Leaderboard

Popular Content

Showing content with the highest reputation on 01/25/17 in all areas

-

I thought I would share my latest mishap. I was repairing a quartz (Ronda 715) which had a faulty date change. The fault was traced to a mis shaped date jumper spring. So I had to make another. I was checking it's size etc. and moved in close to get a closer look & PING straight into my mouth. I did not swallow & it did clean it up a bit I suppose.3 points

-

This is how i check for magnetism and how i demagnetize a watch with my DIY device:3 points

-

I suscribe to this guys site. He is a bit wacky but fanatical about watches. He interviews a guy who shows the latest watches being produced by A. Lange & Söhne Enjoy & drool3 points

-

I use several lights on my bench. - An original Luxo illuminated magnifier. This has a 40W fluorescent light that surrounds the 3X magnifier. It provides general work lighting and uniform object illumination when viewing through the magnifier. - An IKEA JANSJÖ single LED work light. This has a weighed base and goose neck arm that allows me to position the light at any angle to illuminate exactly what I need. The flexibility and power of this lamp is well worth the inexpensive price asked by Ikea. - A home built ring light on my microscope. This uses an aftermarket angel eye projector for an automobile HID headlamp and it mounts coaxially with the objective of the microscope. It provides a very very uniform and bright illumination to the work under the microscope, whether that is electronics or watches. I love this worklight. If I had the possibility, I'd gladly trade the ring light for an AZIZ light from Tangent Audio, but unfortunately this thing is made from unobtanium.3 points

-

Or the courier as these items were delivered. My last order of items from Cousins. Finally I have everything I need to be able to use my ultra sonic cleaner for clocks and the grease for the keyless works on watches, so I'm now finally set up for servicing clocks and to be able to strip down and clean, oil and reassemble watches. I'm still not completely set up for replacing cracked jewels on watches, but atleast I can start on watches now. I'm quiet excited, the next big hurdle is to convince the wife and kids that a small corner of the games room needs to have my workbench set up in it. I've still got my $1000 from my scholarship sitting in its envelope waiting to pay for my work bench and LED light and I want to get it. Picture of my latest delivery which includes Bergeon green watch lume kit so I can also now try my hand at reluming hands.2 points

-

Probably my favourite watchmaker! Thanks for posting CB. PS I did a wee edit on the name.2 points

-

My father was a watchmaker for 60 years and when he did a major overhaul on a watch, he would, in tiny print, scratch his initials and a ticket number inside the case. He recorded the ticket number in a book and included all the information regarding the watch (make, model, material etc), it's owner, what service was performed on it and what he charged. I have those books. As a matter of fact, I have recorded some of the information in them. That was one of the jobs I would do when I worked for him in my younger days. He used different tickets if he just changed a crystal or stem and crown or something minor. The information from those tickets was recorded in different books (with less information) and the ticket number was not scratched into the watch case for those. Of course, most of the watches he worked on were not luxury watches. A big percent of them were railroad watches. He was a railroad watch inspector for Southern Pacific and Missouri Pacific railroads for many years.2 points

-

2 points

-

Here's some information on the output of the Cousins LED light as measured by a lux app on my IPhone. This light is fitted with two rows of LEDs that can be both individually selected and dimmed. The readings were taken with my phone 10" below the light as this is the height I have it when working on watches. I also measured the light colour temperature at the different settings. One row low setting 1,240 Lux ......... 6600K colour. Two rows low setting 3,960 Lux ......... 6000K colour. One row high setting 5,450 Lux ......... 6300k colour Two rows high setting 20,800 Lux ....... 5600K colour To give an idea of how it compares with the Cousins small portable fluorescent desktop lamp that I have currently been using. At the same distance of 10" it gave 3,170 Lux .......5600K colour At a distance of 5" it gave 30,600 Lux ....... 5600K colour although there was a bright hot spot with rapid fall off at the side. This was the the distance I have been using, and it was a nuisance as it often got in my way. This has been the best improvement I have made regarding equipment this year. Please remember that these tests are for guidance only as I have not used specialised equipment. I hope you find the information useful. Here's some information on recommended lighting.1 point

