Leaderboard

Popular Content

Showing content with the highest reputation on 03/25/24 in all areas

-

4 points

-

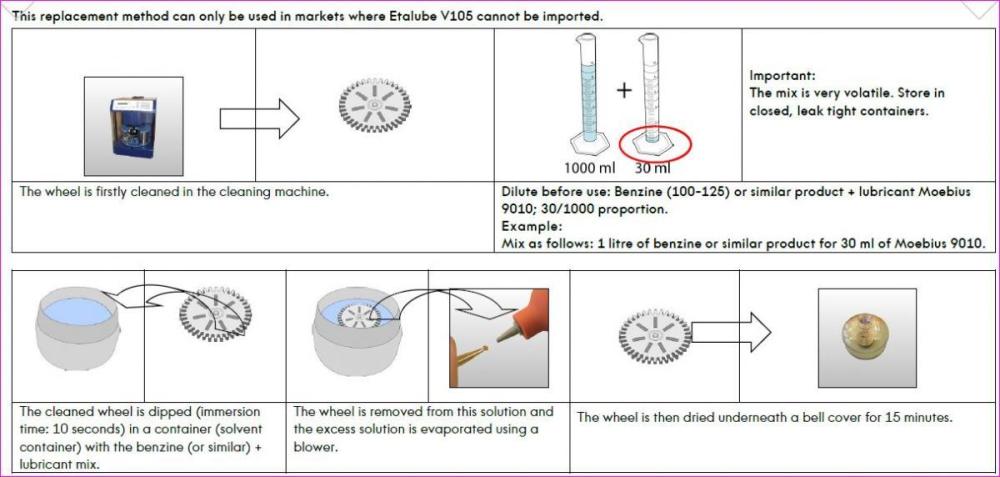

Ross for parts sheets for all watches, you will find them on Cousins https://www.cousinsuk.com/document, or another site I use is https://watchguy.co.uk/cgi-bin/files. The oiling is as every other watch . If you need help, see : ETA_2836-2.Asembly and Lube.pdf One problem I've had with the automatic ETA is the reverser wheels. If you don't lubricate them correctly, the winding can be VERY stiff (or they may just be worn). I always cleaned them and made my own mix of 1/30 9010/naphtha. But I've still had problems - the last watch was very stiff to wind. So I've finally bought some Lubeta V105 - fixed the stiff winding. It's not cheap but will last ages.2 points

-

So the movement was returned to home yesterday afternoon, and my friends who own it are delighted it's now running as is should. (I've not got the whole clock in, as when I was far enough away to see the full height, too much of the room was visible and I did not want to invade their privacy like that).2 points

-

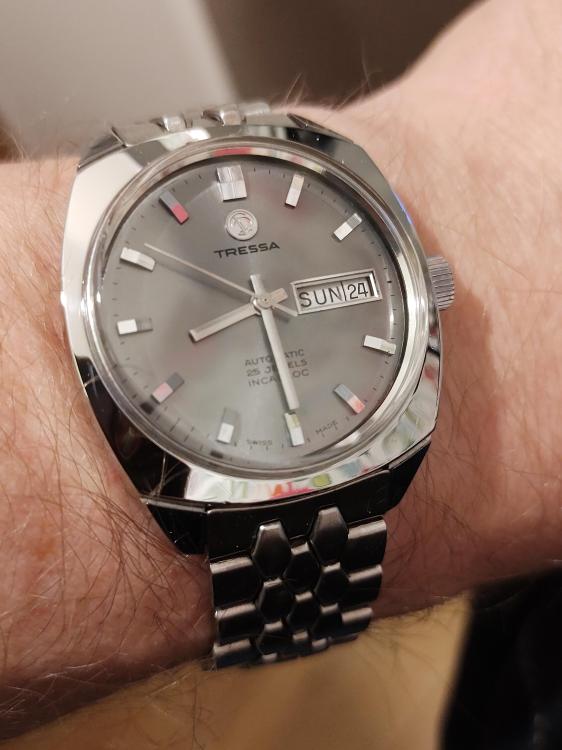

Marc. Thank you for the prompt reply and explanation. 2788 Date. 2789 Day and Date. 2789-1 Day (2 languages) and Date. You have given me the information I require. I have placed a notation of the ranfft in my favourites. I am very conversant with the 2789 and 2789-1 so will easily be able to do the service.2 points

