Leaderboard

Popular Content

Showing content with the highest reputation on 03/01/24 in all areas

-

Hi guys, I wrote this lesson for my second students to understand the theoretical aspects of the Swiss lever escapement in conjunction with the practical application of end-shake and setting jewels using a jewelling tool. Both Seitz and Horia-type jewelling tools were used. Although I talk about measurements using the settings on the side of the jewelling tools, it is more about what 'feels' right, especailly when gauging the end-shake of a particular component, such as the balance, pallet and escape wheel. Ideally, you wouldn't start by adjusting the end shake of the balance to suit your needs, but if the IncaBloc setting has been replaced or the Inca setting has been moved to replace the shockproof spring, then it is important to set the end-shake correctly. This presentation also looks at how to set the correct end-shake of the pallet in relation to the balance safety roller as well as other critical measurements, including the height of the escape wheel teeth hitting the impulse face of the pallet fork in both dial-up and dial down positions. The escape wheel and pallet have to have the exact same end-shake as each other for this reason. Unfortunately, the slides that contain videos can't be played as I converted the PowerPoint into PDF. I have used some diagrams from a WOSTEP handout on this subject, to show the vital measurement of the escapement in relation to the balance safety roller, so all credit goes to the author of that hand-out, which has been posted several times on this forum. All the students that set all the jewels after removing them and the balance end-shake to its optimum got a watch movement working with much improved amplitude than when they started. All ten jewels in the wheel train were removed as well as both IncaBloc settings. Another lesson was created just about the balance setting and disassembly and assembly of the EtaChron balance system which included removing a replacing that Inca setting. I haven't included that lesson. Not every aspect of this work is within the presentation, as it would be very long otherwise. I talk a lot and explain more as the lesson proceeds. This lesson was held over six to seven hours. If anyone is interested in learning more on this subject, please message me. Lesson 16. Balance endshake & Incabloc adjustment.pdf Lesson 16. Balance endshake & Incabloc adjustment.pdf11 points

