Leaderboard

Popular Content

Showing content with the highest reputation on 09/16/21 in all areas

-

2 points

-

I got to wondering if this was a good idea. I have good J.E. Kampe calipers for checking true-ness. But I've always been nervous about correcting an out-of-true balance in the calipers. DeCarle says it can be done in the kind of calipers I have, but I don't like to. I worry about the pivots. So if I see a need for correction by turning the balance in the calipers, I will take it out and encapsulate the staff in a proper sized stump and punch, before adjusting it. Back and forth - check it in the calipers, correct it in the staking set. I've had good luck so far, though admittedly I have not had to true that many balances. Most are fine. Does anyone else do this? It was the safest way I could think of with what tools I have.2 points

-

UPDATE: having put the replacement balance back to where it started, with just the screws it came with, I decided to go ahead and try the original hairspring on it. And, Glory be!, it's slowed down enough that I should be able to regulate it properly! I wore the watch yesterday to work, and at the end of the day (eleven hours total, by the time I got home and changed) it was only behind by about 48 seconds. I can deal with that. So, here is what I suspect is going on. As JohnR725 pointed out to me - " the hairsprings typically came in three strengths somebody might a swapped another hairspring and visually you cannot tell." That's very true; I cannot tell. The old hairspring, and the hairspring that came with the replacement balance are visually identical, down to size, thickness, coil count, everything. But clearly they are tempered to different strengths. And as Old Hippy pointed out, that's enough of a difference that all the horsing around I was doing with it would not have accomplished anything but more hardship. I have to agree at this point: I think that replacement hairspring was originally made and vibrated for a MUCH heavier balance. How it got stuck on this replacement balance is a story I may never know, but it certainly was a bad fit. My original hairspring was in excellent shape, and seems to accommodate this replacement balance very well. And once in beat, it falls into a range I can much more easily regulate. Thank heaven for that. But I know full well that I got lucky. O.H. isn't kidding. Swapping balance parts around is kind of like playing "watchmaker's roulette" - you'd be gambling, and your chance of success is worse than you think. Dang - I wonder if I should even hang onto that other hairspring. If I ever encounter a balance wheel made out of lead, I guess I'll know what to reach for. But this was another small adventure. Live and learn.2 points

-

2 points

-

at the link below scroll down the section titled Joseph School of Watch Making. then download unit 2 truing a balance. This will explain how to do it I don't know how you do it is staking his set it doesn't look very promising to me really need truing calipers if you really want a true a balance wheel. then I snipped out an image for you. The truing caliper is supposed to rest on the conical part of the pivot. This means the pivot isn't touching anything at all and can't break. It also means that the truing caliper has to be really tight on the conical part of the pivot so it doesn't move it all or you break the pivots. then it's really important to pick the right hole size especially we doing bigger pocket watch staffs with bigger pivots. https://mybulova.com/vintage-bulova-catalogs1 point

-

I think your piece predate by much the time when cabinetry started having brands. Material houses also sold tools and benches, it's logical to suppose they had them made in small batches from the most convenient reputable supplier. And any good local woodworker was supposed to be able to make one based on a drawing or customer requirements.1 point

-

Hi Amy that one nice bench, cleaned and polished/waxed it would make a nice piece of furniture. Me I wouldn't part with it it has a history and family connection and as it stands a classic. Keep it.1 point

-

For use in little watchmaker lathes by far the best tool is the Horia hand held knurling tool. They aren't cheap, but do come up on Ebay here and there. The lever action allows you to really control the pressure and coast around and develop a nice knurl. Eagle Rock makes a similar tool at 1/3 the price, but it's screw operated and much less user friendly.1 point

-

If you try taking your photos from further away and then cropping them down you might get better results.1 point

-

1 point

-

Staking sets such as these can be had on ebay at an assortment of prices depending in make and state of completeness, although many stakes and stumps can be bought singly.1 point