-

2 points

-

If it's a thick case (diver), the signal can become too weak. The result is then often that the dots on the graph become more scattered (Weishi). Increasing the gain (Weishi 1900) a bit can then help. I've also experienced that the readings can become unreliable if the signal is too strong (noisy movement). This usually only happens when the movement hasn't been cased. TMs are very useful but can't always be trusted. In my opinion, a TM can't replace testing the watch on the wrist or on a Cyclotest watch winder.2 points

-

Hi. Moving the fork higher creates a shallow lock which leads to fluttering ( skipping teeth on the escape wheel) giving the appearance of the clock gaining. Likewise the lower it gets ithe lock gets deeper and will eventually stop th clock. If you intend to work on these clocks it is almost imperative to have at hand Terwilligers book on 400 day clocks . The 400 Day Clock Repair Guide cost around £30.00. The latest is the tenth edition. The book gives you the relative positioning of the fork on most of the known models of this type of clock plus a lot more. Definitly worth the money2 points

-

1 point

-

I could be wrong, but my understanding has always been that it was only quartz movements that ETA made in Thailand and China for sale in Hong Kong, not mechanical. Reading the interview linked by @Nucejoe actually reinforces this understanding. "Do you still have customers all over the world ? Yes, but we make about 60 % of sales inside the Swatch Group, followed by the rest of the Swiss industry. You have to consider that 80 % of the Swiss watches that are exported are fit with an ETA movement. Other customers come from Germany, Italy, France, the USA and there's a lot of business with Hong Kong where we sell the lower priced movements to. Some of these movements only cost 1.50 CHF ($ 1.00) including the battery. But even these are highly precise quality movements. Are these movements sold to European companies ? We need this type of movement in Switzerland too but we make them here and sell them as "Swiss Made". The movements made in China and Thailand are sold to Hong Kong. Does that mean that parts come from the Far East and are used in Switzerland ? "Swiss Made" is an exactly defined term. It means that apart from the assembly, at least 50 percent of the parts are made here." In his response to the first question above Anton Bally refers to movements that only cost 1.50 CHF ($ 1.00) including the battery. - So clearly quartz... The next question asks Are these movements sold to European companies ? - Being the movements referred to in the previous answer (quartz)... The third answer clearly states what "Swiss Made" actually means, i.e. at least 50% of the parts made in Switzerland and the final product assembled in Switzerland. I would suggest that if the OP's Accurist has Swiss Made on the dial then the movement is either a genuine Swiss made ETA movement or the watch is a counterfeit. I don't believe that Accurist has ever been much of a target for the counterfeiters. @watch3008 That screw is indeed left hand threaded and it should just unscrew. I'm pretty certain that it is in a blind hole so that it can't be tightened down onto the crown wheel as that would stop the wheel from turning so you can't access it from the other side. If you can only partially unscrew it then as @RichardHarris123 has suggested a little leverage (perhaps with some peg wood so as not to damage anything) under the screw head whilst turning it with a screw driver might be the only option.1 point

-

Well, this is esy to determine. For sure, it must be verry hard to impossible to rotate the staff in the balance arm. And the roller must stay firm on the staff and significant force should be used to rotate it. Mark the staff with marker and rotate the roller. The staff should not move, the mark must not change it's position. If the hairspring is on it's place, the studd position must not change1 point

-

That is very nice. You need a lot of space for that.1 point

-

I have used pink rubber erasers to clean battery contacts, as they are slightly abrasive. I have even used them to touch up the grained finish on some movement parts that were marked or stained- but that's hit-or-miss.1 point