-

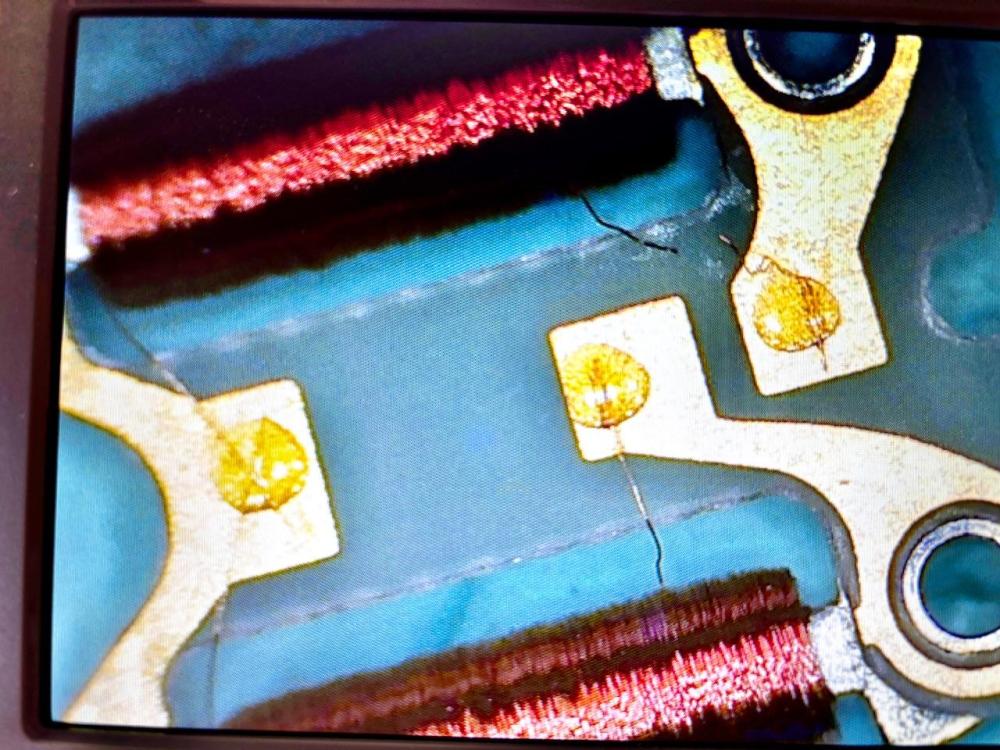

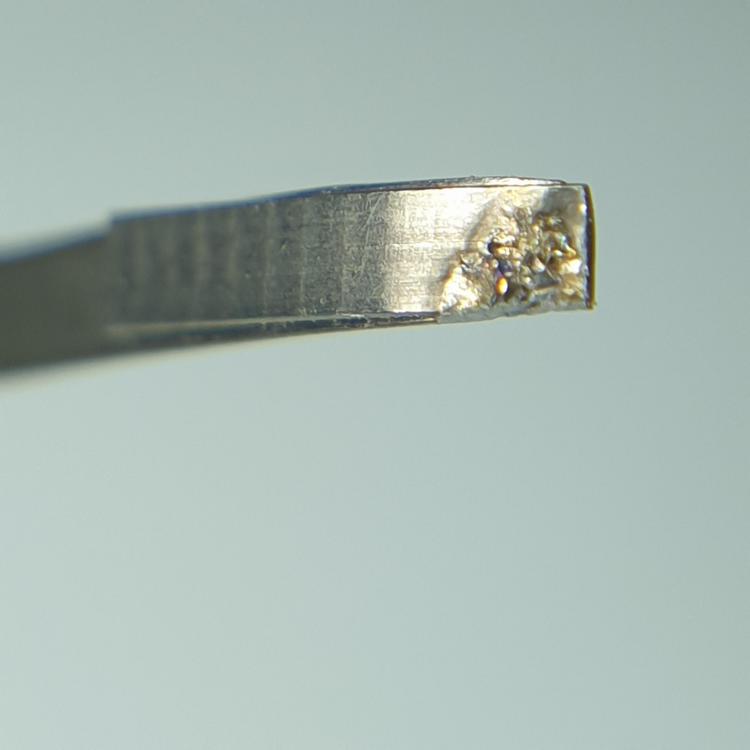

Well, after a service, finding some bit of metal in the gear of the step rotor and reassembly, no joy. Today I broke out the microscope and what did I find but a broken wire! That will do it every time. I was able to unwind the broken wire a turn and glue it down with some conductive ink. Voila! Back to running properly. Thanks so much for all of the helpful documentation and advice. It really fueled the fire of my though processes to get this fixed! I might have to wrist test it for a couple of weeks before giving it back to my brother though!5 points

-

News Update 29/02/2024 Yesterday Cousins and its legal team went to the High Courtin London to oppose the application by Swatch to have our UK claim struck out. The case was heard by Mr. Justice Michael Green, a High Court Judge who also sits in the Competition Appeal Tribunal. In previous news stories, I have explained the arguments that we intended to bring, and I will not repeat them here. However, I am in no doubt that by the end of the day, Judge Green had a full picture of the consequences for Competition if Cousins action is not allowed to proceed. It was noteworthy that the Competition and Markets Authority sent a member of their Legal Team to observe proceedings from the Public Gallery. As expected, after more than five hours of evidence and legal argument, Judge Green advised that he would consider the matter further and release a written verdict in due course. Afterwards, our legal team said that the case had gone as well as it could have done, and better than they had thought likely. There is no fixed timetable for the verdict, it entirely depends upon the workload Judge Green has, but we hope to be able to advise you of the outcome in a matter of weeks rather than months. Regards Anthony5 points