-

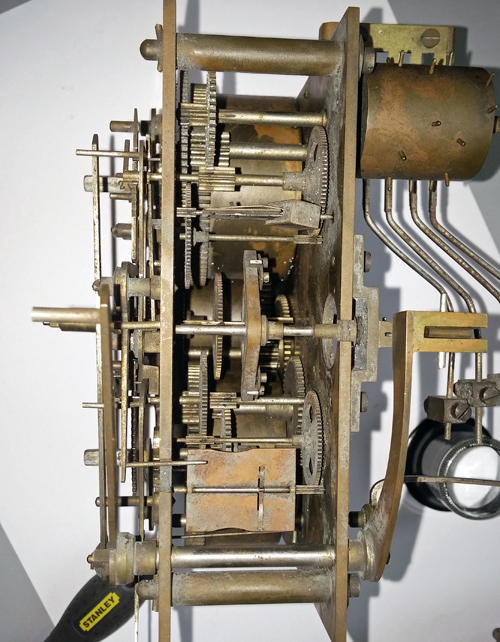

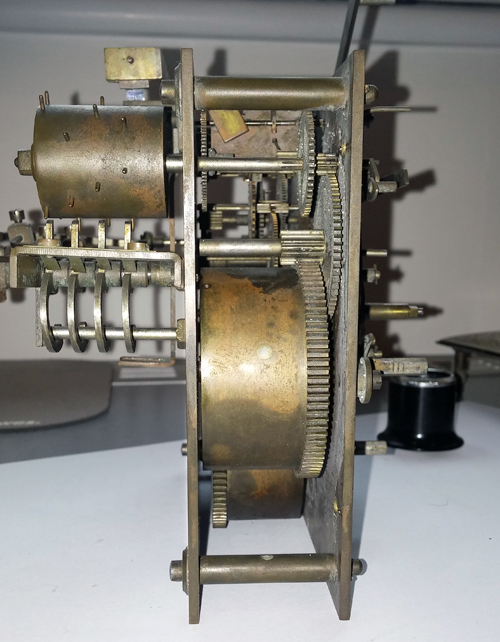

This has just been passed to me for restoration: Quite acceptable on the outside, strikes but does not run, pendulum missing (may turn up soon), movement very dirty & not signed: Shows serial number 169240 with 18 above on the back plate, 20 on the front plate. Apart from the grime everything seems to be in good order. Any information about the movement (age, maker etc.) would be gratefully received. Also pendulum info would be useful (if the original turns out to have disappeared for good).1 point

-

One thing that really has helped me when doing this is to work in a direction. By that I mean after putting LIGHT pressure on one edge of the bridge, try and get the pivot of the closest jewel in first, then move onto the next closest jewel etc. Sometimes I find that if it is not working at the original pressure point, I change to the other side of the bridge and start again. GENERALLY I find starting on the escape wheel side is best as it has the smallest (read hardest to find) pivot and the center wheel the largest (easiest) to locate pivot. Hope this helps! Eric1 point

