Leaderboard

Popular Content

Showing content with the highest reputation on 03/31/21 in all areas

-

A recent online purchase and repair to a 1983 Timex commonly called "Red Dot Diver". Bought in non-working order I found internal damage due to a sheared pillar screw. With the aid of my parts collection all was corrected. Here is the before and after. - New Crystal - replace pillar screw - replace hour wheel - COA ( clean, oil, adjust ) - polish buff Only follow up has been with the seconds hands not seating correctly. This is very common with vintage Timex because there is no center tube. So once lifted off the seconds wheel the hole tends to be distorted. Typically I will place hand on a flat metal surface and peen the metal down. In this case that did not work so I when to next level and add a dot of black nail polish. The watch would have originally come with a stainless steel bracelet and the white strap on it now is for wrist worn testing.2 points

-

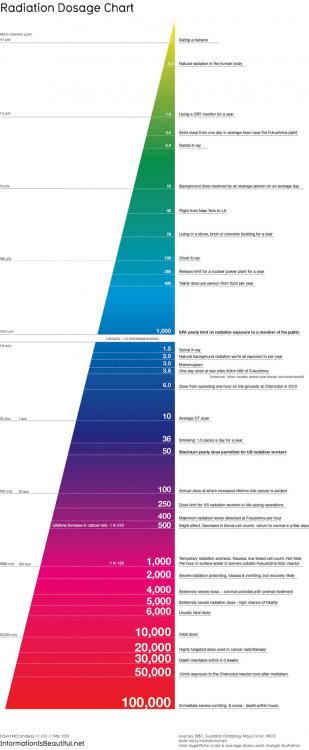

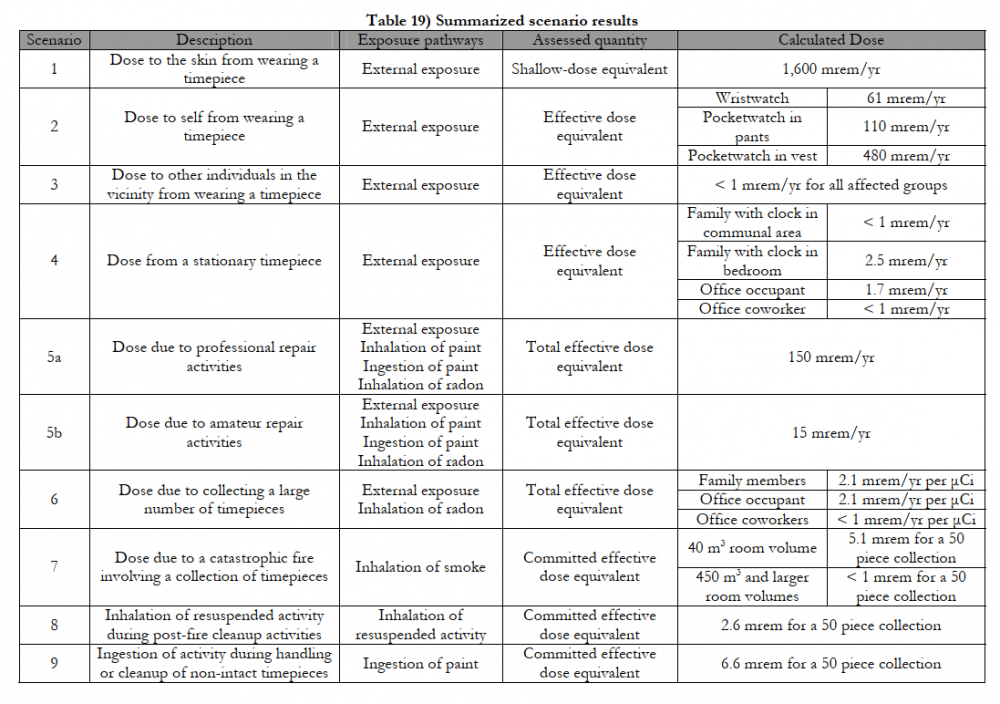

I was pondering this topic again this morning. Here is another Radiation dose chart that looks like similar data as above but formatted differently. I am also posting a document produced by the NRC. A screen capture of the most interesting page that relates to watches and watchmakers is also posted here. My Dad worked on watches six days a week, 51 weeks a year from 1947 to 1980 (he continued working after 1980 but only a few days per week). There was radium lume for re-luming hands and dials in his watchbench for that entire time until last year when I removed it. He lived 92 years. Cause of death was a combination of blood loss and heart failure. Until the last year, he lived a full and active life. He was prone to use those nasty chemicals to kill bugs in the yard...that were later banned. I don't think, anecdotally, that radium had any observable effect on him. Radium exposure.pdf2 points

-

Leave the dial well alone refurbishment will drastically decrease the value of the watch no matter how bad the dial, a new plexi would make a world of difference, service the movement and leave the case unpolished, doing the bare minimum to get the watch running would be the best thing to preserve the watches value. But at the end of the day the watch belongs to your friend so the choice is his but I would strongly discourage him from total refurb.2 points

-

I saw this posted on The Watch Site. Apparently, Frederique Constant is releasing a 40hz mechanical watch using a single-piece silicon balance in place of the traditional Swiss lever. I watched the video at the link below and was pretty impressed (but then again, that is not difficult). ? In the video, they are claiming 10x the oscillations per hour compared to a traditional balance system. They also claim that the oscillator needs no lubrication (!) and replaces about 20 parts from a traditional watch. I find myself wondering what the longevity and shock resistance of watches built around something like this will be. Also, I wonder whether anyone other Frederique Constant will touch the tiny weights on the oscillator, which are apparently used to time the movement. I can't post a direct link to the video, but their marketing page with the video on it is here: https://monochrome-watches.com/frederique-constant-slimline-monolithic-manufacture-video-review-technical-guide-specs-price/1 point

