Leaderboard

Popular Content

Showing content with the highest reputation on 06/13/20 in all areas

-

What better friday night can you have than picking a totaly unfamiliar movement apart while sipping at a nice glas of Barollo wine. Today a new shipment of watches arrived and I got a "Nilax Digital Automatic" among the other treassures. Usually I just throw them into a concrete wall just to see what kind of the effect it does on a seventies watch, maybe a black hole will appear who knows, but tonigt my curiousity took over. Dark thoughts turned up in my mind like, what better combination can one find a Swedish watch with a German movement and probably assembled in Taiwan. So here comes some PDF:s as usuall from me describing my adventure. The first one shows the disassembly and can be found in the link below. PUW1560D Disassembly.pdf Just so you will be prepared, this is how it looked like at arrival... Enjoy and maybe I will post the Part II in anear feature..1 point

-

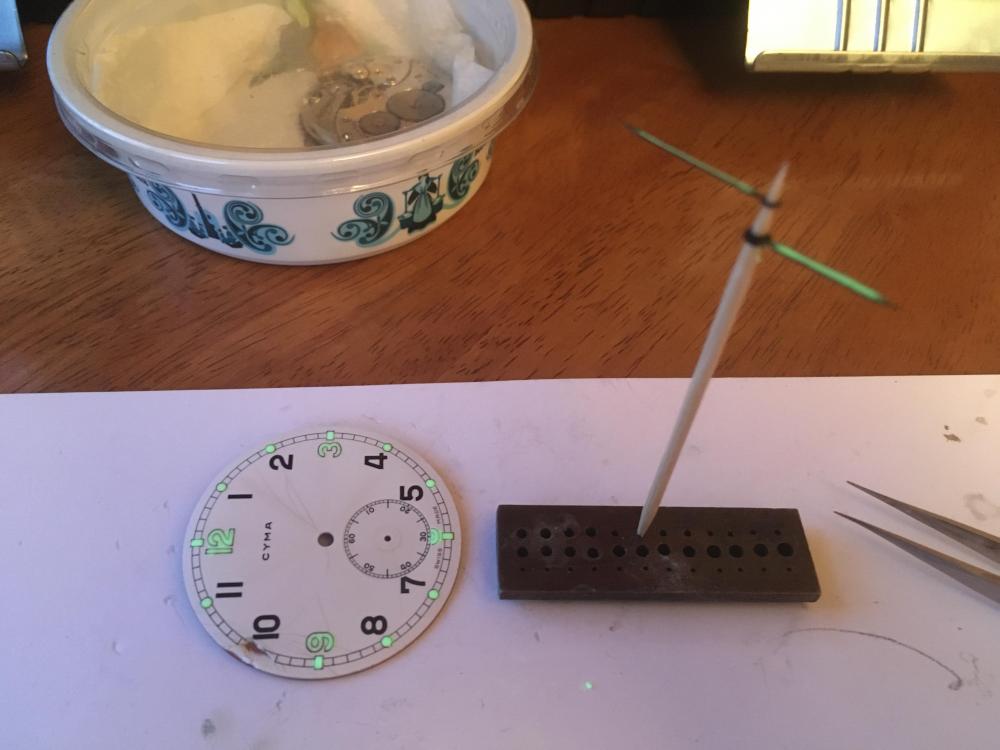

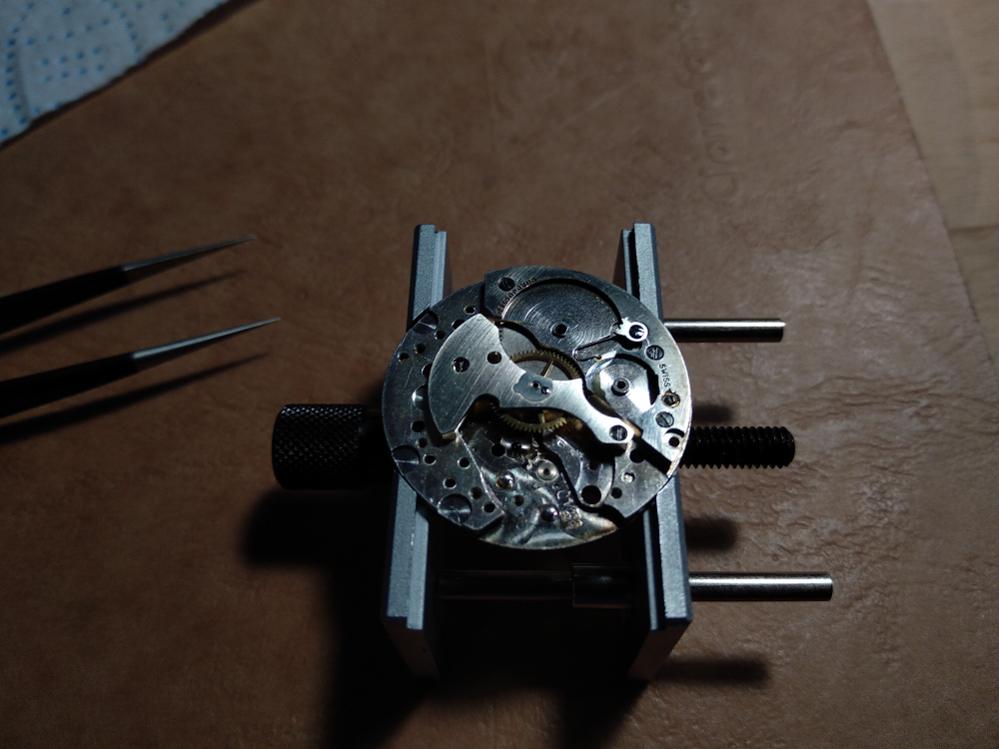

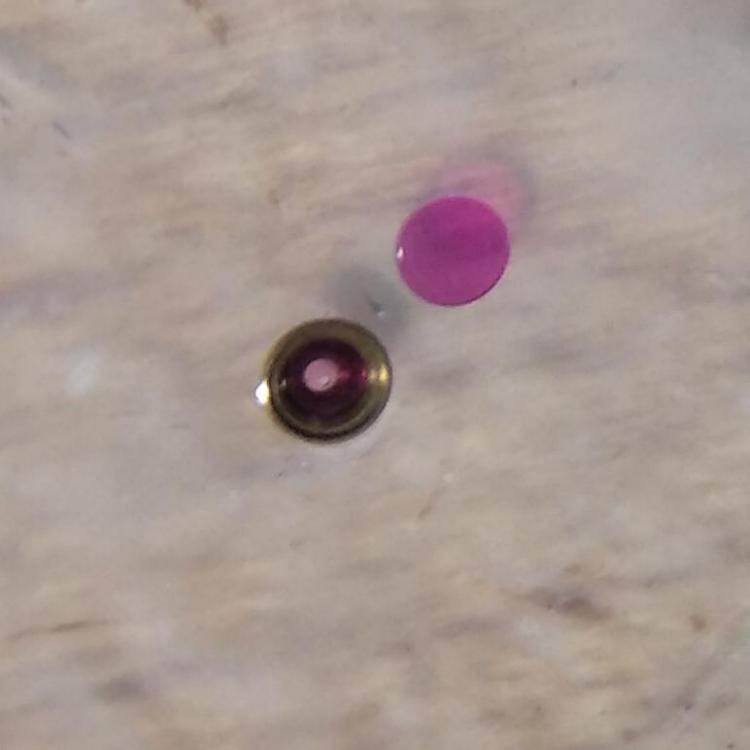

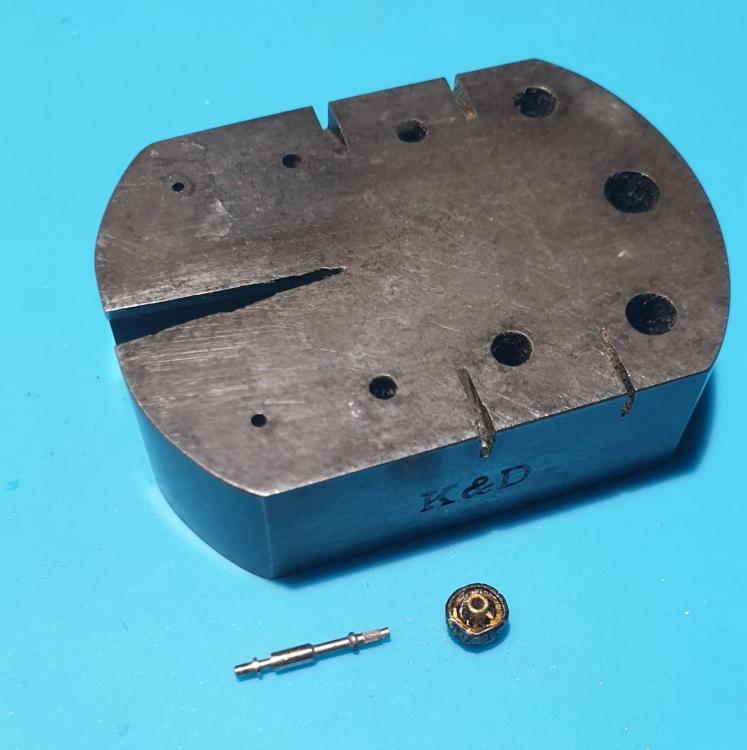

Hi, I thought I’d share with the group this project. When I un-boxed the watch I immediately realised I had a few job to do, the Crystal had yellowed over time and the crown wasn’t winding. On closer inspection I found that the ‘setting leaver spring’ was broken as was the mainspring and the whole movement was not particularly clean. I tackled the cleaning first by hand while getting some useful advice from the forum on where to find a new setting leaver, I ordered new parts while getting on with cleaning and inspecting all parts. Rebuild was a pleasure until I realised I had Installed new mainspring upside down ‘slap head moment’. Purchased some lume powder on eBay a first for me seems to be working fine. Now checking time for a couple of days then it’s getting packed up and posted to my son for his birthday. Hope he likes his 70 year old peace of military history1 point

-