-

3 points

-

3 points

-

@rossjackson01I would start with a perfectly working movement, that has the correct endshake of the gear train and balance, with a high amplitude and a perfectly new mainspring, so you are eliminating as many variables as possible to start with. You can then rule out any initial problems with the movement. Screwing down bridges and cocks tightly should/will have no bearing on amplitude. In fact not tightening them properly will give you problems! I would then move on to using proper cleaning fluid and rinse, rather than lighter fluid and IPA. They work fine, but it would eliminate that variable as well. Watchmaking is witling down what it can't be and you're left with the possibilities, then probabilities. Always do only one thing and measure the result of that change or adjustment. A good movement would be an ST36 from AliExpress, which I use for my teaching. Cheap as chips. https://www.aliexpress.com/item/1005005872942857.html?spm=a2g0o.order_list.order_list_main.23.55171802P4233F Measuring the endshake of a balance is vital. The more you do it the more you'll know what feels and what feels wrong. A lot of movements would be about 0.02 to 0.04 mm endshake of the balance, but the St36 is close to 0.08 to 0.09 mm, as it is a very big movement. I take a class on reducing and increasing endshake of the balance and seeing the huge drop in amplitude by adjusting the balance endshake by as little as 0.03 mm tighter or looser on the ST36. Usually the big drop will be in vertical positions, but also in horizontal ones as well, but not as much. At least using a new movement will eliminate that variable of too much or little balance endshake to start with, although I had an Incabloc setting move with a students watch this week and I had to increase the setting by 0.06 mm so the balance didn't stop when the balance cock was tightened. Checking the impulse face of the pallet stones is also vital, as they have to be mirror clean. I use Moebius 9415, but at a push you can get away with 9010. You'll get there, I'm sure!3 points

-

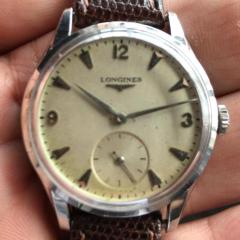

This is clearly a front loading movement. Measure the width of the dial, then measure the width of the opening in the case-back, then you'll understand there is no way the movement could come out of the back. It's pretty apparent from your photos2 points

-

I've just posted this on the forum to help understand the theory in conjunction with the practical aspects of end-shake. Unfortunately the videos won't play because of the conversion to PDF. Enjoy!2 points

-

Looks to be a Valjoux 5. The "R" is for Reymond Freres, the original company name. They changed the name to Valjoux in the 20s, then joined Ebauches around the 40s, after which you see the R inside the familiar shield shape. Staff appears to be available.2 points

-

2 points

-

Haha, that might be one anxious bride that is not receiving the same amount of attention as the watches eliminate the impossible and whatever remain however improbable is still possible dear Holmes.2 points

-

@Jon I didn't realize that end shake was that critical. Very, very interesting reading. Thanks! Now the question I have is; how do you adjust the end shake of a balance? It's not covered much at all or I think I would have noticed over the years. For increasing the end shake, all I've seen is carving up a bump under the main plate under the balance cock or using shims. When servicing a Citizen 8200A I used aluminium foil but it doesn't feel like a best practice. I have no idea about how one decreases the balance end-shake. I would expect this topic to be rather complex but if you could describe the overall idea it would be super interesting. Also, how do you measure end shake? I think I'm able to assess the end shake of train wheels reasonably well by mounting one wheel at a time looking at it through my microscope and comparing it to the gap I see in my micrometre, but when it comes to balance end-shake I can only try to assess the end shake by feel and it certainly is a far cry from being able to tell what it actually is.2 points

-

Using carbon steel from a feeler gauge, I must have got lucky the first time I annealed. The hole drilled just like it was mild steel - it just went straight through. Shaping with a file was also so easy. The next time I used the same set of feeler gauges. Annealed as before ... and broke 2 drills. Couldn't touch it. Took three more attempts at annealing before I could drill a hole. But it still wasn't as soft as the first time. I now have a steel cannister (an old box spanner with the end hammered over) and some activated charcoal for my next attempt at annealing.2 points

-

Forget the old broken spindle piece, heat end of the spring to a glow to bend a 90 degrees reheat to continue bending to 180 degrees, quench in old automotive oil. You have a one piece spring with a bend that functions and lasts longer than the original spindle.2 points

-

The Eakins has finally arrived in one very heavy box, now I need to sort out a suitable camera and dedicated desk as I currently on,y have my computer desk. I’m thinking those electric sit stand desks might work as I can adjust the height as needed.1 point

-

Yes, my question was about fitting a new lyre spring. By the way, it was my bad that I did not notice you mentioned how to do it on page 16. Many thanks for your patience and time, best regards1 point

-

hi Jon, Thanks for your expertise. This is exactly what I am looking for. I wouldn't have thought of the dial vs caseback measurement difference to arrive at the conclusion of front loaded movement until you pointed it out. This saves me the potential mishap. I already learned once to not force my way into a watch without fully understanding the mechanism. Really appreciate yours and everyone else's feedback!!1 point