-

Would need to see the movements to have much in the way of a clue.1 point

-

1 point

-

I have two large sets, both go from 0.38 to 1.00mm on the center runner. My colleague has a large set that seems a little older, but still new style frame with replaceable beds on the runners that goes from 0.35 to 1.20mm. I think you could order these with a choice of sizes; I've seen a number that go to 0.07 as the smallest, others that go down to 0.04mm. Some go in steps of 0.005mm on the smaller sizes, others in full 0.01mm steps. The set I use daily has 5 runners, with the 0.005 steps on the small sizes. The other large set (with center runner) has 4 runners, with the 0.01 steps. That one also has the height adjustable "headstock" (which I've never used other than to get it aligned). One of my small sets goes down to 0.07mm for the smallest size- but has doubles of 0.11 and 0.12mm- so yet another variation! I guess it was ordered specifically knowing they would do a lot of those sizes. I've owned a bunch of these (20?), but I'm not a collector, so I just "upgraded" as better ones came along and sold off or gave away the others. Something to really check on these is the concentricity of the headstock runner. The tiny (1.95 total length) staff I did recently was being a pain with pivots breaking in the Jacot. They weren't ultra small either, 0.07mm, and it's rare for me to break a pivot in the tool aside from just slipping with the burnisher or something. If the headstock runner isn't perfectly aligned with the bed, on very short parts the error is magnified; though it had been checked in the past I re-checked the headstock runner and it had a whopping 0.10+mm of runout! Got it true, next attempt worked great no problem. No idea how it got knocked out of true, but I work in a shared workshop and everyone is allowed to use my gear, so who knows.1 point

-

Well, I am not sure if the question is asked correctly. I guess that the word 'fork' is used for the part that is attached to the suspension spring and actually collaborates with the fork. I don't know what is the name of this part in English, but hope that if I call it 'leader' will not be much away from the truth... So, answering the question now is not simple, as this kind of clocks are something that is not straight forward to regulate, but the adjustments of one thing always leads to changes of the other things adjustments. Something more - this clocks are (according to only my opinion) something strange, and have not much to do with horology, but they are a more like a sort of attraction, to amuse and entertain the public... Now to the point. I will use some terms that I will name now. The first is 'minimal amplitude'. This is the amplitude of the pendulum swinging where the movement still works. If amplitude reduced, the pendulum will continue to swing by itself for about half hour and will stop by itself, but the movement will not 'tick'. The second is 'working amplitude'. This is the amplitude that will settle for half hour after the clock was started and will not change any more, the clock will work normally after that. The minimal amplitude should be more than 120 degr., usually about 150 or even 180 in some cases. If less than 120, then the clock will be not 'attractive'. Further more, the bigger amplitude means better isochronism. The working amplitude should be at least 10-15 degr. higher than the minimal amplitude. This guarantees reliable work. Also, this additional 10-15 degr. that pendulum makes after each 'tick' should be equal in both directions of pendulum swinging, this is of critical importance and is regulated by slight turning of the upper suspension. Now, the higher the 'leader' is placed on the spring, the higher the minimal amplitude will be. On the other hand, the working amplitude depends on the portions of energy that the pendulum receives with every tick and on the losses of energy for unlocking the escapement and from air and internal spring friction. So, the working amplitude has limited value and it depends on the main spring strenght and the escapement adjustment. The clock will work reliably if the minimal amplitude is less than the working amplitude. So, if no idea where the leader must stay on the spring, I will advice first to put it by eye, then check what the minimal amplitude is and correct the position of leader as to reach about 150 degr. for the minimal a., then check if the clock will work and what the working a. will be. And, if needed, to reduce the minimal a. by lowering the leader, or, if the working amplitude is high enough, to increase minimal a. by lifting the leader. The higher the leader is, the better isochronism will be. The things may seem simple by now, but they actually are not. This is because the lower the leader is, the risk of the 'fluttering' effect arises. Fluttering happens when the pendulum crosses the 'zero' position. So, checking for fluttering is when the pendulum has stopped - decline the leader by some tool and release it suddenly. If fluttering happens, then one of this 2 things must be done: making the escapement a little bit deeper (by moving the lever closer to the 'scape wheel or moving the pallet(s) to the wheel) OR moving the leader higher on the spring. The bad thing here is that both this things lead to increasing of the minimal amplitude. So, making the clock working reliably sometimes is hard and tricky and is question of trial and error iterations. This is especially when the main spring has gone weaker with the years.1 point

