Leaderboard

Popular Content

Showing content with the highest reputation on 02/12/20 in Posts

-

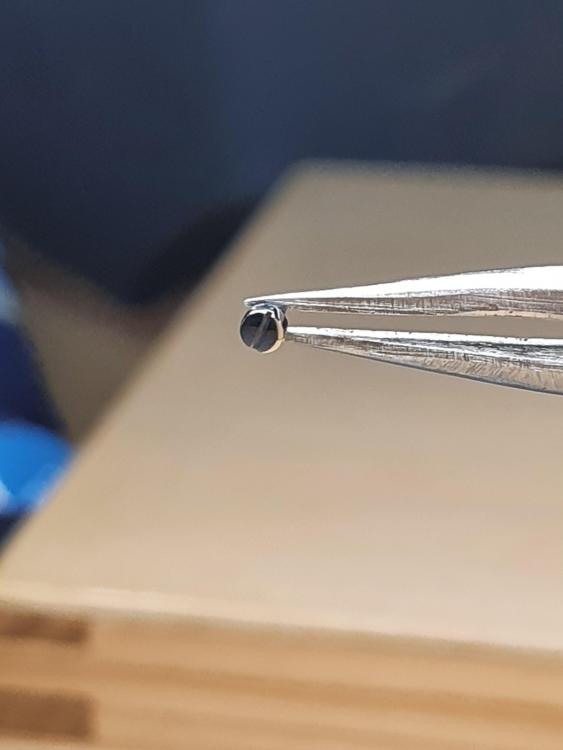

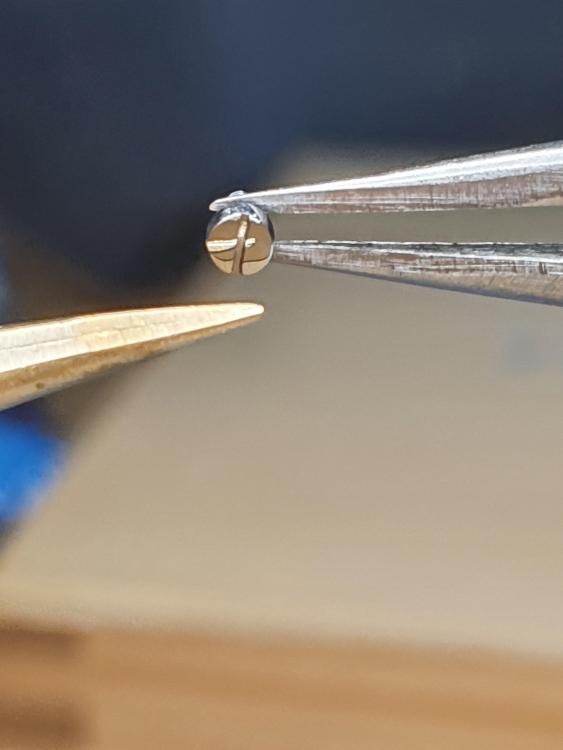

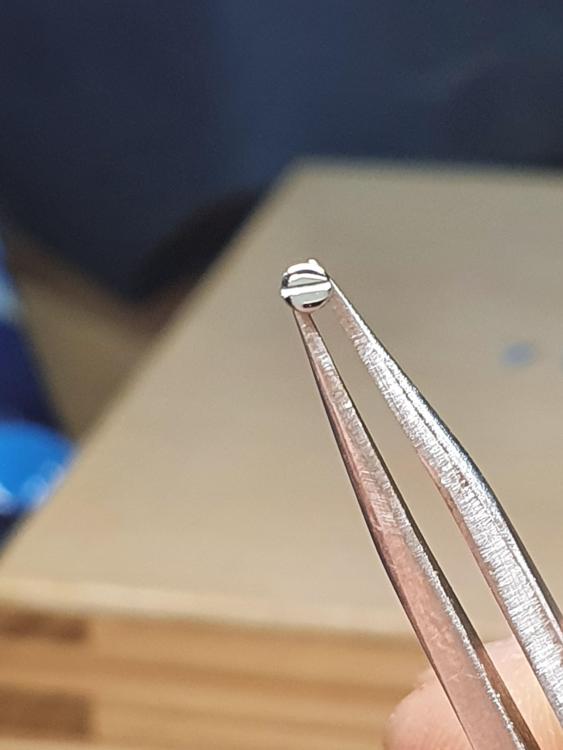

I brought a clone Unitas 6497 for my watch repair course. Whilst learning the autonomy of this movement? I really hated those blue laquer screws. So I decided to file off the laquer with a diamond filer. I purchased loads of diamond paste grit, which came in a syringe. Peg wood and pin vice was all that was needed. God knows how many hours and days it took me? But here's the result. The pic was before polishing.2 points

