Leaderboard

Popular Content

Showing content with the highest reputation on 09/02/20 in all areas

-

Well, that was so easy as to be anticlimactic. I figured 30 minutes was enough curing for a glue I would be removing with acetone anyway, so I gave it a shot using my desktop jeweler's vise (cushioned by some soft plastic). I wouldn't have tried this without a case vice except that I noticed the design of the lugs gave two nice reinforced perpendicular surfaces that would fit easily into a jeweler's vice without significant risk of damage. Slow, even pressure with a 1 1/8" wrench opened the caseback on my first attempt. Easy peasy. Thanks all for the advice!4 points

-

Hi Markr attached id the tech sheet for the eta/esa 944.111 hope is of some use. ETA 944.011, 944.111 (1).pdf3 points

-

2 points

-

I have used G-S with good success in the past to attach chapter rings (which had alignment pins) as well as re-attach applied indicies. The latter had proper pins at one time but not enough left to swage them onto the dial. They provided location and a tiny drop of G-S held them fine. It's a bit "rubbery" too so fits that criteria. It gets harder/stronger with time so don't get scared stuff is wiggling around. Fixture it and let it cure fully overnight before you pass judgement on the stuff. Also, assuming the chapter ring is something you can machine (unlike the dial it seems) you could add a small trench (shallow o-ring groove) on the underside which would contain the excessive adhesive rather than having it "squeeze out" onto the dial. Relief slots on the OD (where it will be hidden) will give it a path. Then you could use a jeweler's epoxy, although I doubt you need anything near as strong as that. A texture (fine grit blast) on the underside of the chapter ring will also ensure it will be bomb-proof.2 points

-

Sounds intriguing and interesting ... will be interested to see your design soon! From your description I'd put forward something like HMG's Jewellers Cement. Despite the advertised time to be fully dry it goes off quicker than that and should grab the chapter ring sufficiently without holding for ages. It allows a lot of control and dries clear. And having used the word 'grab' you could also consider something like Unibond's 'No More Nails' Invisible. A smear of this should be enough and you could dilute to something runnier if you needed to. That probably appeals more to me than messing with epoxy that is not as easy to clear off if it starts oozing out over your lovely dial. Until dry you can easily wipe off this kind of adhesive with a wet cloth or cotton bud. I know you've discounted cyanoacrylate but it sounds like it could still be a consideration. You can get slower drying varieties and it is brittle. Where I'm going with the latter is that you could put, say, four strategic small dots to safely secure the chapter ring but if you need to remove you could prise vertically upwards which should snap a small cyanoacrylate bond; something other adhesives like epoxy would not permit.2 points

-

I find that oil the escape wheel teeth when lurbricating with 9415 is easier to control the amount of grease.2 points

-

I'm so glad this topic popped back up. I'm new here and hadn't seen it. Blue is probably my favorite dial color, in contention with champagne. Even so, looking through my collection I appear to only have 4 watches with blue dials. Then again, my collection seems like it's probably puny compared to some of you here. In order of acquisition: Seiko SNKK45 ("Seikonaut"): Seiko SNZH53: Grand Seiko SBGA375 (it's hard to coax the blue out of this one - it looks black most of the time - had to get in bright sunlight for this picture): Bulova Precisionist 96B257:2 points

