Leaderboard

Popular Content

Showing content with the highest reputation on 11/27/20 in Posts

-

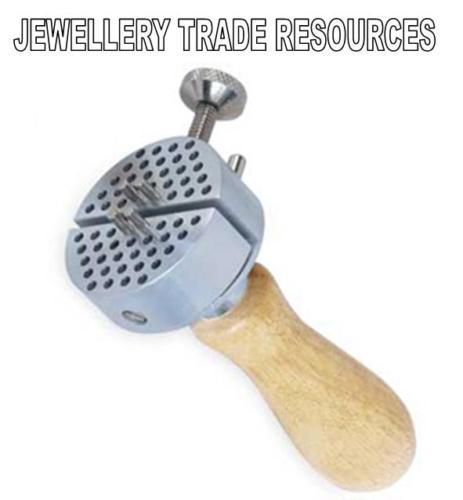

We made a balance tack in school, but aside from that time I haven't really used it. A much handier tool is this one which was a standard tool made in watchmaking schools here. The "tack" is a threaded pin which can be placed in one of several holes (usually 2 or 3 sizes of tapers on several pins). Choosing an appropriate pin and hole location, the balance isn't hanging as it sits on the table, so no risk to the hairspring. The overarm presses down on the rim, which is supported from the inside by the little "V" so that work can easily be done on screws (it's a non-screw balance in the pic but you can see how it works). Access is also easy and safe for moving hairspring collets to adjust beat. Bergeon made a similar tool at one time but it hasn't been available for some time. If mine ever disappeared I would stop work until I had made a new one, it's that handy.10 points

-

I don't know of any real name for it. Here it's "the school balance holder thing", or le truc de l'ecole pour tenir le balancier et pont haha. With all the options for placing the pin there's never a risk of stressing the spring except when you get lazy and don't move it. I use it on pocket watches all the way down to Lecoultre 101- no way in a million years I'd touch a 101 balance without this tool! With all the interest I'll take some better pics and try to make a dimensioned sketch for those who want to make one.3 points

-

2 points

-

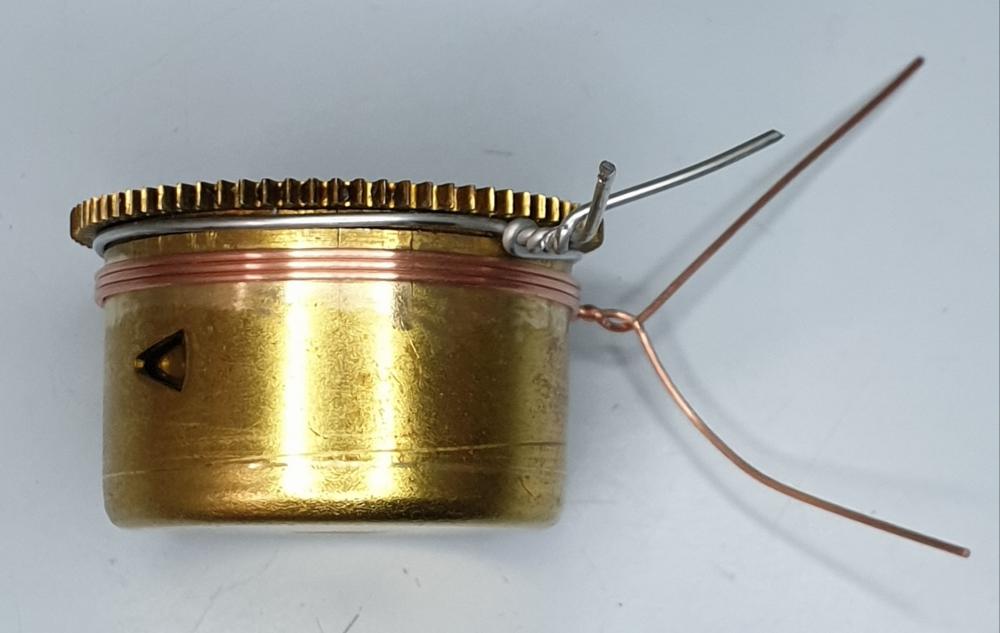

Yes, universal key for key-wound pocket watches. Not very reliable working. Frank2 points

-

2 points

-

The moral of the story would be don't waste money on Chinese fake watches, $375.00 dollars can buy a very good Swiss or Japanese watch these days backed up with a warranty. Get your money back if you can and don't waste your time trying to sort something that will only ever be sub standard.2 points