-

Not sure what you mean. If you turn something with a loose collect, not only there will be no precision in the work, but you risk to damage the grabbing surfaces of the collet also. Other than that, using a 2nd headstock is done sometime, but isn't common. First of all, turning far way from the collet is not an every day occurrence in watchmaking, so supporting the sticking end of the work is most often not necessary. When the cut is far from the collect, and is not possible to shift the work into it, the common way is to mount the chuck drill, bring the work almost all the way in the collet, face and center drill it. Then use a tailstock center and re-position the work for that. There are tailstock centers which cut in half on the vertical plane, or concave cone, or bull nose, to hold and center satisfactorily. Although these all are more for general machining than watchmaking. Last but not least, headstocks were, and are, expensive. Savvy craftsmen would not buy one unless in the absolute necessity, and knowing that it would have payed back its price.1 point

-

John is on the money. Those Vertex ATP had radium lume which is now looking orange / brown. Your hands are the original blues steel type. So, wash your hands after handling. Your dial is a later MoD re-dial by the look of things. I like it. Curious that it does not have lume plots. Perhaps intentional to not have lume. I do think it looks fine as-is. The crown is not original. I know somewhere that has the originals which are unique to this watch.1 point

-

initially I made a nifty drawing for you but something was bothering me so I found the tech guide. So the spring does go where I say it does and then you need the jumper in the right place. One of the things that helps when putting these together is to put the jumper under the disc. This way can get thing in place and then push the jumper back against the spring and then slowly pushed the plate in place. Because trying to put it together and then put the plate on top seldom works and parts fly all over the room.1 point

-

Hi having a close look at the dial I think not there is no residue at the hour markers.1 point

