Leaderboard

Popular Content

Showing content with the highest reputation on 01/10/17 in all areas

-

I have been asked to service a watch and if possible I was asked if I could change the badly damaged crystal. The movement is a cheap pin lever movement but the challenge was the crystal. The crystal had a lens attached to it’s inside & also a chapter ring fitted to its inside. I think there was a similar post last week with one of these. To remove the chapter ring from the old crystal I just pushed the crystal down from its centre using a Robur glass press to open it & chapter ring came away. I could not purchase the correct size replacement crystal with the correct size lens. The old crystal was a high dome 320mm diameter. However despite my best efforts I could not press the chapter ring into a new 320mm diameter crystal so I fitted a 322mm crystal with the chapter seated inside. However when pressed into the watch the chapter ring tightened. The lens was fitted with Seiko two part clear glue. I marked the inside of the glass to aid it’s position. I also fitted the lens to the outside which the customer was happy with. See pics. I will do a separate post re- the pin lever movement assembly etc. OLD CRYTAL + CHAPTER RING Pressing in the new Crystal + chapter ring Crystal marked ready for lens New lens fitted job done2 points

-

I started this hobby some 10 years ago and took it up to see if I could get some skills and knowledge so that I would have something worthwhile to do in retirement and also partially because I avoid the telly and need distraction from a job that is stressfull at times. I have never had any formal training, but always liked pulling things apart and fixing them. I have restored/repaired many watches and dont charge for this as long as the watch owner promises to wear Grandads or Dads old watch every now and again. Everyone promises to do this and I do like to see folks wearing these old watches and not having them in the back of a drawer somewhere. OK so thats where I am coming from and as I see many new to watch repair folks here, I though a thread starter might be what skills you thought necessary for the jobs we do, how you managed to develop these skills and where you got your knowledge. I'll start it off. Some of what we are likley to say will be obvious, but it maybe of help to newer folk. I think patience and a reasonably steady hand factors would be important. Just figuring out how to use tweezers and screwdrivers does take time, so take apart and put back together as much as you can. You will get lots of satisfaction through getting something to work and keep reasonable time. Look for old movements, say Bulova - available cheap, which are simple manual wind jobs...you will soon pick it up. A number of devices can assist eyesight these days but if your eyes are good it really makes it easier. I am not known for my patience, but I think I have improved this somewhat. Taking time to source the parts carefully requires this. Some projects take years to finish. You need to recognise when it is not fun any more and take a break. Don't jump to conclusions about a fault, but think things through as best as you can. Of course knowledge can be gained by things like Marks videos...I still watch these and pick up lots. I also think an open mind to repair techniques is important as well, that is, dont get locked into doing things one way as another method may actually be better with less chance of breaking something. The first skills I learnt were the manual dexterity ones. We all talk about breaking parts of the first movments we work on so develop the fine skills you need through repitition. I know we all like pictures, so here are a couple of my workshop.2 points

-

I have been trying to learn mechanical watch repair for a long time. I had never once successfully taken a non-working item and got it back to working condition. Its depressing. I have this old watch its like 80 years old. It didnt run, so I thought I would service it and see if I could get it to work. So yesterday thats what I did, and it all went very well. It was a design I didnt know, it didnt even have a pallet, I have never seen one like this before, instead it had a cutout in the balance staff that allowed the escape wheel to pass. It took me about 4 hours, but I did actually get it working, it ran for 4 hours. I was in a really good mood, as this was the first time I had ever gotten a previously non-working item to run. I felt like I had taken a first step to something. So 4 hours, good, but still, it did stop. The balance seemed to be the sticking point. It just wouldnt turn smoothly. It seemed to run fine until the balance cock was screwed down tight, then it stuck. I thought the balance staff might be too long. Long story short, on perhaps my 20th attempt to seat the balance the hairspring became tangled. My attempts to fix the hairspring destroyed it. It feels so bad after so much effort, to all come to nothing. And I cant find a replacement as I have no idea of the make or model number. The only good news of the whole thing is that once the POS hairspring was out the way, I was able to see the top balance staff pivot was slightly bent. So at least I was able to find the problem after all. Just feels crap to work so hard for nothing. And, really it makes me worry that if a hairspring can tangle so easily, it feels like it can happen at any time, I mean what are we supposed to do if we cant get replacements? Do we only work on watches where replacement parts are readily available? With all the parts restrictions it feels like working on anything is a big risk.1 point

-

Steve at TT crystals will probably get back to you . Yes , the shipping is reasonable . I looked on the site for the size you are looking for and it said Sold out on both the white and yellow tension ting , but contact Steve from the website anyway . I think the evertite are about $4.95 . I just got 2 crystals from him, and the site said sold out , but he found some . I paid for 2 and he sent me 10 , and gave me a discount .1 point

-

I don't know whether you have seen Marks bit on straightening hair springs and it may be that unlike myself you already possess the skill, but if you need it the vid is quite illuminating. Best of luck but I do feel you are going to win this one. Cheers, Vic1 point

-

Yes, try to fix it, it's very good practice! Slow, and steady hands are the trick. Replacing the balance staff will also be good practice. Mark's video on the subject is excellent.1 point

-

1 point

-

Dont get disheartened by your mangled hairspring. I've been doing this a while and i think I've only managed to straighten out 3 out of what must be dozens in the end i usually end up finding a replacement. Hairspring manipulation is an art form in itself and anyone whole can do it consistently should be awarded a medal of some kind. Mick1 point

