Leaderboard

Popular Content

Showing content with the highest reputation on 03/27/24 in all areas

-

This video demonstrates how to hold a burnisher comfortably, safely, and efficiently for burnishing a wheel pivot in a Jacot tool—a huge thank you to @nickelsilver, who generously shared this information. I can’t thank you enough! https://www.watchrepairtalk.com/topic/28602-longines-balance-staff-pivots-are-they-too-flat/page/2/#comment-2418876 points

-

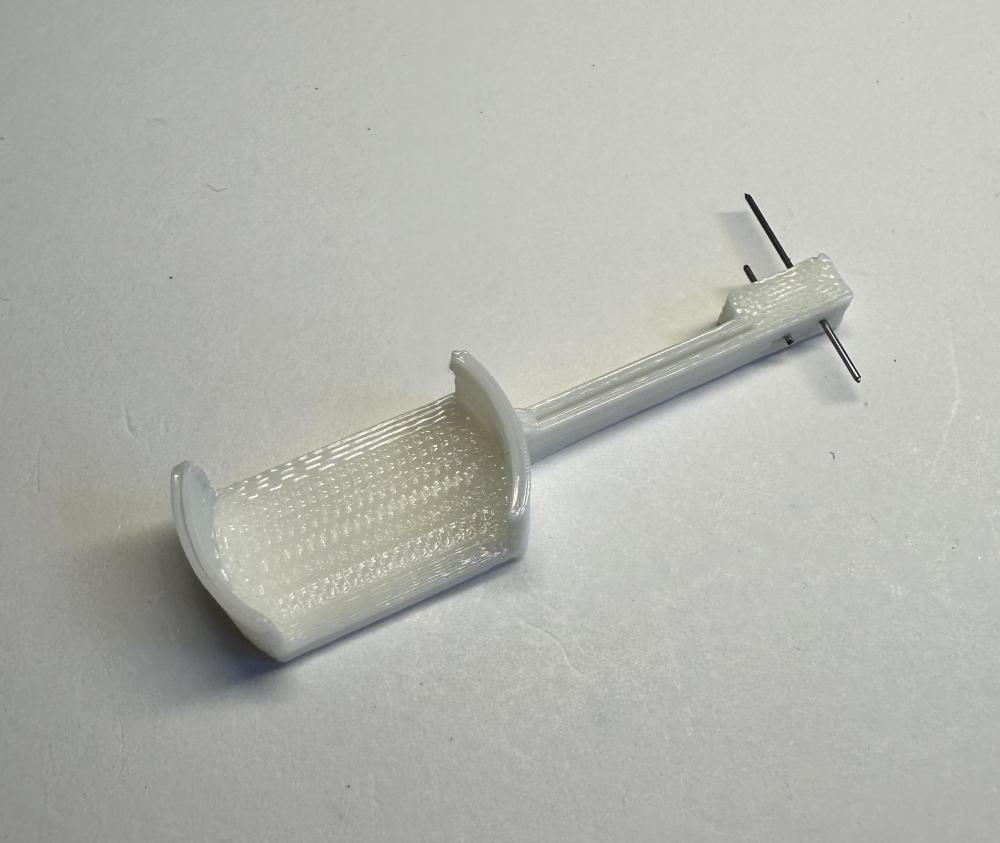

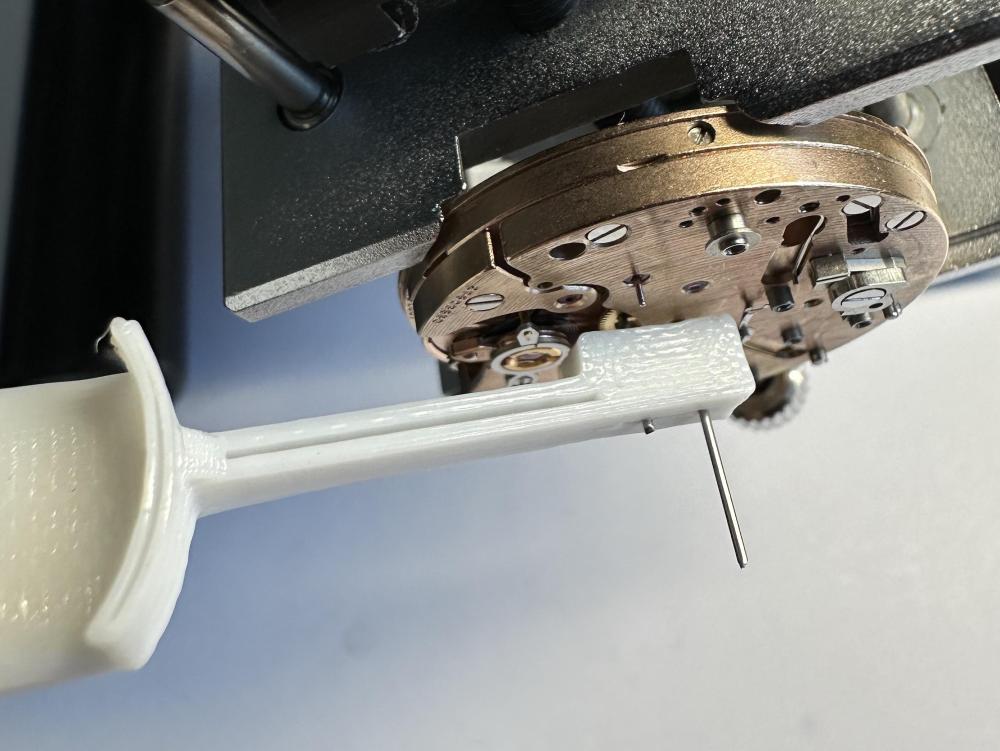

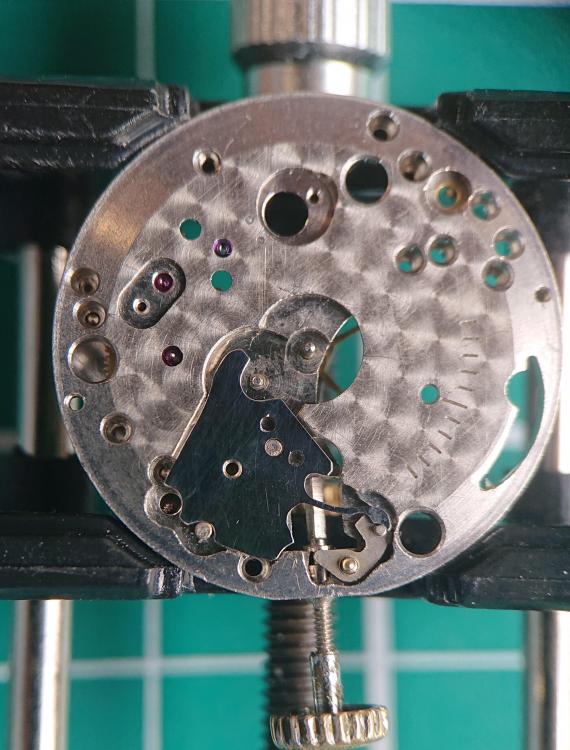

Over the last weeks I followed VWatchies thread about his ETA 2763 showing erratic amplitude: https://www.watchrepairtalk.com/topic/28929-serviced-eta-2763-having-erratic-rate-and-amplitude/page/4/#comment-245378 I have a similar problem on an Omega 861. The base movement shows alternating amplitude in both horizontal and vertical positions. The range is more than 25 degrees, no periodical behavior, pure random. In the above quoted thread there was a lot of talk about the regulator pins, hairspring, collet, geartrain, etc. and I do not doubt that all these may be sources for the problem. However, I couldn‘t get one question out of my head: Can the problem be on the other side - mainspring, barrel, ratchet wheel? Some kind of error which prevents the barrel from delivering constant torque to the center wheel? To find out where to look I built the following setup: I assembled the movement without barrel and ratchet wheel. Then after some research and calculation about torque in the geartrain I 3D-printed this part and completed it with an axle and a pin. The movement in a well chosen vertical position. Please notice the spoke of the center wheel. Now the „torque generator“ is fitted to the center wheel. The axle is pushed into the pinion and the pin is lying on the spoke. Finally I have to choose the correct weight to get a torque which results in an amplitude in the area of 280 degrees ( yes, watchmaking is an expensive hobby - my 2 cents). And that‘s all. When the lever is in nearly horizontal position this setup provides a nearly constant torque on the center wheel for several minutes (I assume you live in an area with constant gravity). For me this one answered my question. The alternating amplitude was gone, less than 4 degrees fluctuation now, which is always the case with my Weishi. So the source of my problem is somewhere in the area of the barrel - will work on that the following days.4 points

