Leaderboard

Popular Content

Showing content with the highest reputation on 11/23/23 in all areas

-

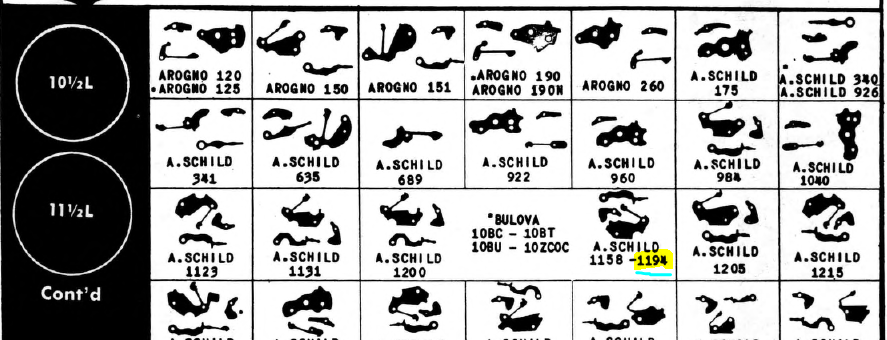

The watch world is littered with examples of ebouche's that have been supplied by one company to be built into watches made by a different company who modify or refinish it to their own requirements (ebouche literally means rough or unfinished), even removing the original manufacturers branding, if it was even there in the first place (it could well be a contract requirement that the ebouche's are supplied un-branded). Such modifications could be technical improvements to the movement, or could just be cosmetic, including changing the shape of the bridges. I very much doubt this is a "copy" of anything, but is an AS1194 supplied un-branded to the client company for them to finish as their own. AS might even have carried out the modifications themselves to the client's specification.4 points

-

Looks like a variant of an AS1194 with a slightly different train bridge shape.4 points

-

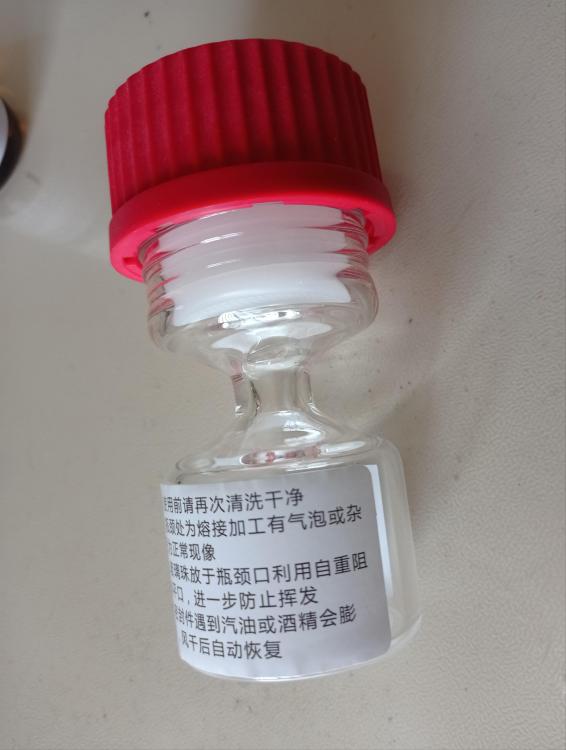

3 points

-

If you want to build an ETA (real one), I can recommend this eBay seller. No affiliation other than I have bought and built with their parts at a friend’s request. https://www.ebay.co.uk/str/swissmadetime?mkcid=16&mkevt=1&mkrid=711-127632-2357-0&ssspo=hL35BJNHR7W&sssrc=3418065&ssuid=suvalalxrs6&widget_ver=artemis&media=COPY pricey but Swiss Tom3 points

