Leaderboard

Popular Content

Showing content with the highest reputation on 02/27/24 in all areas

-

2 points

-

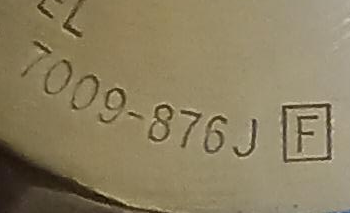

I don't know about the A,J or F. I suspect the glass will be the same. The '310' is the size, 31.0 mm. So measure the case to check the size. There will be a thin plastic gasket to go round the glass, so expect the case hole to be slightly larger. It's not difficult, I just searched for the case number in Jules Borel and Cousins !2 points

-

This case doesn't appear in any of the Casing Guides I have Try the Jules Borel database. http://cgi.julesborel.com/?_ga=2.99547678.1292671413.1673701735-126716363.1672876102 Search using in the Case number with "SEK CS#7009-876" They show a generic crystal which is used on many cases. Or just measure and buy a generic crystal from Cousins. edit - A search on Cousins using case number, does show a glass -2 points

-

2 points

-

You will need a resistance meter to check for continuity of the coil windings, a very cheap piece of equipment. Battery leaks are the main cause of damage in quartz movements. One must always replace the battery once its energy has been used up, the battery case then becomes it's food, then the movement. Pulling out the crown to hack the watch will prolong the battery life.2 points

-

I usually clean battery leaks with white vinegar. Use a brush or cotton bud and dab the vinegar all over the corroded parts. Let it soak for about 5 minutes, then rinse with distilled water. Sometimes the battery juice (potassium hydroxide) gets soaked into the substrate of the circuit board and causes a short. Other times, it eats away all the copper of the pcb track. After the board has dried, use a multimeter in resistance mode and test for continuity of the copper tracks and then for shorts between adjacent tracks. Test the battery contacts very carefully. Sometimes they may look clean but there can be corrosion under the rivets and have several hundred ohms of resistance. If everything looks good, then put a battery in and test that it gives a pulse on the pulse meter. I would also test the current consumption with a microammeter but that is not a tool that most hobbyist have.2 points

-

Hello, I'm new to watch repair. I have several vintage mechanical watches that I bought at Fleamarkets and online. I prefer the more simple, uncluttered look of vintage dials. I've been lurking here for about 6 months and finally have a question to post. Thanks, Steve1 point

-

Check the Incabloc capstones, making sure that the flat side is downwards, facing the hole. Accidentally reversing the capstones will reduce endshake and result in the symptoms you described.1 point

-

1 point

-

1 point

-

There are many discussions about the Jacot tool here on WRT. It's definitely one of my favourite tools as it allows me to restore badly worn and even rusty pivots and pivot shoulders. So, as a little tribute to this tool, I asked my wife to record a few seconds of me using my new Steiner Jacot tool while restoring a centre wheel. Hope you enjoy it and maybe even get some use out of it. Of course, I made a Youtube short video1 point

-

Dry lubricant. 20 or 30 years sitting in a drawer without anything moving and the lubrication is likely to have gone a bit gummy, which is why the one that does run is draining the battery so quickly, and the others won't run at all. One little trick that you could try is to allow the watches to warm up a little on a radiator or perhaps with a hair dryer. Don't cook them, just get them warm to the touch. With any luck the warmth may loosen up the gummy oils a little and allow things to start to move. You could also try a line release tool to spin the movement up which may get things going again.1 point

-

Its already been said the main piece is missing. I would save your money and look for a better complete set. What sort of price are you thinking of. Then I can look on the net for you.1 point

-

The top and bottom chatons are the same, but the cap stones are different. The top one is thicker. I always keep them separate when cleaning. With the pallet removed (check for loose jewels), with a good blast from a puffer, the balance should still be swinging after 30 seconds. Is it? If that's OK, check the gear train. Check that the arbor moves freely in the barrel - has enough end shake. And make sure there is not too much play at the bridge at the top of the arbor, allowing the barrel to tilt and foul a plate or wheel. I always fit just the barrel and bridge to make sure it spins freely on it's own without the gear train. With the barrel removed, check the gear train - a blast from the puffer, the gear train should run smoothly for several seconds. Check the end shake on each wheel - move it up and down with tweezers, checking there is some endshake, but not too much, allowing wheels to contact. If the gear train does not move smoothly, try each wheel individually. I hope the watch is not too valuable - If I was a beginner I would practice on cheaper movements before I worked on an Omega like this. The spring on the centre seconds pinion can kill amplitude if not at the correct tension. BTW, I have bough cheap fixer-up movements from ebay and found they were just a collection of the crappiest parts someone threw together to sell as a complete movement, What is the general condition of the movement?1 point

