Leaderboard

Popular Content

Showing content with the highest reputation on 05/24/20 in Posts

-

No, all Generale Ressorts springs come pre-lubricated. However, note that when you service your first automatic movement, you will have to lubricate the inside rim of the barrel with some braking grease, but that's a different story. Other than that, just do it exactly like Mark explains and video illustrates in his watch repair lessons "C2.4.5 ASSEMBLE THE GOING BARREL".3 points

-

Picked up the Swiss case from eBay, brand new but from the sixties I believe. Unfortunately can’t source a 10 1/2 mechanical movement so fitted a Swiss Ronda quartz movement. The dial is a genuine 1963 uncirculated half penny which I machined down to .5 mm and then silvered. I made it for my wife's birthday who was born in 1963. She absolutely loves it2 points

-

If it were a construction site I'd be fired. An 8-hour day and one successful joint to show for it. I had to tweak the jig and lots of trial and error before I got my tools to behave. Having that behind me, the rest of the drawers will take far less time. So my 14 drawers will be box jointed just like this.1 point

-

When removing springs and parts with the likely hood of them disappearing into the ether work inside a large clear plastic bag, one big enough to cut the end off and work from both ends, That way should parts take off they are encapsulated in the bag for retrieval. Or alternativly use a piece of rodico to hold the part while removing or fitting, being tacky it will assist in holding the part. As to finding a new part try Cousins uk watch parts, wether you will be able to get one specific to the ricoh i think that will be difficult buy you may be able to purchase an assortment and get lucky. Cheers1 point

-

I have used for a while Elma 1:9 - Watch & Jewellery Concentrate - Water Based. It works well.1 point

-

1 point

-

Loosening the pallet cock screws did the trick! She's going along lovely now. Surprised as they weren't esp tight. It's all a learning curve, can't thank you enough for this. You've saved the second half of my hair being forcefully removed!1 point

-

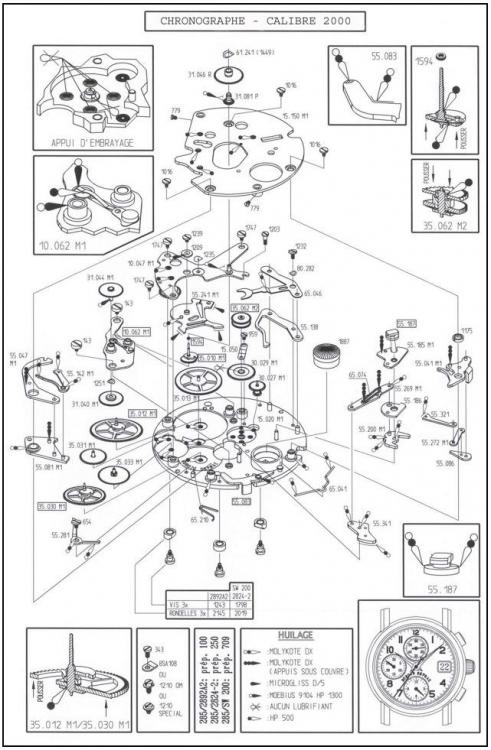

Indeed! A good braking grease would be Moebius 8217. I think many professionals would prefer Kluber P125 but it's silly expensive. You also have Moebius Glissalube B 8212 for aluminum barrels and Moebius Glissalube A 8213 for brass barrels. There are plenty of threads here on WRT discussing the topic of lubricating barrels for automatic movements. You would definitely not want to use Moebius 9501 or Molykote DX, as these would make the mainspring bridle slip way too soon.1 point

-

A check list of sort . Turn the barrel manually. Trun center wheel , just grab a spoke in tweezers and turn. If it didn,t run, Loosen the cock screw a turn, do the same with fork bridge or check the endshake on balance staff, fork arbour and escape arbour. If you take the fork out, balance should turn like ten complete oscillation at least.1 point

-

1 point

-

Interesting, as the general problem is with movements over oiled ,or not oiled at all. cheers for that.1 point

-

So, I replaced the cannon pinion with driving wheel which seems to be typical for many ETA movements. The ETA calibres that I have serviced like the 955.112, 2472, 2772, and the 2824-2 have this kind of cannon pinion. However, the new cannon pinion was sitting so tight on the driving wheel that it wouldn't slip when setting the time anticlockwise . That is, the seconds hand would move anticlockwise (the train being forced backwards) which could potentially damage the movement. The ETA cal. 2772 is non-hacking and has no date corrector so to "quick set" the date the hands must be turned back and forth between 9 and 12. So for this reason I felt that this was a real problem. I had lubricated the cannon pinion/driving wheel rather sparingly but in my mind sufficiently. Still I had the feeling that I just might have under oiled it (I know, it sounds strange ). So, I decided to take it out and oil it some more (Moebius HP-1300) just to see what effect it would have. Well, at first it didn't seem to help at all (watch wound down), but after having wound it a few turns I tried again and to my surprise the seconds hand kept ticking clockwise while I was turning the hands anticlockwise. So, problem solved! I guess the barrel must have some power to be able to resist the driving wheel. So, my conclusion is; make sure not to under oil the ETA cannon pinion with driving wheel. Just thought I'd share my experience.1 point

-

Good morning and congrats on your success. Do you have photos of the watch and movement and the lever in question? The Lever you seem to be describing is typically for when the watch is outside the case so you can install the hands.1 point