-

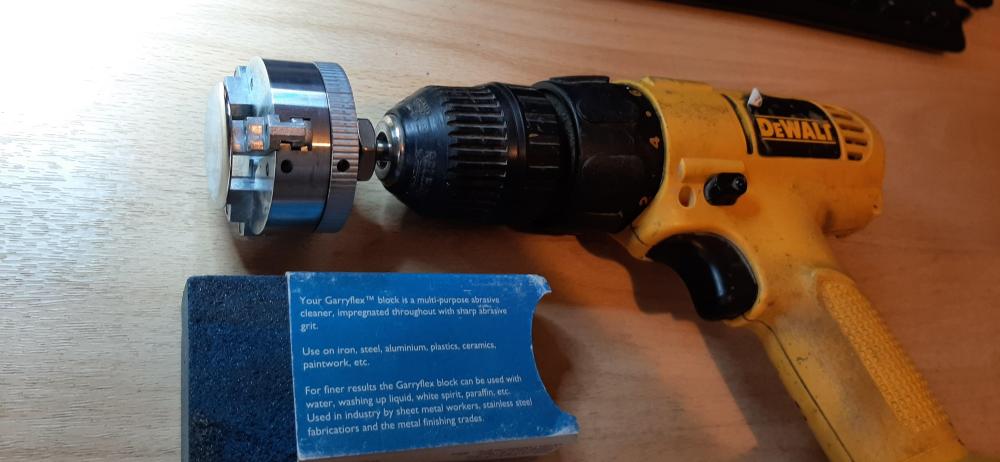

Haha initially i was playing around with different bits of steel wondering what to use, seeing what files i had would cut which bits of steel. No files would touch any of the steel without stripping the file's teeth. So then i set up a little grinding station and it all started to turn into a bit of an experiment. Stuck the broken part onto the end of a feeler gauge, rough cut the part with a grinding stone and diamond wheel which was extremely easy, didn't have a way to anneal the steel correctly, so i just went with making a diamond file which cut into the steel really well and just carried on from there. Short story is ' i got impatient and just wanted to f around ' . Tbh i could have made life really easy for myself and bought the part from Cousins for fiver, but thats just not me, what is me is wanting to learn something which i did. Next time i will do it very differently, the first thing i will do is anneal a piece of steel That is the best way for more than that reason. Next time i will anneal some steel, remove any pins on the broken part and drill through where the pins were located. Stick the part to the steel and drill off all the holes directly through the old part. Fit the pins in the steel then slide the old part over the pins and stick it down, cut out the shape using the old part as a fixed template.3 points

-

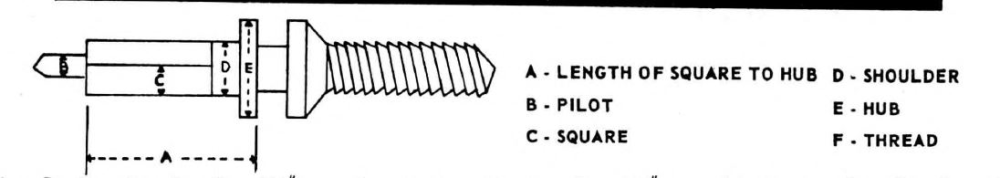

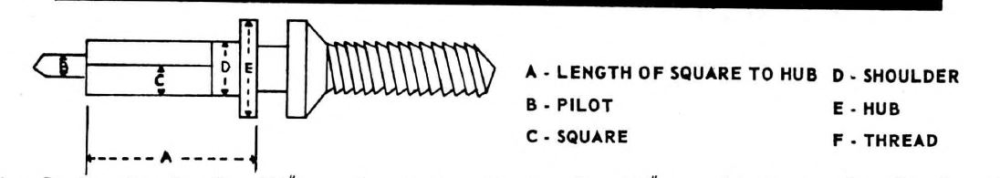

Yes in those earlier days of you might have to make something things were available like that all sorts of interesting things. But as we move into the generation of you can just order it online all of that is slowly disappeared. For instance even the Swiss in their watchmaking books earlier versions will explain how to make a stem the later versions won't even cover that. Which is interesting if you look at the videos of their schools they spend a lot of time learning how to make stuff but they don't put it in the books anymore. Oh and thinking about the book in multiple generations apparently this question is come up in the past and I've attached a PDF of the chapter that's no longer available in later versions on how to make a stem. Then in the earlier days there were material books with all kinds of useful information such as bestfit and others. Often times they would list stems staffs other things by size. For one thing is even if you can't find your exact stem you can at least get one and modify it. At isn't there is something really close. Here's an example of the dimensions that the bestfit book Has But if you're dealing with anything vintage identifying it is really the least of your problems because even if you identify a vintage watch no guarantee that anyone ever stocked parts for that watch. There always seems to be an assumption that if I can identify it parts are available but that isn't necessarily true. Plus if the watch has worn out a little bit then the original staff size wouldn't be right anyway. Which is why a lot of companies made oversize stems to compensate for that. making a stem.pdf3 points

-

It's 100% Bergeon. Well.... Bergeon had it made. I've owned probably a dozen sets of these, some marked Bergeon, some no name, but clearly from mid 20th century. Identical. There are little nuances, also between Bergeon sets of the same period. Definitely Swiss in any case. The big change on these was when they started making "Nivaflex" sets. The only real difference is instead of a hoky (usually too long) hook, the hook is "internal" to the arbor. Basically machined in, on a spiral, like a real barrel arbor, instead of being whacked in raising metal with a punch. I think it was to accommodate some of the unforgivingness of modern alloy springs being stretched out. Caliber specific winders soon followed, as the trend became to make barrel arbors smaller to allow more spring length, and the old standard winder arbor diameters proved to be too large. I might have this identical set- will check tomorrow when in the shop. I like that a lot of folks back then wrote the date purchased under the lid, I think the set I use most is marked 1943 .2 points