-

Not really. That damage came from somewhere and indicates they were in contact with another part. It takes very little resistance to stop a watch.1 point

-

The case looks home made. The stakes and anvils look a little rough, but most importantly it's missing the staking tool itself. If your intent is to have a complete staking set, you'll need to make sure you get a tool that the stakes and anvils fit. If the stakes are not marked, then you'll have to measure them to figure out which tool they will work with and then track one down by itself. Usually they stay together as a set.1 point

-

1 point

-

Don't worry. There are ups and downs. Many more ups than downs. 4 steps forward, 1 back. The back allows more practice. Non-junk? Been there. They are still junk because they were junk to begin with. We, at our stage cannot repair what is broken, only way we think, is to get a donor movement. More junk, just some spares because you don't know if all is correct. I've learned the hard way. I don't by movements now. I might do when I try high end. I stick to two main watches. Sekonda and Seiko. My choice. What do I do? I buy a cheap running watch. Disassemble, then reassemble. Is it better? If not, then I look at my system. I can now do most things on getting a watch to work again. They always work now. However I have to practice to get them better. Been on one of the downs recently. Bugged beyond belief. You won't believe the amount of support I've had from the members. Beginning on one of the ups now. One thing I do notice is that as a result of learning I can assess many of the YouTubes in their efforts. Some are absolute brilliant. They like to display and explain their methods. These I try to emulate. Others, usually, "I started last week and I'm servicing this watch". Rubbish! They show skill with tweezers of at least 2 years. Many have terrible handling skill of movements and application of tools. I use these to learn about a particular movement. I am completing level 3 of Mark's course. I am now able to understand and emulate much of his teaching. On an extra note. It's nice for other members when we give an update. Proves we listen, and they do give good advice. Regards from across the pond Ross1 point

-

one of the unfortunate problem with watch repair is the slow accumulation of tools sometimes expensive tools. then with electrical watches you end up with more tools some of which can be dreadfully expensive but others could be insanely cheap. For instance at work I have a $20 digital volt meter that I purchased a very long time ago. It works really well for checking resistance, continuity through the circuits and battery voltage. then it's really nice if you have pointy test probes with fine tips as everything the watch requires something smaller. if the watch has a battery strap holding the battery in place then it's nice to connect test probes to worthy fool to where the power is going to verify it's actually going there at all. Often times people forget the but the insulator in at shorts the battery out other times contacts are quite where there supposed to be in nothing goes through it all. Unfortunately with electric watches you do need some test equipment to test as you can't look and see the electricity flowing.1 point

-

I would modify a bezel to fit, better than no bezel in my opinion. Plastic can be chrome plated so a 3D printed on may be an option.1 point

-

. No apology is not required. You did not offend me or bother me. Other than if I'm answering the question I get the answer the question twice. I just point out that I was the person in the other discussion. It just ends up being weird for me if I answer the question in both groups. But don't worry you're not the first to do that there are people here that are on both groups and people in other groups. It just seems strange when I'm answering a question and identical question on both groups so don't worry you just did fine I was just pointing out to get the same answer over there. And in that particular case on the other discussion group I was trying to remember where the picture was which I found for this question not sure if I ever got the other picture in the other discussion though?1 point

-

Thank you very much for the support. I've been at the hobby for about 18 months, and have only worked on a few non-junk movements: I should have waited for the skill to increase!1 point

-

1 point

-

If that is what is working for you at the moment then stick with that, you will know when to change and when to play around with making another choice. Mistakes will teach you that, losing a particularly highly tensioned heavy setting lever spring for 20 minutes will have you considering using something more suited to the job of releasing it. Honestly you will find what works for you, even now after nearly 3 years I've just found something i really like using for holding big pieces and wheels thats very different in shape. Another is curved tipped, these have me using a different hand and wrist position altogether, in a bit more of a relaxed state.1 point

-

Hairspring may cone/ funnel due to either magnetism or physical deformation , if you just let the balance hang under its own weight, the coil might just return back to the flat it was, some times coning is due to magnetism, in which case let it hang then demag. As for the substance in the stud , soak in acetone to disolve it, clean and reshellac or use epoxy 5 glue, ladies nail colour works fine as well. Just make sure you don't over glue/ shellac as the extra glue may migrate to the coil, causing problem. Good luck1 point