-

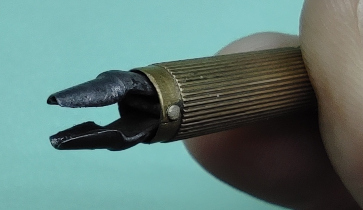

what I find interesting is how our brains like to fill in the blanks. So I saw the word pallet fork up until you mentioned that it wasn't really there. This is actually a common problem on this discussion group we fill in the blanks for the original question without always grasping what the question actually is or the circumstances of the question. The problem of watch repair too many variables. At one time the Swiss used to put a tiny dot on the balance wheel to correspond to where the stud should go. This of course assumes if somebody change the staff that they put the roller where it's supposed to be. that work we had a small Omega watch timing machine indicates it's out of beat. Note I have an obsessed boss that anything other than 0.0 is barely acceptable. So is out of beat it was not acceptable. Visually the pallet fork look perfect between the banking pins. Removing the balance wheel sure enough the stud did not a line up with the mark. That problem was fixed back into the watch visually nothing changed at all. But the timing machine was happy and now gave us a single line. It's amazing for the timing machine point of view of how little it can be off and its upset but visually it looks fine to us. then there is another method I'm attaching an image for your enjoyment.2 points

-

You know that the matter "is debated", in the past you had asked already, a limited discussion is there One can examine and work on the balance in much easier and safer way by removing the stud from the arm. For example if I have to look at the upper pivot is better to do without anything in between, isn't? And same if you have to adjust the collect having no movable stud arm. Any supposed other use?2 points