-

If I'm understanding you, you said how to fit a new lyre spring. To fit a new incabloc lyre spring, it is in slide 16 of the presentation. press out the Inca setting enough so the 'T' part of the spring can fit in the slot of the Incabloc setting, then press it back into place with a jewelling tool. If you mean how to attach the lyre spring arms over the cap jewel, let me know and I'll post something Many thanks! I use the term 'Goldilocks' a lot in my lessons. And yes, there are always three bears. I call them Peter, Paul and Jill. In watchmaking, especially stuff involving the escapement I tell my students, "If you're going to rob Peter, then Paul is somewhere in the shadows with a baseball bat wanting paying and just when you think you've paid him off, Jill comes out from behind Paul with a flick knife because you fell into the trap of making an assumption. If you're gonna rob Peter, you have to pay Paul, so if you adjust the endshake of the pallet jewel , you have to take into account the height of the guard pin with the safety roller and Jill is the escape wheel hitting the top half to three quarters of the impulse face of the pallet jewel. Peter, Paul and Jill, I love those three!1 point

-

1 point

-

Thanks, that worked. I ended up attaching the bracelet and using that with the holder as leverage.1 point

-

Cut some metal or hard plastic to fit inside the gaps where the strap goes. Pack something underneath the crystal and clamp in a case holder. PS, the metal/plastic could be glued and the use a solvent to remove it.1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

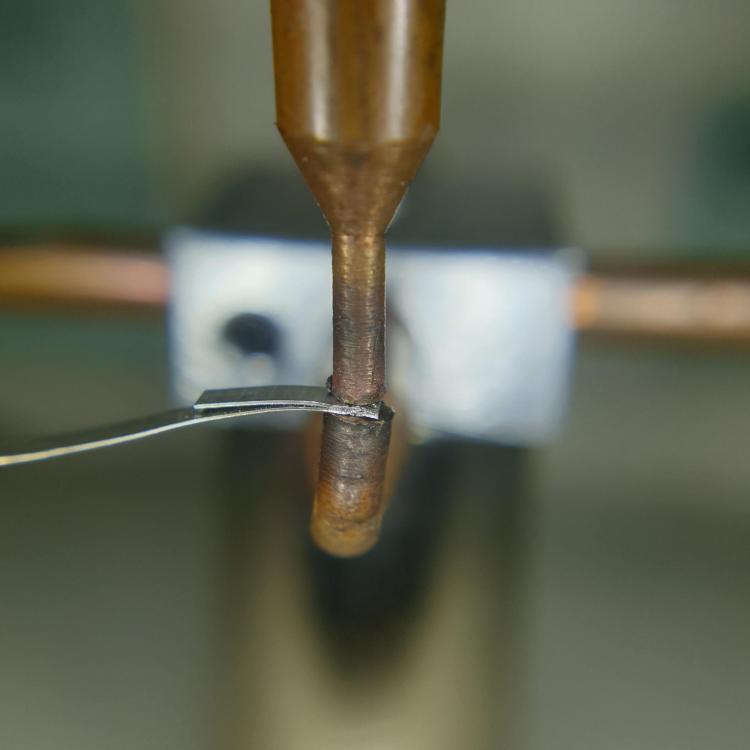

I received a Vostok Komandirskie in the mail last week. It's a non working watch with many minor issues. But for today, I'll just talk about the broken mainspring. I have a spot welding machine, so repairing a broken endpiece like this is relatively easy for me. I just clean up the pieces and clamp them between the spring loaded jaws of my spot welder and hit the switch. But if a spot welder is not available, what other methods would be used to repair a broken tail?1 point

-

1 point

-

Quick thought, the adjustable stop unscrews so does the micrometer adjustment. Drill some brass rod into the ends, one end can have a notch to accommodate the roller pin. What about the one above i just posted using brass rod for pushers ? The micrometer end has a ratchet . Bloody thing has been looking at me and waving " I'm here you muppet I'm here " just realised the adjustment side will need a bearing or it will turn the balance.1 point

-

1 point

-

1 point

-

I think the 4th one in @HectorLooi photo is interesting for this application having changeable “punches” and base. That suggests to me that custom base could be made along with custom punches and stakes done on a lathe. Tom1 point

-

Sure, I understand your admirable reasoning But if you don't mind, my pension budget is limited and I like to keep my hobby alive too Thanks for your (and @JohnR725), for the excellent help1 point

