Leaderboard

Popular Content

Showing content with the highest reputation on 03/10/21 in Posts

-

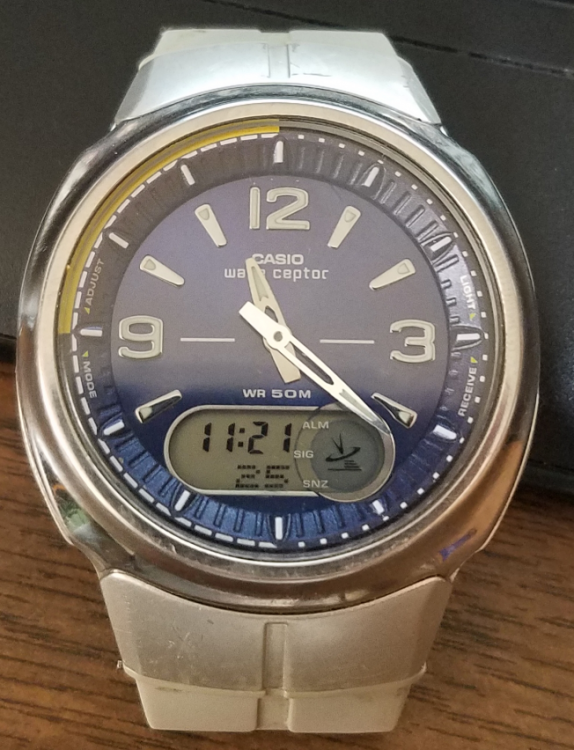

I got this watch years ago. Some time after that it quit working. Then I tossed it into the watch bench that ways dormant. Sat there for years. After I learned about accelerating hands using my demag, I decided to try spinning the hands on this watch. Yay...they spun. So, I installed a battery went through the setup procedure and set the time. Now it is working fine. Receives WWV and calibrates itself. Now I need to get a band for it. I do not know what I did with the one that was on it.2 points

-

2 points

-

Most quartz movements no longer need a calibration. Not sure why the screw is not fitting is it the correct screw.2 points

-

Just to remind that is considered polite to use the introduction section to introduce oneself.2 points

-

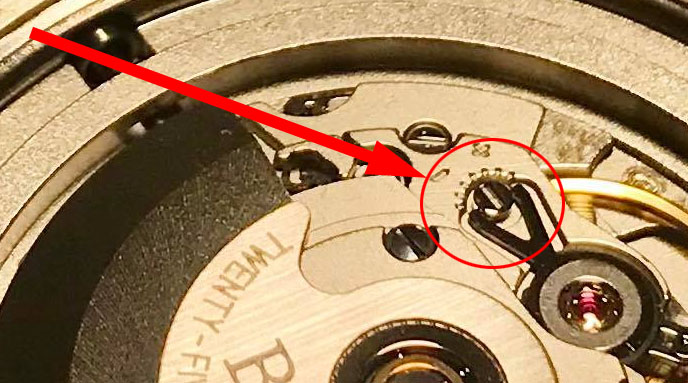

Do you one better (because I can't tell from that photo). Adjust the screw a full revolution (sober), and observe its position relative to the marks. Go slow, and keep an eye on your timegrapher for learning purposes to get a feel for how much goes how far. You'll likely notice that the same degrees rotation with the eccentric closer/further from the indicator marks affects the timing delta differently due to where the eccentric's high/low points are. You've already spun it three times, so any damage done is done (not that I suspect there is any). You'll know for sure (for your own peace of mind if you're anything like me), and you'll learn something valuable in the process. Once you've done this and you're sure everything is where and how it should be, dial it in. Big ol' win all around.2 points

-

1 point

-

Meaning you suspect that the diameter of the cannon pinion might have been reduced somehow for some reason, or is the wrong cannon pinion? I completely fail to see how the minute wheel could have any bearing on this as it in no way is connected to the minute hand (unless this calibre is somehow special in this respect), but I sure like to know and I'm all ears! To me that sounds like a plausible explanation and so I suspect the hole to be too large.1 point