-

I'm intrigued by the idea of solar watches - they're not exactly new these days - and bought a Seiko Solar before Christmas. It's a simple, military-style face, with day and date functions and a hacking second hand. I'm attracted to them because I like the idea of a watch without a disposable battery and, so far, it's keeping excellent time. I experimented with a Seiko Kinetic some time ago - an "Arctura" model - but it was very heavy and I get bored with an automatic watch that I don't wear all the time. One of the problems with the kinetic is that, although there's no battery, the capacitor can deteriorate over time - and I believe the shelf life before that component requires replacing is around 5 years. Which is why you see quite a few going cheap on eBay... Is there a similar downside to solar-powered watches?1 point

-

Congratulations Mike on getting something back together and working again, even though it was a short period! If you did this without any help then you did well! Seems like you cleaned the watch without disassembling the balance wheel from the balance cock. On older watches without shock-protection, this needs to be done to make sure the old oil is cleaned up and replaced with fresh oil. The bent pivot could have been a result of your handling, rather than the cause of poor running. First lesson learnt. 2nd lesson, inspect each part as you remove, not only the part but its interaction with the others. This will save you cleaning and assembling the watch only to be stone-walled by something that could have been identified earlier (like a bent pivot?). 3rd lesson, you started with an 80 year old watch. Not the best to learn on as parts are a problem and the watch may have some value.. buy some (working) Seikos from India (on eb@y)..cheap as chips and tough as a Nokia 3310. 4th lesson.. quote " I had never once successfully taken a non-working item and got it back to working condition. Its depressing" unqte . You don't really have the experience base to identify why a watch is not working. Start with a watch which is working, if you can disassemble it and get it back together again then good. If it doesn't work then you did something wrong. Help is just as far away as your phone...don't hesitate to ask... but this lesson you've learnt already! Cheers Anil1 point

-

We just had our end of year wind up for 2016 (yes I know its already 2017) for the Master Clock and Watch Makers of Western Australia Inc and at that was announced the 3 winners of a $1000 scholarship which can be used to pay this years fees, or buy tools of which I was one of the winners. Looks like I will be getting myself a nice workbench and good light and a few more tools soon which will set me in good stead for my second year studying watch and clock repair.1 point

-

Thessler, Take a look at the Jacot tool sold by OTTO FREI. I am pretty sure it is a Steiner. The cost of a new Jacot set is about equal to the down payment on a house so it would be a good idea to find a used one. Once you can see what a complete set looks like, you can take a look at used ones for sale on Ebay. Also, check with Uncle Larry's Watch Shop. david1 point

-

Hi rogart63 . The evertite is not a true flattop , but it's not domed either . It is a tension ring crystal with a rounded edge comfortably turning up to the top . If you are wondering if it crowds the hands , I have not ever had that problem , even with block indexes that stand a little higher . It is acrylic , not glass . I wouldn't call it thin , but certainly not as thick as a glass diver crystal .1 point

-

From your description it sounds like you have a cylinder escapement. These were quite common from the mid 1800's into the early 1900's. not many people work on them as they can be a real pain to sort out so you did well to get it running. finding a re[placement H/S is likely to be a challenge and your best bet is to look out for a donor movement. I'm sure if you post some pics of the movement there is a chance that someone might be able to help.1 point

-

I'm pleased you managed to find one @anilv and I inspired you to find something out of the ordinary I still have both mine and wear them often. That crystal is great although i wouldn't like to try and find a replacement if it had been cracked.1 point

-

1 point

-

I made a YouTube video on using this tool. Sent from my iPhone using Tapatalk Pro1 point

-

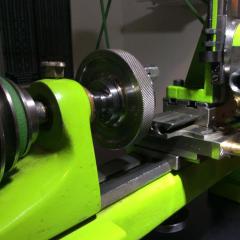

Ok, here are some pictures of the lathes i use at the moment! The lathe I use the most, Boley/Leinen Reform A sturdy Boley used mainly for lapping details on watch cases For bigger objects I use my Boley Prec.2 Currently under resoration, a Wolf / Jahn 8mm lathe with a whooping 493mm bed - intended to treplace my Boley for lapping jobs etc. And finally a Harrison M250 - used for making parts, jiggs etc. for the lathes etc.1 point

-

unless you have a spare dial, don't. 90% of the time you make it worse and I'm speaking from experience of trying the so called different methods found on the forums (lemon juice, vinegar, dish soap, dish washer) and yes, I had roasted dials to test each method on. none delivered what they promised. either buy a new dial, get it refinished or soak up that patina which only comes with age.1 point

-

when installing these springs ... check to see if it is totally flat, a spring with a slight twist will tend to fly off. parts tray.You will notice this if the spring is lying flat in your For springs made from flat stock, also check if the ends are not 'twisted'.. not so easy to spot ... best bet is to view it from directly above. This applies to all springs. Anil1 point

-

I'm guessing that's an ETA 2783/2789 in which case the twist is intentional. I can only think it's to improve the engagement of the clutch during manual winding.1 point

-

I have had a citizen pro-master eco-drive for about 15 years and it has never let me down. I use it mainly when I go on holidays and it quite often stops completely because I keep it in a draw for months on end. I leave it on the window ledge for a couple of days with the stem pulled out. Then I push the crown in and it just carries on. A great watch. These capacitors do not last forever unfortunately but can be replaced reasonably cheaply when they do. To be fair - many watches with standard lithium batteries (Seiko Perpetual Cal., Casio, Timex Indiglo) can last for many years also - so I'm not really sure about a clear advantage capacitor based watches have over lithium battery based watches. But Solar does have a clear advantage over the Kinetic's as there are less moving parts to wear out. Rechargeable lithium ion would be better I suppose - some Kinetic's have those.1 point