Leaderboard

Popular Content

Showing content with the highest reputation on 07/14/20 in all areas

-

I made this yesterday. I know they're reasonably cheap to buy but I thought it would be a fun project. I works quite well.2 points

-

I believe that the base calibre for this is the ETA 2452. Helicoptering of the rotor as you hand wind ETA auto movements is a symptom of sticky reversing wheels. The official ETA requirement used to be to replace the wheels during servicing, cleaning and re-lubricating was frowned upon because they were very sensitive to over lubrication which simply caused the problem to recur. However, people found ways to apply only a microscopic film of oil by mixing a light oil like 9010 with a volatile carrier like naphtha at a ratio of about 1:25 and then just dunking the wheels in it after cleaning. As the carrier evaporated it left a microscopic film of 9010 behind. This has been my standard approach to oiling ETA reversers on my own watches for some time and it has resolved helicoptering rotors without any other issues as a result, but I know that it is a practise that has been frowned upon in the past. However, not wishing to miss out on a marketing opportunity, ETA has now come up with a product called Lubeta V105, which is a lubricant dissolved in a volatile carrier (sounds familiar) which you just dunk the cleaned wheels in and then allow to dry, so I guess that it's no longer considered bad practise. I don't know how the lubricant element differs from 9010 although I believe that it's a more waxy affair. If however the reversers are just worn out then no amount of lubrication, careful or otherwise will solve the problem and replacement reverser wheels is the route to go.2 points

-

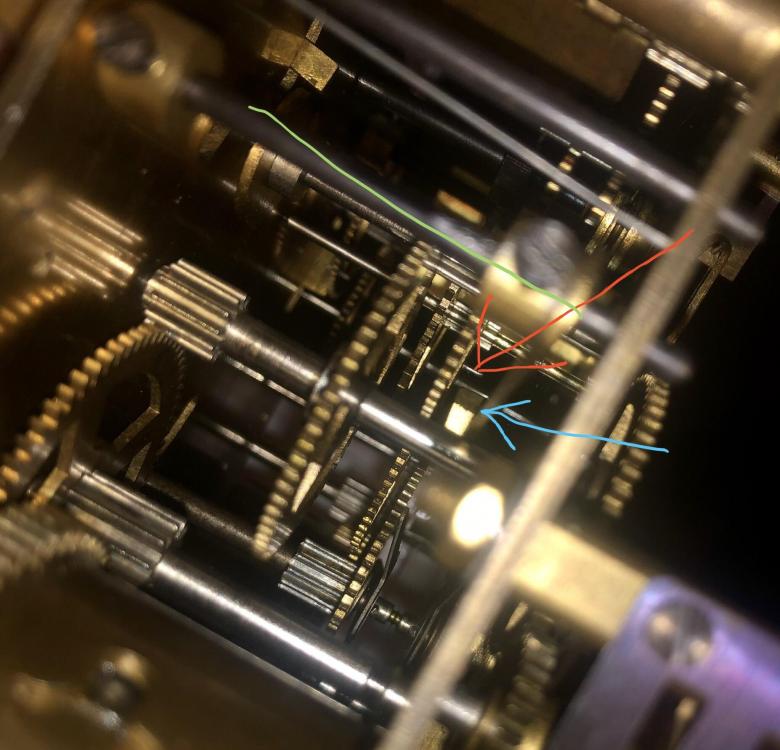

Hello, I’m rebuilding my first Westminster chime clock. It’s made by Arlanza and goes in a Napoleon’s hat mantle piece case. Unfortunately, I’m having great difficulty in getting the chime to trigger each quarter. The Westminster chime triggers roughly every 5 or 10 minutes. The hour strike also seems to be sporadic as to when it occurs. My question: There is a switch on the face, which if pushed down will stop the clock from chiming. Pulling the lever down rotates an axle (green line). This lifts a lever (blue arrow) which blocks a pin (red arrow) on a gear wheel, thereby stopping the chime. Is this mechanism purely to turn the chime on and off when wanted? Or is it somehow involved with how the chime is triggered each quarter, and hence needs adjusting? (Screw setting)1 point