-

1 point

-

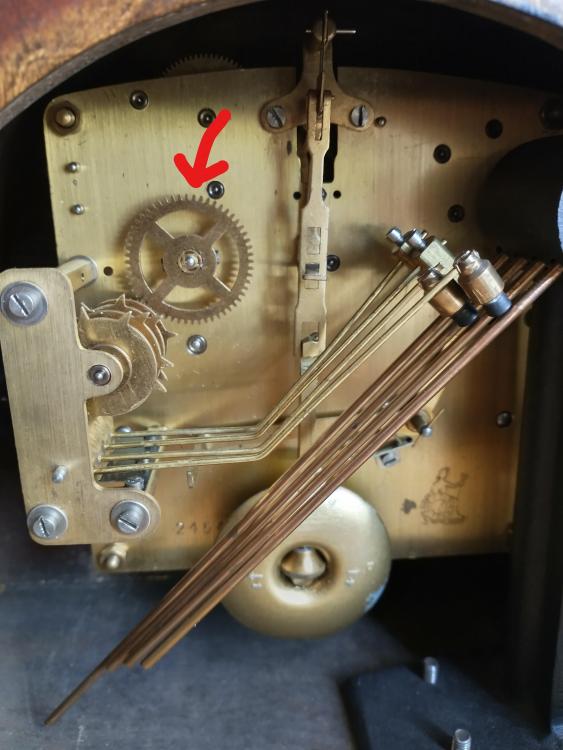

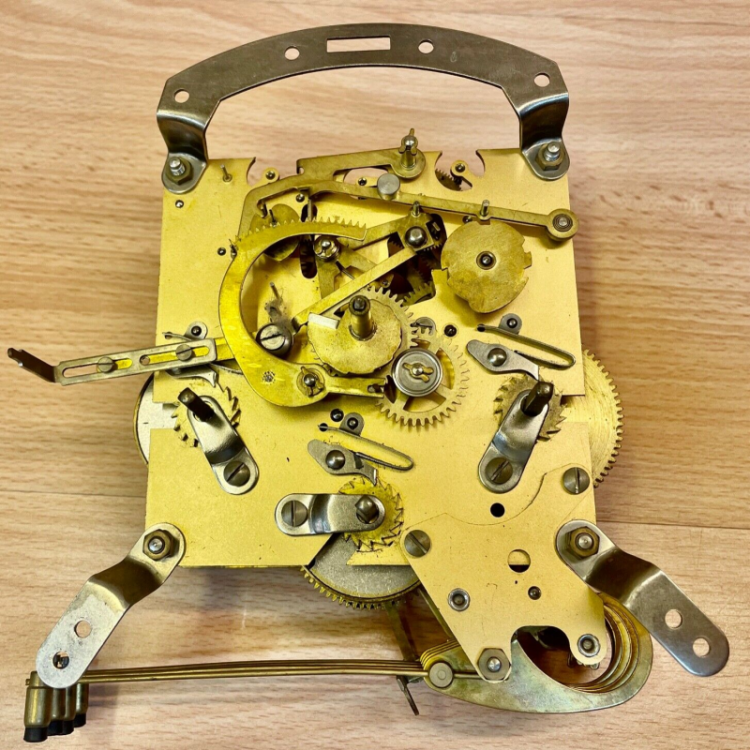

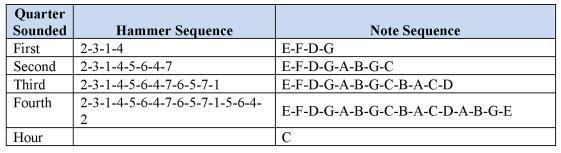

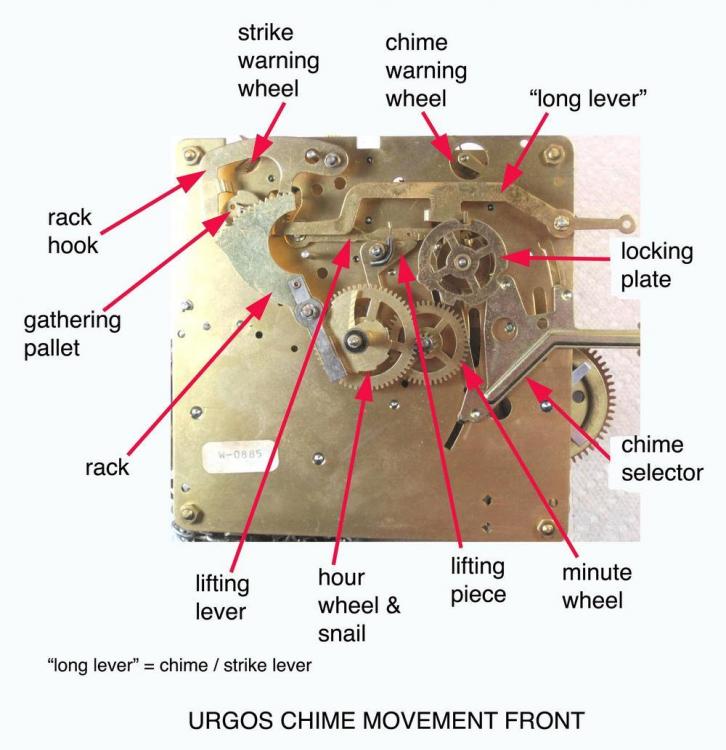

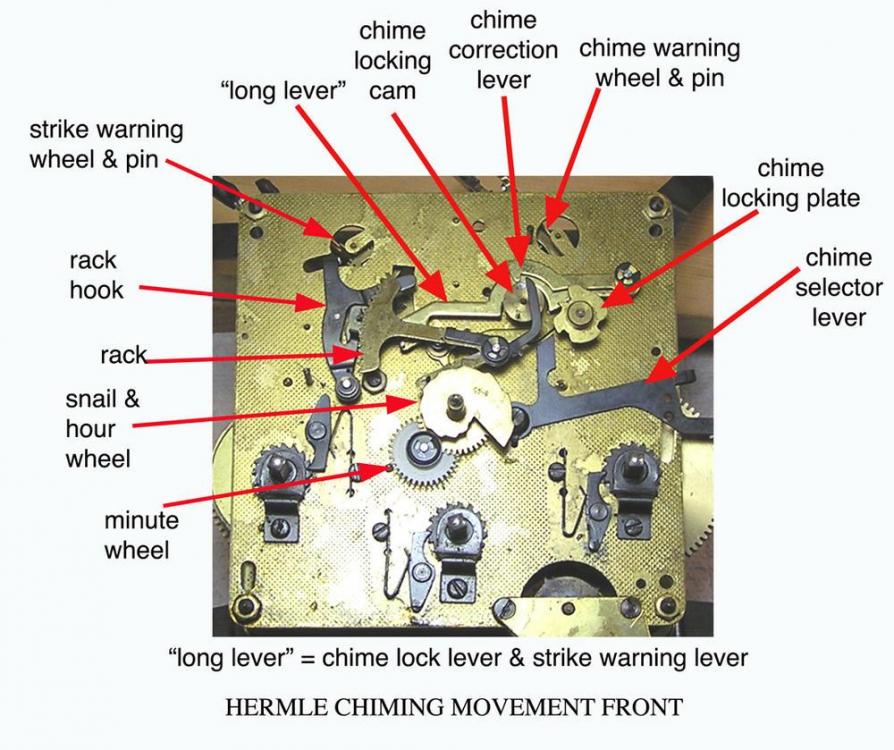

Hi Unfortuatly there are no picture of the front plate which would be useful as all the control of the chime/strike takes place from the levers on the front plate and the star cam on the center wheel. The star cam has 4 points on it, one longer than the others this lifts for the hour strike the other three control the quarters and the chime locking cam on the top right of the front plate controls the duration. Also if the chime/silent lever is at half cock that may cause problems, It is also possible that the pin barrel and drive gears are out of sync. attached two pics of front plates to illustrate cheers1 point

-

Yes I will put up pics when time. The issue with the watch is it was really dirty and I suspect it has been a long period between services.1 point

-

Your star wheel is not synced properly. The lifting lever has to lie between the arms of the star at the end of the chime cycle. The hammers should be completely at rest and not lifted up.1 point

-

Looked up Rolex. They started putting the crown on the dial in the 1930s so looks like this watch is older than 1953. I'd say it could be from the 1920s (art deco styling) but I'm no expert on watches.1 point

-

Is it really that important, aren't we just here to discuss watch repair? Unless they have a background in watches or something relatable to watch repair then I personally couldn't care less about their life history.1 point