-

Your drawing house a interesting problem to symbols in one location? The ghost the image probably means I ghost the quantity of oil minimalistic. I never really paid attention as to whether they had exact meaning are not as usually anytime M assemble in the documentation it will tell you what oil you should be using. For the fun of it I went through a variety of eta documents and snipped out the lubrication symbol meanings. It does look like there is a pattern here. Then it occurred to me that I never paid attention to it we really need a lubrication guide This one from Omega. Sure enough they have symbols lots of symbols and they tell you what they mean sort of. Notice it isn't an exact science and no matter what it would never be an exact science because lubrication changes with time. So if you look at the Omega document and all the images they came out of a variety of eta documents you kinda get a pattern. Light oil is one symbol a little bit heavier is another but it still doesn't look like an exact science to me you really need the full document that you're looking at where it tells you what they think it is and then we translated in something modern. Omega 8645_WI_40_rules for lubrication cousins uk.pdf1 point

-

It's extremely dirty and needs a good polish, clean, screws deburred and re blued. The springs in this type of movement are very strong so a clock mainspring winder should be used.1 point

-

Yes it has been over oiled. If it is running OK then it is not causing an issue but I would still clean. To clean thoroughly remove the spring tension then remove the clicks/ springs etc and clean with a de-greasing solvent .1 point

-

Hi As explained by wls1971 old oil degeneration, Being a French clock it is well made and should be polished, It will come up a treat just be careful of the fine pivots when cleaning and assembling.1 point

-

1 point

-

Hello and welcome Joao to the forum there is much to enjoy tinkering and to that end I have attached the following document for you . TZIllustratedGlossary.pdf1 point

-

1 point

-

Personally I think because the watch is in very poor condition it would only be sold as spares. The biggest issue will be the refurbish of the dial. I had a Longines dial refurbished, cost £150. The bezel is in good order and the missing Pearl button can be purchased, although it will be an aftermarket one. The hands need a relume and as the movement is running it just needs a service. IMO it would take a while to refurbish but it can be brought back to a very nice watch.1 point