-

I will be attempting to build a fully functional, cased Elgin size 6s Grade 206 pocket watch. This all began a short while ago, when I watched a video about getting in to watchmaking as a hobbyist in which the watchmaker being interviewed suggested starting with a scrap pocket watch movement, which can be found on the cheap on eBay. I found the ubiquity and low cost of American movements to be counter-intuitive, as I would think 100+ year old watches would be quite valuable. This led me down the rabbit hole of the history of pocket watches, and America's former status as the worldwide leader in production volume of watches. The Watch Flipping through eBay listings for non-running movements I ended up buying an Elgin one for about $20 shipped. Here is a photo of the movement-side, and here is a link to more info on Pocket Watch Database. An interesting thing about this particular piece is the lack of a seconds sub-dial. None of the examples I see online on Pocket Watch Database share that, which is a bit weird to me. Phase 1: Irresponsibly Hacking Away When the movement first arrived, I decided to just take a stab at taking it apart. I figured, hey, it's a scrap movement that didn't cost me too much money, what's the worst that can happen? Well, I have to say I'm glad I learned the lesson of why NOT to do that, I just wish I'd been maybe a little more careful. As some fine folks here let me know, with a pocket watch or very old vintage movements, unless you're sure what you're dealing with isn't rare or valuable, don't treat it like trash. I went at the movement with the smallest screw drivers I had available and started to take it apart. Here are the mistakes I made: Not releasing the power from the mainspring: parts flew all over the place and I lost the center wheel for a couple weeks until recently I was looking for a fallen screw and came across it on the floor Not taking pictures - there are a couple missing parts from the setting mechanism, so I am a bit unsure about exactly what was originally going on since I didn't do step by step photos (it's also hard to photograph step by step when the whole thing blows up ) Unscrewing the banking pins not knowing what banking pins are During re-assembly, after trying to set the banking pins so the watch might run, I gave the balance wheel a spin with a toothpick with what I KNEW was too much force, and broke off the impulse jewel - this also is a lesson I knew in theory but learned in practice all too clearly, not to force ANYTHING, and also not to treat any part as if it's scrap or garbage So with all that in mind, and with some insight from the community here which got me reading about the different Elgin models and parts, I've decided to source another identical movement, and a 6s-sized case + movement. Hopefully between the 3 I'll have enough good parts to have a fine working watch. I'd also love to hear anyones thoughts about "switching," I intend to attempt to use all parts from the same grade and model movement. The case I'd be using would probably not have originally contained this movement, as I see lots of 6s pieces w/ case and movement for sale but not with this particular movement. Note: since the horrific events described above, I've amassed a bunch of tools (most of them cheap versions from eBay) for watchmaking, including a screwdriver set, tweezers, movement holders, parts trays, cleaner with baskets and jars, hand levers, lubricants, Rodico, and probably some more stuff I'm not mentioning. Will be in a bit of a better position to attack this next challenge. Anyway, stay tuned for Phase 2, when I will make what will hopefully a more measured and informed attempt at the build.1 point

-

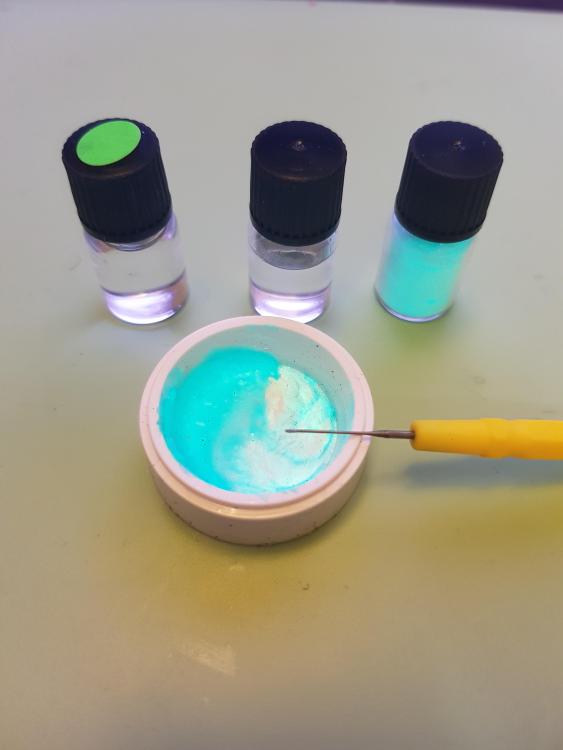

Building a bigger 7750 watch is easy enough. Plenty of dials and hands out for bigger cases. Anything under 40 and it will make your search much harder. I refurbished a 7750 and I built one with a 39mm case and that took me like a year to collect the parts that I liked and fit right. I even had to shave the dial down a mil and clip off the tip off the seconds hand. Lume is often going to be garbage too. I elected to redo mine. Now it is a wannabe Daytona case but I'll drop some pics of it here anyway in case you want some inspiration. Everything I got was off ebay with exception of the chrono seconds hand which I got off sk-watch parts.1 point

-

1 point

-

1 point

-

Okay, saw this and hadn't seen a Hawaiian watch before and couldn't pass it up for $20.00. Has anyone ever heard of this watch. Says swiss 17 jewel movement and Hong Kong dial. Sent from my SM-N975U using Tapatalk1 point

-

Can you get a basket? Just had a look on ebay, some on there but there in the U S A and the postage cost is as much as the basket.1 point