-

Hi all, I'm getting really close to manufacturing my first run of custom dials. I'm not ready to share a lot of details yet, but I would sincerely appreciate some advice on adhesives. My dials will be featuring a 0.25 mm height steel chapter ring attached directly to the top of the dial material. I'm certainly not planning anything stupid like using cyanoacrylate glue to bond the chapter rings to the dials. I'm hoping for something low viscosity that can be applied carefully and will take a bit of time to set before curing. I'm looking for low viscosity because of the tight tolerances involved; height matters a lot here. I'm hoping for something that will be at least a little bit malleable, as I will need to align the chapter rings manually before they set and cure. (I really, really wish I could build some feet into the chapter rings and put them into alignment holes on the dial, but that's not possible for reasons that will become apparent once I disclose the dial material. I will need to align the chapter rings based on the stem location and with the aide of a spare crystal-less case that has an indexed bezel I'll be fixing in place.) Right now, I'm looking at GS Crystal Hypo Cement as the best potential adhesive. It should give me 10-15 seconds of manipulation before it sets, and I hope that I can use a small enough quantity in a few key places to keep the chapter ring secure and as flush as possible to the dial surface. Another alternative would be a two-part epoxy that I've thinned with alcohol or acetone. Since I don't need a hugely strong bond, the fact that solvent will weaken the epoxy isn't a huge concern. Thinning the epoxy with solvent would also extend its curing time, and I really don't want to have to try to hold down the chapter ring in perfect alignment by hand for an extended period of time before it sets. Please let me know what the best way to proceed here would be. Specific brand recommendations are especially appreciated. Of course I can practice, but due to the cost and difficulty of prepping the dial materials, I'd prefer to minimize losing materials here and to get my process right quickly. Thanks in advance for any advice, Dan (I've been documenting my research, design, and manufacturing steps to date and will be sharing information about my project when I am closer to the finish. This has been a fascinating journey into horology, lapidary, woodworking, CAD, and laser cutting for me.)1 point

-

@jdm, thanks for confirming. Glad to hear that I didn't violate either the letter or the spirit of the rules.1 point

-

Sorry if I bring this up again. I understand your point of view however if we look to this forum composition it's mainly hobbyists of different levels with the precious help of few professionals. Many members don't repair and just like to hang out here. No special interests group, no taboo subjects, and everyone is welcome. At some point anyone may need a third party recommendation and cost reality check, all good with me.1 point

-

Maybe should have wrote "clean" instead of rinse to make it more clear.1 point

-

1 point

-

1 point

-

1 point

-

Would you elaborate more. In vinegar you have acetic acid, the acid converts the rust to water soluble Iron III. The safest way to speed up the reaction is by applying some heat since it is an endothermic reaction. If you really want to accelerate the oxidizing you could add something like hydrogen peroxide (not recommended for newbies). But this mixture might even dissolve copper. One could therefor skip the aluminum strips. It will probably just be converted to aluminum acetate Al(C2H3O2)3 Guess the acetic acid creates the same process as your coke cure but with less calories1 point

-

If it can be done that machine seems like the machine that could do it. Good luck. I bet those slices will polish up beautifully once you glue them to the brass blanks.1 point

-

1 point

-

Ooh ... that'll be very nice looking (and unique!). Love the bright colours and wavy lines. Looking forward to seeing the finished example(s)! I've never got on that well with the GS stuff as I found it too jelly/rubbery like. But @Tudor specifically mentions this property and, crucially, has prior experience of it working and good advice. So good luck. On a tangent I had to recently put up a big mirror in the bathroom at home with a friend. I mean big in that it covers one wall. Dubious that the tube of mirror adhesive that was supplied would hold something so heavy and big up but it does. That mirror isn't coming down any time soon. Some of these modern adhesives are incredible...1 point

-

I have found this thread most interesting and though my input has been limited I have followed waht others have to say. Also, nice with a forum were memebers to get involved. I wish you all the luck with solving this. However, I got interested in overcoils and started reading online what I could find. The hairspring is the heart of the watch and real science and should be treated with respect. I found the following link interesting and perhaps others will too. https://watchmakingjourney.com/2014/06/14/week-5-days-3-4-forming-breguet-overcoils/1 point

-

I made another one, a better one, for the 16610 case and it works fantastic! The bottom edge is at the exact angle of the retainer, and the inside step keeps it perfectly centered. Again tall enough to not foul on any crystal. I have it drawn and can have more made if anyone needs one. Also made from 6061, they will be $165 each if anyone is interested. I'll eat the tooling/set-up cost but I need at least five committed before I give the go-ahead to make them. (photos are of my hand-made prototype) I will also refine and have a similar situation for the four-digit cases (refine what I made originally). I figure pricing will be similar, but no drawing yet to confirm pricing with the machine shop. Just PM me if you are interested.1 point