-

Standard grade ETA movements are made in Asia too, the quality you get is slightly inferior to Swiss, some junk ones too. You can tell the difference if you compare gears with Swiss side by side. finer gears and nicer polish on Swiss ones. I am not sure about the hairsprings , just assume them to be lowest grade. If the crown wheel doesn't want to come out, best to just leave it there. unscrew the crown wheel screw as much as you can and get some oil on its bearing. Good luck.1 point

-

1 point

-

My first attempt at silvering of watch hands. First I rubbed the hands back to the brass with 7000 grit paper. Then I polished a bit with pegwood and 1 micron diamond paste. Cleaned in solvent (Essence of Renata is what I have handy). Then used silvering powder as directed from Priory polishes (eBay). Finished of with a brush stroke of lacquer to avoid tarnishing. I think they look quite good, a nice satin effect.1 point

-

1 point

-

In this case usually a replacement cylinder is installed. There are still many NOS PW cylinders around. As correctly mentioned, a watchmaker’s task. Different sizes must be regarded, exact diameter and length being basic but far from sufficient. Frank1 point

-

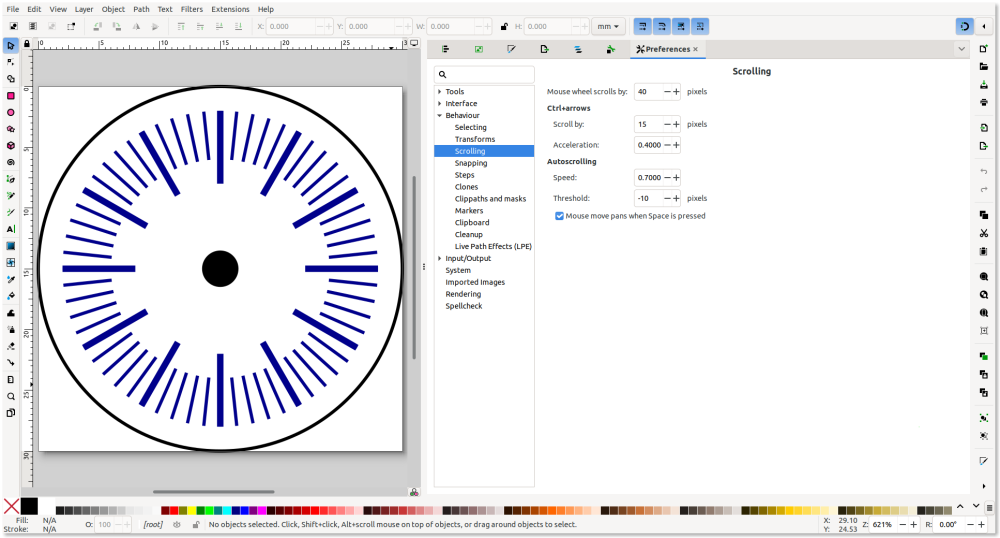

I feel I should call this post "Artificial Intelligence creates a watch dial." I present possibly the worlds first AI generated python code to produce an SVG graphic for a 30mm watch dial. First... I went to ChatGPT and asked it the following question. It responded with the following code... def generate_svg_watch_dial_with_markers(diameter, num_minutes_markers, num_hours_markers, hole_radius): svg_content = f'<svg width="{diameter}mm" height="{diameter}mm" xmlns="http://www.w3.org/2000/svg">\n' # Draw white circle for watch dial svg_content += f'<circle cx="{diameter/2}mm" cy="{diameter/2}mm" r="{diameter/2}mm" fill="white" stroke="black" stroke-width="1"/>\n' # Draw markers for minutes for i in range(num_minutes_markers): angle = i * (360 / num_minutes_markers) x1 = diameter / 2 + (diameter / 2 - 2) * math.cos(math.radians(angle)) y1 = diameter / 2 + (diameter / 2 - 2) * math.sin(math.radians(angle)) x2 = diameter / 2 + (diameter / 2 - 6) * math.cos(math.radians(angle)) y2 = diameter / 2 + (diameter / 2 - 6) * math.sin(math.radians(angle)) svg_content += f'<line x1="{x1}mm" y1="{y1}mm" x2="{x2}mm" y2="{y2}mm" style="stroke:darkblue;stroke-width:1"/>\n' # Draw markers for hours for i in range(num_hours_markers): angle = i * (360 / num_hours_markers) x1 = diameter / 2 + (diameter / 2 - 2) * math.cos(math.radians(angle)) y1 = diameter / 2 + (diameter / 2 - 2) * math.sin(math.radians(angle)) x2 = diameter / 2 + (diameter / 2 - 8) * math.cos(math.radians(angle)) y2 = diameter / 2 + (diameter / 2 - 8) * math.sin(math.radians(angle)) svg_content += f'<line x1="{x1}mm" y1="{y1}mm" x2="{x2}mm" y2="{y2}mm" style="stroke:darkblue;stroke-width:2"/>\n' # Draw solid black circle in the center svg_content += f'<circle cx="{diameter/2}mm" cy="{diameter/2}mm" r="{hole_radius}mm" fill="black"/>\n' svg_content += '</svg>' return svg_content import math # Diameter of watch dial in mm DIAMETER_MM = 30 # Number of minute and hour markers NUM_MINUTES_MARKERS = 60 NUM_HOURS_MARKERS = 12 # Radius of hole in the center in mm HOLE_RADIUS_MM = 1.5 svg_code = generate_svg_watch_dial_with_markers(DIAMETER_MM, NUM_MINUTES_MARKERS, NUM_HOURS_MARKERS, HOLE_RADIUS_MM) print(svg_code) I saved this as 30mmWatchDial.py Next a ran the code (using python of course). python 