-

3 points

-

2 points

-

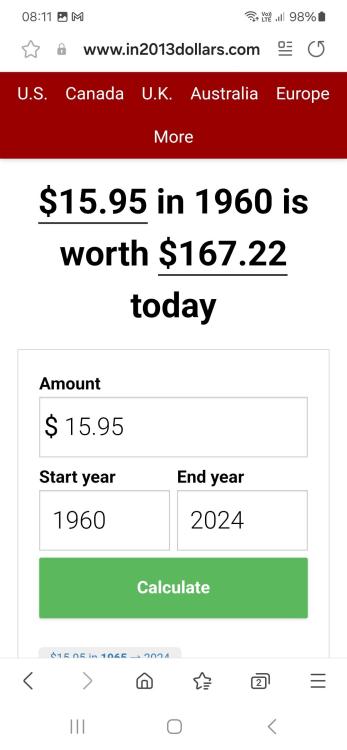

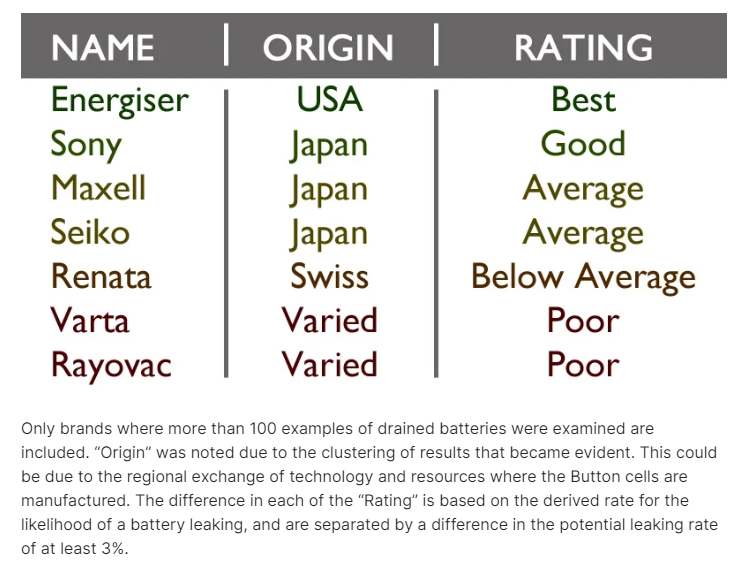

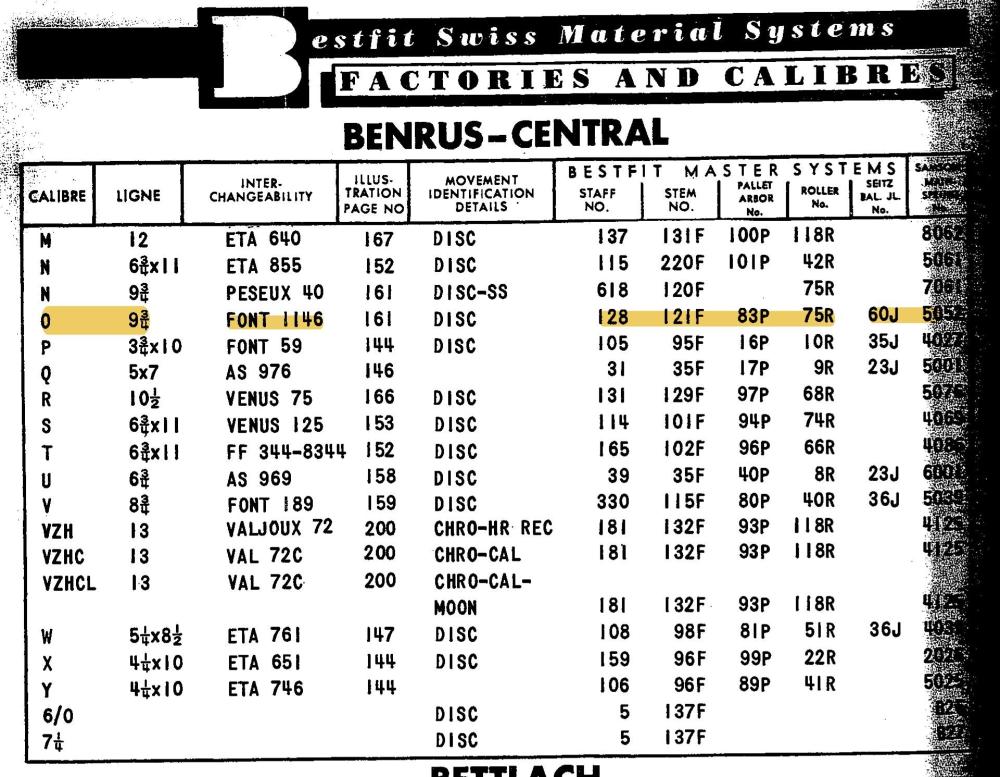

The chart is what I was referring to when Google didn't come up with anything useful for "EnergiSer". Great to hear because I already have a bunch of Renata batteries I'll do some research before I place my next order though. Not that I don't trust you but just to see what I can find.2 points

-

Hi guys. I have used Renate batteries for years and only had one failure and that was no leak it just packed up, replaced FOC of course. I think we must not get **BLEEP** about batteries and surveys because as @Neverenoughwatches said who wrote the chart and who did the survey and who sponsored the survey, probably energiszer . @VWatchie if you have used Renata for years and no problem why switch just because some one wants you to buy their higher priced batteries. Batteries no matter what make even car batteries have a shelf life depending on storage conditions humidity levels, heat cold all will effect the life. Indeed I have purchased the odd car battery in the past that packed in in short order. You buy a battery through many dealers and the price depends on the dealer. The same Exide battery purchased via your local motor trade shop is more than likley tens of pounds cheaper than the main dealer or the AA, RAC, etc. it’s a question of choice, I don’t intend to change just for the hell ofi it. Based on my experience Renata are as good as any on the market regardless of price.2 points

-

In the repair book by Charles Terwilliger diagrams show you where the fork should be on the suspension spring follow that and you shouldn't need to keep moving the fork up or down beside by playing around you can easily kink the suspension spring.2 points

-

Hey great job! Now you have the best vid on Jacot use on Youtube!!2 points

-

2 points

-

2 points

-

