Leaderboard

Popular Content

Showing content with the highest reputation on 10/08/16 in all areas

-

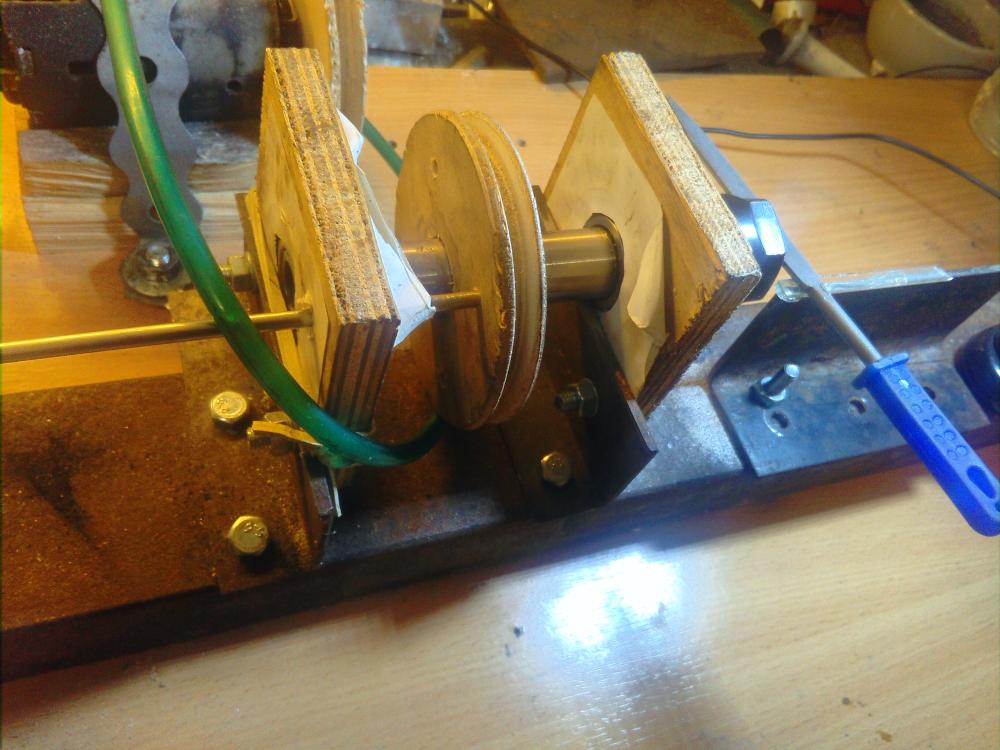

A friend of mine asked if i want to make a stem for him. I have improved my hardware and wanted to try so happily accepted Not in the Dremel now. Here the pulley wheel is serving as a dividing plate with 4 holes making sure that the rectangle cross-section will be perfect. Turning with help of a microscope, no loupe at all. A thin glass strip is hot glued on the "T-rest" which has two purpose. The file is sliding on it easily and it is making sure that the sides will be parallel. Still a lot to file down. The workpiece is a spoke of a Chehoslovak Favorit road racer. Even tungsten carbide is softer if hardened.4 points

-

Looks like Bob has cracked it see below: http://www.ranfft.de/cgi-bin/bidfun-db.cgi?00&ranfft&a&2uswk&Venus_1502 points

-

It's a microphone pick-up for a timing machine. Not much use for anything in its own right but if you can find a way to hook it up to your computer sound card then it would be great used in conjunction with svorkoetter's Watch-O-Scope timing software. Check out this thread.1 point

-

1 point

-

I recommend...prices , shipping costs and customer service are great . http://oldswisswatches.com/Spares/Landeron_Mechanical_Movements.htm1 point

-

Go to a watchmaker and have it pressure tested? Then you can have some relief. And you don't have to think about it for some time?1 point

-

1 point

-

Be careful gentlemen, stay safe, this one is reported by the Weather Channel as being one of the nastier storms.1 point

-

I still thing it is a Venus since the landeron doesn't have the wheels with "columns" as in the parts picture...but.... How about Venus 175? Check this out: http://www.phase-de-lune.net/polo/venus175.htm If the eyes are at 3 and 9 then it should be a 140...hopefully.1 point

-

Hi Tim, We got it already...it missed us for 20 miles. It looked kind of lost looking for your address! I was ready for anything and wearing my tuna can Seiko! Those watches are notorious to inspire fright on Hurricanes and such. That's the reason it backed up in the last minute! In a serious note, I hope it goes easy on you guys. This is a huge hurricane that has already cause a lot of deaths and wreckage along its path. Stay safe! Cheers, Bob PS. It might still double back and get to us, they say! Not taking my tuna can Seiko off yet! and...I didn't give it your address!1 point

