Leaderboard

Popular Content

Showing content with the highest reputation on 10/13/16 in all areas

-

Still mucking about with this movement. It fascinated me with one train bridge on top of the other . The whole watch , movement, case and strap cost £10 brand new. The time keeping was awful, with a complete scattered pattern on the timegrapher. I stripped it down, oiled it and reassembled it. Just regulated it even with an unacceptable low amplitude. Better now but not perfect. See pics below. I think originally the hairspring was hitting the seconds wheel. Anyway was either doing this or jobs around the house this afternoon. No contest really. Sent from my SM-G920F using Tapatalk2 points

-

Thanks folks for your comments. Happy to let you know as much as I do Roland. They take around 4-5 hours to make and so I really could not sell them and keep everything fair, but there is a large amount of satisfaction once a watch repair/service is done and in the making one of these. There is a lot of subtlety to making them as I am sure those of you who have done this will agree. Firstly examine the watch, you need to evaluate the lugs carefully. How thick are they, what is the distance from the hole to the case. These are factors that need to be considered for thickness of the bands leather. You need to use strong leather that will last. I tend to use kid leather for the lining, suede side out as this is very comfortable. I also use leather for padding if I need to. Consider stiching colour and length of the band. Try to get the buckle to lie on exactly the opposite side to the watch once the band is on your wrist. I have made up some simple templates for the bands depending on lug width. You may have a lot of tools already, but these are readily available and cheap from eBay etc. In my view the glue is critical as you need the band to be flexible, so I use Japanese Seiwa glue. It has a long shelf life, dries at the right rate remains flexible and locks on. For a long time I used a hand awl for the stiching holes, but now use the prongs you can get from eBay. Get a 10 and a 2 one. You will need the small one for curves. Think how you use the leather, I try to get matching patterns for both sides, if it has these. I use scalpels rather than knives etc. These are just my ideas, the rest you will pick up easy enough. You sure won't have any problem with Christmas presents...In my view nothing sets off an old watch like the band. Here are a couple more. I like the orange ostrich, but I think I am alone here. And thanks again for the kind words.2 points

-

I finished painting the dial quite some time ago, but was searching for the right combination of components to put it all together! I hope you guys like it, if not, at least, find it interesting! Yes, another Hamilton pocket watch movement converted into a wristwatch. Also, These cases are quite nice and are very well made. The strap is a dark blue crocodile grain leather.1 point

-

1 point

-

Holy crap. Replacing a battery on a Garmin golf GPS is a real PIA. Not really watch work, however, I am an electrical engineering and I can solder. Sent from my iPhone using Tapatalk1 point

-

1 point

-

1 point

-

You have to pla e it on the pusher stem, while pressing the pusher itself. Then, let slowly the pusher go outwards until it locks the c-clip against the case. I use a small piece of rodico under the pusher so that if the tool slips it won't scratch the case and if the clip falls, it will be caught by it.1 point

-

The 'do not unscrew' screw is no great mystery, It's gives access to the setting lever, as the watch is de cased from the front. But what was i originally going to say? oh yes, really nice watch, I'm jealous only I too share the problem of some others in that I cannot wear large watches, appreciate? yes. wear? no.1 point

-

If you search on this very forum there are various discussions about Chinese machine with pro and cons explained.1 point

-

1 point

-

very nice tool ! it is a good way the make the flat sides paralel. a usefull tool to find [ or invent] would be one that hollow ground the tip before honing. part of the concept of "100% contact in the slot" vinn1 point

-

1 point

-

Nice watch if a little on the large side for my taste. I do have another problem with it too. A mysterious screw in the middle of the back with a label that says "do not unscrew" would be too much for me to resist. It's like having a big red button that says "do not press"... you just have to to see what happens!!1 point

-

1 point

-

like it, us Northamptonshire boys must have a funny sense of humour1 point

-

1 point

-

To be honest I have always considered reaming to be a little on the aggressive side when it came to addressing the issue of blocked lug holes. I have always found syringing by my GP to be quite satisfactory...... Sorry, the topic title was just an open invitation and I couldn't resist.1 point

-

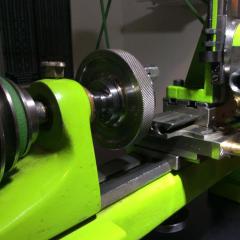

I spent the day literally watching paint dry. I was using black lacquer to fill in the engraving on a pocket watch case to make it stand out. I will send pictures when it is finished. In the mean time I was looking for screwdriver sharpening stone holders on the net. The sticker shock was amazing. So i said to myself, "Self" your only watching paint dry, make your own, you have a sharpening stone and some wood. So I made this from scrap wood while watching paint dry. I'm happy with it & it cost nothing. It is perhaps not as pretty as Bergeon but they have enough money.1 point

-

wow, nice chart, i copied for referance. with some minor math you should be able to select the amount of dome on a hunting case acquired with no crystal.! measuring the opening in the bezile accurately is the next step. good luck. vinn1 point

-

1 point

.jpg.6225a64433578a11e0218b27c20b13f5.thumb.jpg.d82b0cd1e370f3a3a59a06afa957d184.jpg)

.jpg.8a21c5bda26dd240cf8d9417ecce3edf.jpg)