-

I have been asked to look this beauty. It is heavy and is real quality and the name on the dial is (I think) is William Goffe. On initial inspection it looks like the cord /gut has broken from one of the barrels. Also to open the front is via a key which is missing, I will investigate in a few weeks as I am away on a short break. I must say I can't wait to delve.2 points

-

2 points

-

2 points

-

I'm curious too, but I imagine it took some time! Those look great. A lathe sure makes polishing rounded head screws easy; if you have a micromotor (hand motor, i.e. Dremel or similar) you can chuck the screws there and charge wood with your diamond or whatever abrasive to speed things up. Black polish is a flat polish, as flat possible. It is pretty much universally done (even in production) using metal laps, soft metal like tin or zinc, and a tripod tool with two adjustable feet, the third being the part/screw, or in production the screws are fixed to a plate many at a time and polished flat all at once.2 points

-

New kind of felsa bidynator?you wind the watch..it powers the rotor..? 20200211_141700.mp42 points

-

1 point

-

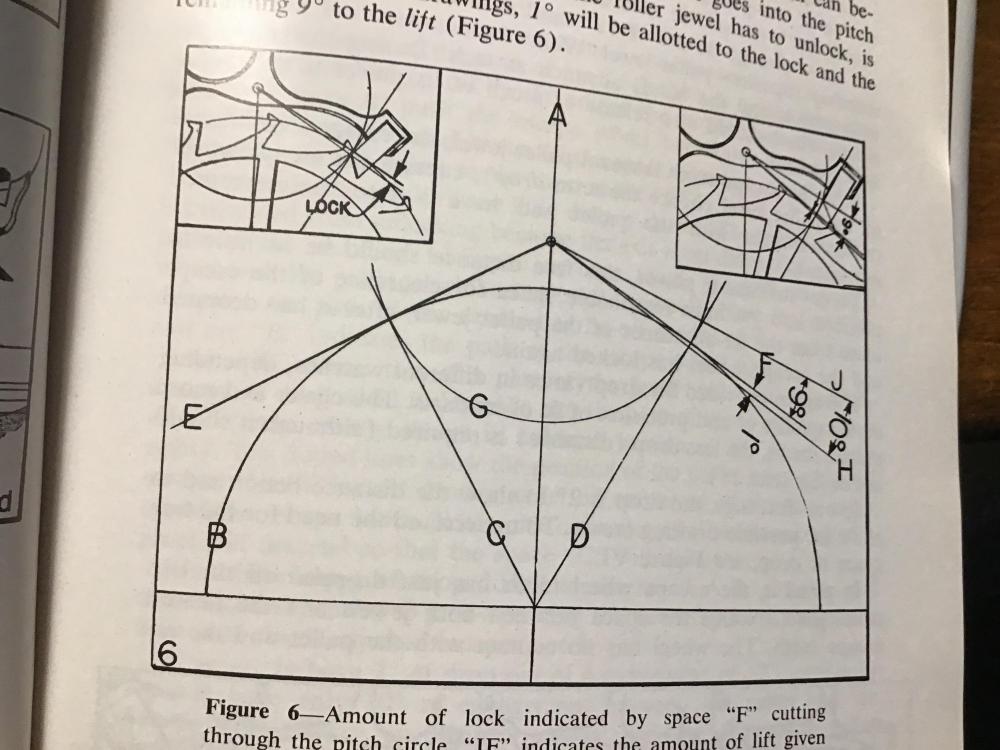

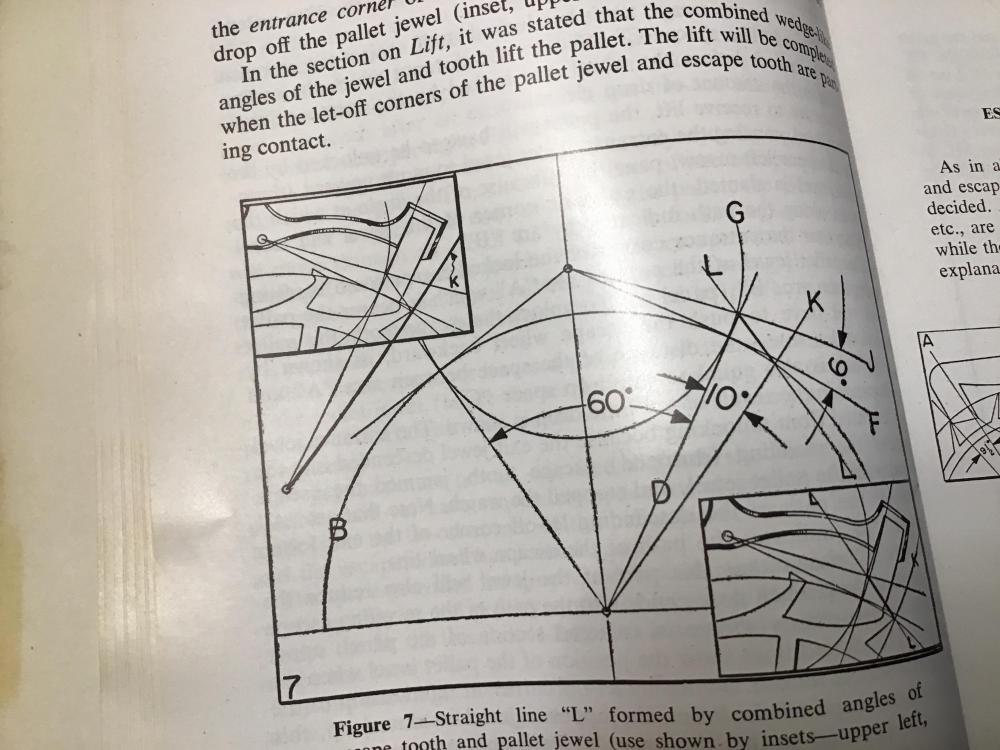

The weishi timegraphers are great but not infallible. Don't assume that the readings are definitely correct until you've established all other factors with the running of the watch are. Disregarding the 9.9ms reading currently. (This essentially is as relevant as it reading out of limits). There's a notable rise and drop in b.e. (where you see the lines separate). Very first thing I'd suggest is remove the balance and check that the roller jewel is centred and secure, I've seen similar results with a loose roller jewel. Still tight enough to fit but with a bit of side to side play. If that is shellac ed securely. Check the lock and drop of the pallet fork jewels and their security of