-

1 point

-

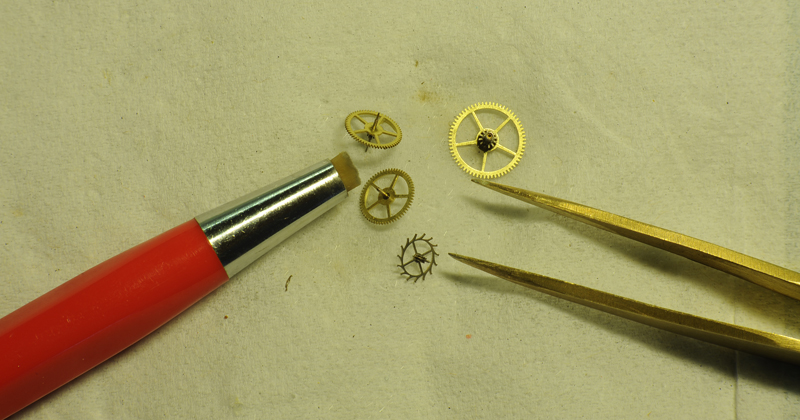

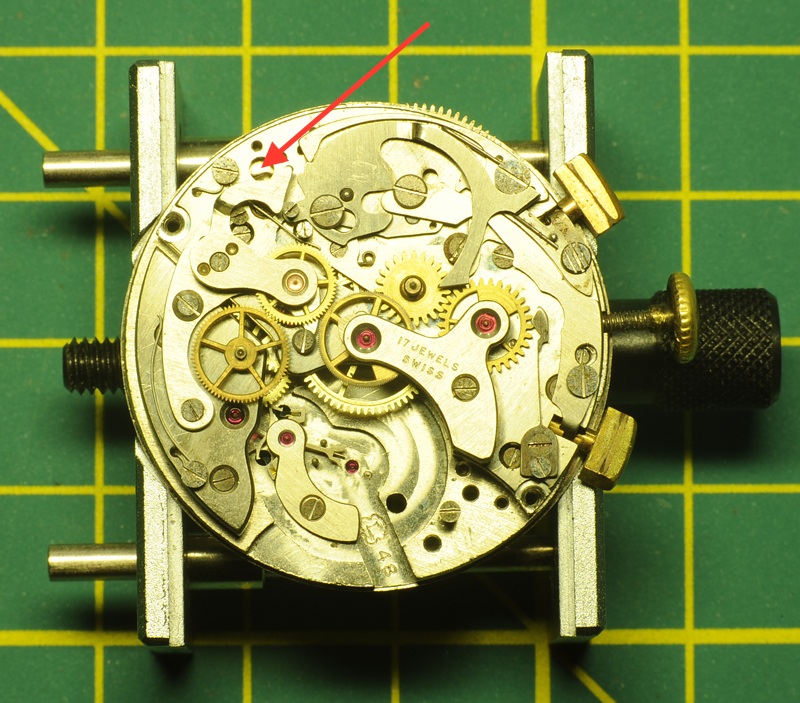

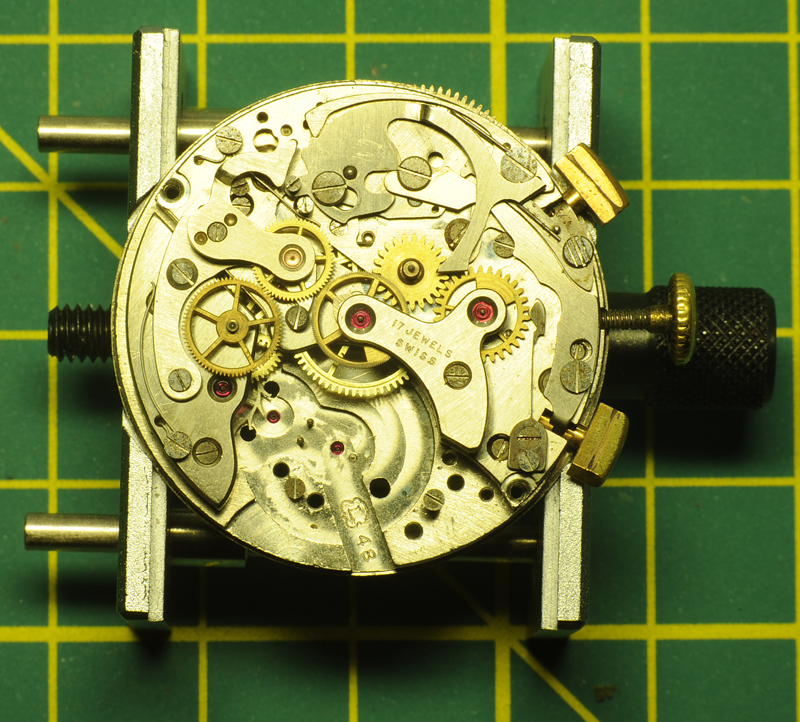

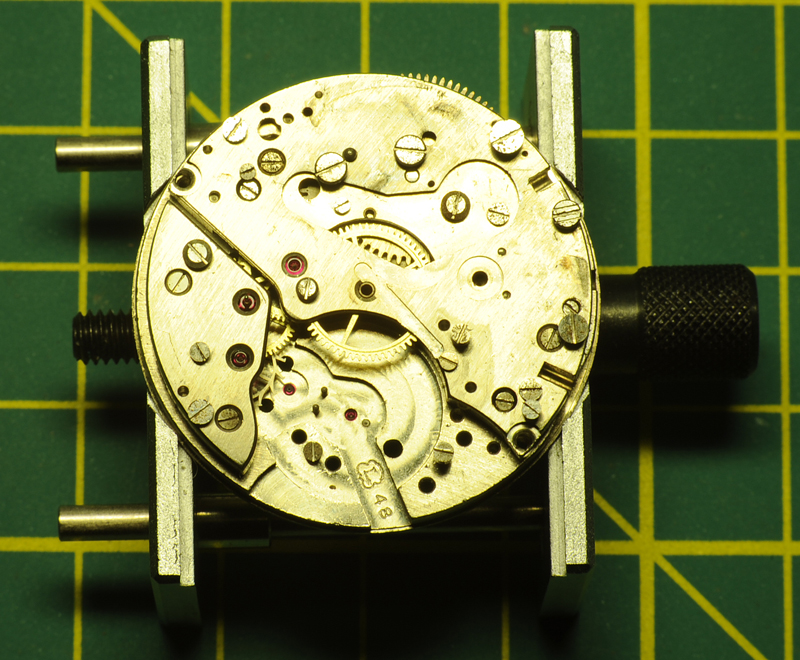

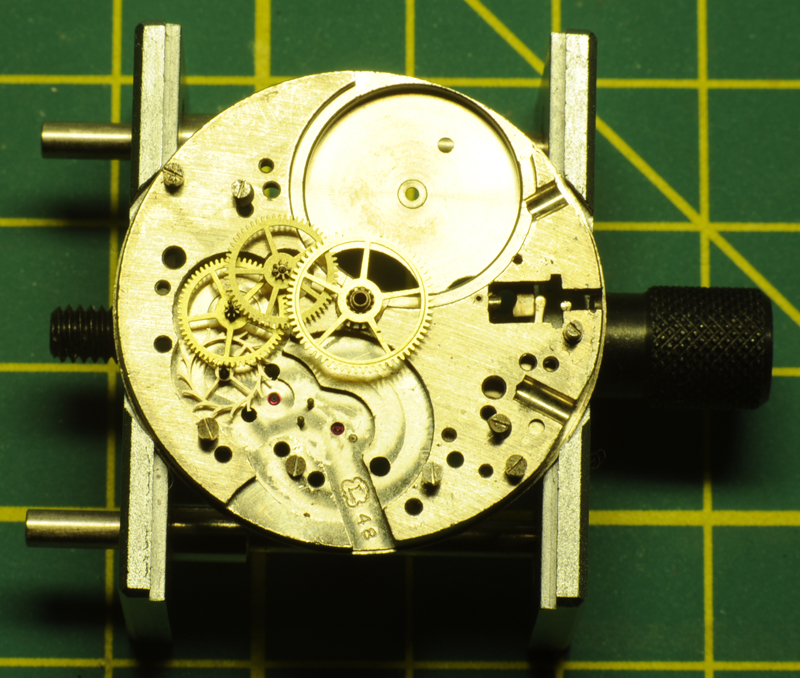

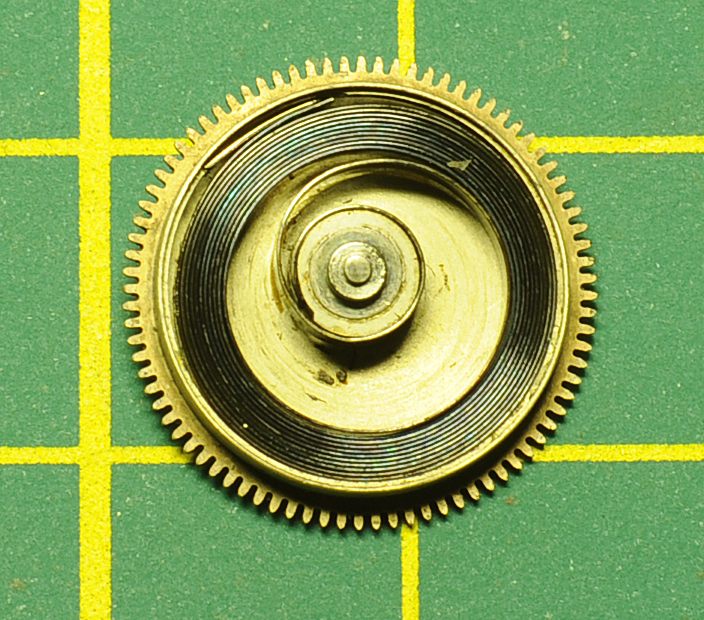

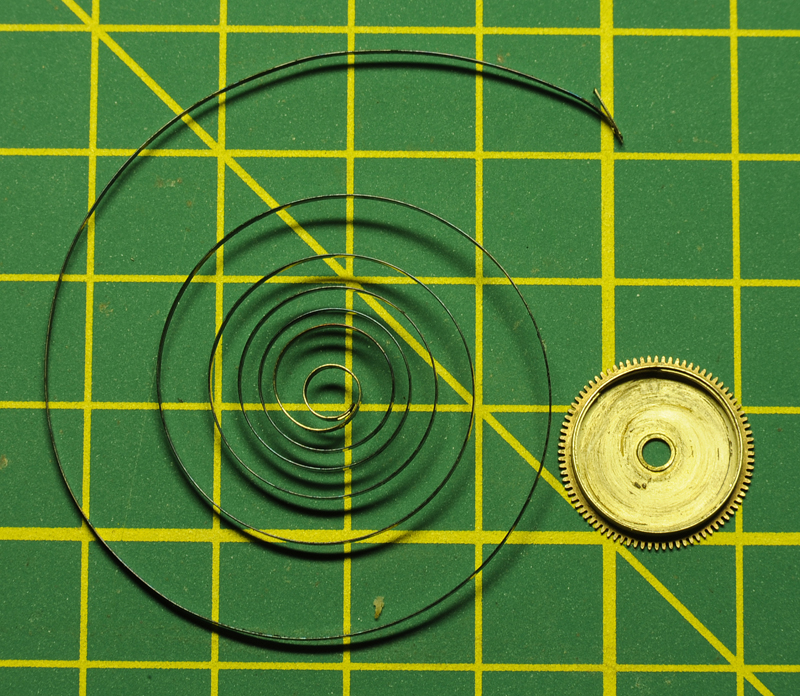

@RyMoeller Interesting article. Good that she is keeping the ship afloat Not so much on the Landeron to report. Today I went ahead to inspect and clean the parts. All the jewels seemed fine. There was however some (minor) surface rust on the metal parts (the sprockets) of the wheels. The wheels from the wheel-train and the runners. The copper alloy parts were fine. Carefully rubbing with a fiberglass brush and it went off. I think this movement has been "off-duty" for a long, long time. Some chronograph levers and springs were slightly magnetized, so I decided to de-magnetize every single part. The balance pivots are in tact. The pivot rotating in the balance-bridge jewel has a slight wear-groove. Most likely because the bridge jewel is the hardest to oil. We will see how that shows up on the timegrapher. The pallet fork pivots and jewels are in great condition. While waiting on the new main-spring, I will turn my attention to the dial and hands. It may be a few days, perhaps a week, before there is more to report, as the main-spring was bought in the US on the 20th of January. Post services aren't anymore what they used to be; the speed is inversely proportional to the postage price...... Stay tuned ......1 point

-

Ah yes, the Esembl-O-Graf. I have the complete collection in hardback and I use them on just about every chronograph repair. Deviating a bit off topic... I did a little internet research a while back on William O. Smith Sr. who put together the Esembl-O-Graf collection for his watchmaking school, the Western Pennsylvania Horological Institute (I was interested in the American connection since there seem to be no examples of actual US made chronographs). Unfortunately the watchmaker school is no longer around but it looks like watchmaking still runs in the family.1 point

-

1 point

-

From scouseget posting "3). I watched a YouTube video yesterday from the AWCI, which stated that not only should a screwdriver be just the right width for the screw slot, it should never bottom out in the slot but rather sit just above it" Whilst I understand what is being said and why, good luck with that, especially the hollow ground enthusiasts. May get it to work on one screw in one watch but honestly! ? my test is a bit sort of simple but I found I was doing it without thinking. With the screwdriver of the right size in the slot vertically try to roll it back and forth between thumb and forefinger, if it moves at all "without the screw moving" the driver is not fit, dress or change the bit. Cheers, Vic1 point