-

The least expensive pockèt watches I know that come with berguet overcoil are Russian made, Malnija, vostock and the like. A bad news is the one on your watch may not be the right one( incompatible with the balance wheel) in which case even if you get as good as paul berguet himself, the two simply would not vibrate to produce the design beat, so while someone may not intentionally ruin the overcoil, someone having slapped a bergeuet overcoil on the balance wheel just to get the watch sold is a strong possibility. Having said that the good news is you have the weights on the rim of the balance which broadens the compatibilty interval, so I wouldn't worry about it now specially that you can find inexpensive assortments of overcoil HS's. I assure you, if you master shaping and vibrating overcoils, you can generate yourself some revenue just doing that. So by all means go ahead, members here got you covered. Regards Joe1 point

-

Post a picture or give the caliber. I think most swiss quartz movements are either made or based on Eta or Ronda electronic boards and know how, including your watch, since making the electronic board requires huge capital investment, well more than what tag heuer can afford. Better grades translates to higher degree of purification of substances used in the electronic board, quartz being the most important substance use in the board. All that means you are likely to get a schematic diagram of the base unless tag heuer released one of its own.1 point

-

Not Bergeon brand one-dip. Another manufacturer (maybe the same one?) purchased from Star Time last week. I checked the label and it contains trichlorethylene. We used to use that to degrease aircraft parts (other than titanium) and there was nothing better. But since it kills everything in a ten mile radius they banned it. (wuuuses) I was surprised to see that on the label, but that's what it is. I don't know the active ingredient in the Bergeon brand stuff. Chlorinated solvents such as this are excellent for removing solder flux from circuit boards, and that is pine pitch (tree sap) same as shellac (sap from a different tree). So that's why I was asking. I guess I could give it a try but most of the junkers I have are much newer and probably don't use shellac adhesive. I am sure the old pocket watches do use shellac...1 point

-

hats off for you gaber to take on this challenge...great to see so many members chimed in to offer possible solution, personally i learned a lot from this...1 point

-

As mentioned above 9415 is better for all uses. Having it already, getting 941 would be wasted money and would not produce the much sought higher amplitude.1 point

-

This is where you should set this aside for future project. This is where you should be in the practicing phase like practicing disassembling, reassembling cleaning a lubrication timing. Then you need to find some scrap balance wheels that no one cares about and practice bending the hairspring's get good at bending hairsprings because unfortunately In watch repair mysterious creatures sneak it at night and mutilate our hairsprings and then we have to deal with that. Unfortunately I checked the mega 37.5L-15P balance wheel I have in the image Does not cross reference to your balance wheel. ut is an example of an Omega balance wheel similar possibly to yours http://www.ranfft.de/cgi-bin/bidfun-db.cgi?10&ranfft&0&2uswk&Omega_37_5L_15P http://www.ranfft.de/cgi-bin/bidfun-db.cgi?10&ranfft&0&2uswk&Omega_30_21 point

-

1 point

-

When I was making the decision to buy the 941 or the 9415, without realizing one was an oil and one was a grease, my thought process was "well, it would make sense that the 9415 would be newer than the 941, just judging by the numbers - as you wouldn't remove a digit for a newer product". So I bought the 9415. Now I think I'll go ahead and get some 941 just so I have options. Thanks for the info!1 point

-

That is kind of what I was driving at - I don't care how slippery it is, or how much it changes thickness under friction, it's grease. It's glommy. Now granted, too much of any lubricant is bad. But it seems to me that the difference between "enough grease" and "too much grease" would be exceedingly minuscule on something like an escapement. When I used 9415 on the exit pallet stone when reassembling the 6498 in Mark's classes, I suspect I used too much. I'm going to remove the escape wheel and pallet fork and give them a good cleaning and re-lubricate using the guidance in that document. Thanks for posting it!1 point

-

Do you think perhaps the seller would just give you another hour wheel and cannon pinion? They may be able to do that if they are purchasing them directly from the manufacturer.1 point

-

The bezels need to be removed with a tool. It must come straight up to avoid damage and it is a friction fit. You may get lucky with a razor blade to start it and then a case knife to get it the rest of the way but it should be raised from two sides at least (better four) to keep it straight.1 point

-

Are you sure that’s the number? It’s underneath where it says “unadjusted”. The last three digits are more likely to be .1111 point