-

On pancakes maybe, but waffles? So we've narrowed it down to aliens, evil spirits or the ancient Celtic burial ground your shop is over. Silliness aside, have you considered sending a problematic watch to someone on WRT to evaluate? Or if someone is close to you invite them over for a shop review and a cold one? At this point I think it might be time for a second set of eyes on the issue.1 point

-

one of the interesting problems in life is seeing things? Also microscopes do not necessarily help for seeing things conceivably they will make things worse. Seeing involves visually observing something sending it to your brain and your brain has to interpret what you see which is the problem. If your brain is unable to figure out what it's seeing or just doesn't grasp well that's why the microscope doesn't help at all making something bigger if you still don't grasp what it is you're looking at or why you're looking at it the outcome will still be the same you just not going to see or grasp the problem at all. then on the very top line of the quote I would agree the problem is you because you're the only one working on the watch. Then I was thinking where do you live? The reason I bring this up is United Kingdom is a relatively small place compared to other parts of the planet and I do happen to know they have transportation like trains unlike other parts of the world. Because the UK is relatively small one of the ways to improve your eyesight issue would be to find somebody else on the group and get together compare notes. Often times somebody else will see something that you cannot. I'm actually quite amazed that since so many people are in the UK that you haven't already formed a support group? then the second problem of the quote is the biggest of all the total failure to grasp what screws are used for in a watch. Screws do not have a double purpose of controlling end shake they must be screwed down tight otherwise the watch will fall apart. The definition of tight can be a bit of a challenge. For instance trying to disassemble watch were somebody had a much heavier hand than they should have and the screws don't want to come out that is too tight. But gently tightening them down hoping your watch will run is totally wrong and using them to adjust the end shake is extremely wrong and you still have a problem here. But I guess the good news is we've narrowed the problem down to the balance bridge providing all the rest of the screws are down tight. in my first school as far as I know no watch went into the sawdust. but in the second school that we attended there was the danger of that and other things you had to be extremely careful about wasting the instructors time. On the other hand I don't recall anyone that ever did have a watch glint of the sawdust maybe it was just the threat that was there the intimidating presence of the instructor.1 point

-

1 point

-

Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement.1 point

-

Welcome aboard the S.S. Rabbithole. If you don't think you have too many tools, then you don't have enough tools.1 point

-

1 point

-

Welcome to the WRT forum. Some members post vids on youtube and gives the link here.1 point

-

OK, have to say that I ment the chinese tungsten carbide bits that I use, which are pritty brittle and easy to break.1 point

-

It's a matter of preference really. You should keep the #5 aside and just use them for fine hairspring work though; otherwise they will end up damaged and be useless for that. Some like #1, some #2, some #3 for general work. Some use brass or nickel tweezers for general work- this is good as they are less likely to scratch delicate parts, and are much "grippier". On that note, the finer the tweezer, the more likely it will be to want to launch parts. I have a bunch of nickel tweezers that have been retouched so many times they are like 30% shorter than new. Those become handy for when you need very strong tweezers- just used a pair to unscrew the bond from inside a floating barrel. My general use tweezers the last few years are a couple of pair of #5 that have been sharpened enough times that the ends are now very strong; useless for hairspring work, great for general work. These are Dumont Dumostar, which is a much more tough alloy than the Dumoxel, and less brittle than their carbon steel ones.1 point

-

Back in the day you would always dry parts in sawdust; it soaks off the solvent (benzine, maybe alcohol) and avoids condensation. There were little boxes with a layer of sawdust at every bench. The "dust" part is misleading- more like dust-free micro wood chips. This was still common, at least in the restoration end of things, when I was in school. If you brought something to the teacher to check that was clearly wrong, you might get away with it once, but after that your movement went in the sawdust. Meaning you got to take it all apart and reclean and oil it... so you got good at bringing things up that were worth the teacher's time, haha!. I still use sawdust sometimes, but I didn't drop student's movements in it when I was teaching, and don't do it to the new guys at the workshop- though I have been pretty tempted.1 point

-

Hi bob, make the pivot wire to suit the hole not the hole to suit the wire, once fitted the pivot can be burnished down to size. In the case of a balance staff you would want enough on the wire to blend it into the staff cone.1 point

-

I only will say that replacing the heart cam will probably lead to the need of new adjustment of the resetting hammer, which is done by filing.1 point

