Leaderboard

Popular Content

Showing content with the highest reputation on 02/21/20 in all areas

-

2 points

-

Has anyone here worked on an ultrasonic such as this one? L&R Maxomatic.. I was told it will smoke when powered up. After opening it up I pulled the tube and right away I see it failed because the top cap fell off! Also I noticed debris inside which of course is not a good sign either. So what to do? I found a used tube for BIN at $20.00 and best guess is the machine is maybe worth $40.00 Is it something I should get into just for the fun of it? Heck yeah, what is the worst I can be other than burning down the house1 point

-

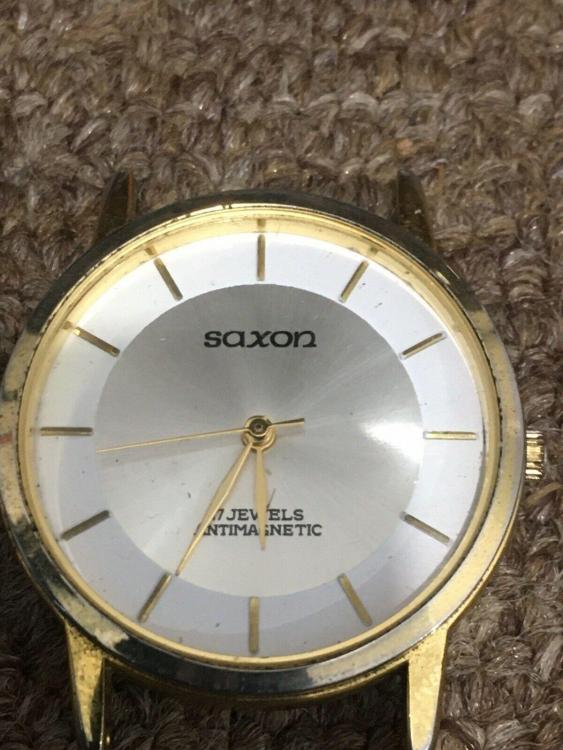

I've received a 2824-2 watch with the complain that it stops. Just looking at it in jeweler's shop I noticed: date misaligned date changes at the wrong time caseback opening scratches doesn't hack weight hardly turns Then while disassembly one casing screw missing both dial feet snapped flush and consequent double side tape lots of oil in the oddest places, like under barrel bridge missing stop lever barrel bridge screws lose, likely that's why the ratchet wheel left marks on it and it would not auto wind. driver scratches on the barrel One could think that was the result of an improvised repairer or owner. Not so, as it happens it was given to this small town shop which proudly has a sign outside: "master watchmaker". After a long time and much money the desperate owner wanted to try someone else to repair it. I hope to be able to.1 point

-

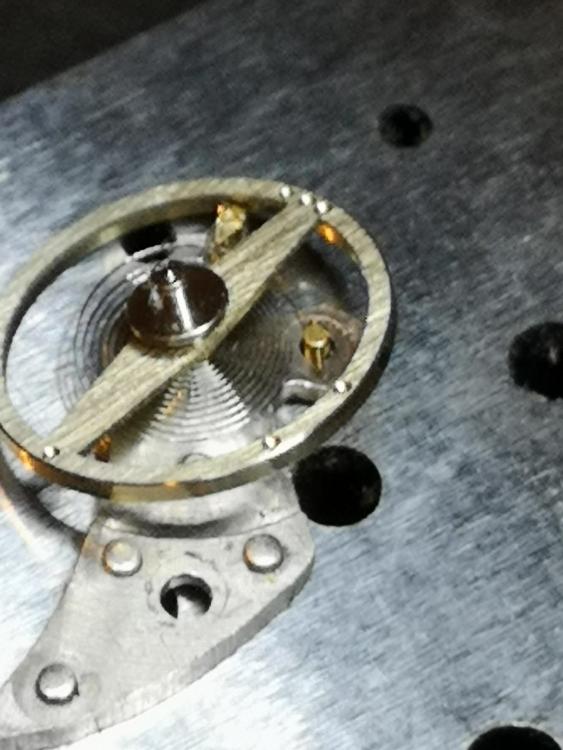

Hey sorry if this is the wrong section. But i have been doing watch tinkering now for approx 8 months and i have finally rebuilt a balance , or is hat restrung? Anyway im always getting great advice of you guys when i am stuck so thought i would show a success. See pics cheers everyone sorry pics are not great but its a mobile phone pic1 point

-

Hi probably the safety valve to protect the max pressure the glass will take, whenits reachin critical the valve will blow.1 point