-

It certainly could be. They were already producing wrist size movements by then, and I imagine those took off and pocket movements went down in production after that. Almost definitely pre-40s when they joined with Ebauches. Though- there are cases where movements get assembled long after the parts are produced, so you might see something odd like the R without the shield, but the watch was actually finished in 1950. Balancestaffs.com will sell to anyone, very easy to deal with. On edit- looking at the pics again I realized this is pin-set. For me that would make this pre-20s pretty much for sure.1 point

-

Hi. Looking at the bestfit book. Equates to a Valjoux 5. As suggested ny nicklesilver. It’s 19 Ligne. The Valjoux 8 is similar but with 3 functions and 1 pusher 30 min register.1 point

-

I had a very small staking tool with punches and plugs. The tool I could hold in my hand. I have never seen another. I was lucky I was given all the tools at my place of work including stock and machines, some of the tools were extremely old going back to late Victorian.1 point

-

What about a pin vice, or something similar with finer jaws, to hold the staff, tweezers to position the collet or roller, and a freehand stake to push it into place?1 point

-

Hey all, been a while since the last post but i have some update info on drilling hardened steel for setting levers, @mikepilk if you're interested . It's a real shit of a job without the right gear After annealing my setting lever i did manage to drill 2 holes the first was ok and relatively quick i think i was just lucky and had something right,the second was tough and the other 2 i needed i just gave up. Pivot drills work but not great, this is supposedly after annealing. The steel is softer and shaping files seem to cut better, but hand drilling with the cheap carbide drills just does not work they break and chip like billyoh, unless...............you have the right gear. This is someway of getting the right gear. Proxon micro drill, the runout 1 1/2 from the head i cant see with x20 loupe holding a .4mm carbide bit. Proxon drill press stand makes it very useable. It isn't cheap but it is , its kind of entry level micro drilling and milling but on a fair quality tool. 0.4mm cheap crappy carbide drills eat through hard and tempered setting levers and feeler gauges ( nothing annealed ) at 5000 revs, the lowest the micromot 240v can go. No chipping of the carbide, but there is a technique involved, you cant just push your way through in one go and i think that might be to do with hardening of the steel as the drill end sits burnishing away on the surface of the steel or maybe the bit needs to bite in. The bit has to bite and back off a dozen times to get through but its about 30 seconds to 1 minute depending how brave you are, i drilled dry so a drop of oil could very well improve the situation. Its not the exact setup i was after but i figure i have some multi use here . Proxon do a few bigger more versatile milling machines and Dell put me onto a make that I'm considering but more like next year now. The little setup i have here is a little introduction to milling for me, i think i like it for now.1 point

-

Hi @RichardHarris123 not necessarily, on the some the dial is in two parts. Once the bezel is removed the chapter ring is removed gaining access to the stem release, once done the top watch lifts off allowing both batteries to be changed. They all seem to employ the same method just achieved differently On others the bezel is removed by removing screw on the bezel , others use pry points. Its a case of careful inspection before proceeding.1 point

-

Turns out it was the incabloc. Not sure if the jewel was upside down on if it just wasn’t centred on the pivot. I took it out and the watch worked fine. So I cleaned and re-oiled it and carefully reinserted it, and everything works fine now. Problem solved.1 point

-

I usually do it with drill in a pin vice, hand held, but I do put a rod in the tailstock that is a very loose fit in the backside of the pinvice. This keeps it more-or-less lined up. The main reason I do it like this is for very small diameters I freehand grind the drill, so not only are the lips not exactly equal (I do try to get them equal), the drill isn't really centered on the shank. Holding it in a well aligned tailstock just wouldn't work. The upside is you do have a terrific "feel" of what's going on, and also if the drill suddenly hangs up the pinvice can spin in my fingers hopefully saving the drill. For diameters over about 0.40mm I can make the drill on my tool grinder, and these end up well centered and can be used like normal drills, either in a live spindle like a drill press or jig borer, or in the tailstock of the lathe.1 point