-

If the mainspring is genuinely new, then the lubrication from the factory will be fine, but if the mainspring is sold as NOS or new old stock, or similar, especially if the spring is not hermetically sealed in its packaging, then I would be tempted to clean and oil it anyway. I have a bunch of such mainsprings from various random ebay auctions of junk lots, and they vary from pristine to tarry (and in at least one batch, actually rusty). If sealed, and sold as new, then it should be good to go. Otherwise, I would inspect it carefully, and if in any doubt, clean and oil it as you would with a mianspring being serviced.1 point

-

taking it on and off would add a new variation of having to wait at least 30 seconds for the watch to stabilize otherwise that's going to introduce a variation. the timing machine has a start/stop button. Each time the button is pushed it cycles between stopping which is freezing the display then starting a timing cycle starts over from the very beginning no need to remove the watch. that's an interesting observation which implies we would have to compare it to something? when the Chinese 1000 machines came out one of their selling points was the screen there were very proud of their backlit screen. At that time there comparisons were with the witschi watch expert II as it does not have a backlit screen. if we use their comparison then you're right the Swiss machine does have a nicer microphone considerably more more analog processing circuitry enhanced features plus a minor price difference. okay perhaps it's not a minor price difference comparing a professional Swiss machine that is just under $3000 to a Chinese machine that's under $200 is an interesting comparison isn't it? then how does the Chinese timing machines compared to the Swiss? I've already done that experiment couple years ago. I compared the witschi watch expert 2 with the Chinese 1000 and 1900.. for the most part they are very very close so close that I have no problems recommending either Chinese machine.. although I like the display better on the 1900 machine.. being curious about the start and stop problem I decided to try an experiment.. The benefit of collecting timing machines.. The witschi watch expert two and the Chinese 1000 machine.. Basically the 1000 analog and programming for the most part is identical to the 1900 at least close enough. The watch that I was timing is a Hamilton 992B pocket watch. Mainly because it was convenient and it's a lot easier to have two microphones attached to a pocket watch.. basically the exact same set up I had before just a different watch. but there seems be a problem with the 1000 machine not correct technical term but it's not happy? The LED is flickering but not in nice rhythmic way. the machine is having a problem figuring out the beats per hour it's just taking a long time. Once it figured out the beats per hour the rate was fine but the amplitude took almost a minute and was wrong.. basically the machine is not getting a good clean signal? this is a problem more common with wristwatches in their case.. A lot of times of the case is big heavy cases sometimes the movement is plastic a variety of things can cause the signal not to get out.. This is where the recommendation is rotate the watch until the crown is pressing against the part of the microphone where the sensor is located.. This should give you the best signal.. repositioning the pocket watch and the microphone the LEDs looking better everything is looking nice now. The witschi microphone is now clip to the side of the watch case it is working just fine. So there appears to be some minor signal problem with the pocket watch that the 1000 as having issues with the witschi is not. This is where in our oscilloscope feature is really nice missing from both of these machines. now that both machines are simultaneously appearing to work let's look at the numbers and see the difference between them. The witschi indicates +2 seconds 226° 0.5 ms. The Chinese 1000 is +1 225° 0.5 ms so other than the initial microphone issue which I still think it's odd both machines are basically tracking very very close to each other. I do curiosity I thought I would do a test where did I turn the machine off turn it back on and it's roughly 25 seconds to reestablish all the numbers then looking at the witschi machine it looks like everything is real close the amplitude is off by 5°. Some of this I think is because on power up it defaults to an averaging where sample time of four seconds and that's going to change things a little bit. now for the final insanity part? Were not exactly comparing the same thing in that the witschi is averaging over 20 seconds updating every two seconds. Watching the display I noticing a amplitude variation anywhere between 229 up to 240 something this is a very slow variation over several minutes and it's not exactly rhythmic or consistent. as a guess this is what happens when you have several variations in issues seeing as how I know the watch hasn't been serviced in a while. So with the Chinese machine I push the stop button right the numbers down the rates are very very consistent the same as the witschi machine so I'm going to ignore the rate for this test only look at the amplitude because that's the only thing that's showing any variation. So what I push the stop button I write down the number wait a moment push the start button once stabilizes right that number down this is why made a reference to insanity. Of and as a reminder the 1000 machine is set default sample time before seconds and we have no idea how the machine actually averages it would definitely be more stable if I would adjusted 20 seconds but the person who originally posted this never change the setting so I'll keep it where the machine would be for him. So stopped 237° it starts up at 225° compared to the witschi at 237°. Then running the test again 225° starts up at 236 and the witschi's 237. so the basic conclusion of all of this is the Chinese machines are relatively stable the microphone isn't quite as nice as the witschi the amplifier and so forth aren't quite as nice but it still doesn't really impressive job. For the original person posting we need more information? Like if you stare at the timing machine do the numbers change at all over several minutes? Are you seeing a slow variation. Because if there is a variation and you stop and start the machine up you going to see that where you had a number and it's going to jump to the variation number. If the graphical display is not a nice smooth line like mine is you're going to see a variation in the rate. Then if you change the sampling time to 20 seconds it will help to smooth things out.1 point

-

1 point

-

Correct. It sounds like we have a fault/displaced keyless work blocking the stem and the only way in is via the front, so it means hands and dial off, then re asses the situation again whilst fitting the stem1 point

-

Thank you for your introduction and welcome to this friendly forum.1 point

-

Hello and welcome. I have a similar background and impressions to yourself.1 point

-

The spring is lubricated from the factory. Place the disc over the barrel (the right way up!) and push the spring down evenly using a flat object.1 point

-

1 point

-

1 point

-

1 point

-

I did that for about a year straight and developed 2 massive calluses. Made my fingers look like hell, so I quit. Now I just let them run down naturally and wind them when I wear them.1 point

-

1 point

-

1 point