-

1 point

-

That's hilarious! When I saw Pauly's Accurist (BadAccurist?) and Andy's Voyager (clever nickname not found), "rat rod" is exactly what came to mind. I even went so far as to write up a brief explainer for the non-American niche car enthusiast population (which I imagine is the vast majority), and then stopped because it got too nerdy in the wrong realm and I was afraid it might come across as insulting (NOT an insult). I had to CMD+F the page to make sure I didn't misremember not posting it. Those two watches are liquid inspiration! Possibly the coolest watches I've seen on this forum so far.1 point

-

It's certainly not a ridiculous question but an interesting and very relevant question @plop and one that I've been asking myself. I don't have this set myself but my guess is that these winders are all right handed as they are for Swiss movements and not for Japanese movements (I'm thinking Seiko and Orient here) which I believe are all left handed. So yes, it's critical that you get the correct type of winder (left or right) depending on in which direction the spring is pushed into the barrel. I don't even dare to think about how much time I've spent trying to figure out what would be the best and most affordable mainspring winders. In this case, as I don't know the sizes and the quality of these Chinese winders, I have refrained from ordering them. That doesn't mean to say that I think they are bad. They could very well be excellent but I just don't know and I don't want to take a chance. Currently I have a vintage "K&D No. 128 IMPROVED" winder which I don't like one bit. Anyway, I've had my eyes on the Bergeon winders for a long time, and I'm guessing they are among the very best and safest to use, and just yesterday I placed my very first order for these on CousinsUK.com. I ordered a "Right Hand Mainspring Winder Handle", a "Right Hand, Ø9.80mm (No.6) Winder and Arbor", and a "Right Hand, Ø8.60mm (No.5) Arbor only". The smaller Ø8.60mm arbor is just in case the Ø9.80mm arbor is too thick for the inner coil (it can be used with the Ø9.80mm winder if you are careful). My plan is to use these tools for Vostok's 24xx calibres having a barrel diameter of 10 mm and (and this it may surprise you at first) my Seiko 7S36S and my Orient 46E40 barrels 10.5 mm. Now, as the Seiko and Orient barrels need left handed winders the plan is to first push the spring into a mainspring spacer and then push the spring from the spacer into the barrel. That way I will hopefully save the money for a dedicated left handed winder. Now, if this plan will be successful or not remains to be seen (you never cease to be surprised in watch repairing), but if it does I'll let you know. BTW, as you are a new member you are perhaps also new to watch repairing? If that is the case you won't be having a stack of mainspring spacers laying around so that would be a problem if you eventually would want to adopt my approach. Anyway, if that is the case I'd be happy to send you a spacer or two (free of charge). The spacer diameters that I currently have are 8.9 mm, 9.9 mm 10.4 mm, 10.75 mm 11,4 mm, and 14.5 mm. Just let me know what you need when and if you do! EDIT: Just saw that you're located in the UK so www.cousinsuk.com will be a great place to pick up tools, parts, and what not. Info about their mainspring winders here.1 point

-

I have that tool and have used it many times. If you have a hand that is smaller than the gauge can not measure then you measure the pinion it fits onto.1 point

-

That did cross my mind, but I’m not sure the moving magnet would work like a degaussing coil as it’s a fixed magnet which is moving radially, rather than its pole changing, ie. if the fixed magnet’s pole was effectively rotating, which it is not. Still, the rotation may have some effect which I’ve overlooked. I can’t remember if I mentioned this here before, but when HD TV first appeared, I had a lecture where the lecturer used a white board marker to point at and circle the various measurement aspects of the then-new Testcard HD. That was all fine until he used the whiteboard eraser.... he’d forgotten it was a magnetic one and made a real mess of it. It was a £50k Sony with built-in degauss on startup which made absolutely no difference. I think that one had to go back to the maintenance department.1 point

-

Hi A line release tool is a transformer which creates an alternating magnetic field and is used to drive quartz watches at speeds greater than the circuit block. Used to loosen up the gear train on sticky watches and remove gear train jams through dirt. Its no substitute for cleaning and oiling the train but handy for diagnostic work. The Inventivness of members is brilliant and must be encouraged in getting round dificulties and sharing their ideas is just great long may it continue.Not everyone can afford swish tools but make do with DIY soloutions. Magic.1 point

-

1 point

-

1 point

-

Just to close out this thread concerning low amplitude, I finally got around to addressing the issue of too much lock. The pallet stones were probably not original as they were already set back into the pallet fork as far as they could go. I removed the pallet stones, ground down the back ends, reinserted them and applied shellac. After making some adjustments, the amplitude jumped from the initial 166 to 265 degrees.1 point

.thumb.jpg.9a471f9f88b6ca5d7c0fa31e8d18b329.jpg)