Leaderboard

Popular Content

Showing content with the highest reputation on 10/07/20 in Posts

-

Just that "tech guides" for many old watches amount to a parts list, and when they were really motivated they'd say fine oil here and there and grease here and there. The Valjoux 23/72 family is pretty old, so... Oil the train, grease the high friction points, like you learned in school right? (haha) When these watches were made nobody imagined they would be serviced by a nonpro. Now we have tech guides that tell you to use 8 different oils and pitch certain parts because you can't oil them like the factory does. These Valjoux calibers are tractors. Moebius 9010 on balance pivots, 9415 on pallet jewels, pretty much whatever Moebius oil on the rest of the train. Grease the winding and chrono functions, and when these were made a lot of guys would have used Moebius 8300 or Vaseline for that. That's about it. It's not a Frederic Piguet where 9020 where Jismaa 124 is needed will result in disaster- it's a real watch.3 points

-

When you think of ladies vintage Swiss watches, probably something small, delicate and tasteful comes to mind. This is not that watch. This thing is so bizarrely bad and entertaining that I think I'm going to have to make it a custom fabric strap. I wonder what is the most "trippy" fabric I can dredge up with from my wife's extensive collection of quilting fabrics. I had a quick rummage, and this is what I came up with, but I'm sure i can do better. There is also scope for some kind of bezel, as that gap around the dial looks as though it should have something spectacularly tasteless embedded in it. In case you are wondering it has a "one jewel wonder" BFG 866 hiding its embarrassment inside. It was described as not running, but a quick clean sorted that out. The next question is, do I splash for a replacement crystal and double the cost of my "investment"? ?2 points

-

The case might be worth trying to re-guild it using Gold leaf which is not as difficult as one might think. There are many youtube vids showing how. The movement must be serviced and it must be perfect or it will not run. I have serviced many of these so a pic of the movement will be helpful if you encounter any issues.2 points

-

Cant find the trademark but I am certain the movement is a French Japy Freres 8 day cylinder platform movement made around 1900 identifiable from platform shape and separate bridge plate for the barrel , made with both round and square plates and used in thousands of timepiece wall and mantle clocks. Maybe a retailer or importers mark2 points

-

If getting it off is hard you may also have a problem getting it back on without a press tool. Another argument for sending it to a shop. Anilv2 points

-

1 point

-

1 point

-

1 point

-

1 point

-

My watchmaker friend has been asking me to sell off his collection of clocks. So we started with the smaller ones. Here I two I could not resist to try and get running. The Westcox dates to 1940 - 1942 and to wind it you have to pull a string. My guess is the Inghram is same time period or ealier. Both are much like a dollar pocket watch inside and with some cleaning a nd fresh oiling and grease are now running again.1 point

-

Glue( epoxy five) a small ladies watch crystal about the size of the cub to the treen thingy. ?1 point

-

The only way is re-gilding. Gold paint will make it look odd against the movement. We only need a photo of the back plate to id it. Get one of these to help you to set it in beat when it comes to clean and oil the movement. Because of its long handle it gives you better precision to enable you set the clock in beat.1 point

-

1 point

-

Hi That a vintage pot, Glass in a treen case, too good to use its a collectors item. I made my own stand and used contact lens cases as oil pots. They have a hard plastic coating so as not to damage the lenses and screw caps. If they should become damaged they are easily replaced at low cost. will post photo if required.1 point

-

When I make a balance staff, which is about once a week, I rough turn the pivot leaving about 0.02mm on its diameter and then count on the Jacot to give me a beautiful cylindrical pivot coming off of the conical portion. The whole point of the tool is to get nice cylindrical pivots- with the exception of the 4th wheel runner, which will purposely produce tapered pivots. If a Jacot tool is making tapered pivots then it is out of alignment*, either from being dropped, or having its runners mixed up with another tool. Older tools aren't adjustable, though some have a "headstock" end that can be raised and lowered, but the more modern Steiner/Horia (Hahn) tools provide means to adjust the height and front-back alignment. * in some cases when doing conical pivots, if the burnisher has too large of a radius it will make horrible unusable "tapered" looking pivots. The Bergeon tool above comes standard with a radius that corresponds well to most wristwatch movements. If buying a secondhand Bergeon carbide burnisher beware that the radius on some older ones is larger and really for pocketwatches. The very old Bergeons have a metal cap for the end, the middle period a purplish bakelite cap, and new ones an anodized purplish aluminum cap.1 point