Hi on the subject of tools as you are just starting out buy the best you can afford, Tweezers,Dumont not cheap but the best,, screwdrivers , French ones are very good, Good loupes in two/three sizes 3X 5x 10x. and a couple of decent movement holders Bergeon 4040 is a well known make and quality and a larger one for the pocket watches. When all is said and done tools are a personal choice. Cousins uk have a comprehensiv selection so for the moment just bthe basics and some cheap Russian movements to practice on and as your confidence and experience grows add to the tools and up grade to better ones, There is no definative answer to this question as peoples opinions on the subject differ greatly. cheers1 point

-

if you want to understand how to adjust the watch there's a book. Go to the site below do a search for this number 3706 which is easy way to do it and the book comes up. the reason why you want to go to the website below for the book is it doesn't seem to be in stock on Amazon anymore what you're looking for would be Watch Adjustment by H. Jendritzki (Author) the reason you're going to the site below is he's the publisher.. then what sort of wonderful stuff can you find in this book? The image for changing the pivot shape that came out of the book.. Lots and lots of interesting stuff on everything affecting timekeeping.. But a lot of it is totally irrelevant unless you're designing the watch. Basically you have what you have and its within specifications. other than adjusting the timing screws on the balance wheel not much else you can do other then if you adjust the screws incorrectly can probably damage something which is why you're supposed to use a special tool which I assume you don't have.. http://www.booksimonin.ch/1 point

-

Spot on! It only needs to be out a fraction and that's where those few seconds are gained or lost. Personally, 5 seconds between vertical and horizontal is good for me. Because it is really 2.5 seconds difference. So let's say you gain 2.5 seconds on vertical and lose 2.5 seconds on the horizontal reading, that's a total of 5 seconds difference. Or am I missing something @CaptCalvin? 2.5 seconds difference statically on a timegrapher, may be something less on the wrist. I concur about timing 7750's, which I have found amazing to regulate and adjust. The one I'm wearing gains 30 seconds a month... Perfect!1 point

-

Absolutely. That friction that you should feel is the clutch mechanism between the movement and the motion works. It slipping allows you to interfere to set the time.1 point