A few months ago I was looking for a video that explains how a mechanical watch works. Long story short - I watched a few videos, was intrigued, bought some tools and a few movements and started a new hobby. I have thus far learned to disassemble and reassemble/oil an ST36 movement as well as a NH35. I have also made a few watches with those movements. I now find myself what next. I would kind of like to learn to repair pivots, build my own dials and cases, who knows. But I have very limited space so that creates a bit of an issue. The other option is to learn about more complex movements, such as chronographs. Just wondering what the logical next step is (assuming there is one).1 point

-

Repairing pivots generally means larger and more expensive equipment, plus a lot of practice! In the meantime, try getting a mixed job lot of watches from ebay and see what you can do with them? Different makes and eras of movements with different features etc. to work through.1 point

-

Thank you @VWatchie for the excellent and clear video. Also thanks to @nickelsilver for the comprehensive information that led to this video. Tom1 point

-

1 point

-

Agree, this setup cannot spot long term effects. But in my case the alternation was quite fast, about 7 peaks in 5 minutes. Btw: Endeavor was right. Bearings in the bridges were ok but barrel and cover itself have excessive sideshake to their arbor. Ordered a nos one.1 point

-

Hi We all know why they leak and what causes them to leak, therefore we avoid the causes. We keep them in environmentally safe conditions. I have witnessed a leaky battery that cleaned up ok and still worked but I have also see a watch where I removed the back an all there was left was a crusty deposit that’s how bad it can get @RichardHarris123i doubt you will find any meaning full data as each manufacturer will keep his failures out of sight. Most of the batteries are constructed from the same or similar materials and the most common cause of failure is the separating membrane breaking down , gassing causing pressure in the can and breaking the seal, end of story. Whether you would ever ge5 an un biased report is doubtful1 point