-

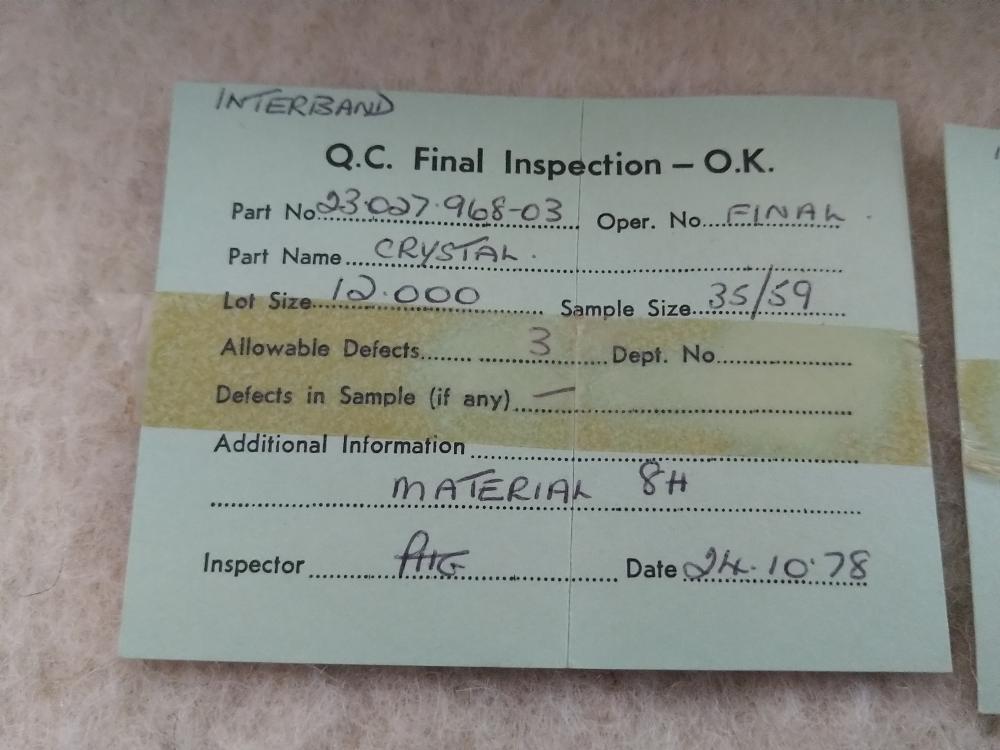

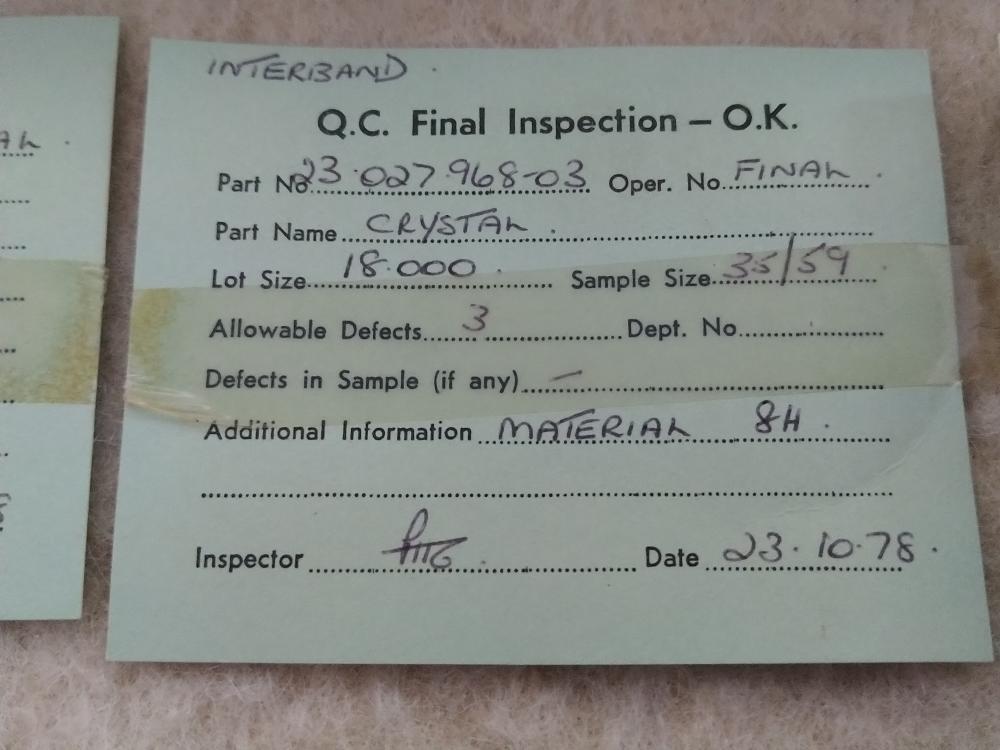

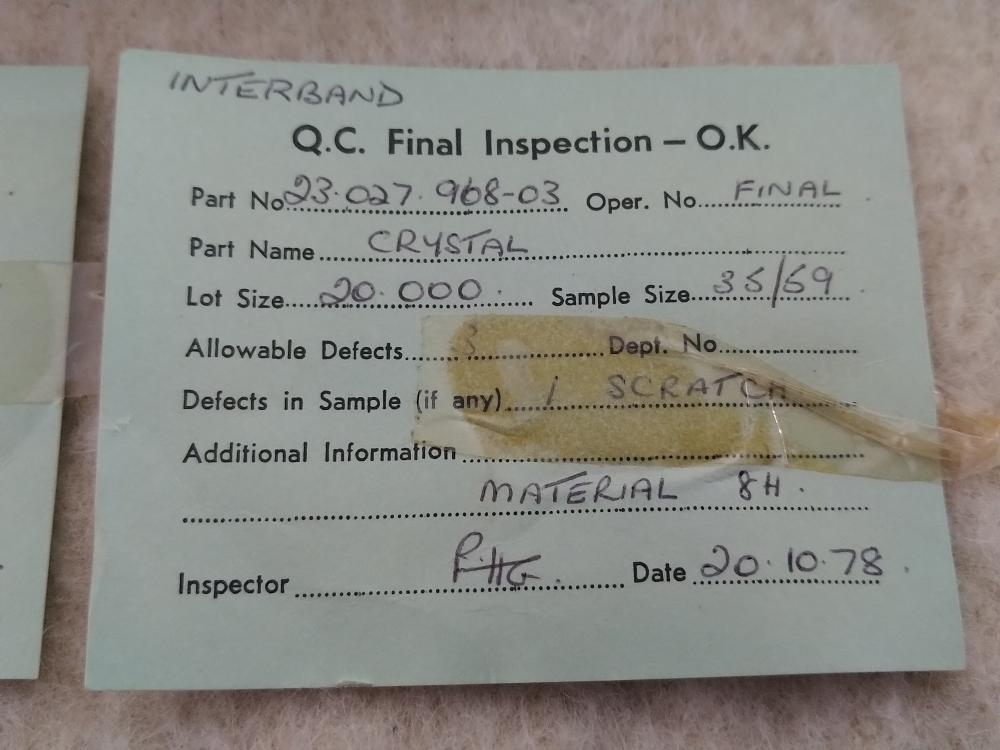

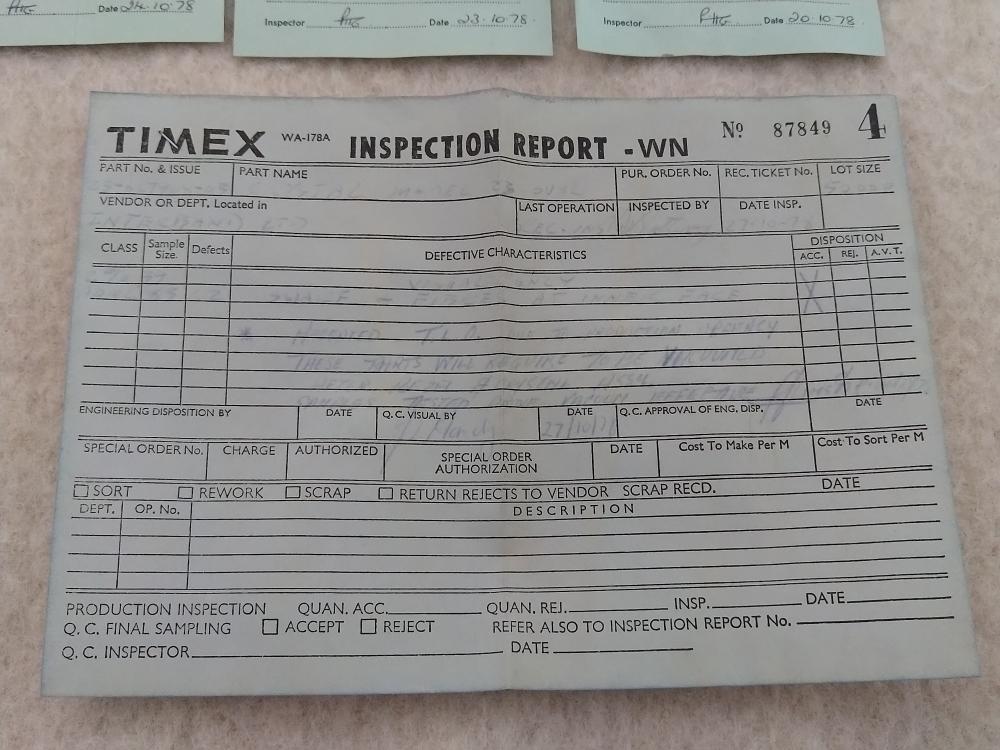

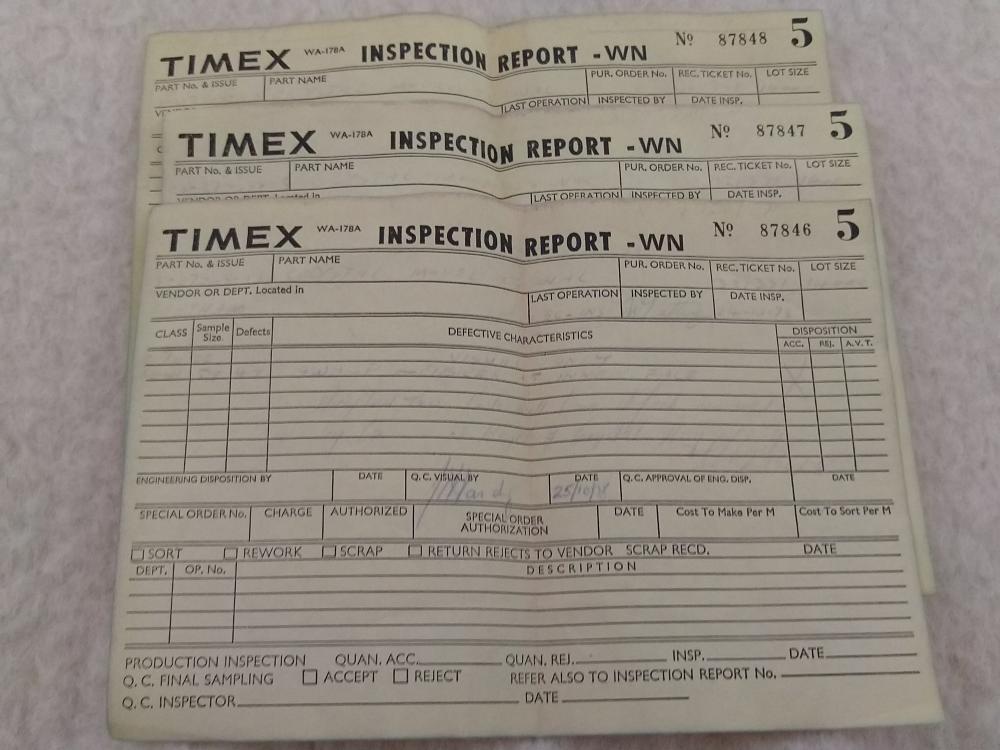

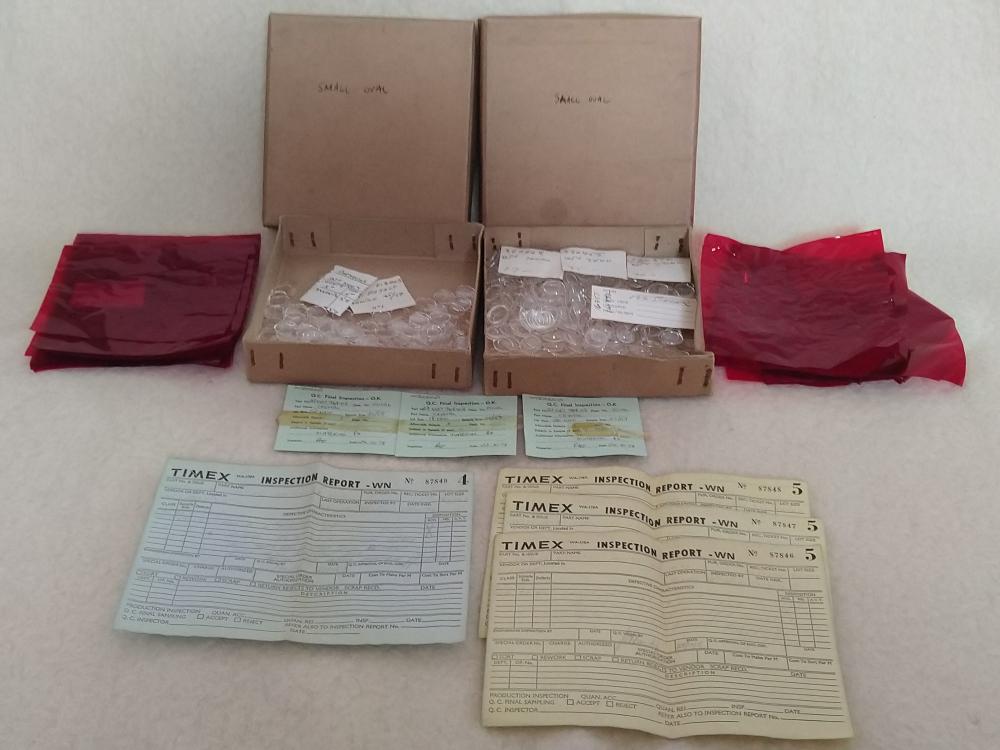

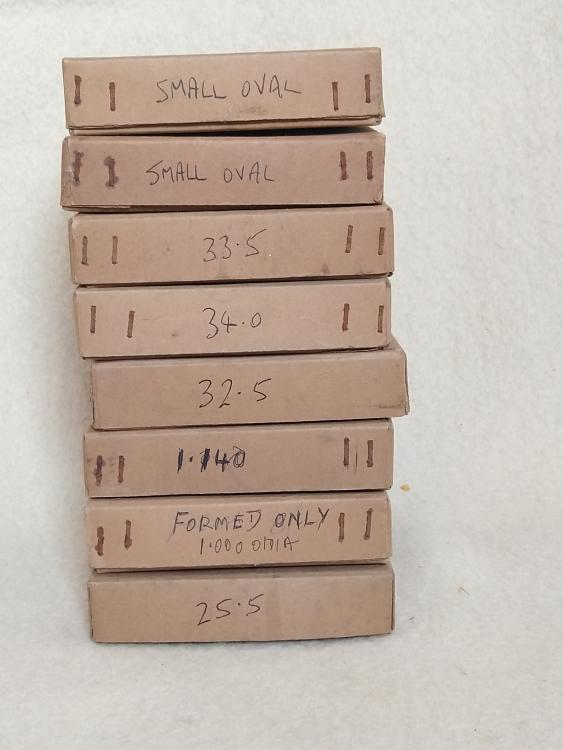

I managed to buy a few boxes of Timex watch crystals, they once belonged to someone who worked for Timex for all his life and sadly is not with us anymore. They came from Aberdeen and the gentleman worked for the Dundee Timex factory in the sixties. They have different sizes and shapes and it seems they were actually samples for quality control. I cannot take out the writing on the "TIMEX inspection report"s as it is faded away but the smaller sized "Final Inspection: is dated as 1978 and I can read/take out the same year on the TIMEX inspection reports too as far as I can see it. I found it very interesting so I thought I would share with you. I know there are Timex fans out there. An interesting BBC documentary: The Rise And Fall Of Timex Dundee - Full BBC Broadcast - October 2019 There is some glitch with the voice at the end, unfortunately you cannot watch it on the BBC at the moment.1 point

-

