Leaderboard

Popular Content

Showing content with the highest reputation on 12/09/20 in all areas

-

There might be a tiny chance of getting replacement stones for a currently made tool like Bergeon (though I seriously doubt it), but finding shaped ruby suitable for anything else no way. Then installing them wouldn't be easy at all, they have to be perfectly parallel and level with each other.2 points

-

2 points

-

2 points

-

You might remember me literally destroying a Chinese movement on my Loreo Sub homage watch. I also got a Corgeut Seamaster 300 homage with a malfunctioning date complication, with the same movement as the Loreo. So, I contacted Corgeut about the malfunctioning date, and they offered to send me a new movement. I asked for a Miyota 8205, and they agreed. So, great customer support from their part, quite frankly. The movement arrived a few days ago, and I went and replaced it with the Miyota. This time I took all necessary precautions, I got a proper movement holder, new hand setting tools, and a 15x loupe. I also used the dot of rodico on the tip of the hand setter method to set the seconds hand, and it worked like a charm. Now I have a Seamaster 300 homage with a Miyota movement. Success #1. Now, what can I do with the remaining movement? Other than a misaligned date wheel, is a perfectly working and very accurate movement, so I decided to put it on the Loreo. Sadly the dial had a broken hour marker (I applied so much force trying to fit the seconds hand, which was already broken, that the tool slipped and punched the marker away, and fell in the floor, nowhere to be found). So it looks weird, but I was able to put them movement back in, and setting the hands went also very smoothly. So, long story short, both watches are working and ticking very fine. Success #2. The mods are not finalized, though, as the date window on the Loreo is still showing a crooked date for some days of the months, so I purchased a replacement sterile no-date dial with a nice vintage design, kind of a 1958 Rolex. It'll remove the cyclops with a torch and go no-date. It'll have the ghost date position on the crown, but I don't care as I'm looking for the vitage no-date look. You might also notice that the date on the Corgeut is still a bitt off center, and I agree that it might not have been entirely the movement, but the dial itself. They did sent me a new dial and hands, but I decided to reuse the old one, so I might replace the dial and see if that fixes the date issue. In case you are interested, here are some details on the mod:2 points

-

2 points

-

Finished my dual balance tack today. Made from brass, the first intent was to allow the balance to rest on the tack to reduce stretching of the hairspring and to provide a tool that would stabilize the balance for work, such as adjusting the beat error. The second reason was to have an additional tack that could be used for smaller pocket watches and watches. I made a quick video to show the process of building this tool. Missed the band saw cutting, but that is obvious. Always use cutting oil. Enjoy. https://youtu.be/nhhGzgypWPk1 point

-

1 point

-

1 point

-

EB 8800 came in 1/7/17 jewels versions, which one is your watch? I can't figure out, what in the sam hill where they thinking to make the one jewel variant and claim concern about positional variations too. As for your concern about hairspring material degredation, unfortunate as it might be, it simply sounds like an unchartered territory, 100s/d doesn't sound like a fouling hairspring either. Good luck pal.1 point

-

1 point

-

1 point

-

Practical Benchwork for Horologists by Louis and Samuel Levin. It's a great book, definitely for advanced work, but great. I've been in Switzerland for almost 20 years now. Sure doesn't seem that long!1 point

-

There is a very interesting story documented which is too long for me to give justice by writing here, but Smiths in the UK needed to fabricate their own jewels rather than buying from the Swiss for the War Effort. So they basically sent a spy over to Switzerland to investigate and to smuggle a huge number of watch jewels which were stitched into a jacket that he wore on his return to the UK.1 point

-

Following up on john and rod- rod, I usually line up any notch with the hooking point on the barrel as a matter of course. If there's anything to line up that's it. John, I think we agree. A quick tap is not the same as a hydraulic press. To smack an arbor to release the lid is ok. There are a lot of calculations on this but a quick tap vs a prolonged push just aren't the same in mechanics. My first job in Switzerland, when my future boss learned I'd worked in automotive, was way reassured on his hire- (he was already happy with the hands I'd filed). This is something I've tried to drill into the very talented heads I've come across in the last couple of decades. Smart kids. Explain building up a -smack- instantaneous calendar, vs an automatic winding system. Same stuff I drill in my daughter's head when her mom freaks that there's sulfuric acid, acetone, cyanide, and ammonia in my workshop. She quotes to me now even when we talk about sugar "it's all about dose,dad". Try doing the math on an uppercut punch, then see if you can reverse it over 5 seconds. The smack is everything. I have numerous presses I use where regular watchmakers would use a staking tool. But when I need a smack! it's all hammer. This is applicable all over, but suffice to say I've yet to disort a barrel lid from a smack .1 point