-

1 point

-

1 point

-

Seems we have a few of the same interest. I like to mess with some electronics, wood working now watches.. In general I like fixing broken stuff I am not an expert at anything, but in most cases I can hold my own and get the job done. Thank god for the internet. https://www.dropbox.com/sh/7usqy0ib4hvkib0/AACtQqWU04bhn6NQHfj6ODiIa?dl=0 https://www.dropbox.com/sh/08brzllftklna5e/AADl5_GJa_vP2TGEyAYat8Cna?dl=0 https://www.dropbox.com/sh/0pbn62e9klcmfzk/AABpDiBtUh4J0X11BwOkmSpua?dl=01 point

-

That's nice and wide. Mine is only 21" wide. That must be a huge monitor. I think it will be some time before I have the space, but I'd like to build a full sized bench too. Both for learning more woodworking and to save money. Just a standard bench is $700-800. Even if I screw up and have to do it twice, I think I can still beat that - and have it personalized to my liking.1 point

-

Well whodathunkit ! It took a bit of research, but I have discovered the rationale is for low light conditions and common for dive watches. The Autozilla has a black plain dial that is adorned with long-lasting, super-luminous large hour markers. This enables reading the time in dim light situations with ease. The markers for 3, 6, 9 and especially 12 o'clock and the zero marker on its unidirectional rotating elapsed time bezel are conspicuously styled to prevent disorientation induced read out errors under the darkness of the seas. There is a day-date display at three o’clock position. The day and date of this watch can be quick-set. The rugged looking rotating bezel have a minute scale going up to 60 minutes with a marking at every 5 minutes interval. It is easily detachable for cleaning after a dive. For a diver's watch the rotating device shall be protected against inadvertent rotation or wrong manipulation. The Autozilla also has a register ring clamp locking lever near its crown. For diving purposes, an indication that the watch is running in total darkness also has to be present. The Autozilla employed a running second hand with an arrow luminous tip. It also has a large, easily identifiable bright orange minute hand. The hands design is also in such a way that no hand can totally overlay and hence obscure the position of another hand to prevent read out errors. Both minute and hour hands are heavily non-radioactive, photo-luminiscent treated. Source: http://watchopenia.blogspot.ca/2014_06_01_archive.html and for 2017.... Source: http://www.bestproducts.com/mens-style/g1193/best-dive-watches-for-men/1 point