-

1 point

-

1 point

-

There's an optimal drink level: enough to get the courage to open up a watch and try something you haven't before, but not enough to compromise your abilities1 point

-

As far as I am aware the stamping 94 dates it to the 9th month of 1964. the movement is a 400 calibre 60461 SmithS... or maybe a 50461 as its an Astral. as for click springs maybe worth looking here; https://www.cousinsuk.com/product/smiths-generic-parts?code=SM434 FB1 point

-

Always nice to help out to get an answer a model number as a company like longines Probably has made more than one watch. Then maybe even a picture would be helpful.1 point

-

By "calibration" the OP meant fixing the reset position of the chrono hand. He mentioned that in another post which I have now merged. He did not explain or picture by how much the hand is off, as the reset is normally done with a combination of pressed buttons as mentioned above. He then proceeded to remove screws from the module in the attempt to reach to the dial side, that is of of course never needed, even more on a front loader as this one appears to be. Correct he was instead in saying that attacking a watch without tools and knowledge is a bad idea.1 point

-

These watches are made by Fossil in southern china for Armani and as such there appears to be no technical information available regarding diagrams etc. So other than checking the various screws you removed for length and position, why it doesnt screw in. parts not seated correctly, wrong screw (too short) stripped thread, It is a process of elimination.1 point

-

So....the combination vacuum/pressure vessel takes shape..... Before being poured to make a mould, mould silicon needs to be 'degassed' in order to remove air bubbles, and similarly the resin that will be cast to make the crystal needs to be degassed before pouring - for which a vacuum vessel is required. Once poured, both materials are best placed under pressure in order to compress into nothingness any remaining air bubbles in the mixtures, for which a pressure vessel is required. So, a combination vacuum/pressure vessel is now awaiting cure of the polyurethane sealant/adhesive used to bond all the various sections of high-pressure PVC agricultural irrigation fitting together. To change between vacuum or pressure, the topmost fitting is exchanged between a tyre valve or a straight brass nipple. Vacuum pump is the suction side of a spare refrigeration compressor, and the compressor is a 12 volt car tyre compressor. Max required pressure is around 4 bars, and the chamber is from Class 6 and above fittings so it should all be ok. Where my extended fingertip is in the picture is where the unit separates into two pieces to allow for loading and unloading, by means of unscrewing the two large 110mm male and female threaded fittings - an automotive oil filter wrench is used for doing that. Total capacity of the vessel is about 2 litres. Now to have the laser profile cutting done in order to make the blank or plug from which the mould will be taken.....1 point

-

1 point

-

1 point

-

From an engineering perspective (not watchmaking as a begginner myself) the microscrew looks to be an eccentric cam, your full range of adjustment in that case would be 90° in either direction from central. I would suggest turning screw head to line the slot with the marks on the balance just a fraction at a time. Graham1 point

-

If this is the first watch you have ever worked on, that's normal. When I started, it could take me an hour to get the train bridge on. Sometimes I had to walk away and take a break, then come back later. You'll getter better at it eventually. Karl has given you good advice. Just remember to keep calm, have good lighting and magnification. Apply light finger pressure on the train bridge. You'll be able to feel a click whenever a pivot falls into a hole. Start with the biggest wheel first and work your way to the escape wheel. Sometimes I have to put the screws in but only turn them a couple of rounds. Do not tighten them or the pivots will be damaged. This is to prevent the bridge from lifting and allowing all the pivots that you manage to get in to escape. Fine tweezers is a must. But sometimes I use an oiler to nudge the pivots into the holes. That's all the tricks I have. The rest is practice and luck. And praying helps.1 point

-

Try removing the board and coil and using the same screw, screw it into the hole and observe what is happening. Is the thread of the hole stripped? Are you screwing into plastic or a brass insert? And check all the other screws you have taken out. Are all of them the same? Sometimes we think we didn't mix up the screws, but your bench gremlin will switch them around when you are not looking.1 point

-

UV nail polish gives unlimited working time. There is no solvent evaporating away and making the lume paste lumpy. There is no need to hurry. When you are happy with the placement and thickness of the lume, then you cure it under a UV nail lamp.1 point