-

I assume I PA equals isopropyl alcohol? What's interesting is with our cleaning machine at work the last rinse is isopropyl alcohol industrial-strength the Cayman a big metal can. I'm pretty sure it's in the last rinse for longer than a minute and I'm reasonably sure it has ultrasonic. If I remember how to get a picture of the canned so we can make sure it really is isopropyl alcohol that usually it's not a problem for shellac I was always taught with roller jewels especially since I spend a lot of time working on American pocket watches that when they come out of the cleaning machine you grab them and see if they wiggle. American pocket watches have a misfortune of interestingly weird repair histories and sometimes the shellac isn't shellac and a lot of times the roller jewel is loose. On a modern watches they do appear to be pressed in. But if you're not sure where gently grabbed the jewel and see if it's loose it's in their nice and tight your fine.1 point

-

Unfortunately there is a problem with 9415? I'm attaching a PDF starting on page 13 it covers lubrication of the escapement. notice where they're putting super tiny quantities on? This is because if you get carried away with the quantity which normally wouldn't be an issue if this was an oil you will lose amplitude. This is because on impact the grease becomes a fluid it's very slippery and outstanding but if it's heavy the edges of the escape wheel are not an impact and there literally tearing through the grease. Omega 8645_WI_40_rules for lubrication cousins uk.pdf1 point

-

It’s a tough nut but for all the “common” high end watches, charging that much or more, it’s part of the game. Ive rebuilt a nasty old Omega 2500 for the practice but I’m not intending to pull my Planet Ocean apart myself. Just a weird thing because I have no such reservations about my 1680, which is worth considerably more. Worst case you have an uncommon original model in mint condition for $2600. Not bad in the grand scheme.1 point

-

I'd bet it's Tritium. Radium had no markings that I've ever seen. And Radium tends to be much darker at this point. Geiger counter will tell you for sure, but I wouldn't hesitate to work on it personally. Most of my watches and projects are Tritium. EDIT_ hands look to have been re-lumed at some point. Do they still glow?1 point

-

Thank you for this. I love blue and even my car is blue. Beautiful watches you guys have and I'm impressed with how many nice, blue watches, Seiko has made thru the years.1 point

-

I was looking through all of these and realizing that so many watches look quite pretty with a blue dial. I do not have a single blue-dial watch. I may have to rectify that.1 point

-

1 point

-

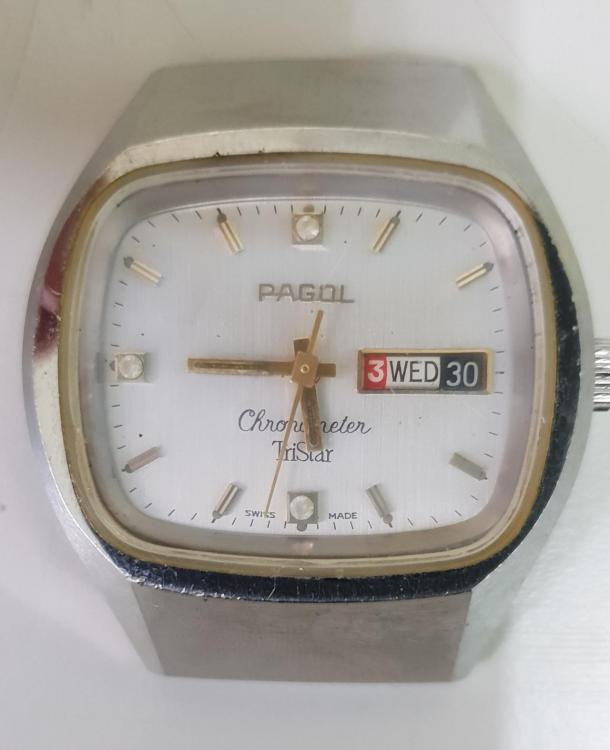

Here is a watch that belonged to my late father. It was never serviced before. The caseback was so tight that it broke the jaw of my mentor's bench mounted caseback opener. We sprayed WD40, we heated it with a microtorch, we dripped acetone into the threads, we superglued a nut to the back... We didn't just go full gorilla on it. We went all out King Kong! It still wouldn't budge. In the end, I used 5 ton epoxy and glued a really big nut to the caseback, mounted my caseback holder to my bench vise and used a 15" wrench on it. Finally it opened. Broke my caseback holder in the process.1 point

-

0 points