-

I have to confess that Harry Enfield was much more amusing than my fellow Scot, and so called father of economics, Adam Smith. Smith did delve much deeper into what drives the wheels of trade than most people imagine. Its a pretty tough and stodgy read for modern tastes though. Most people have heard of his work "The wealth of nations." (strictly speaking its actually called "An Inquiry into the Nature and Causes of the Wealth of Nations", but that is a bit of a mouth full), but far fewer have encountered "The Theory of Moral Sentiments". Smith's "Wealth of Nations" is much misquoted and rarely read by those who profess to follow the capitalist religion, but such is the way of blind faith followers. Few if any of these religiose zealots will have even heard of , nor be interested in his theory of moral sentiments, despite its in depth analysis of the very behaviours they indulge in. I doubt that he realised when he penned his works that they would be so often used to attempt to vindicate the baser inclinations of the greedy some 265 years later. If you are ever in the area, you might like to take a trip down the Royal Mile in Edinburgh to the Cannon Gate church, and ponder a while with him, the changes that have taken place since his time. As to actually reading his works... I suspect you may need to stock up on the extra strong coffee before you dive in, but they are, arguably worth the effort. "As we have no immediate experience of what other men feel, we can form no idea of the manner in which they are affected, but by conceiving what we ourselves should feel in the like situation. Though our brother is on the rack, as long as we ourselves are at our ease, our senses will never inform us of what he suffers. They never did, and never can, carry us beyond our own person, and it is by the imagination only that we can form any conception of what are his sensations. Neither can that faculty help us to this any other way, than by representing to us what would be our own, if we were in his case. It is the impressions of our own senses only, not those of his, which our imaginations copy. By the imagination, we place ourselves in his situation ..." Or as the great man never said, or even implied... "greed is good".. Rant over... normal service has been resumed.1 point

-

I haven't actually encountered anybody selling data from this site, but I do encounter people who are selling non existent electronic components, and flogging free PDF datasheets, so it wouldn't surprise me to find my ramblings from WRT wrapped up in a PDF and offered for sale on the "free market" internet. Don't get me started on the so called "free market" and all its pseudo-scientific mumbo jumbo. A near infinite number of euphemisms for "greed" dreamed up by the "Loadsa-money" generation. Don't worry that we are poisoning the planet, killing ourselves with corn syrup and cheep ass food and lining the pockets of the already rich, the "market forces" will fix everything, and "trickle down economics" will make us all rich. Everything else, we can fix it all with technology we haven't invented yet... and probably never will... carry on and consume, consume, consume! We won't be able to breath the air or drink the water, but we will be rich I tell you RICH!! Give me a moment, I think my medication might be wearing off..1 point

-

1 point

-

In the past i have had them land on my side with seller issues, but this is the first time i have had something missing from a lot. Impossible for either of us to prove ( i should have recorded the unwrapping which i have done in the past with expensive buys. The seller has just told me that the complete listing was there when it was sent, asked if the parcel was damaged and has no idea how just one watch could be missing. Hmm i know exactly why it's fooking missing . Ebay is nearly always on the buyer's side, i spend a lot of money on ebay, so helping me out should be important to them. To add the seller's feedback isn't squeeky clean so i expect a good outcome.1 point