-

1 point

-

1 point

-

I have made a compilation which is for the ETA 25 jewel version, but I walked it through and it should apply to the 17 jewel one too, just some wheels and and a lever has changed looks a bit but are in the same places. And ofcourse the oscillating weight bearing. Here you can see some steps in how to adjust the movement too after servicing it, if you print it out you also can make some notes till the next time you service one. ETA 7750 HSL EDITION.pdf1 point

-

Yes ofcourse. Here is a slightly washed version of it, since the most Rolexes has the same service procedure they usually compile the data like this. The 1500 series starts at page 7. ROLEX TSI HSL EDITION.pdf1 point

-

My guess is they just can't be bothered making them anymore. The Inca assortments I have are things of beauty but are from a time when all watches were mechanical and watches were serviced regularly and parts got sold all the time. Sad though. Inca was always really cool with those kits. Kif never did them like that.1 point

-

1 point

-

practice movement is an interesting question in this discussion because ideally you should have hand eye coordination for working on a mechanical watch before you even think about this watch unless you have lots of money in which case just get another one of these to practice on. If you look on the discussion group there are quite a few discussions on getting people started with watch repair. For instance I have a link that will get you started. https://www.watchrepairlessons.com/ as far as practice watches go I usually recommend a brand-new Chinese clone of the 6497/98. the reason why this is my choice is it's relatively inexpensive and it's running. It's very important to start with a running watch typically people want to start with broken watches and fix them. If they aren't running after they attempt to fix them they blame the watch. If you disassemble and reassemble preferably several times a running watch and it's no longer running it is a lot easier to narrow down whose fault that is. Everyone breaks stuff when their learning and the easiest way for new person to see that is to start with something running and break it. but once it's broken you still can practice taking it apart and putting it back together multiple times to get your hand eye coordination so that the next watch you work on you probably won't break hopefully. one of the problems with electronics is typically you cannot look at it and ascertain whether it's good or bad. So this is where you'd hook up your electronic test equipment usually specifically made for watches and see what it's doing? this is actually outlined in the manual. You hook the watch up to a power supply you measure the current consumption and see if it's oscillating. If it's not oscillating you can attempt to measure coil resistance in figure out which coil is probably bad. Fortunately this is a slightly easier watch to work on as you can remove the electronic module without even taking the watch out of the case.1 point