30mmWatchDial.py >30mmWatchDial.svg ... and here is the result displayed in Inkscape. Here is a png of the .svg .. and the .svg saved as a .svg.rtf is attached to the bottom of this post. Save it as .svg and you can open it in Inkscape. Some things to bear in mind when playing with this idea. The free version of ChatGPT can only write short snippets of code, so don't try to get too fancy or you will get incomplete results. Image generating AI will produce arguably more interesting watch dials, like the one below, but they wont be in SVG format. ChatGPT is available here -> https://chat.openai.com/ DeepAI image generator is here -> https://deepai.org/machine-learning-model/text2img Have fun. 30mmWatchDial.svg.rtf Just for fun, here is another AI generated watch. Spooky stuff.1 point

-

Ha, for erasing pencil! Don't know why it's there (I'm not super tidy)1 point

-

I do the fine-tuning with the movement in the watch-housing (with or without bracelet), but one has to be aware of the fact that a housing can cause extra vibrations and those extra vibrations could cause interference / "corrupt" the timegrapher signal. When the movement runs fine without the housing, and the build-in went flawless, but the timegrapher results are slightly "off", I take in consideration that it may be the housing which causes the interference. Most of the times, at least in my experiences, housings don't cause a problem, but if the signal on the timegrapher suddenly changes after the build in, the housing may be the culprit. There could be other reasons too, like one of the hands touching the inside of the crystal. Changing the position of the housing in the timegrapher microphone, or having the crown against the pick-up may help too.1 point

-

1 point

-

just so everyone understands that is not universally true statement it depends on the balance itself and whether the staff was designed to be punched out there other factors here. that this would be interesting procedure that I don't recall ever reading about in any book? why don't we go back to the beginning sometimes reviewing things helps? For instance I don't recall ever seeing the watch model number which watch is this your getting a balance staff for anyway? Then it's always good to measure the old staff preferably with a micrometer then measured the new staff to verify that all dimensions are exactly the same did you do this? then the balance staff does it have a part number and where did you purchase it from?1 point

-

For sure there will be no beter chance to rivet a new staff there if You did not suceed wit the first one. Thinking that the pnches are not propper and the problem is there is misconception. If the hole is too big, then no riveting will be possible. Bit I actually don't know how big the hole really is. In the normal case, the staff should fit tight in the hole, some force will be needed to push it in place. If there is just a small free play, riveting is possible, but some danger of eccentric rotation of the balance exists. This means trueing, poising and timming problems. If the hole is really big, then the only reasonable way is making of custom balance staff. Some compromise moves exist, like soldering of the staff in place with led solder. The led is good enough way to fix the staff in place and it is easy to remove it when needed.1 point

-

Add a picture of the balance parts so they can be assessed. Dont assume that everything else will be ok, its very likely it wont be. Take it step by step with help from here.1 point