fit, Check the swing between guard pins is even. (I've seen so many old pocket watches with bent guard pins it's almost become an expected sight). Check that the roller jewel is centering after a gentle rotation in both directions, check the hairspring is securely pinned and it's flat and reasonably concentric. Double check this with the balance installed viewed dial up. Dial down and pendant up etc. If your phone has a slow motion video facility. (Most do these days). Take a short clip of the balance and visually verify that it is oscillating roughly at the amplitude shown. Again don't assume it is 216 degrees, I've seen watches barely pushing 160 where the timegrapher reports a much higher amplitude. I know a chunk of this is repeated from the above good pointers but assuming you've checked all that and jewels are secured, endshake and side shake are OK, motion is acceptable and hs are OK then this should see a consistent line gap and a b.e. of 3.0 ish ms at the most. Also be sure to check the timegrapher reading with the watch on other positions especially the love you checked the roller jewel visually in, DD? I'd assume. See if there's a noticeable difference.1 point

-

No, I did the course on complications and restoration, they haven't offered it for some time. Down the rabbit hole I've made a few for other people though... hahaha1 point

-

1 point

-

1 point

-

I know these dont actually qualify to be classed as black polish, as my edges are not at true 90 degree, But at an angle they do appear black, this was what I actually meant. That's because of the mirror finish I have given it. To get a true black polish, you need a true 90 degree on edges of the screw head and a mirror finish. I did all by hand, no machines, lathe etc. A member of my family is a watchmaker graduated from " W.O.S.T.E.P he challenge me to it. And showed him without all the fancy tools what can be achieved?1 point