-

your only sort of correct? If you go to Eta website you can download current documents but the original question related to some specific numbers which I'm going to give you. So as soon as you find them I'd be curious to know where I could download these from. Although thinking about it I didn't check cousins they might have them but in a case I still be curious if you can find them. so this is what you're looking for L888.2 = ETA A31.L01 Acier and Tissot Powermatic 80.111 even though it says that it is a tissot the tech sheet is actually made by eta.. They also have the really useful manufacturing information sheet for the same watch.1 point

-

what we need is a service guideline by Rolex for the watch was manufactured. Not the current service guide because more likely they change their recommendations. So for instance we see above the recommending an HP oil could they have recommended D5 at one time? That would give you your organic components. Then one of the issues with servicing watches if you've ever been to a lecture where they explain high cost of servicing a Rolex watch is a lot of the components are meant to be replaced. Which is also why those components are available. It's one of my concerns as they extend the service life where lubrication really can't necessarily last for 10 years the assumption from the factory may be that you will just replace all the faulty components. So this means for us unless you want to be replacing stuff if you know it's a problem then maybe the next servicing should be five years from now.1 point

-

Hello, Here is an update on my project. I finally completed the cleaning an reassembly of the watch. It is now running, I have been wearing for a week and it's accurate enough. I do not own a timegrapher so I can't give you an accurate reading. The missing setting lever spring has been scavenged from a second AS 1187 watch I purchased of eBay. I also noticed some corrosion on the pallet fork. I did not replace it. I ordered a new crystal, but somehow never managed to install it. So I put back the old one. The watch was cleaned using zippo fluid. I have oiled it with Moebius 9010 and D5. Thank you all for your help and advices. VID_20200527_222540.m4v VID_20200525_180546.m4v1 point