-

I think the movement is genuine, the dail being made in Thailand. Put a screwdriver under the head of the screw and apply slight upward force.1 point

-

There are still a few old antique dealers that show up to the local shows around where I live who are stuck in the mindset of 20 years ago when the antique American watch market was much hotter than it is today. They know I like watches and I often have to politely decline their 7 jewel Walthams that don't run and are missing the bow etc for $250. I don't have the heart to tell them the value is closer to 0.1 point

-

Hi from what Ali express are saying either it won’t get back to them or they don’t want it back so if you try to return it and it gets lost!!! You end up paying for it any way so best keep it and take the $5 discount of the next one. Not an ideal situation but you still have the oiler.1 point

-

@nickelsilver I finally got around to start learning the Jacot tool skills Starting off, I was puzzled which runner to use, so I had to re-read your explanations. Thereafter I thought it may be an idea to put a "face" to each type of runner bed to clarify your explanations. Runner #1 and runner #4; (the runners with the caps) for smaller pivots. Runner #1 has the sizes: 5/6/7/8/9/10/11/12/13 and runner #2 has the sizes: 14/16/18/20/22/24/26/28/30. Runner #2; for the 4th wheels with tapered end; Runner #3; (like runner #2) is indeed an additional 4th wheel runner for tapered pivots; Runner #5; with beds on both sides, for the larger pivots, i.e center wheels. Covering the sizes: 32/34/36/4045/50/55/60 & 65 on one side and 70/75/80/85/90/95/100/110 &120 on the other side;1 point