Hi, I hope you all are fine Those days I found an old omega f300 cone case sleeping on the drawer polished as a mirror when I bough it, many years ago cheap as scrap. I decided to give it a try and among other tasks, rescue it's finish, and discovered that it's impossible to do it by hand, each run marks his scratches in a different direction giving even worse impression than mirror polish, so decided to take the challenge of scratching it in a radial and homogeneous pattern. I read somewhere a post about redoing an Omega cone surface, and found it really difficult, doing supports, regulators and so on, and requiring even a grinding machine, impossible and not to inspiring for me. Saw even someone using a dremel that took the hell out of me. Below it's the simple contraption that allowed to do it, maybe you can find it useful for your projects, it's cheap, easy to build and makes the redo a piece of cake. All the secret is to guarantee that sanding paper (or whatever you use) attacks the surface always in the same "radial" direction, this is impossible if you grab the case or sand paper by hand, any minor deviation will shine as a photo flash ruining the look. So to do it you may elaborate a complex rotating support, or take a simpler approach. As the watch is round, almost any "support" that "fills" the case will allow to rotate it around that position keeping the angle and relative position of the case. So with just a few sticks laying around I've been able to "build" a really simple "fill" to firmly support the case in a fixed position, allowing it to rotate freely but preventing any displacement up down, right or left, so keeping the case in the same relative angle no matter how much you rotate it. The second challenge was to make a sanding "device" to scratch the cone wall without any lateral displacement, so, just up and down motion along the cone wall, with any lateral distraction. Again an old lumber piece and a single carpenter clamp did the trick. Below are a few photos of the job, cheap, easy and efficient, I hope you find it useful. It was fun to repair a watch case with lumber, sand paper and carpenter tools, still thinking what use give to the hammer. My apologies, but don't know how to lay the photos in their place Ask if any doubt. Cheers and take care Ricardo1 point

-

Get into a habit of using Rodico or two sets of tweezers, or a pair of tweezers and a peg-wood stick to hold the part in place while removing or installing it. Sometimes you can use a small piece of plastic wrap on top of the movement during disassembly of certain components. It's clear plastic - you can see things and the parts are not going to fly across the room.1 point

-

Relide is just a name on the dial. Some Relida watches have Felsa movements. Have you noticed any marks on the bridge or main plate (under the balance)? Once you find out which movement is fitted, it should be easier for you to find replacement parts.1 point

-

Hi Markr I would suggest a nice pastle green, Its easier on the eye yet light enough to be able to see errant bits. the colour also has a calming effect which you may need at times?1 point

-

Many thanks for looking for me @JohnR725. I will precisely measure those dimensions again and have look to see if there is a match. I couldn't find that diagram with what ABCDEF mean so thank you for that. I agree AM220 does look very close. I'll add that to my ebay auto emailer to see if I can get a donna movement. I guess nothing last forever. At the very least, I can clean this watch up for display in the hope that at some point I can revive it. Maybe if I get better at this hobby I can repivot it myself. Again, thank you all for your input.1 point

-

Now I need to make one of these tools as I do fear stretching the hairspring on the tack. Making this one, you would not need the upper arm to hold down the balance as only a shock would move it... I think there is more chance of damaging the pivots by grabbing the balance and cock together with the tweezers, as the pivots could stay in the upper jewel and be bent by this action on removal. As well, I always fear the balance cock falling off the movement on installation and the balance staying in the movement resulting in the hairspring getting really stretched.1 point