-

2 points

-

2 points

-

I have enrolled on many different online courses timezonewatchschool.com, learnwatchmaking.com, and, of course, watchfix.com. With the reservation that I haven't gone through all the material, I still have to say that @Mark's courses are the ones I appreciate the most. He is incomparably pedagogical both in terms of the explanation and the video material. It's like a one-man well-made BBC documentary. Truly world-class! No, I don't get any kickbacks from Mark, and I'm not trying to kiss the part of his body where the back ends. I had no idea! I'm on my way to the Philippines in 2024 and will be staying there for about six weeks, so I'll look into that and see if I can visit them. That would be very exciting!2 points

-

From what I have seen in the few years I have been dabbling in this Scott being paranoid and having a healthy dose of scepticism/cynicism does no harm. Saying that I haven’t heard of Oz being the new Mumbai. Getting parts, tools and training in Oz is very limited as I’m sure @Michael1962 can attest too. The Philippines are probably the next in rank to Mumbai for Frankenstein watches then Eastern Europe. I just remembered, in the past year I have seen several UK sellers that appear to be buying ‘Mumbai specials and reselling them on eBay as UK origin. Ashamed to admit I got caught out by one of the buggers, luckily I got my money back when I threatened to report them for selling counterfeit goods which is a criminal offence here. Tom2 points

-

2 points

-

Oh, so it was a documentary?! I have so many watches to work on and told myself not to get any more until all (or at least most) have been serviced and are running well. Then a voice within told me I needed a regulator dial watch with a Peseux movement. So, waiting for this from a seller in Germany...2 points

-

Hi, Sorry, no such things as replacement jaws. They are grinded and polished together as a couple and the way of replacement is the same - glueing, grinding and polishing. If no other chips anywhere on the jaws, the tool still can be used as normal, just avoid this exact position where the chip is.2 points

-

Thanks for showing how you do staffs on an engine lathe. I've had to set aside my work for a while, as we are moving, again! Third time in three years. When I get things set up again, I will be back trying to make staffs on a Sherline lathe. A little more practice and I will get there. Cheers!2 points

-

2 points

-

Nice work @Neverenoughwatches, it looks good. My only question is : if you now need to anneal it to drill the holes, why didn't you do that first, which makes shaping it so much easier. When annealed, I could have sawn and filed that in 30 mins, not 4 hours grinding My problem is drilling the holes. I always do that first, so if I screw up, I don't waste time shaping. How are you going to drill the holes ?2 points

-

OK, I usually make balance staffs for big pocket watches out of rollers from roller bearings. This are rollers from car driveshafts bearings. I know people with car services and thus have unlimited source for material. The rollers are size 1.8-2.4mm diam. X 10-15mm, usually made of good steel and are hardened, need only tempering to deep blue. Actually, the tempering slightly depends on the steel sort, and there is a rule by G. Daniels that says 0.1mm test pivot should bent to 30 degr. before it breaks. I also check if the test pivot is normally strong, as in some cases it will break much easier than a normal pivot, and then this lot of rollers (or steel) is not good for staffs. For wrist and small pocket movements, where the pivots are thinner than 11, I usually use 115CrV3, this steel is superior to everything else that I have ever test, but I have limited quantity, it is soft and needs hardening and tempering. Working with this steel is a pleasure. I also have and use soft У10А, which is Russian analog to O1. Usually make of it screws, stems, etc. It needs very careful heating when hardening, as overheating is easy and it ruins the steel, developing big grains structure and parts break easy. Here is my main lathe, as You see it is really big and actually nothing to do with watchmakers lathe, just regular general purpose 70 cm lathe. But, I am able to make staffs for the smallest wrist calibers on it. I also make threaded parts on it, directly from blue steel, but with milling attachment instead of cutter. The interesting here is this set of cutters, which are accepted on the place of the tool post. They are pre adjusted in high and ready to use. Changing the cutter takes minimal time. The cutters are tungsten carbide and are made of CNC router bits, which are cheap and easy to source. I use this kind of diamond disks to sharpen cutters. The smaller disks are cut from a bigger one, the disks also easy to source, grit 600 or 800. I sharpen the main cutter every time when start new staff turning. If the cutter needs re-sharpening during the turning, this usually means that the steel is to-hard. If it is possible to turn 2-3 staffs without re-sharpening, then the steel is softer than needed. I have developed technic for easy maintaining the sizes in high and making one staff usually takes me about 30 min.2 points

