Leaderboard

Popular Content

Showing content with the highest reputation on 03/12/17 in all areas

-

Look at this wonderful clock a fantastic piece of craftsmanship. Most clock makers/repairers will never work on clocks of such quality. You do not see many like this around. I am wondering why this is on ebay and not in a specialist auction. It was auctioned around a year ago but no price has been given. http://www.ebay.co.uk/itm/B-W-Schmidt-8-Day-Chronometer-2-CIRCA-1932/182484615488?_trksid=p2045573.c100033.m2042&_trkparms=aid%3D111001%26algo%3DREC.SEED%26ao%3D1%26asc%3D20131017132637%26meid%3D2140847fee55437eb43c00d6dd4811fe%26pid%3D100033%26rk%3D5%26rkt%3D8%26sd%3D3118202207152 points

-

Okay, for those who notice nitty little details (as I think most watchmakers do) I am aware that the hands need to be corrected. My only excuse was that when I got around to putting on the hands it was towards the end of the day and I just wanted to case the thing and see how well it kept time. Haven't had the time to go back to it. Anyway, I titled this entry the way I did because it indicates something I love and the reason I entered watchmaking. For I found this watch in an old box (of old remnants thrown in free with some things I bought at a trade fair), lens-less, dirty (inside and out) with a broken mainspring. I replaced the lens and mainspring, gave the movement a good cleaning and did as much restoration of the dial as I could do with the primitive methods at my disposal; dial restoration being an art requiring far more time to master than I've so far put into the craft, but someday I hope to get better at it. As I said, the watch was in sorry condition and I felt sorry for it; as one might feel towards a waif on the streets, I decided to take it in some months ago as a practice piece. I mean, it literally had "cobwebs" in the movement; some kind of moldy stuff which I've seen in a lot of long--neglected timepieces. I put it through the cleaning machine and was pleased to see how it had brightened up and its quality began to show through--like a chronographical David Copperfield or Pip. I removed the remaining dirt with pegwood (Peggotty!) and Rodico and carefully oiled it. I was gleeful when, after final placement of the balance, the piece started to tick like a newborn baby come into the world. I, the parent, felt jubilant and, so far I haven't been disappointed as it is keeping good time, living up to expectations. I wear it regularly and someday maybe I'll come across a stray strap--lurking even now in some forgotten recess--that will do it justice. The watch is a 17j Elgin, with a gold plated case, as you can see. I haven't taken the time to look up the movement to see when it was made, but my guess is pre-WWII (any thoughts?). Would this have been a ladies watch? It's a bit bigger than most at that time. An unusual feature is the sub-seconds dial at 9 o'clock as opposed to 6 or 3. I may return to it someday when I am more skilled but it's still a joy to own.1 point

-

Bedford on the L line? Yep, know that area. I live right near there in Bushwick. Glad you found that watch....right where you hang the keys. It figures, right,? Ha ha ha. Yes I noticed there seems to be some discrepancy between the 2824 and the 2824- for the part. I will look up on my materials database in a bit and get back to you. J Sent from my SM-G925T using Tapatalk1 point

-

A bit confused what this movement is. I have a incabloc catalogue but no ST1686 or 1786. However in this range, the lower spring is 170.03 & upper spring 173.031 point

-

Welcome to the forum Sal! That's a rough draft for a short story you've got there. I saw that episode of twilight zone too, and it gave me a chuckle to see you mention it in that ad--which is hilarious. Where is that posted? Bayridge....Bensonhurst...maybe Court street?!? Glad you found the spring, sad you lost the watch. P.S. Isn't that part the date jumper and its spring? Watchmaker, Writer, Philosopher--You're a Renaissance man! Welcome again and look forward to more posts. JC1 point

-

Hi, Salvatore! Gee, what's it like to lose a watch part... I've never lost one (total lie). In reality, probably most, if not all watchmakers have a similar story. I'm no different. Honestly, if lost watch parts could glow in the dark, my house would be lit up like a Christmas tree! Welcome to the flying watch parts club (and the Watch repair talk forum) P.S. Glad you found your lost watch! Shirley1 point

-

1 point

-

Ha Ha Ha. The reaction of engagement of the great wheel with its pinion is transmitted to its pivot and, in the usual layout, the pull of the fusee line adds to this load. In the alternative layout, the chain unwinds from the opposite side of the fusee, and the mainspring's pull is in opposition to the load imposed by the great wheel's pivot reaction, thus reducing the pivot load.1 point

-

Vintage watches may have burnished/rubbed-in jewels, friction set and jewels in settings. One beautiful and frustrating thing about them is the huge number of variations that exist among old watches. Two watches of the same caliber, even by the same company may use different parts. Whew! Means you gotta start collecting watch material ASAP if you want to do vintage work.1 point

-

The dial and case crop up several times on a Google search but that exact style of bracelet does not. It's not untypical of Longines watches of the period and no reason to think it's anything but the genuine article. I presume it has an ETA movement and the dial and bracelet are gold plated. What were you wanting to know about it? Maybe someone can help. Cheers Neil1 point

