Leaderboard

Popular Content

Showing content with the highest reputation on 05/21/16 in all areas

-

Hello, I just finished this Lorenz chronograph with a 17 jewel ETA 7750 powering it. I had some rough patches when I lost the chronograph wheel friction setting and the hour lock. I ordered new ones and things went OK until I misplaced the hour counter wheel and had to go back in. After that I adjusted all the settings, which took removing the chrono wheel, hour counter, and minute counter hands twice to get them perfectly centered and resetting properly. Now I look at the crystal and my confidence wavers because I've never changed a glass crystal and this one is curved. I have all the tools needed, but would like not to break the crystal removing it in case a replacement turns out to be a challenge. Any input is appreciated. I'm not going to post all the pictures of the overhaul because @Lawson has done that to perfection already. Thanks to @Mark for his excellent video repairing the rusty Breitling whose owner was pushed into a pool. JC2 points

-

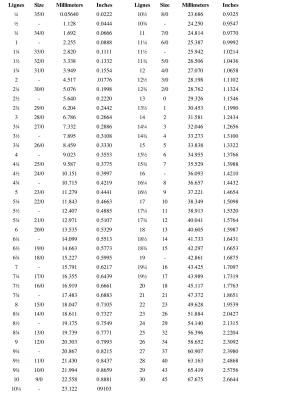

vernier calipers AND special micrometers are required to order an after-market crystals. original pocket watch crystals may be the same. so that the crystal is held as a "press fit". polease correct me if i am wrong. the test is try to turn it in the case ( wrist or pocket watch). Vinn2 points

