Leaderboard

Popular Content

Showing content with the highest reputation on 04/25/20 in all areas

-

When I was in college, I decided I wanted a watch, which, let's be fair, isn't unusual save that my generation is the first where we never really did watches and just used our phones. I have a thing about batteries though; I hate them. Nothing disappoints like a dead battery, especially one that's not easy to find/replace. PAYING someone to replace a battery was utter insanity. I didn't want a battery powered watch, and I remembered my dad once showed me an old watch on a shelf in his closet that was mechanical, and worked just by moving around. I got online and tried to figure out what such a thing would be called, and whether or not they still existed. I ultimately found my way to eBay, and found a watch that went a step further requiring the wearer to physically wind it! "Crazy!" thought 22 year old me. It looked old, was some brand I'd never heard of nor knew how to pronounce, but had a really cool patina. Most importantly it was cheap at something like $35 (if my memory is correct).It eventually made its way to me from the Ukraine (again, if memory serves, but definitely somewhere formerly Soviet), I had to make a watch band for it, and it sorta worked for a few weeks! I figured for $35, I couldn't really have high expectations, but my curiosity had been piqued, and I decided I would have it serviced. I got lucky and found a WOSTEP certified watchmaker in my town, and he was kind enough to let me bring the watch by. He even gave me a tour of the shop. I eventually picked up the newly functional watch, but the watchmaker knew quite a bit more than I expected. It turns out, the watch was a WWII German officer's watch, the D# had been scratched off the back, the crystal had popped out and been battlefield repaired with a knife by tapping little tangs around the crystal to hold it in place. Given where it came from, it was likely either picked up off a dead soldier or traded for ??? in a POW camp on the eastern front and kept by some former Soviet denizen as a souvenir (though not without scratching the Nazi stink off the case back). I contacted Cyma to ask if they had any information that could trace me back to the middle from the other direction, and all records had been destroyed a long time ago, but they could confirm that they made watches for the German government during WWII.The Nazi origins were dark, but the connection to history on my wrist was compelling. It was a relic out of time that was a part of, and contributed to one of humanity's darkest hours, and I was using it to get to class on time! I was hooked.I ultimately decided I had to stop wearing it save for very special occasions though. The watchmaker did his job well, and the work he did was very sympathetic to the history of the watch. He left the knife marks around the crystal in tact, but that meant it had zero water resistance of any sort. Even getting caught in the rain risked getting water in the case. So... I had to buy another watch! I was hooked, but all these affordable eBay watches kept needing work to run well or for long... I went back to the watchmaker, and gave him a Komandierskie that caused him to establish a "no Russian watches" policy... I seem to recall he said he had had to buy two donor watches to get enough parts to make it work right. I told him I was interested in watchmaking, and he effectively talked me out of it saying he had "millions" in tools and equipment in his shop. That may have been true, but who knows (the shop was a room in his house). Either way, it caused me to put that interest on a mental shelf and pursue other things. I've always had a thing for machines and how things worked. Since graduating from college, I got really into cars (started with air cooled VWs and ventured out into just about anything with an engine). I taught myself luthiery at 16, and have restored a number of old woodworking tools and machines over the years. I taught myself software engineering (the day job), and occasionally work with leather. With my car hobby, I was able to have all manner of fun while making a little money in the process. My goal is to approximate the same with watches. Buy what I like, fix it up, have my fun, sell it for a profit, and get another fun watch to tinker with! First though, I need to sell off some tools from my car hobby. Time to convert!2 points

-

You're forgetting two very basic principles of physics here. Friction and Mass. No matter how polished your jewels and pivots are, or how slippery your lubricants are, there will always be a minute amount of friction. Specifically where the teeth of the gear train mesh with each other along with the barrel, mainspring and arbor. Add to that the inherent friction of the pinion and the hour and minute wheels and you have quite a bit of friction to overcome. All watches have a minimum amount of power required to drive the works at the correct amplitude. When the spring winds down, friction takes over. Finally is the mass of everything in the gear train but most of all the mass of the balance wheel. That alone is enough to bog the works down at very low power. An engineer who knows the mathematics involved should be able to calculate all of this information and give you the optimal power needed to properly drive an average watch movement at the correct amplitude. Nearly forgot, the balance spring itself also becomes a source of resistance at very low power. It can cause a tiny bit of feedback resistance that has to be overcome.2 points