-

1 point

-

Welcome to the forum Stewart, feel free to ask any questions. Make sure you post photos of your pocket watche when you ask for advice about it.1 point

-

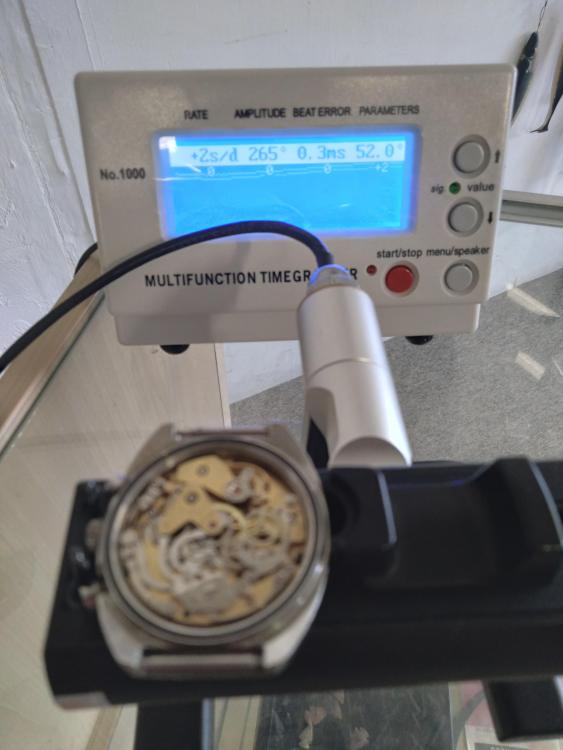

A staking tool is not used to adjust endshake, if you are talking about adjusting jewels. For that you want a jeweling tool. There are some American staking tools that do have a micrometer adjustment, but your realy want both a staking set and a jeweling set. For a timing tool ebay is your friend, the Chinese Weishi timergraphers are actually very good for the price although throw away the adapter power plug that comes with it and get someone qualified to fit an Australian plug on it so you don't get electrocuted. Have a look at the different models on Ebay and choose one that fits your budget.1 point

-

1 point

-

Looking good. If I remember correctly I finished to high polish with Dialux Grey and then Dialux Green. Used several soft mops in a Dremel. Need to change mop regularly for good final polish to avoid 'carry over' residues into next stage.1 point

-

1 point

-

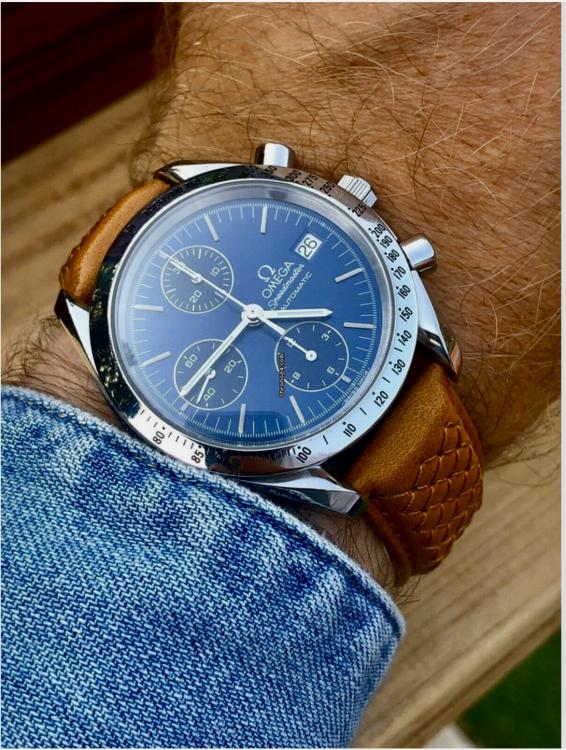

I acquired this watch not running with the stem not doing anything. I called around locally and only one person would service it for $475 dollars. I've always been afraid of working on a chronograph but after that price I decided to give it a go. Some of the keyless was rusted and I ended up breaking the setting lever removing the stem. I ordered a new one and got to work and I'm happy with the results. I also changed out the crystal.1 point