-

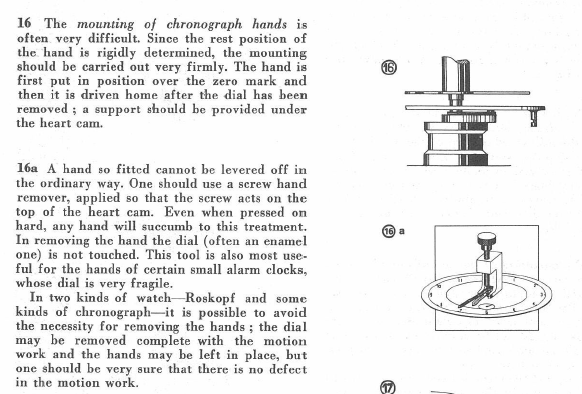

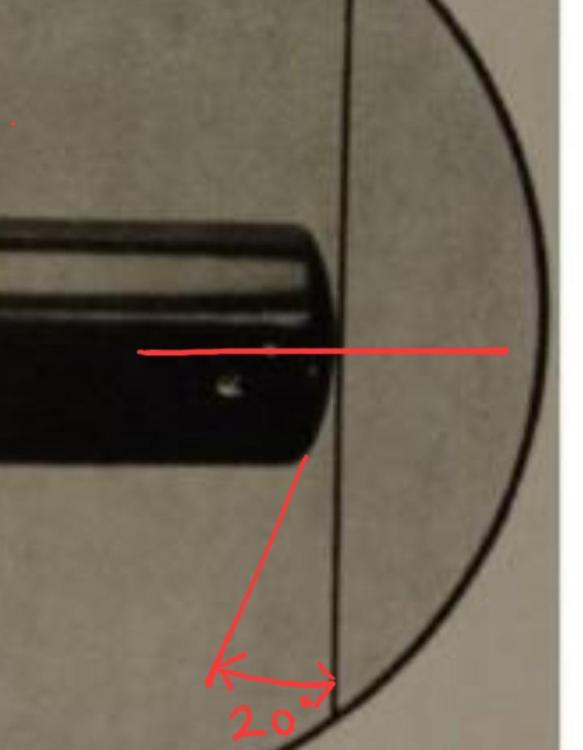

I wonder if I could just copy and paste the answer from the other group? It would save time for me writing it again. Then I did find your picture I need to post a picture of the other discussion. Then just a reminder some people don't use the same identity everywhere the other group they tend to use real names sometimes. Now even though the discussion uses the word chronograph it really applies to stopwatches. The heart-shaped cam is attached to the hands with the extreme force. So when you're removing the dial the hands and the heart-shaped cams go with the dial there held on with a little spring onto the driveshaft. The reason they go on with considerable force is in the case of a stopwatch the hands are really big and long and have a lot of mass and when they come to a rapid stop on reset if their word on super title start moving around. This unfortunately also means that removing them can be a bit of a challenge. The picture isn't exactly what I remembered I remembered something a little different but you get the idea. Similar to conventional hand removers something goes underneath but a center pin pushes the heart-shaped cam out of the hand. Probably makes more sense to look at the picture than my description.1 point

-

1 point

-

Perfect, thank you! I have a spool of PAHT-CF drying out right now, planning on printing these baskets tonight.1 point

-

Hi. Thank you much appreciated. Other members can see what’s on .1 point

-

1 point

-

Well spotted @praezis - just testing you . There was also no end shake in the barrel, which is what was causing the problem.1 point

-

But that cannot have impact on performance. The arbor moves when winding only.1 point

-

Just to end this thread - I put in a new balance staff and shock jewels. After having 12 hours to run in, on a full wind, the numbers are : DD 290° 0s DU 284° +7s CD 235° +2s CU 227° +2s CL 228° -5s After fitting a new staff, I thought I might need to tweak the balance, but I'm more than happy with the numbers. I think one reason for the good performance is, all the pivots in the gear train are beautifully polished, AND the shoulders of the pivots are polished. Not something I've noticed on other makes. The original poor performance was due to lack of end shake between the barrel arbor and bridge.1 point

-

1 point

-

1 point

-

So in the end, you built a watch. I have a few like that. With my Paul Breguette, the dial, rotor, and I think the power reserve hand are original. And I also have a gold watch that I assembled from a collection of FHF (ST) 96 parts, a generic non-branded dial, and a vintage case I had on hand. That one I may name S.O.T. for fun (Ship Of Theseus).1 point

-

Hi. Old and Grey as long as you are still young at heart thats all that matters. A few very knowledgeable old timers here and also plenty of us chasing at their heels . Accompany questions with plenty of photos so everyone can see, understand and help. Movement identification is very important so if you haven't already then add that information along with your question. If struggling to ID something then post pictures of any logos, initials , letters and numbers you find inside. Enjoy.1 point

-

I didn't get it. I am on a Levin lathe binge. Turning my small fortune into a smaller one1 point