-

I can see that watch mechanism perfectly. It is pin sharp super bright, and fills the frame, furthermore I can work on things easily and see specks of dust and other debris that I might otherwise have missed. This camera , however has problems even when I have it in manual focus mode. Currently it adds too much additional magnification, and struggles to focus correctly. This about as good as it can manage currently. I have a couple of other cameras which may be more suited to the task. Time for a bit more experimentation.2 points

-

Absolutely spot on mate, yes they are slightly tapered on this one, I’ll be making some more next week. As for the length, they are running in a brass plate, so no cap jewels to worry about but I’d like to get the length so the pivot just shows proud of the actual hole.1 point

-

I got a much simpler answer: index gap. Depending on the width of this gap, the lower the amplitude, the more time the hairspring spends floating between the gap, which = slower rate.1 point

-

It looks to me like your pivot is tapered, that's a no go in the world of watches. The pivots must be perfectly straight otherwise they can drive themselves in and lock. I'm only going by your photos, I'm not able to measure your pivot vs the jewel hole clearance. Also, the length plays a major role. If it's too long it puts pressure on the cap jewel, if it's too short it rides on the shoulder. All of that has already been mentioned above by others though.1 point

-

1 point

-

1 point

-

It doesn't come out very often but I'm wearing my Burke today. I bought this in Plymouth back in 1985/6 when they first came out. All original and still keeps almost perfect time, loses about 2 seconds a month. I just wish I still had the box, but that probably got dumped by my parents when they moved house and I was away in the navy.1 point

-

Kind of... I was trying to un-clash the "logic and the physics"1 point

-

Friction means loss of energy, isn't it that simple or am I putting it too simple?1 point

-

I think I'm right in saying that if you could eliminate all energy loss from a balance wheel then for any given temperature its rate would remain constant regardless of its amplitude and it would oscillate with a perfect conversion between potential energy, which is at a maximum at the point where its direction reverses and for an instant the balance is stationary (kinetic energy zero) and the hair spring has maximum deformation from its rest state, and kinetic energy which is at a maximum (highest rotational velocity) at the instant the balance passes through the rest state point of the hair spring (zero potential energy). However, even before we introduce the rest of the escapement into the system there energy losses, mainly through friction, but also through hysteresis in the h/s, both processes which ultimately cause energy to escape from the system as heat. So you have to top the system up with energy via the escapement in order to keep it going, a process that introduces even more friction and therefore even more energy losses. The escapement transfers energy into the balance wheel via the interaction between the pallet fork and the impulse pin. This process only happens for the duration of the interaction between these two parts (i.e. the lift angle of the escapement) and during this part of the balance oscillation the balance wheel is accelerated by the input of energy as it rotates through the lift angle. The lift angle is a fixed parameter and does not change in relation to the changes in amplitude. However, during the engagement between the pallet fork and the impulse pin, frictional losses in the system are at their highest. This effectively means that the overall rate of the balance system is made up of two components. The period of acceleration as the wheel rotates through the lift angle (rl), and the period of swing through which there is no outside interference (r). r can be considered a constant determined by the physical parameters of the balance and h/s. However, rl will vary because as the m/s winds down and provides less torque, less energy will be delivered into the balance through the lift angle and therefore the balance will accelerate less. rl at full wind will be higher than rl at half wind. Also the influence of rl over the overall rate will increase as the amplitude reduces. When the amplitude is at say 310 degrees at full wind in an escapement with a lift angle of 52 degrees, it effectively operates as a free oscillator (without outside interference) for 83.23% of its swing, its rate will be r for 83.23% of its oscillation. During the remaining 16.77% of the oscillation, as it rotates through the lift angle its rate will be rl, so its overall rate will be (83.23%r+16.77rl). The escapement delivers enough energy into the system for the overall rate to remain constant. If the balance amplitude drops to 180 degrees at half wind (the lift angle doesn't change) then it effectively operates as a free oscillator for only 71.11% of its swing, so r only operates for 71.11% of the time which means that rl now influences 28.89% of the overall rate, so the overall rate is (71.11%r+28.89&rl). But rl is now slower than it was at full wind so it's impact on the overall rate is further amplified, and the overall rate will drop even further. If the balance amplitude drops as low as 52 degrees at a quarter wind though then the overall rate will be 100%rl, and rl will be further reduced by the fact that at a quarter wind the m/s delivers even less energy. So the watch slows even further. The ideal is to keep the torque from the m/s as constant as possible over as much of it's wind as possible so that the rate remains constant. However, once you get to the threshold below which the m/s torque starts to drop appreciably the rate will start to drop. If you've read this far then congratulations. If you've managed to follow it as well then I'm impressed This is just me thinking the system variables through though and coming up with a mechanism that seems to work. I know that it's not perfect as I know of scenarios in which very low amplitudes can result in an increased rate. In the true spirit of "The Scientific Method" please anyone, shoot my mechanism down.1 point