-

Haha check your predictive mate , I've already been pulled up for that today, i was being too ambidextrous with my spelling thanks OH just needed you to confirm that for us Multi handed ? If you have more than two hands then errrm yes that makes you wierder still Richard in fact extremely wierd1 point

-

1 point

-

I would say for sure! The source of a problem can be super complex to find and can of course also be a combination of errors that together cause the symptoms. Fault finding by function group or elimination as you do here is most of the time the only way to pinpoint the cause of the problem. Generally, it is my impression that we tend to underestimate the importance of investigating and if necessary remedying problems with the mainspring, barrel, arbor, and/or the barrel bridge and mainplate arbor bearings. I must say I was impressed to see your 3D-printed part for eliminating problems beyond the mainspring-related parts! BTW, the ratchet wheel has no role in the performance of the movement. Its only role is to wind the mainspring1 point

-

Yes, same as with my 861. The 861 has a problem with wear of the arbor in the barrel bridge and the spring barrel self around the arbor can be worn; a common problem with the 861. In my case, the wear of the arbor hole in the barrel bridge wasn't too bad, but combined with the main-spring barrel, I had all sorts of problems. Luck had it, that there were a few cheap (€120!) 861 NOS barrels+arbors on eBay and I snapped one up....... that helped a lot. I still have a wave-line and amplitude fluctuations, but on the wrist the watch has gained no more than 2.8 seconds in 2x weeks. I checked every day for consistency and it runs rock-solid. I will try to find the thread in which we discussed this 861 wear-problem. This is a part: You could ask the seller if he has some more: https://www.ebay.de/itm/2045941171991 point

-

1 point

-

1 point

-

We had a young guy in (many years ago..) who wanted to change careers from photography to watchmaking. He worked out an arrangement with my boss at the time to work as a sort of apprentice, for a small wage. Boss wanted him to learn filing, as one does, so showed him how to hold the file, how to make proper strokes- this was a "full size" file, mind you, all that. Gave him some parts that needed a few licks here and there (like deburring on large stuff) and left him to it. Came back 30m later and all parts were destroyed. What the?! Boss: "Please show me how you did this" Kid: (starts filing wildly) Boss: "That is not at all how I showed you!" Kid: "But you're right handed- I'm a lefty!" It definitely wasn't an issue of which-handedness. Ended up he couldn't follow instruction on anything. He didn't last long. And that boss was an absolutely marvelous teacher, very methodical , descriptive, and always demonstrated exactly how it should be done. Side note: One of the best pivoteurs I know is a lefty. But he actually uses the Jacot with burnisher in the right hand. You guys are a weird bunch.1 point

-

1 point

-

Can't you just rotate the Jacot tool 180° (work on the other side of it) and get yourself a burnisher for left-handed people, for example, the Bergeon 2933D? Perhaps that is what is different or am I missing something? In the video, I do mention there are two types of burnishers for those who are either left-handed or right-handed.1 point

-

Plus, Vostok movements are Swiss in their construction, so nothing odd about being Russian! Everything you learn when working on cheap Vostok movements can be applied when working on the more expensive Swiss movements such as ETA, Sellita, Unitas, Omega, Peseux, and so on.1 point

-

Indeed! That's why I have been buying Renata (Swiss quality ) batteries for all replacements. No more. Next time I'll go for Energizer (with a z). Thank you!1 point

-

Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement.1 point

-

dnhb Okay all I repair & restore are torsion ( Anniversary) clocks altering the fork height alters not only the amount of rotation but also the supplementary ark ( amount pendulum turns after escape), there is a so called sweet spot for fork position, .to low it flutters to high it won’t run , there also must be a very small gap between fork tines and anchor pin when fork fully left or right ( I use a slip of paper ), the most important thing is supplementary ark not total rotation, I start by getting the clock to run with fork to low ( but fluttering) then raise it 1/2 to 1mm if it still flutters then I raise it a bit more until it runs but without fluttering, I must also stress that as these clocks are very marginal on power then everything must be as friction free as possible and as someone said get the Horolovar 400 day repair guide but be aware there are quite a few errors in it including wrong dating . I restore lots of torsion clocks for other clockmakers because most won’t touch them but I love doing them and yes they can be frustrating at times but that’s a challenge for me , if you need help just ask. i do not use oil on the fork, anchor pin, escape wheel or anchor and I use thin Mobil 1 engine oil on mainspring ( not grease ), watch oil on pivots . Dell1 point