-

It really is! The old ones were always made of German silver like this one and very nicely made. A friend of mine who did his schooling in La Chaux de Fonds made one in school but they were using brass by then (about 10 years ago) with a bit less focus on aesthetics and more on just function. Another friend who did his school in the Vallee de Joux didn't make one, and didn't even know the tool. It's funny how things can differ by region even in a tiny country like Switzerland.1 point

-

1 point

-

1 point

-

Best to keep it in a stretched state for as little as possible. I don't believe in most cases that it just resting on the balance tack will cause permanent deformation, but the danger is in transporting it on and off the tack. You will see that the balance bobs up and down and if you are not absolutely steady with your hands when holding the bridge/cock it only takes one good bob to stretch the hairspring past its region of elasticity. The same procedure for observing balance pivot can be achieved by resting the balance on an anvil with roller table resting in appropriate hole and lifting up the balance bridge/cock. Allows you to achieve this procedure better too as you're not having to deal with movement of air or work bench causing the balance to dance around while hanging off a tack. All in all useful for pretty much nothing but Instagram photos.1 point

-

I use mine every day. Some people claim they bend hairsprings, but I’ve never witnessed this.1 point

-

1 point

-

1 point

-

I doubt very much it will fit. You will have to find someone who is able to make the set or if you are able make it yourself.1 point

-

just looking at your stem is telling me that this is going to be an extreme longshot. The problem with the reference books are that there are aimed at newer watches. But is still worth a try. I'm attaching an image that shows the specifications that are needed. if I did my math right the only dimension we get is 5.25 for the length labeled a in the image which narrows it down to several stems. It be nice to have the rest of the mentions. Also I have another book from the 50s and I looked at the fingerprint system there because being an older book it has all their watches unfortunately I did not find this watch. The problem with any of these systems are they assume that the watch was made a great enough quantity that spare parts were available. Or it came from a company that supplied spare parts. So somebody making a watch not supplying spare parts is unlikely to show up in any of these books. that I've also snipped out an image of with the fingerprint system looks like. but unfortunately looking at either stem number it doesn't appear to match your watch.1 point

-

I'm cheap, so I use an old oiler stood in a hole in a wooden oilpot stand. I've often wondered if it does the BS some harm and wondered if somebody made a balance tack with a moveable table with a hole for the balance staff. Probably no need or it would already be a thing after all these years.1 point

-

1 point

-

I think you'll find that a vibrating tool is a luxury item and almost none of us have one. as an alternative you can put a hairspring in the watch and see what the hands are doing. Is not a great way to vibrate but if you had similar hairsprings which you probably don't. but fortunately the Swiss made lots of inexpensive cylinder watches out there so should be similar things available that might work. At least they get the hands moving.1 point

-

I use mine If I want to get a good look at the lower pivot without removing the balance. I rest the balance wheel on a piece of Rodico to stop it bouncing around and spraining the hairspring. I work on all sorts of movements. Not enough to say it never causes problems, but enough that I would be surprised If it did. The spring doesn't get stetched further than when removing the balance from the movement for example, so why should it be a problem? I never store the balance on the tack.1 point

-

1 point

-

Hi I have one only seldom used as when the balance is removed with the cock it is laid on the bench with the cock on its back and the balance laid on top The spring is relaxed and under no pressure and coverd untill required. There are others who swear by them so you will get some interesting points of view. All valid. Cheers1 point

-

Its Big 'Q' Timex Thursday today. This 404 club watch is most probably late seventies or perhaps early eighties. Either way it is not far shy of forty years old and still going strong. It wasn't a particularly cheap watch in its day, retailing for around £34.95 GBP which equates to about £157.00 today.1 point

-

you might take your question to a different discussion group then report back here if you get an answer. Then on the same website they also have technical stuff that's found that the second link. https://www.thewatchsite.com/ https://www.thewatchsite.com/forums/user-technical-manual-casing-guide-downloads.14/1 point

-

1 point

.thumb.jpg.796f86233d594b9944f4949506b5e439.jpg)

.thumb.jpg.9940a1cd9b1ec9e8f4a09d3a4445ddac.jpg)

.jpg.bda943e163ba401ddd8c8b8450df887b.jpg)