-

I think I see what you're getting at, logically with less power the balance should swing less distance and therefore have a faster beat rate. However, the balance doesn't swing faster at a shorter swing with low power, it swings slower. Again, the power is reduced. If you adjust the amplitude by moving the regulator, you are shortening the effective length of the balance spring which in turn speeds up the balance. With reduced power, the effective length of the spring hasn't changed any, you just aren't pushing the balance hard enough to give it a full swing. It can't logically move faster with less power, it just won't move as far. The balance spring exerts a return force on the balance at the end of its swing. It's proportional to the amount of power applied to it by the escapement. I guess this is where logic and physics clash, lol.1 point

-

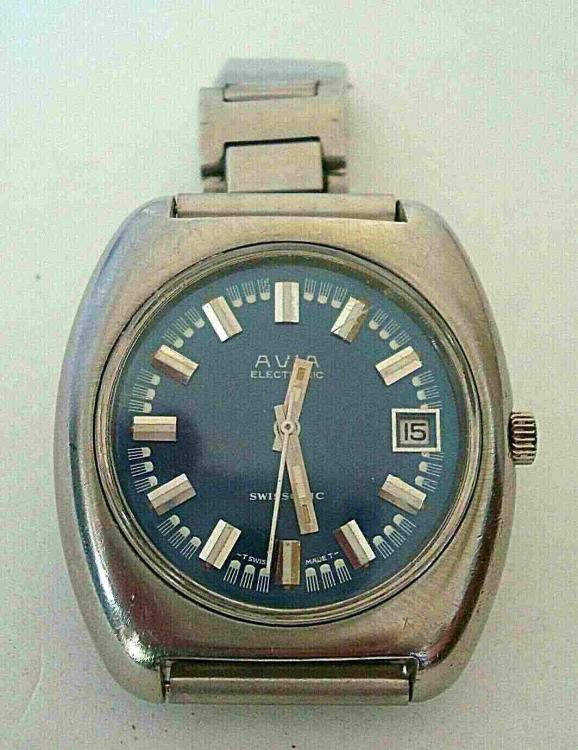

Hi Step one is to verify the received movement works ok , put a battery in and fit the second hand and run it for a few hours, Then fit the dial and hands from the old watch and again leave to run a while, (cover movement) and if all goes well fit into the case But be careful of the fact that the coil is fragile and will not stand abuse of any kind.1 point

-

Hi Probably ebay will still remain the best supplier look under the heading "spares or repair" there are usually a few cheap casualties to be picked up, Tools can also be picked up, its just a question of keep on looking. Aliexpress is another source of tools , Chinese copies of mainline tools but as other members state they are usually adequate for the job. in fact I have two myself and have found them to be ok. If just starting out look for the Russian makes on ebay Raketa or Wostock (Vostock) usually picked up for a pound or two so no great loss in case of a mishap, good luck cheers.1 point

-

As I understand it watches do not work that way. A watch needs a certain amount of energy to run & the energy release is regulated by the escape. Its only when the mainspring is nearly fully un-wound does the mainspring effect the running of the watch. With automatics this of cause does not apply.1 point

-

Hi Watchie, nothing wrong with that reasoning at all , and I for one would agree with it. As the power diminishes as you state the arc of vibration will also diminish proportionatly, maintaining the rate of the watch due to the shorter arc speeding up the watch. I am sure others will have an opinion as that is what the site is for.1 point

-

What tools do you have? If import charges to your country don,t exceed items value, Mumbay special is a good start and buying two of the same caliber smart. There are some pieces there in like new condition with original dial plate, which at end can join your collection.1 point