-

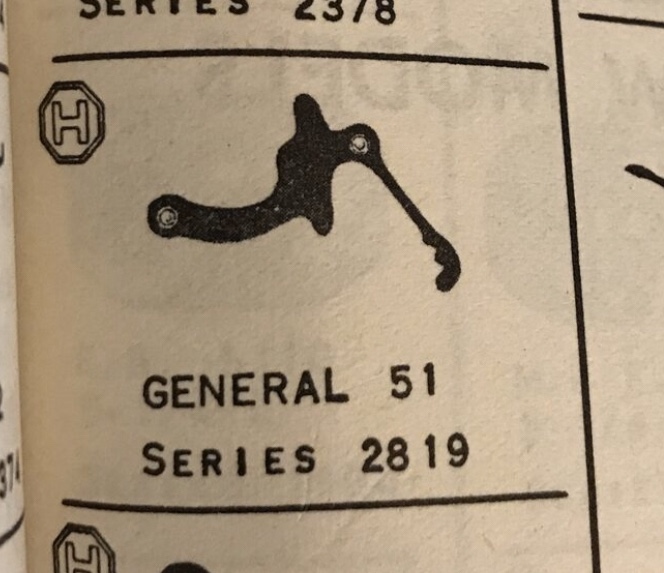

My first step on this process. 1.I tried to draw the best I could the original part to the annealed steel (I used the right thickness from the feeler gauge). To draw the broken part that is missing from the original, I used the drowning from the swartchild watchmaker guide. I actually copy the drawing to the steel. It was quite of challenge to do it but I managed. By posting every step on this process and explaining the best I can to my knowledge, it may benefit someone else on this matter. So I hope you all agree and help on the way with good and constructive advice as you all did here. Once again I would like to thank all for the impressive response to this subject.1 point

-

1 point

-

Ha, I'm American and Levin is an American brand . Most Europeans don't realize there was a serious U.S. watch manufacturing concern. When I was here for school I had my grandfather's Hamilton with me and everyone was asking me what ebauche it was and didn't believe it was pure American, down to the hairspring.1 point

-

1 point

-

Are they chipped _all over_ ,or just in one area? It takes some effort to chip them, and while I have my gripes with Bergeon their poising tools have always been really nice. You only need a sweet spot of about 5mm to be useful. I have a Levin, humongous ruby jaws, built in level that's spot on. They made a couple of grades, but the german silver ones with ruby jaws are the best I've seen. If you scan Ebay you can find them around 50 bucks, still probably 100 shipped to you, but a seriously nicely made and beautiful tool. Whenever a European watchmaker sees mine they're like "OH MY GOD!".1 point

-

1 point

-

Just stumbled upon this thread and had a read though. I don't mind admitting I shed a tear for all your friends that have been lost over the years. I've been there a few times, it never gets any easier. We currently have 4. Lorenz (Lorren), Sierpinski (Spinney), Mandelbrot (Delli) and Rusty. Can you guess the one my wife named? At the beginning of lockdown I made a cardboard tank for the cats. This is now Delli's favourite place to sleep.1 point

-

1 point

-

1 point

-

My mom handed me this Gubelin “Ball of Light” from the ‘20s and asked if I could do anything with it. It’s a manual wind 17-jewel movement that started up immediately when I wound it, so I’m not inclined to do anything with it other than find a necklace or charm bracelet to pair with it for my wife. Kind of cool looking, though.1 point

-

Hello, short question, but a bit difficult answer. This error has little to no influence on performance as it is compensated by right and left swing of the balance wheel. There is little info on the topic. Values claimed in the net are just opinions without substantiation. The manual of a timing machine gave the answer: limit for the esc. error is 15 degrees. Here the unpowered escapement still rests in lift position. Unfortunately most TMs do not display the real esc. error (degrees) but just milliseconds that are not directly related to the real esc. error - ms value changes with amplitude and with bph despite a constant esc. error! One exception is PCTM that displays degrees, too. If you convert deg to ms, 15 degrees equates 9.6 ms @ 200 deg amplitude, @ 18000. Adjustment to 1/10 of that limit = 1.0 ms will be excellent. Frank1 point

-

1 point

-Copy.jpg.b1605e838a357d1961f639a05a9d0e8f.jpg)