-

I would try to get some opinions from vintage tudor experts, who don't have commercial interest. The whole rolex and tudor (which is some kind of sister brand to rolex) vintage world exploded some years ago into complete price madness. So this watch (if genuine of course) could be worth several thousand bucks for a collector, especially because it has a "SWISS" marked early dial and a PCG (pointed crown guard)-case. Here is a link to give you an idea about original parts prices: https://tswisst.de/tudor-ersatzteile/rolex-zeigersatz-fuer-tudor-7928-3/ I would take some good pictures (daylight, smartphone-camera and 6 inches distance do the job) and ask your questions on www.rolexforums.com (as mentioned tudor is a sister brand so they deal with tudor too). A very good picture of the dial is essential, so it would be best to take the movement out of the case and take a pic then. BUT: The dial is marked "SWISS", much lume fell of the hands and the lume on the dial is black dirty. This shouts: Be careful, could be radium! So I personally would not open the watch. Maybe you can polish the plexiglass a bit to get a got pic of the dial? Anyway good luck with that piece. Nowadays about 98% of the rolex/tudor-talk is about money, I hate that. But I love such stories of watches with a personal history.1 point

-

1 point

-

The clock has been over oiled at some stage in the past the green goo is oil that has deteriorated over time, this is something that would be removed by cleaning, this kind of greasy goo is easily dissolved in clock cleaning fluids.1 point

-

1 point

-

1 point

-

Hi there all, thought I would share this with you. Some time ago, or should I say once upon a time, I got this Longines pocket watch in a box of parts that I bought off a fellow who just wanted to get rid of it all. Most of it was just old movements and wheels and old tools and bits and pieces. There was a few complete watches amongst the box. Anyway I have been at the bench off and on for months between other things, stripping this watch down and checking out why it was not working. Firstly I found one of the screws on the click spring was broken in the plate so it would not wind. Then I noticed the hairspring was not connected to the stud. The brass stud pin was non existent. I could not find any other reason why it wouldn't work. I did not service it as this would have been a waste of time at this stage. So I removed the broken screw from the plate and fitted the huge click spring back on, then the cover plate and bingo it wound. Next thing I removed the balance and filed down by hand a brass stud pin and after using my hairspring vibrating tool to find where to stud it, I put it back together and low and behold it worked. I contacted Longines for information about the Watch and they sent this, The original serial number 480'958 identifies a hunter pocket watch in metal. It is fitted with a Longines manually wound mechanical movement, caliber 18LS and was invoiced on 10 November 1888 to the company Zivy, which was at that time our agent for Mexico.Zivy was a Paris and Mexico boutique of watch and jewellery merchant Hauser, Zivy & Cie. I did not take photos of the work because I didn't think this old jigger would ever work again. But I will when I service it. Just thought I would share this with you. VID_20210330_230238.mp41 point

-

Hello from Indianapolis! I plan on taking the full set of courses here in a little while myself. Welcome to the forum!1 point

-

Yes often overlooked by newbies. If the watch has never been serviced the mainspring is probably okay or at least okay enough to get the watch to run. But on older watches where they been serviced all sorts of interesting substances end up in the barrel that at one time supposedly were a lubricant and now are not. It's amazing how much energy can be lost to sticky glue like substances.1 point