-

Hello and welcome to the forum, the only problem starting with a non runner is that when done if it still doesn’t run you won’t know whether it was a non starter from the beginning or whether you did somthing to it. Best to start with as runner that way you know if it’s dead when you finish it it’s you fault. Added a little reading to get you started. TZIllustratedGlossary.pdf1 point

-

1 point

-

1 point

-

It should be as you see in the photo. watchweasol has told you about oil this is to prevent friction and it prevents fluttering.1 point

-

You also happen to pick a bit of a weird construction. Not knowing where you are on this planet, but you could try to find a few cheap Vostok movements (2409 or 2414) to learn on. The are cheap to get and the world is full of spare-parts.1 point

-

1 point

-

1 point

-

Well I have around 30 years experience restoring clocks and watches. I have serviced many floating balance movements and always added a tiny drop of oil to the floating balance,not only Hermle but Smiths it improves the rotation of the balance and I have never had any come backs.1 point

-

The floating balance should be oiled, just a tiny drop of watch oil at the top jewel so it runs down the wire. You really need to get to the mainsprings as they are the source of the power.1 point

-

For cleaning up some dials, black for tough finished grubby dials , white for light cleaning of delicate dials and pink for inbetween .1 point

-

https://ranfft.org/caliber/4167-ETA-2788 2788 Date 2789 Day and Date 2789-1 Day (2 languages) and Date Follow what you have for the 2789 and you will be fine.1 point

-

Ricoh has a similar pallet fork Tressa 1970s ETA 2788 Unusual Grey Sunburst Dial all original except for the crystal Running really well for its age, + 0.5 SPD, 300 degrees amplitude horizontal after 12 hours. I have another crystal arriving next week with a wider tension ring that I hope can hide the gap between the dial and case (XAC 321.577). Wide tension ring crystals appear to be few and far between so if anyone has any tips for a good source then that's most appreciated. I did look at ATCB range from Sternkreuz but they seem a bit higher than I would like based on the dimensions.1 point