-

My watchmaking tutor told me earlier that he experimented with "essence" and found it to just be repackaged naphtha (lighter fuel). Not that I'd know what's in this Anchor solution.1 point

-

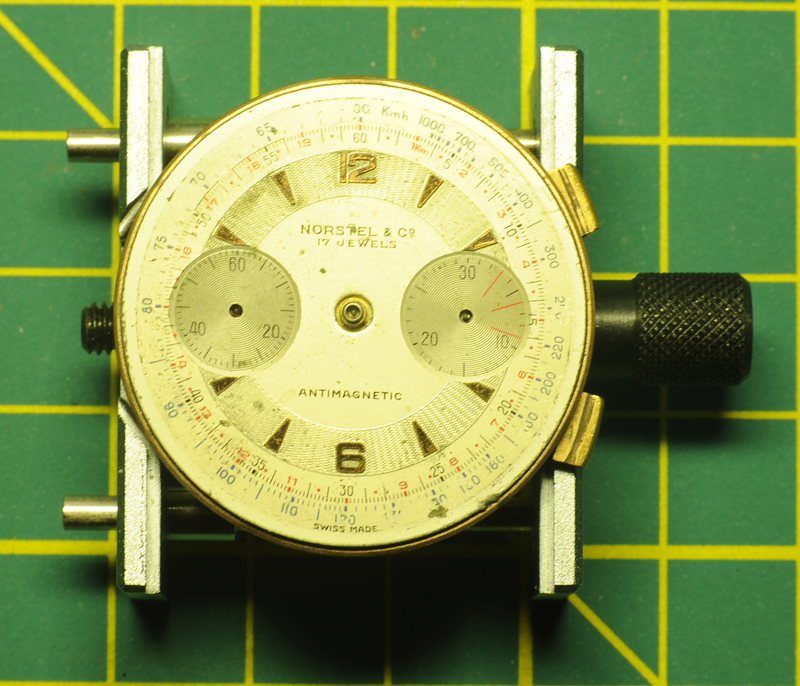

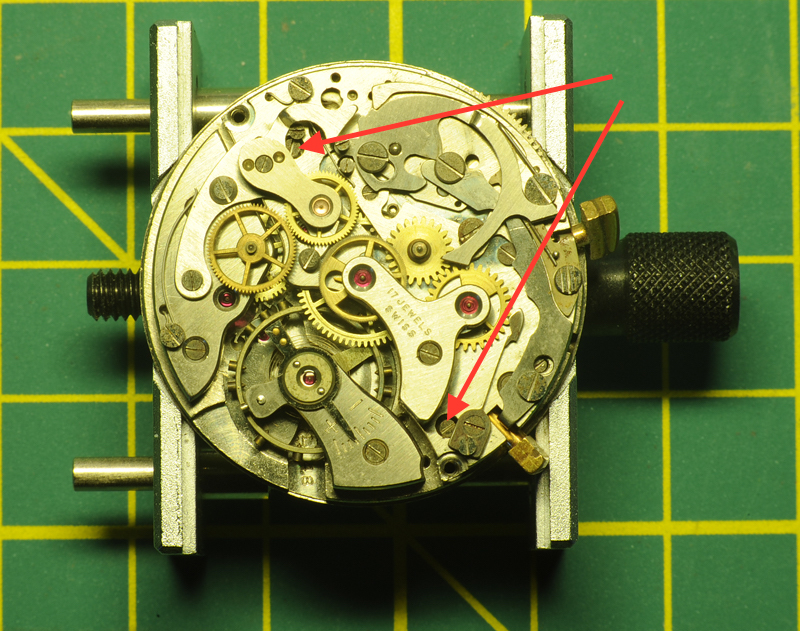

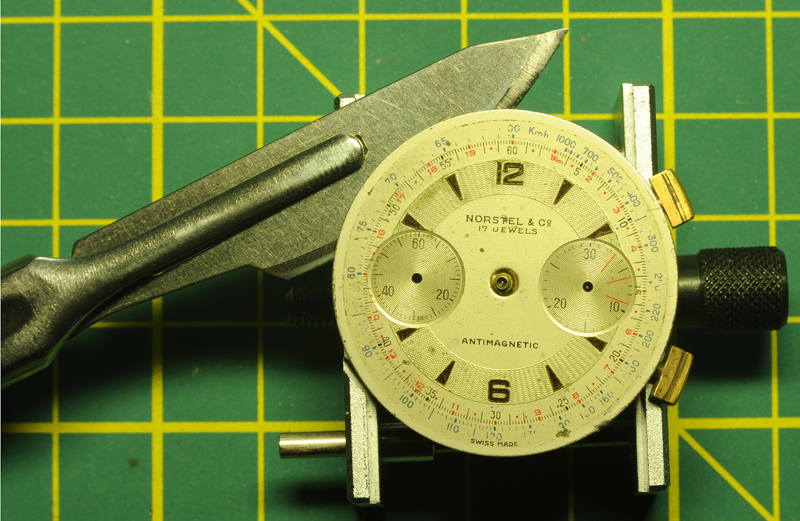

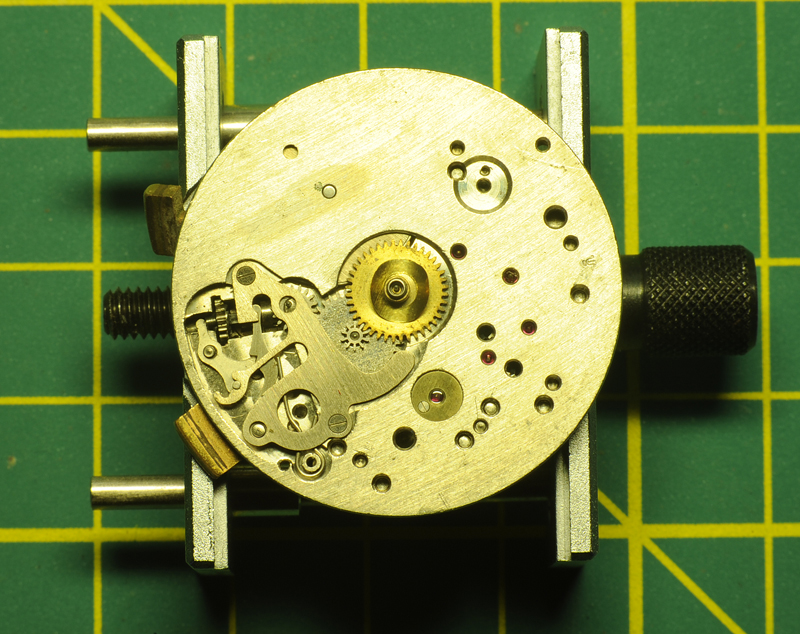

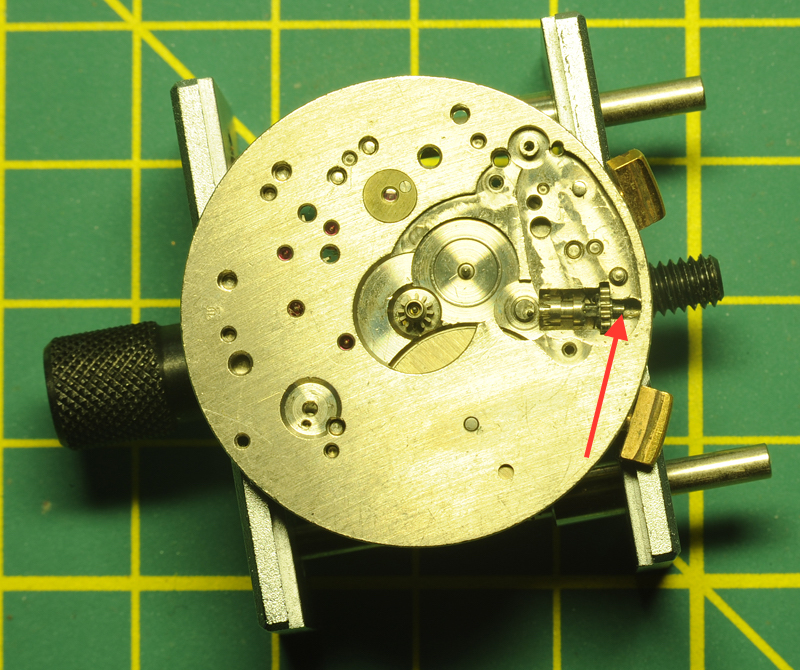

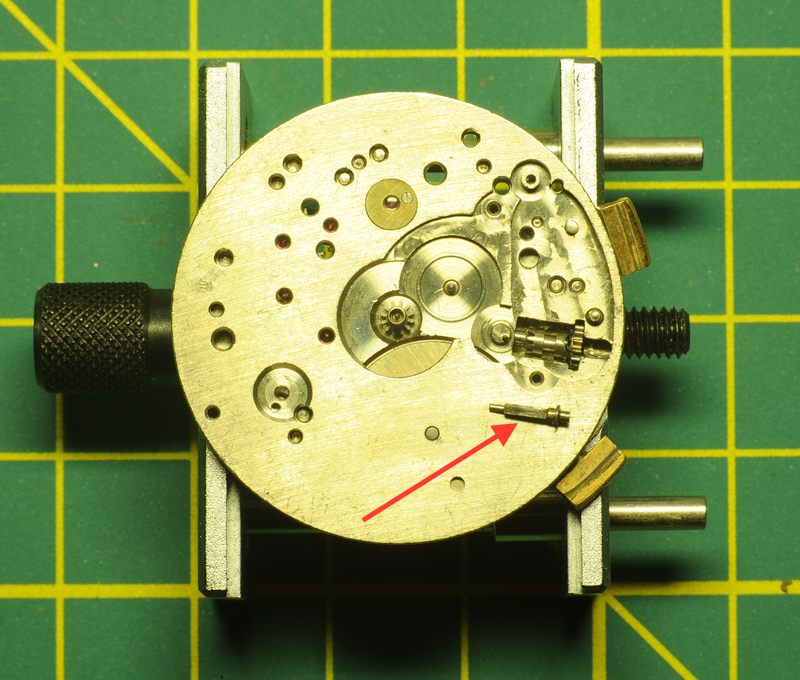

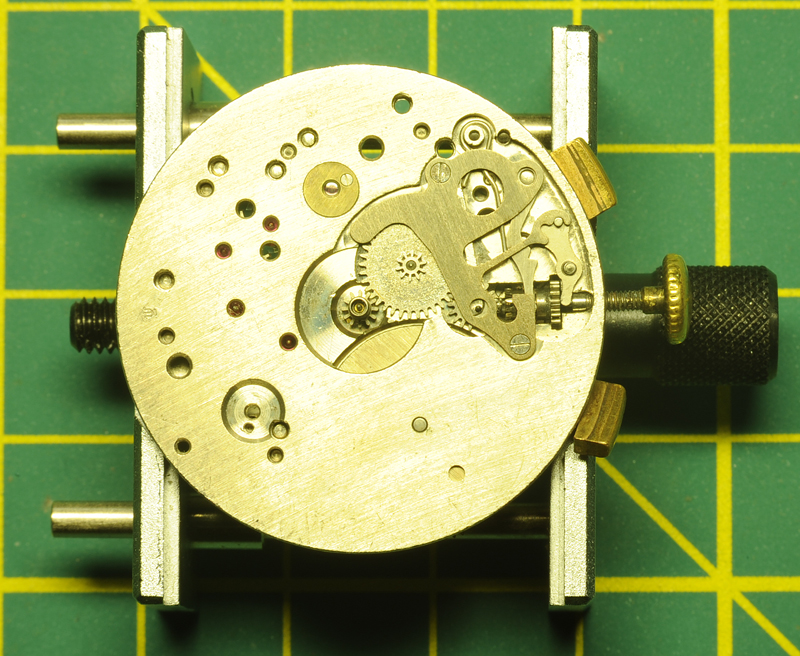

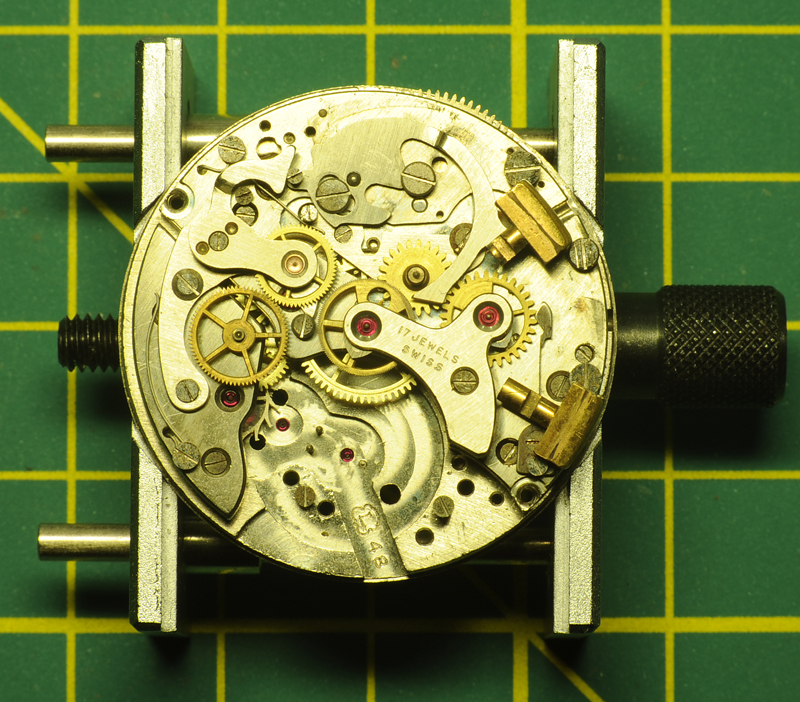

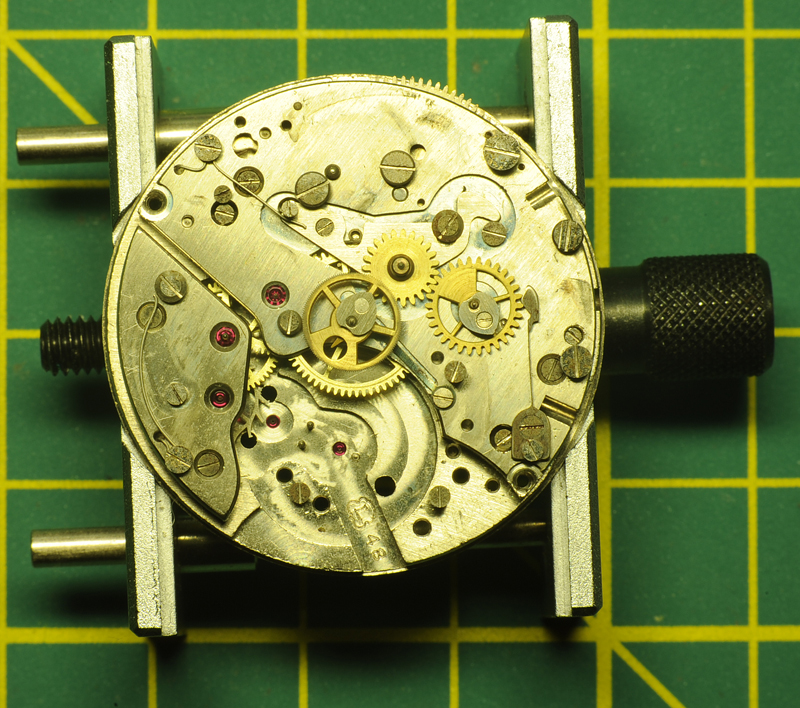

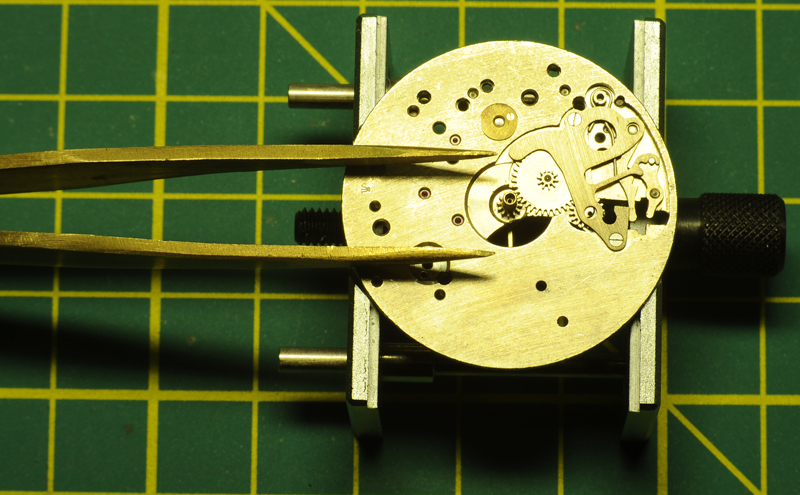

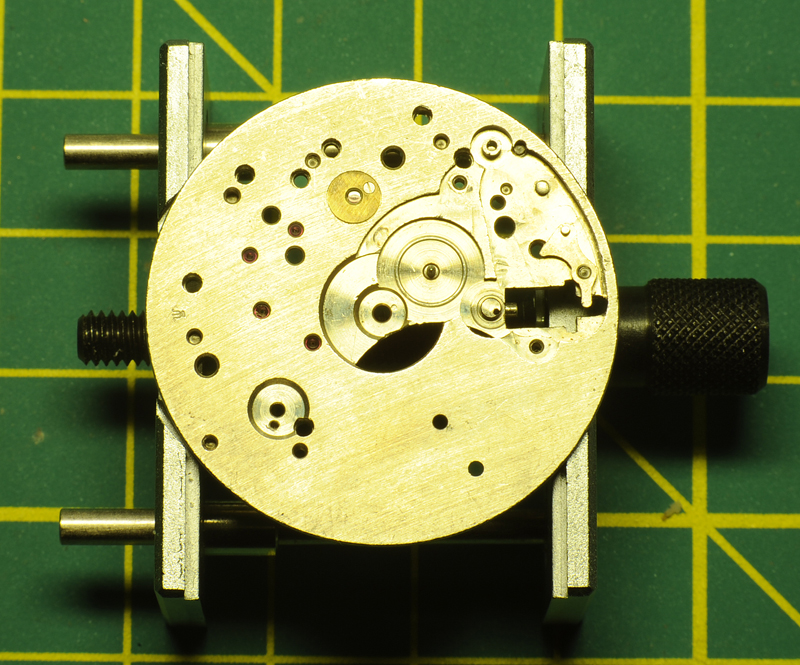

Good news ....... the Landeron 48 arrived today !! In reality it was even better looking than on the pictures and the hands were less bend than I thought. All seems to be within my capabilities .......... I hope We'll see... Here my own pictures, but unfortunately, due to the artificial light, not a whole lot better than the sellers pictures...... The chronograph functions seem to work fine and, maybe my wishful thinking, the balance-wheel showed attempts to get back alive agian. However, upon further inspection the