-

Prior to this watch what was your experience with watch repair? In other words is this your first watch your taking apart? With new bees and problems like this you need to slow down and do the basics. When you disassemble and clean the watch did you take the mainspring out? Usually when people are reassembling the watch things become obvious before you reach the stage or in them but not always. Like for instance when you've assembled the gear train without the pallet fork in the wind the crown does the gear train spin effortlessly? When you put the pallet fork in your lubricating the escapement did the pallet fork snap nicely with energy? Oh and trying to swap the hairspring bad idea each hairspring is matched to the balance wheel That it is on. Okay as I'm reading through things again I see your order a new mainspring what does the old mainspring look like? Then even with a set mainspring the watch will run it won't run overnight if super set but the watch will run fully wound up. How easy was it to get into the watch? In other words they hairspring and didn't just bend up itself somebody did that. If they bent that what else did they do while they were playing with the watch? This is where conceivably you may have other issues issues that you normally don't have because somebody has played with it with zero idea of what they were trying to do. I'm with a repeat some things from above. Mainspring barrel out pallet fork out just the gear train. If you give the center wheel a gentle push does the trains spin effortlessly? It should require very little force on the center wheel to have the entire trains spin. This is where when you were assembling it you should check the end shake of each of the wheels to make sure there was a little bit and shake and you should verify that the train would spin effortlessly. But the mainspring barrel back in a wind on the crown the gear train should spin. There is a test for gear train freedom called back spin. his is where when your winding the watch the gear train is spinning you stop winding and the momentum of the gear train will go past the end of the mainspring basically and back wind the mainspring just a little bit. So if you looking at the escape wheel and you have to look carefully for this you'll see the escape wheel spinning you probably can't see the direction Elgin stop and actually spin backwards a little bit this is usually a clear indication most the time that you train is free then pallet fork in wind it up a little bit and I assume you lubricated the escapement? When you pushed gently on the pallet fork doesn't snap if it doesn't snap your watches and going to run. Once you verify that the pallet fork has energy going to it and everything's fine even with a set mainspring the watch should run providing the balance wheel is correct and it's exactly where it's supposed to be? Although it looks like in your first picture it may be correctly located? That is with no power the pallet fork should be between the banking pins your watch should be in beat. Then we need sharper pictures in the absence of that you have to look carefully at your balance wheel and hairspring. Often times when people start playing with the hairspring this they fail to grasp how important it is that it be flat and not touching the balance arms. If it's touching the arms the watch isn't going to run. This is why asked what your prior experience to watch repair is because you need to have experience with knowing what the watch is supposed to look like and how things are supposed to work so as you run into problems it makes it easier to grasp where the problem may or may not be.1 point

-

Both of these products say there for degreasing and for cleaning hairsprings. So both of them should work fine although I like the second one in the description better but they're probably more or less identical. But if you're trying to actually clean a watch it seems like watch cleaning fluid would be the way to go as it's designed for cleaning versus just degreasing even though the greasers claimed there for cleaning also. It's just that watch cleaning fluids have additional things to help things go in the solution beyond degreasing but both of these would still make good hairspring rinses1 point

-

1 point

-

I use Naphtha I buy from ebay, from an industrial chemicals company sold as "Petroleum Hydrotreated Light SBP3. It's not too expensive bought by the litre, much cheaper than something like Horosolv But I always finish with 99.9% Isopropanol to remove any residual oiliness.1 point

-

That's a good point. I will check that later (wifes 70th birthday today. My 74th yesterday so a little fuzzy) ???1 point

-

No idea if they have copy protection it would be nice if they didn't. It be nice to the Chinese could clone it or would clone it or even make a clone of the idea of it. Because once you go to a PC-based timing machine all those nice enhancements become relatively easy to do versus a dedicated machine where where limited. Even witschi understands that like the machine at work when I did the firmware update a new feature appeared which was their time plot capability that wasn't there before. Just because of software it adds a lot of flexibility the things. The sad problem with witschi and a lot of Swiss companies are as their cost the machines go up the quantity of buyers go down. The Chinese have demonstrated if you make a timing machine for lesson $200 you can sell them all across the planets it be interesting to know how many of those they've sold. It's now really a must have if you're working on watches to have a Chinese timing machine unless of course you just won the lottery than you can a witschi machine warrior in a business. So I guess we can hope that the Chinese will pay attention to what witschi's doing and give us a really nice timing machine at maybe $500 may be less? Add in all is missing features that would be helpful especially in this discussion like to have in our oscilloscope see what's really being picked up.1 point

-

1 point