-

2 points

-

1 point

-

1 point

-

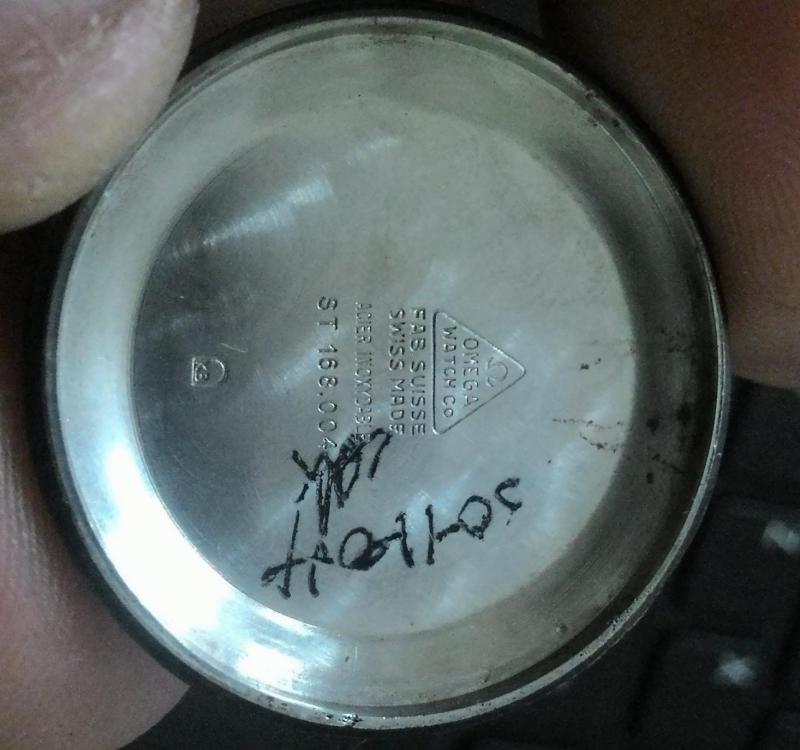

Hi All, Just got this Omega Constellation which is also known as a 'pie-pan' due to the dished dial. This is the larger cased version which is not as common as the normal sized Constellations and apparently produced for Japan, Singapore,Indonesia and Thailand markets (no mention of Malaysia , where I'm at!). It also has a hidden crown, not so common among Omegas of the period. It dosn't have a gold constellation on the back tho'. Now the interesting bit....Prior to this I have read about the 'landmarks' in Omega where they had produced consecutive batches of watches which passed the COSC test..historical because all the movements were consecutive. The three landmarks were a run of 1,000 (in 1949), 20,000 (in 1959-60) and 100,000 (1964-66). When I got the watch the first thing I checked was if I had gotten lucky and 'scored' one of the watches from the batch of 100,000...Well the batch of 100,000 comprised of movement serial numbers from 24,410,000 to 24,509,999...as it turned out I got lucky! My watch has the serial number of 24,422,084 which is the 12,084th of the batch of 100,000. Movement runs well but I think it could do with a clean..the plates look a bit tarnished, hopefully a cleanup will improve it. Also the rotor has been changed as the colour doesn't match. No real issue as this was probably done back in the day when function overuled cosmetic appearances, I'm just happy that it was swapped out before the worn pivots marked the main-plate/bridges. I do have some other 5xx movement so I may swap a more appropriate one here. The balance bridge is also the same hue of the rotor but I don't think I'll mess with it for now. cheers! Anil1 point

-

1 point

-

1 point

-

1 point

-

An excellent find Anil, Pie Pans are among my favourite timepieces.1 point

-

Not really, There are only two parts that can fail in quartz watch, and one (the coil) can be diagnosed with a common multi-meter ($10). No more knowledge than turning a knob and reading a display is needed. Sometime the parts are available but if it's a cheap movement as in most cases is, it will just cost few dollars to replace. Quartz watches are easy and fun to learn with, although most collectors and watchmakers look down on them.1 point

-

Excellent advice from Anil. I would also recommend a cheap, working Russian movement - Raketa, Vostok, etc. to play with. They're generally cheap'ish and quite rugged. A small Molnija pocket watch is a nice size to play with as well. And, while I'm banging on about it, don't disregard Indian HMT watches. There are lots of them on eBay, they're basic, standard-style movements, and it doesn't matter if you crash and burn on them!1 point

-

Take the bezel of, pull the stem out to the setting hands position, I can see the case screws are out so just gentle push the movement out a little from the opposite end of the stem this should start to release the movement from the case.1 point

-

Soak it in acetone Bob, it works a treat.1 point

-

Hi Jesmond If you want to learn about watches, taking them apart and putting them back together again... start with a watch that's already working. No point wasting effort on something that may baffle an expert. There are quite a lot of tips and tricks on the internet and Marks videos will give you the confidence to get going. Russian watches are robust and can be had cheaply off the net. You'd want something like ths.... http://www.ebay.com/sch/i.html?_from=R40&_trksid=p2050601.m570.l1313.TR0.TRC0.H0.Xlot+of+russian+movements.TRS0&_nkw=lot+of+russian+movements&_sacat=0 Seller says that the balance is OK and the watch will run if shaken. This is a good sign as it probably means that all it needs is a good clean and oiling. USD 7 for shipping is fair. For these simple watches you will need. 1. A GOOD pair of tweezers.. cheap ones will only frustrate you. I can't stress this strongly enough. 2. Good screwdrivers.. not as critical as tweezers but get some from a watch supply house specially meant for watches. The ones sold in flat plastic cases at general stores is pretty much useless. 3. Lighter fluid to clean parts (ronsonol or zippo works), and a small cup to hold said fluid while cleaning. 4. Pegwood .. this is a special type of wood used to clean watches. You sharpen the tip and use the pointy bit to poke the tiny jewel holes to cean them out. Pegwood is a special wood that won't splinter easily. Don't try to use those cocktail sticks, a splinter in the jewel hole is not good. 5. Rodico. This is a special watchmakers 'plasticine'. Typically green in colour. Faber-castell blutack is the same shade but useless for watches as its too 'oily'. Rodico is a great help for cleaning parts and picking up stuff like cap jewels. 6. Pithwood...another special wood that is used to clean pivots and the tips of your screwdriver/tweezers. Not strictly necessary .. I use Rodico. 7. Oils... you will need a light oil for the jewels (moebius 9010) and something heavier for slower moving wheels (moebius 9020). These oils are expensive so for a beginner you may use some cheaper oils like novastar. Also in the beginning you may find that your 'oiling technique' has not developed fully and you will waste a lot of oil. Finally 8. A good data-plan, help is just a click away on this site! Mechanical watches are good to learn on because they're ...well.., mechanical!. (I assume you have a bit of mechanical apptitude otherwise you wouldn't be bothered to walk down this road). Problem with quartz is that troubleshooting is only viable if you have the electronic equipment and the knowledge to use them. Once you've identified the problem, chances are the part is not available individually and you would need to replace the whole movement anyway. Personally I can get easily understand how any mechanical device works and even if I can't fix it at least I have a good idea of what wet wrong. But anything more complex than a DC motor I'd probably need help! I realize that the comments you have been getting may be a bit discouraging but it's done with the best intent. Hopefully you will find the same gratification in this hobby that most of us have! Looking forward to hear more from you. Anil1 point