-

Here is another place where I have purchase crystals.1 point

-

1 point

-

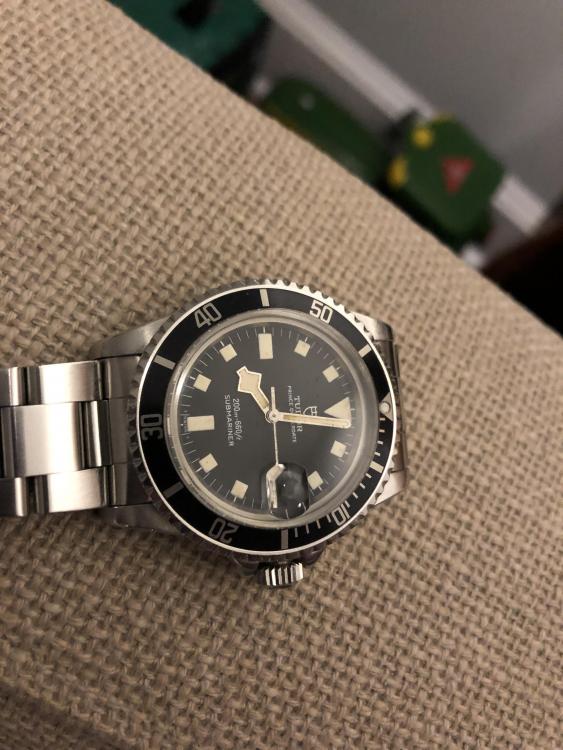

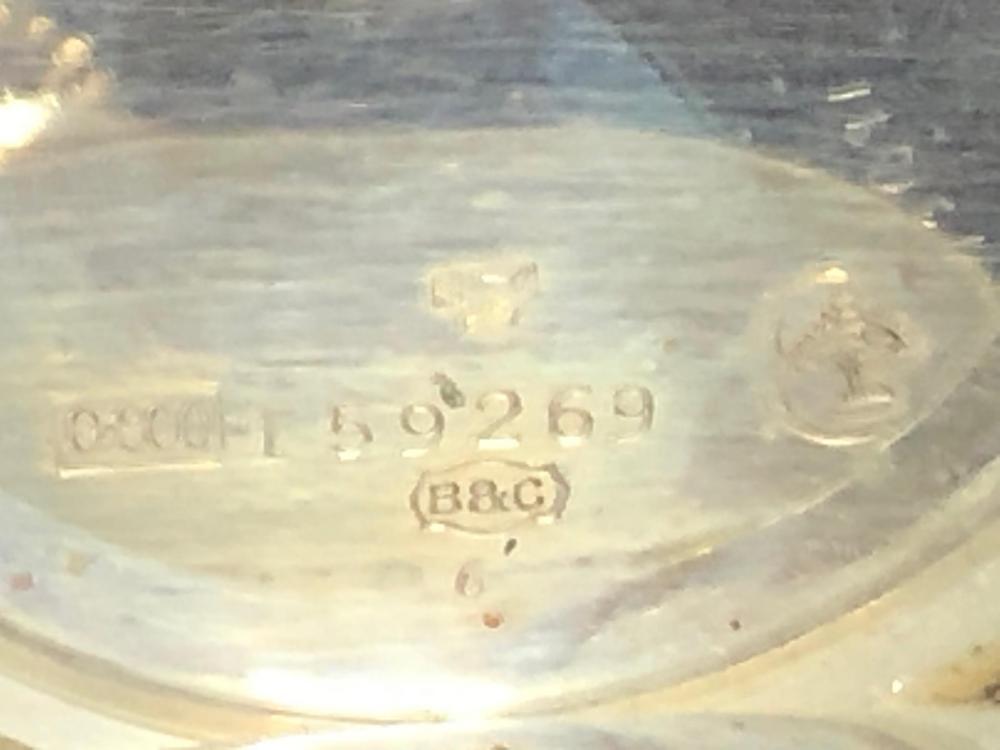

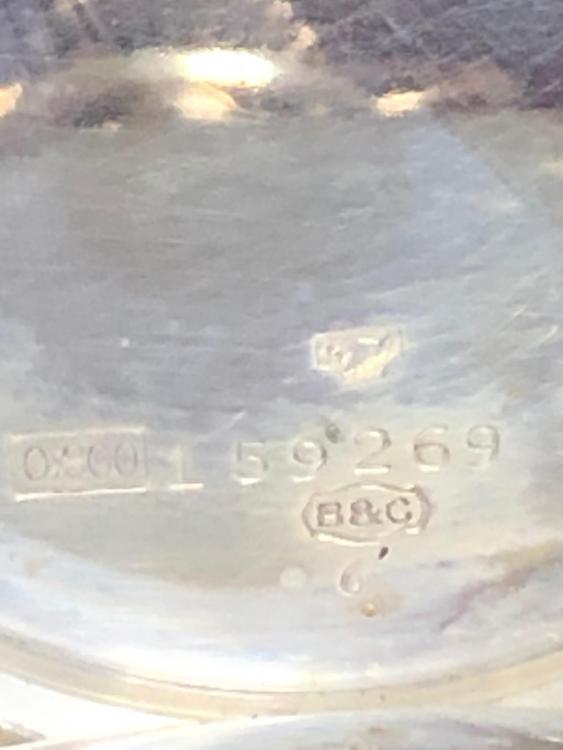

This watch was the score of the decade for me. I always liked the Tudor “snowflake” hands and block markers better than the 5513 Rolex for sure. This gem was an eBay score. I checked it over carefully- the crown was worn; crystal was horrible; bezel didn’t rotate. It was sold “head only” and was scarring a lot of buyers away. I grabbed it for a very good price. Not Y2K good price (when these were trading VERY cheaply) but for the time, well below average. Based on what I could confirm as genuine, I would break even as a parts mule. Got it home and popped the hood- Tudor marked 2784. One set of service scratches on the case back. Popped the bezel and crystal- correct silver date wheel; correct dial. Hands I had confirmed before purchase, and reconfirmed. Case markings and bracelet wear indications present and correct. No corrosion on the case! All good. De-funked the bezel assembly- all original and correct. Insert is original and correct, although the “Pearl” was missing. I installed an NOS Tritium Pearl and that was about it. The crystal was replaced with an NOS paper bag (early) T-125 “top hat” crystal, which is correct for this watch. I see a lot with Rolex 1680 T-127 crystals, which fit, but are wrong. I think the crystal is the most critical element in preserving the original “look” of the watch. Soon after introduction, they started beveling the top edges of the crystals, due to chips. They don’t look the same. I also installed an NOS 702 crown, onto the original tube (which was perfectly fine). New