-

1 point

-

if it is a two piece stem , i usually tilt the movement up and slowly turn the stem.( which is split) when the movement is at its highest tilt the split is perpendicular to the case and the movement can be removed..1 point

-

1 point

-

Great timings, even after 24 hours! Great job there. I've found the 2824-2 to be one of those movements you can adjust close to COSC standards for a relatively small amount of money for what it is. Also they're a real joy to work on. I bet you found that too? I would love to see it cased up when you do1 point

-

Hi It would seem so although one can transpose the names from another service sheet as I would suspect what is an escapewheel in russian is the same in German or Swiss. It is a pity that they dont put the listing in Russian but I suppose translation was a problem back then.1 point

-

1 point

-

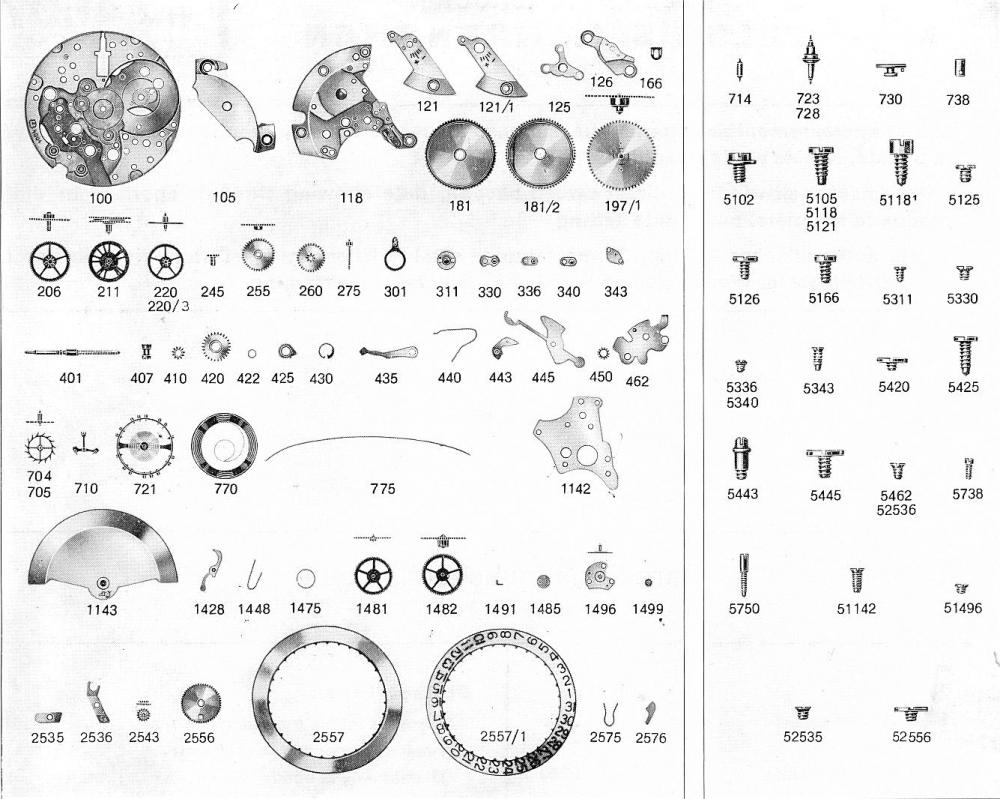

@yankeedog, my BFG 158 31/7 did this to me after cleaning, There is a small click that I had forgotten to engage with its spring. it allowed the rotor to spin like a propeller, lol. In the Felsa it's call the "Stop Click" and the "Stop Click spring" Part numbers 1428 and 1448 respectively. Unfortunately, Jules Borel is currently out of stock, in case they're broken or missing.1 point

-

If this is one of the watches where you press on the crystal, you should be able to see a cut-out around the crown area which allows the crown/stem assembly to move downwards. But since it 'specifically' mentions open thru crystal then that is exactly what you need to do! Anilv1 point