-

Wearing my favorite Seiko 5, the SNKE63K1. Several weeks ago I opened it up to regulate it, messed it up a bit and then set it aside. Last week I put it back on the timer and got it nearly spot on - it's averaging about +2 seconds a day for the last week! I also ran the case and bracelet through the ultrasonic.1 point

-

@oldhippy Darn straight! This is the reason why I got into watch-repairing/servicing to begin with:) I work in I.T. and have well over 300 watches in my collection but do not have the millions needed to service them all since I do work in I.T. All joking aside, that really is what got me into it...I had so many watches that were in need of a service and once the crown/stem popped out of one, that was the end of my "non" watch repair days! Over a year later, I have not come up for a breath of air. ALL my free time goes into this and I am more than happy doing it on a daily basis. I envy the fact you worked on clocks for a living, awesome job to have, especially when I cannot get enough of the hobby!!!!1 point

-

I've attached an image out of the eta manufacturing information with the timing results they expect from this watch. The problem with waiting long periods of time before servicing your watch is a variety of problems can pop up not always visible on the timing machine. For instance rust because the gaskets breakdown with time especially on the crown. Rust makes a really nice grinding compound. Then of course the lubrication's don't last forever they can do a variety of things usually none of them good over time. Then it just depends on how much you using your watch taking out occasionally couple times a year conceivably might never have to service the watch ever again they're just not going to be enough where. But on a watch being worn on a daily basis past five years and a little moisture the cost of servicing will go up considerably conceivably reaching a point of time where the watch grinds itself to dust and I can't be serviced.1 point

-

1 point

-

Hell fire my tablet writes what it wants. I would find a donor if rest of the watch us fine.1 point

-

I was diagnosed with Dyslexia which is very poor short term memory. However the technic I was shown many,many years ago & this worked for me. When reading an article read it through once then read again BUT hand right down the relevant points as you go & some how it just sticks in the brain box.1 point

-

I absolutely agree with you, but as I had no smoothing broaches I decided nevertheless to risk the job very carefully and by successive attempts with the smallest reamer I have. I think I managed to sucressfully put the roller on the staff : So, finally, it was time to go on with the assembling of the movement whose story I began here: http://www.watchrepairtalk.com/topic/3784-a-cauny-with-a-landeron-248-to-service/1 point

-

Pm me your name and address with all the parts you want for this movement and I will send you what ever you need, got loads of parts for these in my graveyard box.1 point

-

I am with Geo on this: had the same issue on a Landeron 248 movement I got for spares and then decided to fix. Old oil was blocking the balance wheel to turn properly, so I soaked for a couple of hours in the liquid I use to clean parts ( alcohol or spirit as some may call it) and then disassembled the jewels, to find out black stains of oil. A sharpened toothpick was used to remove all the solid material and an ultrasonic bath did the rest of the cleaning.1 point

-

If there was any hard dried old oil left in the jewels after cleaning, it may have expanded when you applied fresh oil. One of the first movements I worked suffered from this. A thorough clean as described below fixed the problem. Soak the main plate complete with balance attached in a jar of lighter fuel for twenty four hours to soften the dried oil. Now place the jar in an ultrasonic cleaner and give it a blast. Since doing this I have never experienced any problems.1 point

-

That's good advice from JiminOz. Another thing that can reduce amplitude is oiling the pallet fork pivots. The drag from the oil can retard the incredibly fast action that is required to give a strong impulse to the roller Jewel on the balance wheel.1 point