-

1 point

-

1 point

-

@RyMoeller Nice find As in my walkthrough, IMHO best is to take a scalpel knife and a small hammer. Put the case on a scratch free "hardish" surface (so the vibrations don't get through to the movement) and slowly work, gently tapping with the hammer, the scalpel around the whole seam (360 degrees around), slowly opening the seam. After you created a big enough gap (you still need some dynamite) you insert your blunt watch case opening knife and it should "pop-off". Next to the damage I had already done trying it the "supposedly" way, this caused no additional, or minimum extra damage / scratches, but it may damage the flat O-ring (which isn't that hard to get, not the original, mind you). The movement number 31659 should be stamped on the chrono-bridge, and the date on the balance bridge; at least that was the case on mine, which had never been opened since it left the factory in 1988. Having said that, I noticed missing screws in mine, so one never knows what the factory worker decided to do with your watch on that day Oh, yes ......... you may need a 10 ton press to close it @ricardopalamino Me president?1 point

-

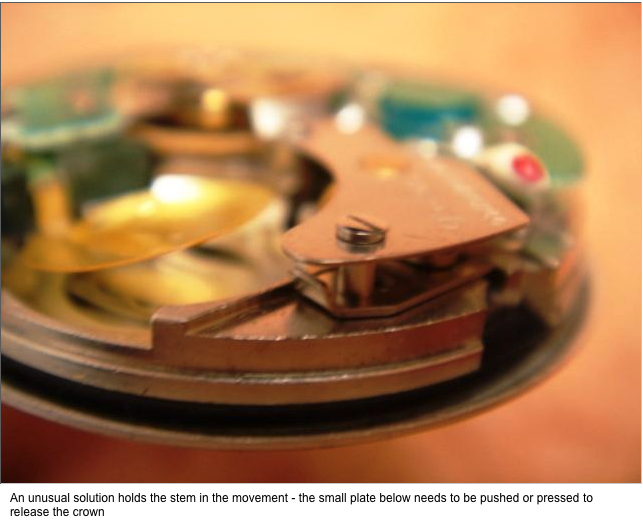

Picked up this Poljot Sturmanskie from the Bay the other day after following @Endeavor through his Poljot 31659 service. I may have paid a little much but this one did come with the original box and papers and also the original bracelet (which is absolute garbage). It's a 1988 model which should have the 31659 movement inside. Most everything runs fine although the stem is bent as the crown wobbles and the hack doesn't seem to work. It also sounds a bit tinny... I'll have to get it properly cleaned and lubricated before wearing it. I would offer up a pic of the movement but getting the case open is about as easy as getting into Fort Knox. I'll have to figure out how to get inside without damaging the piece. I'll post picks of the service when I get to it but right now I'm knee deep in another chronograph repair.1 point

-

You are right, the Cannon pinion and wheel are sold as a one piece unit, part #1219. The important lesson I've learned is how crucial a properly tensioned pinion is, and how easy it is to take apart and clean. With any further 10?? movements I'll definitely be taking the cannon pinion off for a clean and lube1 point

-

Very nice I like..Making tools like this is where you can save money to buy better precision tools also a lot of pride in knowing you made it yourself. I need to make myself a screw driver holder and an oil station also. I did purchase plastic oil holders I can fit into a base similar to the one you made.1 point

-

Like yourself , I bought a staking tool but don't have formal training to know how to use most of the stakes and stumps . I bought the book , "The Watchmakers Staking Tool " by George G . Lucchina and Archie B. Perkins from amazon . So far it has definitely been worth the price of the book and am glad I started out with this book . This quote is from a member of The National association of watch and clock collectors and mentions a couple of other books . " The most valuable info I've found on how to use the staking tool is contained in "The Watch Repairer's Manual", and "Bench Practices for Watch Repairers", both by Henry Fried. One book has a chapter on the various types of stakes and the other has a chapter on the various types of stumps. I think "Bench Practices for Watch Repairers" is not as commonly found as "The Watch Repairer's Manual", but it's every bit as informative. "1 point

-

1 point

-

Setting up to replace jewels will take some considerable expense, I'm still just gathering the tools now. It also depends on how old the watches are to watch exactly you need. For modern watches you want a Seitz jewel press or something similar, make sure you get one with a complete set of presses or reamers, or you may struggle finding those parts separately, a good micrometer, preferably a watchmakers one like a JKA, but they are getting harder to find for a good price and a pivot gauge. All of these items do turn up on ebay, but you need to be patient to find one for a good price. If you are working on older watches that the jewels have the brass rolled over the top to hold them in place rather than friction fit like modern watches then you need other tools. Have a read of this website http://www.geocities.ws/dushang2000/Jewelling.html This video also explains the Jewelling tool, its a modern Bergeon, but all the brands work the same.1 point

-

Seiko hairspring are very (insert "very: 5 more times here) delicate. If it is still within repair your best chance is to bring it to a watchmaker to be corrected, otherwise a new balance complete will be needed (out of stock at Cousins at this time). I understand that you are serious having even bought an expensive tool (actually a smartphone app would have been pretty much OK), but to be honest with you I strongly recommend that you practice first with junk movements before moving to the watches that you want to wear or have any value.1 point