-

1 point

-

1 point

-

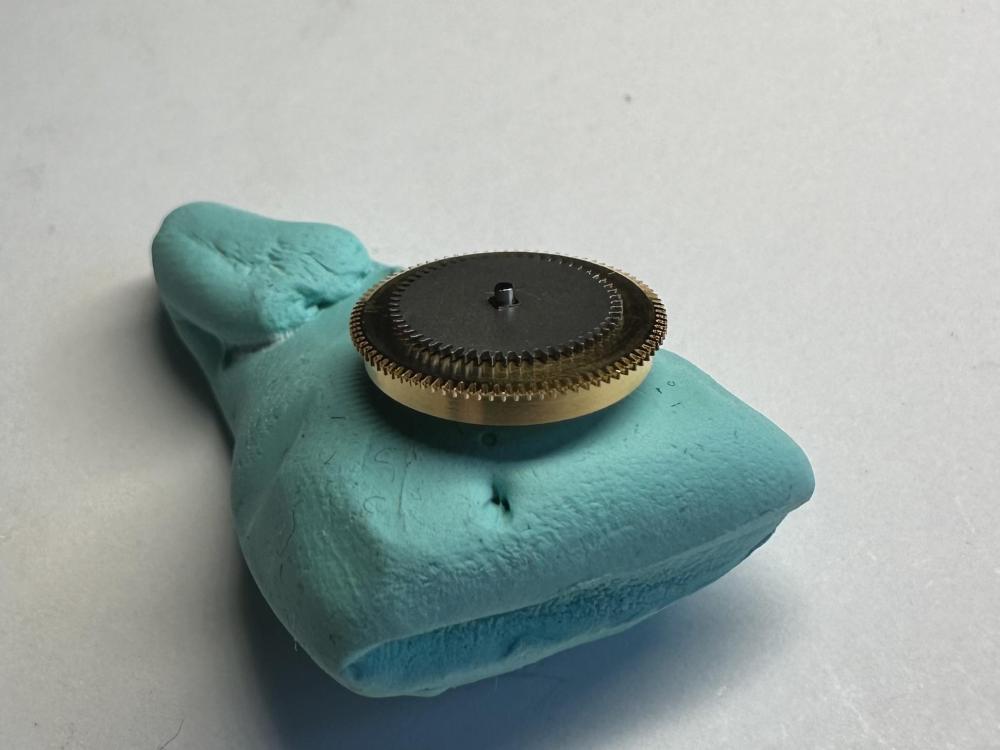

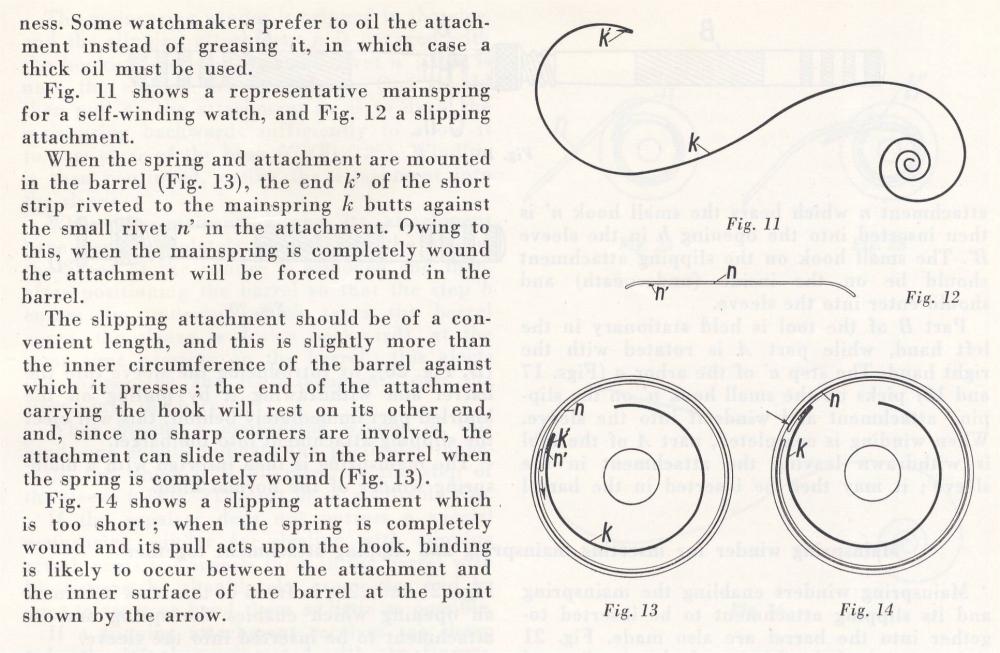

Somewhere in the discussion group in the past someone had a special set of the winders for the inside piece. That's because a lot of times it's much stiffer than the regular spring and getting it in is a pain. Then you still need your breaking grease on the outer barrel wall. Then once the inner pieces in that gives you something to hook the standard spring. Going to my images I knew I had something but turns out I have two images.1 point

-

Thanks for the tips everyone. I went with the feeler gauge option as it was to hand. Rather than risking the temper I used a mini angle grinder (plus constant cooling) to cut a rough blank, then carbide drills and diamond files to drill and shape the part. I tried scribing the shape on to the part but eventually having scribed a copy as a template I glued it to the blank and worked on that: I changed the design of the detent spring slightly as the original obviously had a stress riser at its root. I couldn't match the exact shape of the detents but their positions are identical to the original. Time to check for functionality and fit: I bent the spring slightly (about 0.3mm at the tip) down towards the setting lever. It functions perfectly and feels smooth with a distinct click from one detent to the other, so I'll polish it ready to fit to the watch when it is cleaned: Thinking of stress riders I polished the cut edges of the spring with metal polish on the tip of a toothpick . It will be interesting to see if it lasts.1 point