-

Hi I would not take it as read them being serviced, Take a good look at the movements and check for worn pivots etc and the presence of oil on the pivots. Some peoples idea of service is to slop on oil and away you go. Not trying to negative here but cautious. Just take you time and enjoy the clocks, I have around 30 of them all types from mantle clocks to 400 day anniversary clocks and love all of them enjoy. Cheers1 point

-

Hi As you will have realised each sub dial has its own coil stator and stepper motor each driven from the circuit block. If all other functions operate ok and the coil resistace of the particular faulty sub dial is ok it could be dirt jamming the stepper, if thats ok then we are looking at the circuit block. As jdm remarked its is sometimes more prudent to change the module. But without dismantling and testing the components including the output of the block hard to be specific.1 point

-

It won't be a mistake unless you'll want to take machine shop jobs , I had considered it as well, it has the best accessories and documentation, and reasonable price. In the end I choose something else (Unimat 3 clone) but I think our learning path will be similar. There is always room for a watchmaker lathe and the Sherline will be good to make tooling for it.1 point

-

Of course they don't have to be 100% original.There is a whole industry based on modifying them! What is most important is that you like it.1 point

-

I finally got round to fitting a “proper” balance and it works great! I was a little worried at first as the timegrapher was showing snow, but managed to regulate it to at one point 2s/d and BE of 0.1 - so well happy [emoji2] The moral of the story if don’t be tight and get cheaper OEM parts.... [emoji2357] Thanks for all your input[emoji106] Regards Carl Sent from my iPhone using Tapatalk1 point

-

1 point

-

We need the I D of the movement. If you don't know it, take photos of the complete movement back plate, remove hands and dial, a good clear photo of the keyless work will help us.1 point

-

I took the forum advice and inserted the lever from the dial side and everything worked perfectly. Many thanks to all!1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

The simplest repair can often make us feel like heroes! Hopefully this encourages you to continue this journey.1 point

-

It's funny because a CNC is fairly simple in this day and age, but... complicated too, when you're seeking microns. My machine is shop built. The mechanical components are swiss, high precision stuff, the X and Y axis have high precision antibacklash screws, the Z slightly less but still high, spindle is a Gepy for 8mm collets, that spindle registers 0 runout with an Interapid 0.002mm test indicator. This is all stuff obtained second hand. The machine uses servos (no question better than steppers) with a control built by a guy in Hungary. The control software is Mach3. I've made a number of complete prototype watches with it, the precision is amazing. But the software, running on Windows, bugs sometimes. It's an open machine so no oil flood (reduced cutter life). No tool changer, so you have to babysit. It's in essence a "hobby" machine, but where it counts it's a serious machine. The cut time for that jumper was about 10 minutes for 2x pieces. I know the hole locations are correct. The jumper point is correct within 0.005mm and I used a dull end mill. The measuring, drawing, and handwork later (harden, temper, bevel, grsin, polish the functional bit, thin the spring) was much more work. Just making the steady pins is a task (short, polished ends). If I had done the dimensioned sketch, laid out the holes and point with calipers, it would have been an hour more. So the machine made me 100 bucks on this job (and a 0/6 sawblade or two). Maybe another half hour because the point position was perfect mostly because the hammer wasn't mic-macked and I zeroed it and found the "null" position of the minute counter wheel and it was good. When I say "a hundred bucks more" I mean in saved time. This is a 6-10k watch, great client, I charged 150 for the jumper. Honestly, would have done it on the house for this great watch, probably why I'm still not rolling in it! The "saved time" was probably wasted fluffing up my collar because it worked out so well!1 point

-

1 point

-

Today I am enjoying this Seiko 5 (7009 movement). I bought it for almost nothing and it really didn't need much. The crystal was in bad shape and I replaced it with a magnifier (like that look and this watch does not have to be 100% original). The lume on the hour marks is gone, hands still glow fine. This thing moves right along and keeps excellent time.1 point

-

Another 'job lot' here, coming soon. Bought primarily for the Timex M84 Electric... Never seen one with so little written on the stainless back, or with a knurled battery hatch before...? The Avia might be interesting as well........1 point

-

1 point

-

Or they wanted to sound a bit like Biel/Bienne? Fact is, there in Hong Kong they also shown respect to Seiko.1 point

-

1 point

-

As the trimmer on this is a tiny low value variable capacitance it is probable that some contaminant has bridged between the two capacitor plates, at an edge, and dramatically changed the value of the trimmer, preventing the quartz oscillator from running. Turning the trimmer would break any bridging at the edge. 'All' you need now is to reset the trimmer for accurate time keeping , fortunately something I can now do on these, since I realised that if I set the gate time on my Seiko QT-99 Quartztester to 120seconds it reads these and allows you to adjust them accurately. My M58 jump minute watch now runs to +0.5 secs/day1 point

-

1 point