-

Loose canon pinion or mis-meshed motion world would be my first guess. How does it feel when setting the time?1 point

-

That Schaublin brass ring is smart. You could make something like this without too much difficulty in brass. Back to the original question, I think simply that ring/stepped collets are going to be more accurate. But there are advantages to using an adjustable chuck - you may get deeper jaws and you can customise your own jaws. I made a set of smaller brass jaws for one of my Burnerds last week so that I could increase the maximum capacity. I also prefer brass jaws on some watch cases.1 point

-

In a watch with an overcoil isochronal error can be adjusted by adjusting the overcoil curve, bring the body of the curve closer to the staff to raise the rate at lower amplitude, away to reduce the rate at lower amplitude. This is only ever done with everything else perfect- escapement adjusted, regulator pins (if present) gapped correctly-- and also if the adjustment can't be made with those--. balance pivots perfect and hairspring otherwise perfectly flat and centered at the collet and from the stud. Most of the time a watch that is free sprung will have an overcoil. ETA does a heat treatment of the last part of the outer coil, the "dog leg" which is very clever and allows them to achieve timing that normally is reserved for overcoiled watches. You mention a 7750 and 3135 that timed superbly; these movements are particularly good, even though the 7750 has a flat hairspring, so no surprise. The free sprung versions of the 2892 are fairly new, and a 5 second difference between horizontal and vertical is really no big deal, should be COSC OK. But, if you really want to chase down those 5 seconds, there are some things you can do. Flattening the pivots is one, but you would want to go slowly and check the overall rate both at full wind and after 24 hours to be sure the effect isn't overly amplified at different amplitudes. When dealing with flat pivots you have to be extra extra careful that your balance jewels are absolutely impeccably clean; a microscopic piece of dust will almost inevitably find its way to the pivot end and create sort of a ball bearing effect and your amplitude will go up tremendously. Some makers have used modifed cap jewels to reduce the amplitude in horizontal; Vulcain used to use cap jewels which were conical, this would force the pivot against the side of the hole jewel. Some others use what's commonly called "Daniels" jewels (as they are described in his book), which are the opposite, a divot is created in the cap jewel slightly off center which has the same effect. One thing I have only heard of through knowing some real beasts of regulating work- that is, not in any book- is to ever so slightly through the hairspring out of true at the collet. Like half a hairspring thickness. Whether that is toward the collet or away is simply trial and error. It's not enough to make the hairspring visibly out of true in use, but it really does (sometimes) catch those last seconds between horizontal and vertical. Back to the 3135- I have a friend who is perhaps the most fastidious watchmaker I know. He had a 3135 that had a 2 second difference between the two flats. I know, I know... Anyway, he decided that must be rectified, if only for the experience. He tried tweeking the hairspring, recleaning, no good, finally he put a microflat on the pivot of the "fast" side and boom that did it. Didn't even really show up as an amplitude difference on the Witschi either.1 point

-

Hi Mike With these monocoque cases as you say the movement comes out the front. In most cases, The stem is in two parts (split stem) and requires pulling apart to leave the innermost part still in the watch. and the watch glass is removed using air pressure from a syringe/pump through the stem hole. But there are some where the bezel is removed either complete with the glass or the glass has to be removed with a tool. So its a question of close inspection to check out which method is used. The attached document will explain what I am talking about. cheers Omega_Omega The-monocoque-case-for-the-new-Seamaster.pdf1 point

-

Personally for me I find it interesting that were trying to reduce friction In a watch and hear you want to have friction.. Then for my own personal experience as a young student I made those pivots nice and round after all we do want to reduce friction don't wait? Then on the timing machine the early days of those paper tape machines the sound of the galloping horse could be heard all over the classroom.. It's nice when you've quiet timing machines today no one knows what you did right a wrong.. As it looks like were in agreement leave the pivots alone..1 point

-

This is one area where I think Rolex got the design wrong. If you google you will find how if not lubricated and serviced this pinion not only can rust but can wear away and has to be replaced. Cousins sell them but replacing this pinion without distorting the rotor weight is a challenge.1 point

-

That is a bit pricey and it looks like parts are missing. A complete new set will set you back about £1,3001 point