-

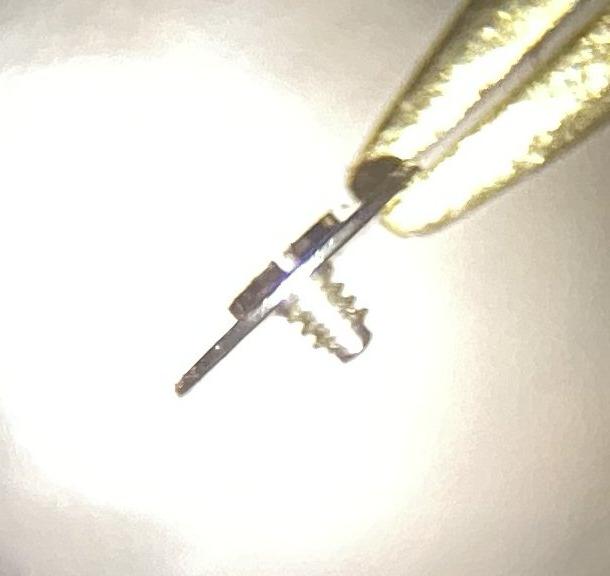

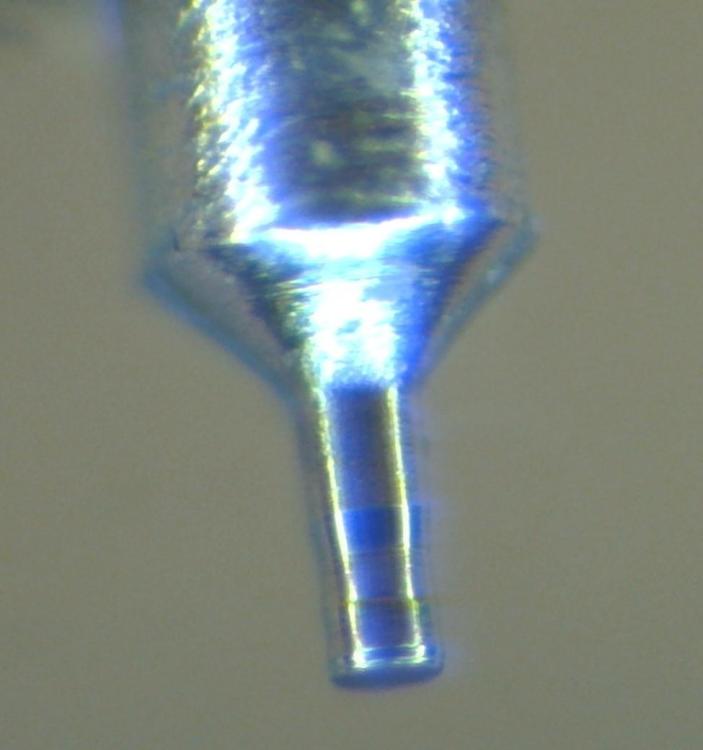

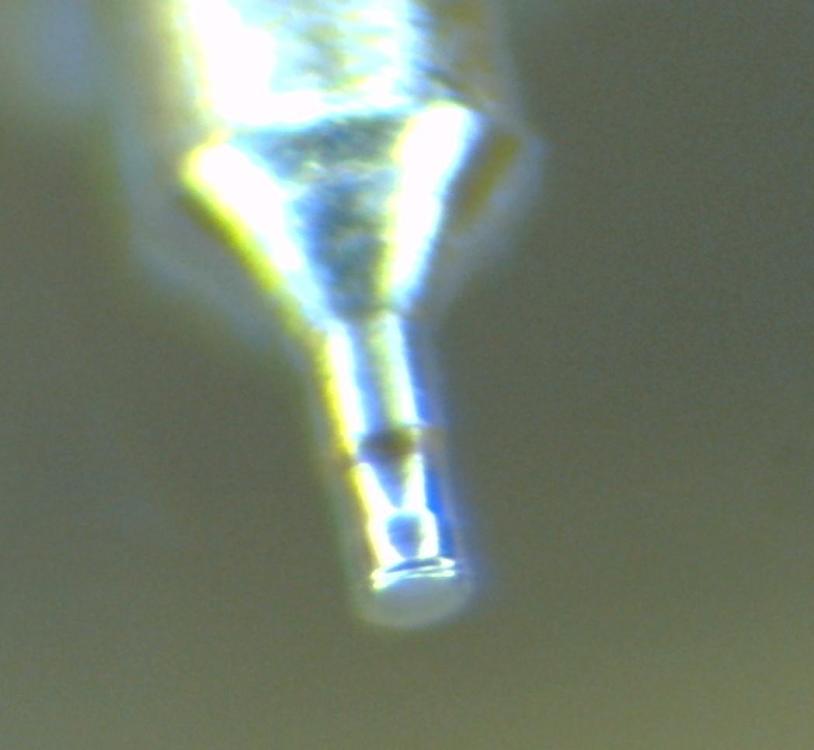

Just for you @JohnR725, I broke out the 2x Barlow lens - wow it's hard to get a steady picture with the microscope head on a long arm, attached to my desk, on a wooden floor. The ends are very slightly rounded, but you can also see grooves where the pivots have worn away against the jewel holes (look at the reflected light lines). The pic is the bottom pivot, the top was more worn. I was thinking that a new staff would be best, when it was decided - adding a bit more pressure on the burnisher, the balance jumped out of the Jacot and broke the top pivot . (Not the first time I've screwed up on the Jacot tool). Idiot. I want this watch to run well, so it's probably a good thing to get a new balance staff. I'll change the jewels too. I don't know if jewel holes actually wear? But if it's worn away the pivots, then a paste of hardened steel has been rubbing on the jewel for a long time, so probably. The cap jewels have slight dimples in from wear, and they are clear, not red. They're a nightmare to find in a liquid.1 point

-

I'm aware of the tool. It's another of those ££ Bergeon tools which I would only use very occasionally.1 point

-

How did the jewels look when you got it apart? The upper pivot looks a little worn, and almost like it has formed a bit of a burr around the tip. This could happen if they were super dry and it ran for quite some time in that condition. If it were mine I would give them a lick in the Jacot tool and round the ends slightly. It is possible though that they were made flat. Some watches have flat pivots to help have closer amplitudes between flat and vertical, but rare to see on mid 20th century Swiss stuff.1 point

-

Another mystery tool of the day chaps. This design is 120 years old, no idea how old this one is that i have. Had it for ages and almost binned it as it doesn't look like much. Then someone posted on another site they had one along with an advert for it. Its open to anyone, tbh i think only the pros will guess it. Only clue i can give is that it used in conjunction with another tool that only the pros will use, although its condition is also a clue. This has to be the most difficult yet. Oh dear i seem to have inadvertently masked out the patent on it, thats a bugger.1 point