-

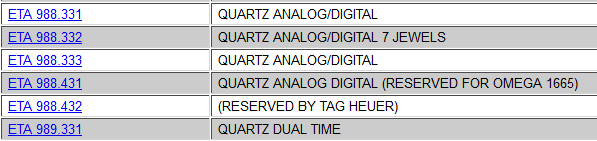

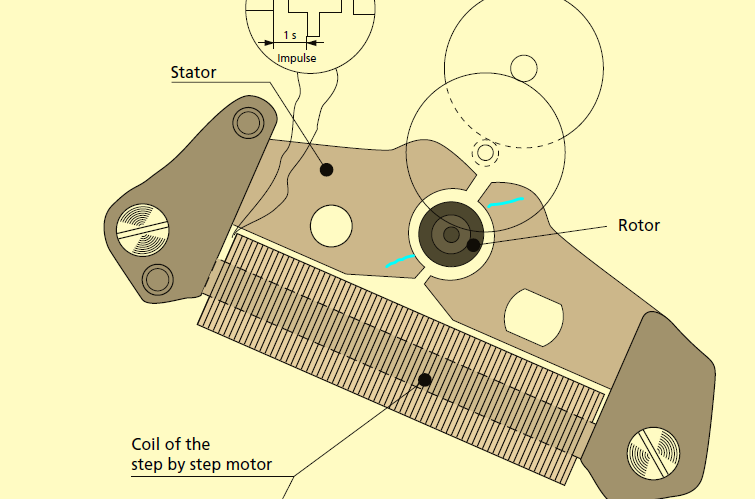

I was curious about parts cross references so looking at the link below we see the image I have below and another classic problem of movements reserved for specific companies. http://cgi.julesborel.com/cgi-bin/matcgi2?begin=ETA_937.681&end=ETA_&label=CALIBRES_MANUFACTURED_BY_ETA&flag=C what I was hoping for was or curious about as to whether any of the stator's cross reference to is kinda hoping of maybe it was like a basic it referred to all of them but it's hard to tell. Because that really is the key component in all of this http://cgi.julesborel.com/cgi-bin/matcgi2?ref=|[[GWGX then I found a better picture of the stator. Unfortunately it doesn't look like yours but it does actually show things in a more correct fashion. you see how the rotor is not actually in the center sort of and why put marks you can see is physically closer to the edge. In other words at rest these are where the north and south poles will be the whole design allows the rotor to turn in the correct fashion unlike yours which is now slightly distorted but as you can see from the spacing with extreme magnification it probably really doesn't take very much to screw that up.1 point