-

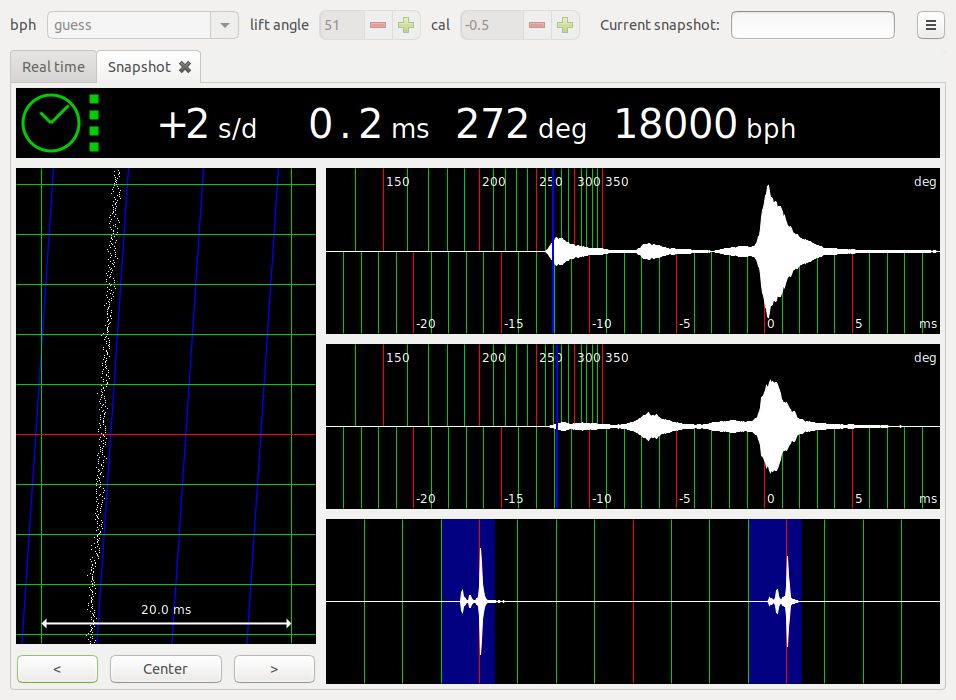

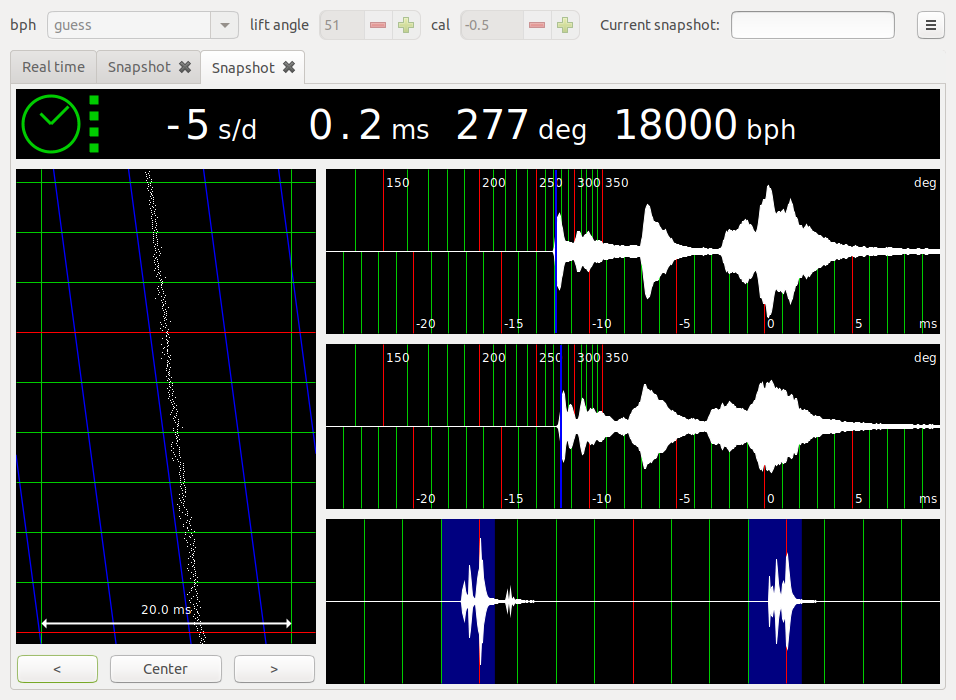

use of the dip oiler's requires practice. One of the things that might be helpful it is if you can get your oil cup close when you insert your oiler you can see by the reflection how deep your going and if you dip it in as deep as you can you're going to pick up a lot of oil. just barely dipping it in you will get a smaller quantity but it does require practice. This is why typically in schools they teach students how to lubricate the watch with a dip oiler so they can practice and get a feel for how much oil to use. But it does require practicing lots of practicing. this is where schools are different than real life in schools they work on the same watches over and over and over again here your learning as you go which makes it much harder to learn. Lubrication of the escapement is a really interesting subject with lots of different opinions points of view etc. Whatever you do it does have to be even. If one stone is somehow the different than the other or uneven quantities on the escape wheel it can show up on the timing machine as an un-even trace. or a variety of things can cause on the evenness if something isn't quite even on the pallet fork. then a couple of links in case you haven't seen them. The first one a variety of interesting PDFs unfortunately this is not the complete set Omega has much more than this. But there's still some interesting ones here like number for the covers lubrication. Also at the bottom of the list number 81 I think you'll find helpful it has interesting things. Then the video it makes a reference to lubrication and the escapement. Yes he really does cover the lubrication as the preparation that takes all the time and things to check etc. the third link is here for several reasons one Iowa's like the look at the watch somebody servicing but it's here for another reason. As we know in this group amplitude is the most important thing and occasionally timekeeping. Notice when your watch was made up to about 1974. Have you ever wondered why the tech sheets typically don't cover amplitude? Now the reality is if you look at eta for instance it's typically not in the tech sheet but it is in the manufacturing sheet which are a little harder to find. Now the reason why amplitude isn't prominently mentioned in the tech sheets especially in 1974 because the quantity of timing machines that would measure amplitude were limited choices. You don't even start to see a digital machine until about 1980 and then it was astronomically expensive. The Chinese machines like the 1000 doesn't even come onto the market until about 10 years ago. Witschi machines were available before that but you had be really obsessed to have one. even in the watch factories if you were to visit one they typically had paper tape machines they visually looked at the amplitude. So this is why it's not prominently featured on the tech sheets especially the early ones because it just wasn't practical the measure. That doesn't mean you shouldn't be concerned about it but watch companies do attend be more concerned about timekeeping than they are amplitude. https://www.cousinsuk.com/document/search?SearchString=working https://youtu.be/Gy0o0KKBqeQ http://www.ranfft.de/cgi-bin/bidfun-db.cgi?10&ranfft&0&2uswk&AS_19301 point