gaskets throughout of course. Picked up a 93150 bracelet with almost no wear for it. Not the correct year but I do have a correct year 9315 (folded link) clasp squirreled away, if I come across a decent bracelet that I can afford. So, that’s the story. Keeps good times but needs service. I may tackle it soon. Loved it so much I started collecting parts to build a blue dial one, and that’s almost done now too... another post perhaps.1 point

-

Unfortunately there is a problem with 9415? I'm attaching a PDF starting on page 13 it covers lubrication of the escapement. notice where they're putting super tiny quantities on? This is because if you get carried away with the quantity which normally wouldn't be an issue if this was an oil you will lose amplitude. This is because on impact the grease becomes a fluid it's very slippery and outstanding but if it's heavy the edges of the escape wheel are not an impact and there literally tearing through the grease. Omega 8645_WI_40_rules for lubrication cousins uk.pdf1 point

-

Shouldn’t have.. Bit couldn’t resist bidding.. I always wanted a pocket watch. You know classy looking. Bit “chunky” with loud and “chunky” ticking. Won this at a good price. I have no clue what it is. Seems like a no name. But is in nice condition. Have been serviced at least a cpl of times. There is some watchmakers markings. Include a few pictures. So Maby one of you specialists have some leads? It has now been laying ticking on my desk for 6hrs. Seems to keep time very well. Took a look at the balance with my loupe. Someone has been adjusting it. But the hairspring doesn’t look concentric. Well, it is Maby a project for the future. I’m happy just having it, ticking on the desk!1 point