first Gremlin stuck his head out off the winding hole. The winding-stem had broken off and the remaining part was stuck in the keyless works. Now, I was not able to check whether there was any tension left on the mainspring. This problem had to be solved first. All the hands came off easy.. The dial screws are a bit hidden. The two arrows are pointing them out... I don't think the dial had ever been off, so carefully with a surgeon's knife. Take care of the little pinions !! All seems fine. I couldn't get the stem out, so had to remove the whole keyless work. With everything removed, the Gremlin held tight and it was a struggle to get him out ..... Here he is ...... red arrow........ Installed an old winding stem (leftover of my first Landeron 48) and re-installed the keyless work. Time to check the main-spring tension. The click is a bit hidden, the following picture shows where it is hiding; I didn't notice a lot of tension, if any. While working on the broken winding stem, I removed, as a precaution, the balance-assembly already. The pallet fork can now safely be removed. The disassembling of the chronograph went as per Ebauches S.A Landeron 48 pdf-file, which can be found here Landeron 48.pdf Also, this time I replaced all the screws after the removal of an item. I've seen this "trick" on a YT-video from forum member George Clarkson. There are many different screw-types and it does make sense to replace them immediately. See how that works for me ....... ? The pushers had different length, the pusher with a longer stem at the bottom, the shorter stem at the top... The runners 8020 and 8000 ... The Landeron stripped off its chronograph components, screws replaced. Next is the removal of the barrel-bridge and the wheel-train bridge. With all the wheels removed, except for the center wheel, the movement is flipped over. I don't have a fancy cannon-pinion puller, so I use brass tweezers and the main-plate as a base for the leverage. Thereafter off with the keyless works again. Main plate empty......... so far I haven't noticed any obvious broken parts. Slight surface rust on some screws. Main spring winding-direction. Not broken, but I ordered a new one which will replace this spring. Tonight the main-plate and bridges are soaking in Zippo lighter fluid. Tomorrow cleaning and inspection of parts and jewels...... So far so good .........1 point

-

@Watchtime I bought it like that. The pictures are taken by the seller and the watch is currently in transit. I must admit that the movement looks in an amazing shape, for being 25 years old. Studying the pictures, I haven't discovered any irregularities so I hope it is not one of those: "if it is too good to be true, it probably is". If you look on the very informative website: http://www.polmax3133.com/ , on the right-hand side "1992 - 1H", then under "Sport" you see the watch depicted. If you click on "Nuclear", the author makes a remark about how pristine the movement looks, a movement of the same time period.......... so perhaps I'm lucky? Not knowing the watch history, I go from the assumption that it needs a service. I hope to see the watch in reality by the end of this week / begin next week.........1 point

-

My response was really written with larger quantities in mind. I realized the 20mL size you are asking about is a very small amount. You might want to consider buying One Dip 2oz or 8oz bottles. I would still use a wide mouthed glass jar and to place the balance with hairspring inside and then drip the solution onto it. J1 point