-

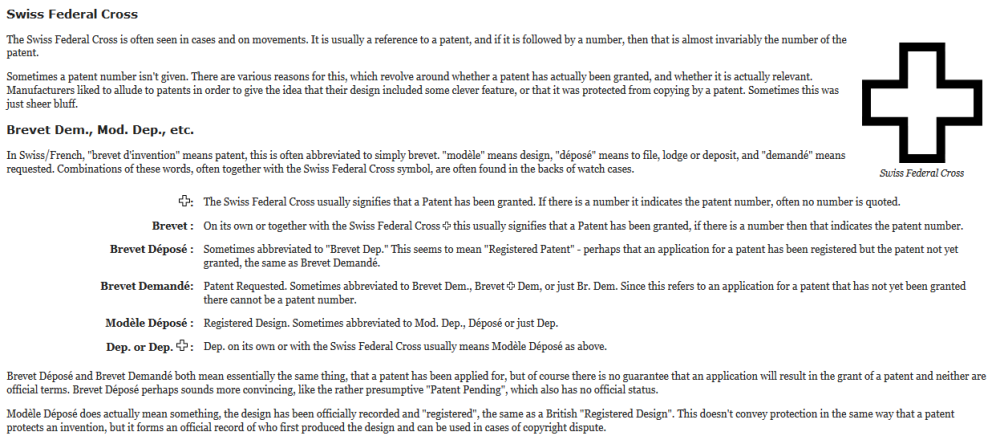

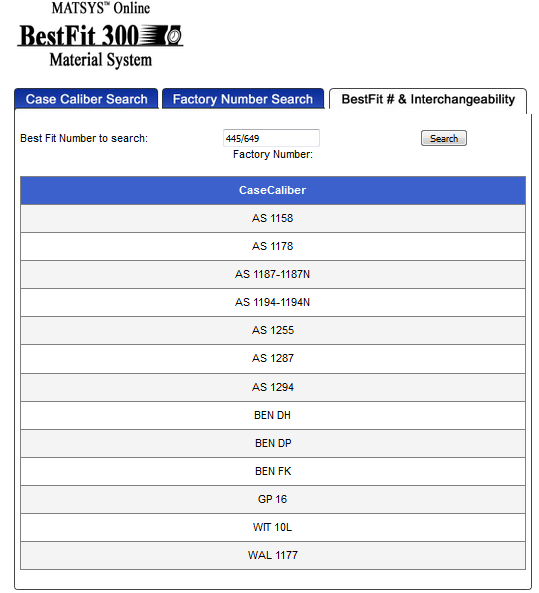

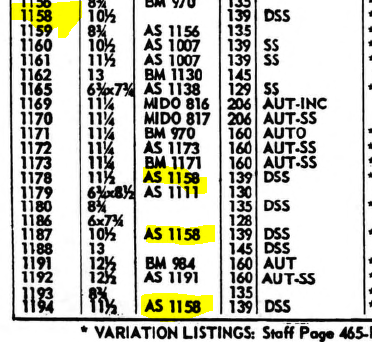

People collecting or repairing watches often are very confused by who made their movement. I was a lecture where somebody was giving the history of the Gruen Watch company and there is something quite fascinating. The collectors for being fascinated with who actually made the Gruen movements. What I was fascinated with is the company who made the movements who else were they making movements for who else needed high grade movements? Then some of the key players like their OEM company so much they purchased stock in the company with one of them finally purchasing the company as their own in 2004. You can see the sales price at the link below and you probably be surprised with who the company is you probably thought they made their own movements. Well they do now comes the own the company. The other thing of interest in the lecture was for OEM type movements when you have several high-end companies purchasing to make their movement look different they change the plate layouts and took out a patent. They still have people having the same movement but the plates will be laid out differently. This is why in the Gruen lecture he said there's still trying to figure out who made some of the movements and then be comparing with other companies to see if they could figure it out similarities and things. https://www.watch-wiki.net/doku.php?id=aegler So back to the problem of your watch identifying it? So yes the identification seems simple look at setting parts if they agree we have a number or do we? Why did companies like bestfit come into existence? So for instance we've identified the set bridge a key component in identification of your watch but have we identified the watch yet? Let's look at the top of the bestfit book noticed what it says gives you the caliber number the size the page where we can find the setting parts the part numbers and movement interchangeability? Let's go to the bottom of the page and we see that the 1194 as a base caliber of 1158. Notice in a few other movement still use the same base caliber? Now back to why do companies like bestfit exist? Even in this example we see in that a lot of parts will interchange and then we end up with a lot of other companies conceivably purchasing the movement putting their own name on it some companies like Bulova would possibly sell their own parts and soon you can end up with hundreds of parts packets considerably all containing the exact same part. Or maybe the company doesn't even have parts than you don't get that many parts at all. But then companies like bestfit come along they help you to identify your watch they give you part numbers and then you can hopefully purchase parts. Or maybe you do something a little different digital bestfit is online at makes it a lot easier to do things like this for instance that unique set bridge that identifies your watch I wonder who else is using that set bridge?1 point