-

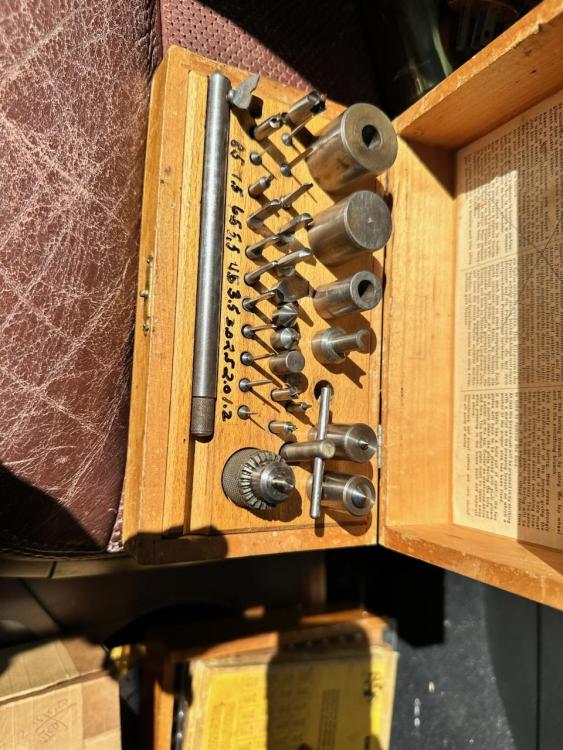

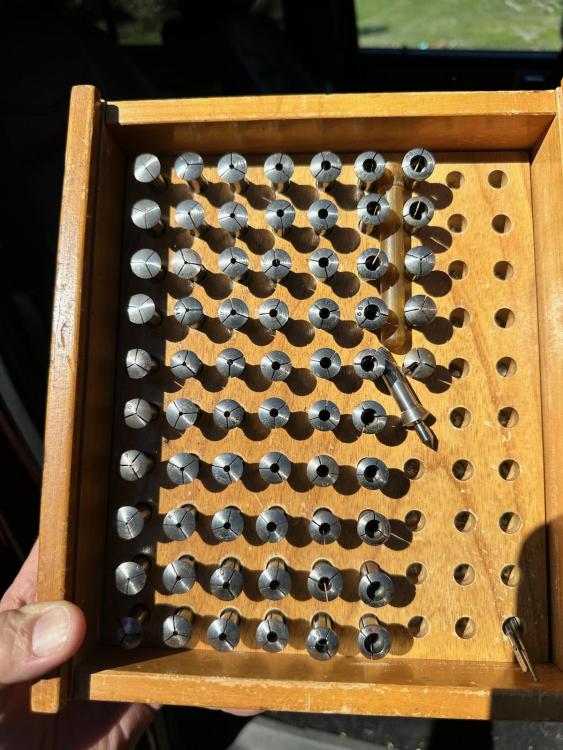

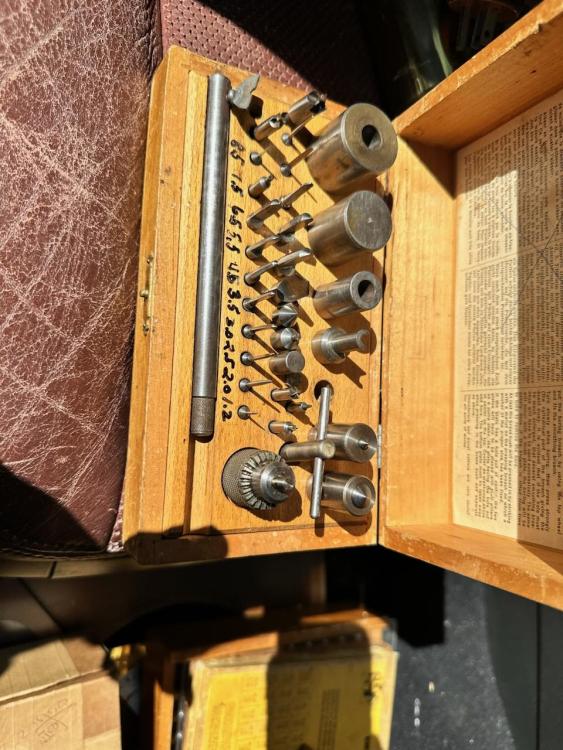

Pardon me. Is "policing" equivalent to "observing?" The marketplace is just fascinating. You have the person who happens upon these crystals for watches that most people do not care about, but he does not know it. He gets on ebay and finds somebody selling a Mido crystal for $30 (those are a pain in the @ss...I have had to buy a few) and thinks OMG, I have 2000 crystals!!! That is $60,000. I will offer a bargain at $1000!!! It is just funny. Then you have the case, in real time, where some dude gets a storage locker full of clock repair tools and takes no effort (I suppose) to search ebay and sells them to me for 1/4 the ebay value. Probably less than 1/4 because I have cataloged the collets in the deal--65 total of which 36 are Levin. That is at least $700. Add the Bergeon bushing tool plus bushings and the lathe with collet-holding tailstock...prolly $2000. This does not include the misc stuff. The market determines the winner. That is why I love capitalism.1 point

-

The bladder for another fountain pen arrived today. So here is the follow up. How now *not* to replace the bladder in your precious fountain pen. The process started innocently enough. I attempted to unscrew the cap. Instead, the stainless sheath parted company from the plastic of the top and started to rotate. This produced two new problems. First, I obviously now needed to re-secure the stainless sheath to the cap, but more importantly, I couldn't actually unscrew the top from the pen. I reached for some light oil and attempted to dribble it in to the threads. In the process, I managed to pour it down my leg. Nice. "Well.." I reasoned, ".. these jeans needed to go in the wash anyway." so I pressed on undaunted. Next I wrapped some masking tape around the body and the top, and carefully grasped them with mole grips, trying in the process to avoid crushing anything. This worked better than expected and the cap started to unscrew. Unfortunately however, the next problem became obvious pretty quickly. The pen still had ink in it, which it proceeded to vomit on to my leg... "Well.." I reasoned, ".. these jeans needed to go in the wash anyway." so I pressed on undaunted. I cleaned up as much of the mess from my hands and leg and the pen as I could, and set about replacing the bladder. With the pen now spotless, and no obvious possible source of further trouble in view, I set about securing the stainless cap to the body. The cap by now was considerably more stainless than I was. I poured out a small measure of shellac into a little plastic container, and started to dribble it into the gap between the two components, and ... promptly poured the contents of the container onto my leg... "Well.." I reasoned, ".. I am clearly an idiot." so I pressed on undaunted. The job is more or less complete, but I suspect the jeans may never quite be the same again. Now I need to sneak them into the washing machine before my wife sees them, and hope that a quick boil wash will hide the majority of the evidence.1 point

-

I have and still do see ludicrous asking prices on eBay, however I have seen recently lower winning prices for watchmaker tools. I just snagged a JKA Fientaster for less than half price and about a third of what they were going for. With the current belt tightening we will hopefully see something more sensible on pricing. Tom1 point

-

Jewels correct. Demagnetised every time. Love Maple syrup. Tried what you said. 9010 tastes horrible.1 point

-

1 point