-

As the watch ran until the -ve battery connection came away and you have now managed to remove the circuit, surely the easiest and cheapest option would have been to solder the old connector (or a fabricated replacement) back to the stud on the underside of the circuit board? Nothing to lose......... However as you have managed to obtain a replacement movement the easiest option is just to fit the circuit from that to the original movement or am I missing something here?1 point

-

Replace the movement... That's what I did on mine. I bought a working 218D movement on eBay for about $50. Relatively simple swap, though the 214 is a bit more rare and desirable, and expensive. You can find complete watches too and just pull the movement. It's a place to start for sure.1 point

-

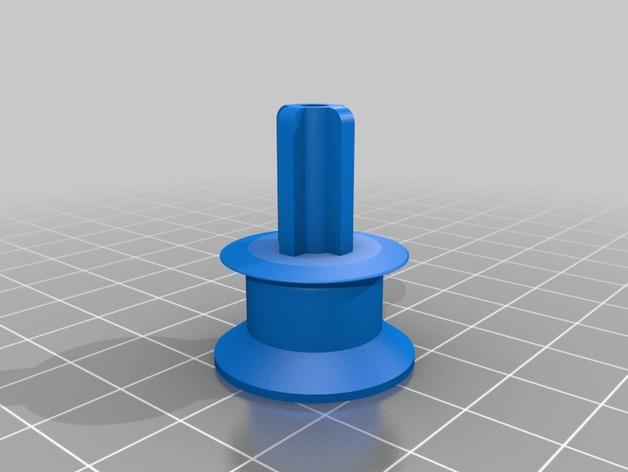

A slight hiatus in the microscope building today, due to a minor breakage in the kitchen, which necessitated a 3D printer part. Braun insist that if you break this flimsy little plastic linkage... You need to buy this... .. which naturally costs almost as much as simply replacing the whole hand blender. However a user on Thingiverse has done the work for me, so instead I printed this. Time will tell if it is as robust as the original, but since it cost about 20 pence worth of plastic I can print about 150 of them before I come any where near the cost of the Braun approved alternative. Back to printing microscope bits tomorrow I hope.1 point

-

I read your intro. My sister lives in Sac. Thanks for the welcome! My universe also thinks I'm an oddball. I like machines of all sorts, and have this odd notion that adding computers is cheating. By day, I work with computers and electronics. My best friend has a horological connection in that he built a new experimental resonator for the atomic clock at NIST that's 10,000x more accurate than the existing one. He thinks my tube amplifiers and pre-war woodworking tools are weird. I did get him into a car to wrench on though! I think you're onto something with the attraction to artisans and craftsman... A moment of personal revelation here (thanks for the inspiration!): the reason I have no real love for silicon probably has a lot to do the lack of artisanal craftsmanship. The engineers are mostly divorced from the final product. The devices are made by machines, and half-assedly slapped together by unskilled labor defined solely by price point... Certainly there are exceptions (and it's those exceptions that have me writing code today), but there's just no "soul" in a television set... There's a clear tie to the automotive world here too in terms of differentiating desirable classics from modern appliances, but I don't think this is the right crowd.1 point

-

Great story, just fascinating! i joined this week and unlike all the cool people I already met, I have no cool stories nor experience. i just like to take things apart, and most of the time i can get them back together. Looking for a hobby that pulls me away from modern technology for a bit. I assume that you and I are relatively close in age and this is a skill that is atypical for the generation - at least in my universe of people - making it all the more special. I have an admiration for artisans, craftsmen, and the like. Mostly because as I stated in an earlier I have the finesse and elegance of a hippo. Anyway, welcome, good luck, and I am looking forward to more stories1 point

-

Please post in English only. Now, those that took the time to translate the above: What has been written is false. It is insulting to only think that Italians are "exhausted". Far from that, everyone is doing is his part, and nobody is left behind. Food and medicines are delivered by organized volunteers to the elder or quarantined. Families and individuals in need are already receiving food packs, and additional welfare money will be distributed within a week. It is just logical that non essential business are closed. However, beside food shop of any type and size, non-prescription medical, also hardware stores, electrical, plumbing, house items shops, tobacconist (they do a lot of additional services in Italy) and few more are open. And one can normally order online, post and couriers are doing a great job. I could go on with more details, if you are curious just ask. This battle is being won already. But whining doesn't help.1 point

.thumb.png.ff62a6dcd7f84c84d5c69425d1053e8f.png)