-

Casually it looks like everything is there except looking at the nice higher resolution picture a few things appear to be missing? I also noticed you're missing the manual would you like one? If you're looking at eBay did you notice is another seller with one for $700 right now? Except it's missing a few more of the things that are located up at the top left.Then a couple of other things scattered around are missing but most of its there.. Then I don't feel like looking at the manual to give you the official name but the things that are at the top left hold the little brass bushings that are in the little aluminum containers if there's any left.. They have a habit of jumping out and finding themselves in the path of the closing lid on the edge there and they get broken. The entire set is nice to have but how often do you use everything in that set?1 point

-

If you would like to avoid rust in the watch you have to avoid water in the watch.. This means If you are are doing a overhaul you want to change all of the gaskets and do a water resistance test. If you send the Rolex out for commercial servicing they always test the water resistance.. Then there's the other itsy-bitsy thing what is the recommended Time between servicing? Typically and you see this in watch collecting groups with automatic watches they have a potential of running a very long time until they stop. They will run away past life of the gaskets and the lubrication in the watch.. Which leads to an unfortunate consequence of a lot of times they basically disintegrate and very unhappy collectors that the watchmakers greedy wanting so much money to service their watch at least what's left of it.1 point

-

If we really had an absolutely poised balance wheel statically and then dynamically poise and there really was zero positional error.. Then free sprung so there's no Regulator pin issues the only problem it can be is the escapement.. The problem with escapement's is it artificially Is controlling the timekeeping.. This is why Marine chronometers use detent escapement's less influence of timekeeping. I think there only in contact with the balance for just a couple of degrees versus 50 for a lever escapement.. It's also why you see some other escapement's out there less influence. So amplitude with the escapement is an issue. you want to have equal amplitude in all positions. I've attached a picture it shows how the ends of the pivots are supposed to be flat almost. This increases the friction on the ends to hopefully bring it in line with the friction on the sides.1 point

-

Companies like ETA are interesting they have technical information for servicing the watch. But some of their watches they also had the manufacturing information sheet. I've attaching an image from the 2836-2 . A little newer than your watch but it give you an idea about specifications. Notice comes in four separate grades of quality important to remember when you're doing timing.. What I wanted you notice was let's compare your hideously bad timing and amplitudes to this? First off the watch companies almost never worry about what the amplitude is except at the end of 24 hours. Then your horrible +4 to -15 Timing Variation Really isn't that horrible if you look at this.. Unless of course this is a chronometer grade watch then you write totally sucks.1 point

-

Hi As I remember its no more than 5 deg from the upright anymore is not good.1 point

-

The Maprox chucks look nice but will probably be above my budget for the next few months - unless there's a bunch listed at once, I've emailed a supplier for a price and will keep checking ebay. Would a bezel chuck have an advantage over a step collet when in use? The Schaublin expanding arbor looks a great idea, and more economical than the usual forms of expanding arbor.. thank you for the suggestion, I'll probably be make one of those. For external gripping the 5c blank step collet blanks should probably squeeze 0.5mm, so 6 or 8 with rings stepped at 1mm intervals should keep the clamping movement within 0.33/0.25mm and keep the runout minimal while covering all the fractional millimeter sizes from say 25-65mm.. individual import 5c blanks are pretty cheap but the total cost is heading towards that of a bezel chuck.. luckily I could choose to make the size ranges needed one at a time until the set of 6 or 8 is complete - while I'd like to think I'll eventually be able to make enough money from working on watches to afford nicer tools, between a bit of regular repair and servicing I'm presently trying to focus on being able to complete difficult, interesting, or unusual tasks as a way of self validation and to be able to later use for publicity pictures.1 point

-

1 point

-

One of the things interesting about some PDFs found online is if somebody has them others may also. So the subscription firm has cleaned up the copy but it's available in its entirety someplace else like at the link below. Nice thing with this website is everything is free and it's available in a variety of formats. Just hasn't been cleaned up as nice as the other site but it's very very usable and it's 100% there Then while you're there why don't you do a search for other books or to get you started I have the second link should keep you busy for a few hours or days. Looks like they've added considerably to the collection since the last time I was here. https://archive.org/details/cihm_03260 https://archive.org/search.php?query=subject%3A"Clocks+and+watches"&page=31 point

-

Yeah, thanks, I just double checked and it is doing it at exactly 1 minute intervals, goes crazy for about 15-20s then backs off during the other 40s, so 4th (seconds) wheel would be a good bet since it is turning once a minute? I'll probably strip it again and take a look tomorrow evening, will report back what (if anything) I find.1 point

-

I check the center wheel, that is the biggest wheel on its arbour the seconds hand gets mounted, check its arbour, gear teeth, pinion, jewel, for wobble as it may rub, also check the center tube. Did you remove and check its end stone? its pivot. How near the bridge is center wheel turning, it can rub under the bridge.1 point