-

I think that call only applies to the forum called "Watch Repairs Help & Advice" because that prompt, about introducing yourself, is only under that heading. Anyway, always nice with a bit of background.1 point

-

1 point

-

1 point

-

Thank you for your introduction and welcome to this friendly forum. I will need to see the movements and their cases when it comes to clocks.1 point

-

Hello and welcome to the forum, There are many books on the subject of Horology, If your interest is in collecting clocks and watches then here is a few starters, Brittans Old Clocks and Watches. History of Clocks and Watches by , Bruton. Timepieces by David Christianson. These are but a sample there are many more and also on the repair of clocks and Watches and also tools and their uses. You could probably fill a a room and then some.1 point

-

1 point

-

Yes, it all started with one 1964 Timex Marlin and years later I had this collection to show for it. Most of what you see has been sold off and is now being cared for by other Timex collectors. Since selling off I have focused more on the 600 ft and 200 ft divers. Here is my latest 600 ft repair. video-1628947180.mp41 point

-

I did make some earring backs for a pair of hook earrings I had a habit of losing. They weren't perfect but did the job. It would have helped if I'd had a decent magnifying glass to see what I was doing better.1 point

-

OK it’s a fake. The hologram on a genuine Rolex is not visible unless it is under a strong LED light and even then it is well hidden.1 point