-

Hi Depending on you point of view it may be the best course in this case, but I would ask the question of the person who changes the battery if it is a snap on back for further reference. The Investment of a proper tool for the job out weighs the price of battery fitting (£10 £15) depending on where you go. The price of a tool £20 £40 . Let us know the outcome. good luck1 point

-

My mom handed me this Gubelin “Ball of Light” from the ‘20s and asked if I could do anything with it. It’s a manual wind 17-jewel movement that started up immediately when I wound it, so I’m not inclined to do anything with it other than find a necklace or charm bracelet to pair with it for my wife. Kind of cool looking, though.1 point

-

1 point

-

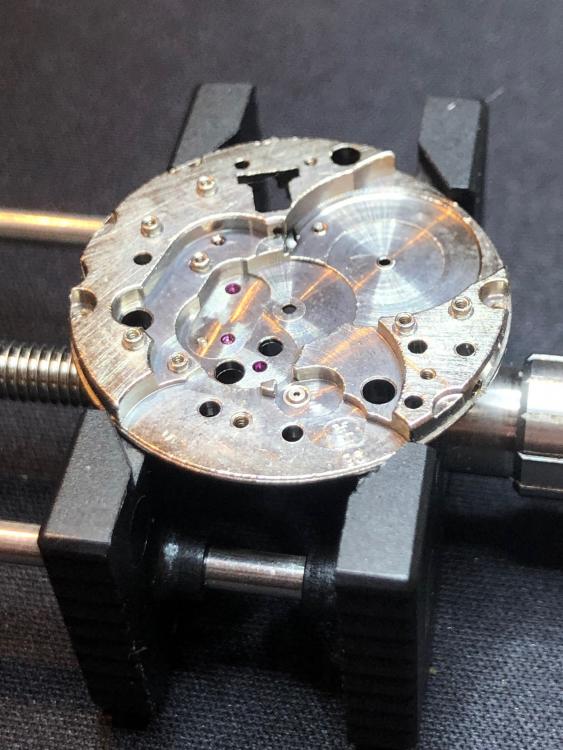

Yesturday afternoon. I started to work on the donor st96 movment. It is in much, much better condition, than the one I started with. Nice experience! It feels that the skills are imroving. But springs and clickworks are still my nemisis! ?(but starting to get a hang of it) A few pings. But only a clickwork yokelevel/cam lost. Also have to say, it seem to be a bit better production quality. I always seems to forget to fit the yoke, the one that is connected to the stemscrew..Ofcoarse when the barrelbrige is all set and done. Including the clickspring! ? During the night. I discovered that the tweezers needed better dressing. Made a noticble improvment. Eventhough I was getting tired. Bit had so fun, I couldnt stop working. Finding ”pings” in a better way. I took some extruded pvc board (commonly named Forex) that is used for advertising/signs ect. Fitted a few feet of selfadhisive magenticstrips. To sweep the floor and desk with. Had a few lucks with that. Things seems to ”ping” to other places, directions. Than you actually think they do. ?? The movment was quite clean. But did try a regime of letting it soak in 3M industrial cleaner. Then rapidly flushed with hot water. Then final rinse in IPA. (Not the beer, though it’s nice) Pallet fork and balance did have a bath in lighter fluid. Did take my time oiling. Including first proper removal and cleaning of the cap jewels. This morning it was up and running! ????? What a joy! ? Sitting there watching the movment ticking away friskly! Albeit tired and with sore eyes and neck. It feels really nice! Realized a few things. I need a stem and crown! Also a few screwdrivers needs dressing. So I went to order a stem, crown and the classic dressing tool. While browsing cousins. I realized, it would be nice to see how well the thing ticking on the desk. Actually runs.. So clicked and added a timegrapher to the basket. Expensive morning. Cant wait for the stem though! ? Wish you all out there, a nice sunday! Dont forget to fika! (Google Swedish fika)1 point

-

1 point

-

Thank you Andy, it took some time but I have figured out a way to get them perfect.1 point

-

I could not find a single video on how to wind a mainspring back into the barrel after cleaning. I purchased a three set tool and figured it out myself and then made a video for others to learn. Thanks Sent from my iPhone using Tapatalk1 point