-

This is a typical benrus case they been making these since the 40s. You have to remove the crystal using a brass jaw type crystal remover. Once it’s out you have to separate the split stem. I could explain how to do it but a video is much easier and there are plenty out there. Just do a search on the net “ how to remove a split stem” and there is a tutorial on Esslinger.com on how to use the crystal remover. https://blog.esslinger.com/how-to-replace-a-watch-crystal/?_ga=2.79089757.839292711.1581400550-1065094695.1581400550 what i will suggest is to use a wire cutting plier and go from the outside of the case not between the movement and the case to avoid damage. Do not pry just allow the tapered shanks of the pliers to pull it as you close down. You may need to do pull it a bit yourself just make sure you pull straight don’t wiggle or pry. It may take some force so don’t be shy with it. do not push on the crystal and remove crystal before separating the stem1 point

-

I have a link to someone supposedly servicing a 1520 but it's missing the hack? Then I'm attaching PDFs for the 1520 and the base caliber 1530. Also attached is a service manual ancients one which on PDF page 7 shows the hack mechanism and how it's supposed operate. https://watchguy.co.uk/service-repair-rolex-air-king-5500-calibre-1520/ 1520.pdf 1520-1525.pdf 1530.pdf1 point

-

@martygene at the time I made that post I was using a 3x clip on magnifier by Eschenbach same as this . Not the cheapest available at about £45 to £55 but very good. They have become a little scuffed since then but do still get used occasionally. The biggest issue I have with them is that my spectacle lenses partially counter the magnification. I have since acquired a vintage Binomag head set. These can be picked up off eBay for between £15 - £25, the lenses are glass so don't scratch too easily, and are very comfortable to use. These are also about 3X mag but because I can use them without my specs I get the full benefit. Working distance for both the Binomags and the Eschenbachs is about 100mm (4") and width of field about 8cm (a little less with the Eschenbachs). I now also work at a bench the top of which is at upper chest height when I'm seated so posture issues are a thing of the past too. My microscopes sit on a desk next to the bench so they are also at a much more useable height.1 point

-

Hi Endeavor find attached the 2416 tech sheet as requested. cheers Wostok 2416.pdf1 point

-

Thanks guys, this is a family heirloom that belongs to a dear friend. there are some missing parts however, but I was able to find a donor movement on ETSY. I soaked it over night in Mineral spirits to loosen up the crud and penetrate into any recalcitrant screws Once i get it apart and clean I will then delve into the works, from what I have read there is a tendency for the main plates to wear. It is not my intent to clean and slap together, but rather to get it to a point where it may run for another 100 years thanks again for your time and interest.1 point

-

1 point

-

Well the watch guys database turned out to be extremely handy indeed! I filtered all GR4502 springs and noted it is also used in the ST1686 - the very movement I bought in a box of spares a couple of years back. So, I installed the ST1686 main spring into the AS1186 (much longer and now looks proportionately correct) and immediately it ran up with gusto! On the timegrapher, with no regulation Im getting 280degrees amplitude, +7s/day rate and a BE of 1.0ms This is similar in all planes except pendant down. I think after another clean and proper lubrication this will improve. [emoji106][emoji16] Sent from my iPhone using Tapatalk1 point

-

Just put this Omega Constellation quartz on layaway. Ive had my eye on it at a local pawn shop since October. They finally brought down to a reasonable price. I was able to spin it that it was broken because the minute hand didn't turn when I turned the crown, only the hour hand turned. Fortunately for me, they didn't know the minutes hand sets with a hidden button in the crown. So, a legit Omega quartz for less than $1001 point

-

Hi Vinn is spot on. Its a quartz module and this is the standard fitting usually I use a screw driver aka Old Hippy but its easy enough to make a key/driver to fit as per Old Hippy Photo.1 point

-

thats a spanner nut. there are tools available, modify a pair of divider or one shown above. vin1 point

-

1 point

-

You know you have caught the bug when you seek out broken timepieces, rather than working ones. Also, you own more watches that anyone could wear in a lifetime ha-ha.1 point

-

Greetings! I bet Benrus us a fun brand to focus on. I tried to focus in Bulova, but failed, couldn't keep my hands off of whatever caught my eye.1 point