-

Only way to tell is checking the actual gasket. If it is still flexible and not deformed, a coat of silicon grease and back in the watch would be enough. Now, they are not expensive and I normally put new ones regardless when I service a watch. BTW, 3 years might still be ok but it all depends on many factors so if in doubt just check it and/or replace it. Normal use would be check after about 5 years...I do every 2 when in the watches I dive or fish with, and even less if I suspect anything or have a slight doubt...but then there is the machine to test for water resistance....1 point

-

1 point

-

1 point

-

I believe that's a Landeron 48 or 248. Not too uncommon so parts shouldn't be too difficult to come across. You could probably find a parts movement on eBay for a fair price. Interestingly the bridge piece in the tin goes to an Excelsior Park movement. They were often used by Gallet and Zenith in the 40's and 50's. I've been dying to get my hands on one for repair but haven't just yet. EP movement parts are hard to come by so you may have a little treasure chest there.1 point

-

1 point

-

1 point

-

Thanks Bob not in the US, but I buy a lot of stuff from Ofrei, the small packet postage is not too bad, and arrives quite quickly. Speed is not an issue though, working on watches has taught me patience over the last few months cheers dan1 point

-

Try ofrei.com...assuming you are in USA...otherwise the shipping will be too much.1 point

-

1 point

-

Somehow I responded to the initial inquiry without seeing your latest pictures. It appears the hairspring is either magnetized or sticky (from the last picture it certainly appears that the coils are sticking together to the left of the balance staff). If magnetized, a demagnetizer will fix that problem. If sticky then I definitely suggest One Dip. If you feel comfortable, you can tap the hairspring coil with the tip of your tweezers (touch just the outermost coil) to see if the coils stick to one another when they contact. Keep in mind, the balance and hairspring is the heart of the watch so only do this if you have the skill of a heart surgeon (If you've followed me on this forum, then you know I've killed a hairspring or two). Possibly the hairspring wasn't completely rinsed of cleaner or your cleaning solution has been contaminated with oil.1 point

-

I've had an old blue steel mainspring break into three pieces the day after it was installed. Never had an issue with a new one though. Anything is possible though. The labor charge is exceptional even given your business association. Replacing the mainspring involves tearing down just about the entire watch. With that much effort involved in stands to reason a complete clean and lubrication would be advised. That is a gorgeous watch by the way.1 point

-

ordinarily i'd agree,old hippy, but at a labor charge of £5... you might wipe out the poor guys entire profit on the job.1 point

-

A little confused on your first point, you bought a watch and got a refund without returning the watch? Anyway it all depends on those aerospace movements, they're all listed as 'breitling <double digit numer>' could be that they're effectively re serial numbered ETA's, you see that sometimes, or it could be that they are indeed, made in house, which wouldn't surprise me, if that's the case I don't think any independent will be able to acquire the requisite parts to effect a repair, if movement parts are faulty. Maybe someone knows something I don't, though.1 point

-

1 point

-

Well while we are at the confessional, this in from our UK correspondent today (in my defence it's my first every strip down and service attempt) Sent from my iPad using Tapatalk1 point

-

Well its been a while since i shared a post and i thought id share a mini project with you splendid folks as i know you all like looking at new and shiny things Ive spent several months working away almost non stop on various repairs and services, so when i finally had a chance to clear my table i figured id get stuck into a small project idea i had. When i set out with a specific idea/design in mind i usually write down every dimension and draw up diagrams and spec sheets etc, but i figured for this project id just play it by ear, or eye in this case. I was working on a pocket watch movement when it occurred to me how boring ( although reasonably functional ) my movement holder was, and i thought to my self why not make my own. With some metal stock lying under one of my cabinets i got to work and just lost myself in my machines........... Top corner is my trusty albeit ragged holder, with parts machined by eye underneath..apologies for lack of focus After a clean up and light polish ( lets not go too crazy it is a tool after all ) i got round to assembling the holder and setting the bar shims and threads with some Loctite > As you can see i didn't go too crazy with the finishing of every piece as it is going to be put to work but i think its an improvement over the standard el cheapo i use for large movements. As i used thicker parts overall , the holder is much more rigid Im sure i will likely be making some more in the near future but im going to design them next time rather than play it by eye I do like Bergeon Holders but nothing quite beats something you made for yourself . Next project is a new tweezer/forcep stand for my trusty Dumonts ( For those interested in boring details > M4 Threaded centre stainless steel > 12mm Free Machining Brass Knurled knob & retainer screw > 6mm Brass shims > 4mm Brass sliders with M4 threads 3mm long >2 x Aluminum flat bars machined in mill and hand finished angle ZZZzzzZZzz )1 point