering and near his end whilst we were out walking in the woods one day. Happy to say he has now been adopted by us and in fine fetter. His name is ‘Monty’, and settled in perfectly. Thankfully he is not as interested in watches as is his ginger step-brother Joey1 point

-

The mere vibrations destroy pivot hanging in solution. No need to vibrate against anything. Regs1 point

-

Are you by any chance trying to regulate using the fine regulator adjustment rather than move if the arm which carries the index pins directly?1 point

-

1 point

-

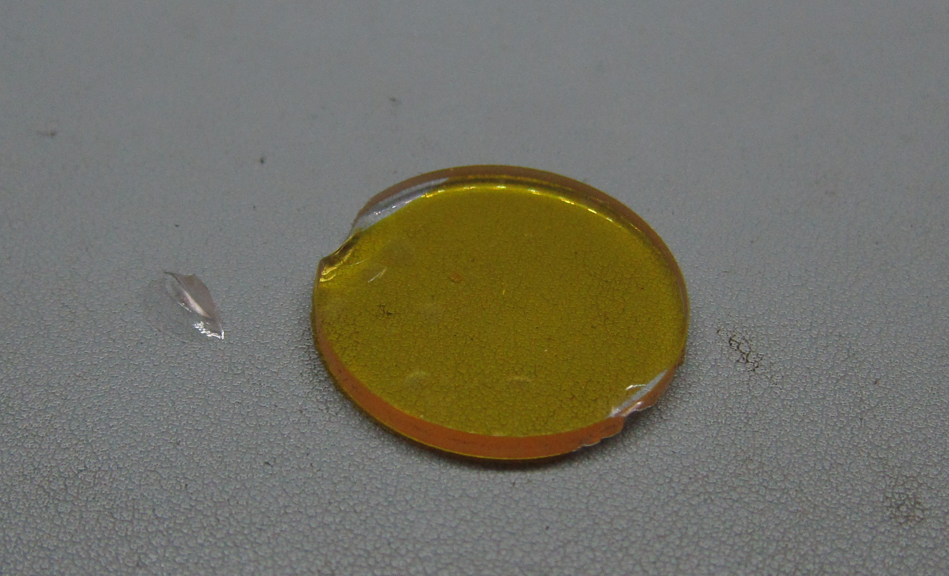

Finally got around to this. Here is a pictorial. I first taped the crystal with Kapton tape because the stuff seems to not stretch. Once I put it on, I trimmed around the crystal so that the tape would not touch the bottom fixture. I had already printed the upper fixture that perfectly fit inside the case. Both fixtures were 3D printed. Then one swift squeeze and voila. There was a little bit that chipped off. I had already ordered a crystal that was the correct diameter. However, I was off on the thickness by 1mm, so will have to order again.1 point

-

1 point

-

I didn't see a "media" sub-forum so I hope this is an OK place to post this. I just finished watching this documentary about George Daniels and Roger Smith. I read "All in Good Time" over the summer and enjoyed this documentary as well and wanted to share it with you all. https://www.amazon.com/gp/video/detail/B06Y39YSC4/ref=atv_dp_share_cu_r1 point

-

Cut a 5-6cm round from a credit card. On top of it place a round of 280 grip wet paper if there are deep scratches or dings. This is held on a mandrel in the rotary tool. which is much better if is hold horizontal by some support. Place a cup of water under the work and dip often. Set low speed. Better to keep the glass in the watch otherwise you risk it to fly away and chip it. Keep the watch as much as vertical as possible, Look well where the wheel is grinding. You want it to go where the scratch is, by including the watch just a little but, not just anywhere around. As you practice, you will be able to recognize when grinding in the right spot , as the white streaks (that is glass) shape differently on a scratch. Replace papers as needed, like once or twice, it will be difficult to tell because the glass will be very hazed, but try your best. When sure all is gone switch to 600 grid and polish where you worked before, again no need to go all around. Glass will be still hazed, but less. Next, do not waste time with finer paper, use an hard felt wheel, 50 x 15mm, and cheap oil diamond paste. This time you will be working with the outer wall, not the face of the wheel like before. For quick work you can use a single grade like 20, finer than that does not make much of a difference. The way you do it is to place a little paste toward you, and draw from that gradually with the wheel. Clean well with dish detergent. Very likely you will see more defects, in which case you will have to go back to wet paper. It takes practice to do all the above right but in my experience the paper/paste combo is the faster and most effective method. but after you mastered all the steps you can bring a terrible glass to perfection in 45-60 minutes.1 point

-

In my experience, if doing this by hand, it simply takes a long time. Dremel type tools are much quicker, but take a bit of practice to get the technique sorted. With acrylic you can use pretty much any abrasive, including toothpaste if the scratches are light, and you will usually get results in only a few minutes. With mineral glass, you require harder abrasives and more time. With sapphire, you will need probably need to to use diamond pastes, and it will take longer still. If you search this forum, you will find a number of good threads on the subject. For glass and sapphire, you can polish by hand, but it takes forever, you will almost certainly need to use a Dremel or similar. If you are using polishing disks in a power tool, you need to run them at a relatively low speed. There are a number of youtube videos about this too, most of which are trying to sell you their whizz bang product, but the technique is the important point in these videos. The brand of the abrasive is not really important.1 point