-

Both my daughters and my as of last week or so 7 grandkids are all in Oz, Gippsland and Brisbane. If I can help get you stuff in the UK and ship just shout out. Tom1 point

-

Thanks @Marc, I knew about ebouches but didn't know that they could be unbranded.1 point

-

You are quite right Tom. There is not a lot to be had for anything like the prices that I hear people talking about on here. Tools? Another goldmine for the companies that sell things. Check Labanda and you will see what I mean. I Google things as well and find things and think that I am seeing a great price until I dig further. Sorry we do not ship to Australia. Or freight costs that are more than the purchase price of the item. 400 day clocks which I like? (Sorry @oldhippy) Quartz examples which I am not interested in. >$100 Non working mechanical ones or ones with flaking paint etc which you just would not be able to match. >$175 mostly. Courses to learn? Zip. BHI which entails a mandatory trip or possibly 2 to the UK. Online via Watchfix which is one course that I have yet to hear a bad thing about. I stumbled onto 2 clocks that I have. One for $20 which has a lovely movement in it. An Urgos Grandmother clock for $5 which needs some work. I hear you saying, “There you go. They are out there.” That was it in about 4 years. I have another clock which I bought as I loved the look of it. $185. Apparently serviced and running. Nope. Another common mantle clock that I picked up from Darwin. By the time it got to me with purchase cost and freight? About $180. And that is going to be my learner movement. Where I live in Geelong, there isn’t even a clock repair company. Watches. Take them to a jeweller and hope they can get someone to service them. I took my Seiko in. Too old. Can’t be repaired. I hopped on the internet and for postage and a reasonable charge, I have the watch that I got from my parents over 45 years ago repaired. Australia. The lucky country. Yeah, right.1 point

-

Hi Vizard I am in Ireland, We have laser cutters, engravers and welders for all kinds of materials. We tend to concentrate on small component services. I build laser machines for a hobby and working on a small watch makers CNC lathe at the moment. Hopefully will be able to produce the likes of custom watch case backs in the future.1 point

-

will have to look into the Garryflex blocks. Looking forward to seeing the finished case back1 point

-

Hi I would hazard a guess that Tom is on the right lines regarding the Philippines. They also have a very professional Watch School run by Israel Angeles which is associated with the AWCI in the states. Israel Anglese also makes by hand a very professional testing equipment for watches. His quartz watch analyser ( which I have) is very good, not cheap but good as is his other diagnostic tools. Look up pinoy watchmaker on the net. The brand name is Le - Arsi can also be found under that name via Google.1 point

-

I’ve noticed more inventory originating from Oz as well- watches, parts, straps. I assumed the vintage trend was strong and they still have lots of old watches stashed away. Based on some of the auctions from US and UK inventory feels kind of picked over … The two watches I purchased from Australia were fine btw a d shipping costs reasonable…1 point

-

My 3 Tissots get here shortly. They are in Melbourne awaiting posting out. The tools I ordered don't get here until December by the looks of things. Looking forward to this. Have to get my butt into gear and enrol in Mark's course. Can't do the BHI thing as yet. Life getting in the way a little bit. Hopefully in time. Sill reading my clock books as well.1 point

-

1 point

-

Hi all I haven't been on this site for some time due to health issues. However, my interest in watches hasn't waned over the years and I have accumulated quite a large collection of various makes. My big interest though is in Seikos particularly divers of which I have quite few in various states of repair. A selection are shown in the attached photo. I'm hoping to be a more active member of this forum in the future.1 point

-

One of the ways of sorting out if the pallets are worn is to re-face them. Some advice is getting out of hand with this type of clock movement. Providing the escape wheel teeth and pallets are fine you just adjust the pallet cock so the escape is not to shallow or to deep, to deep and it wont work, to shallow and the pendulum will hardy swing. It is also good practice to mark around the pallet cock before removing.1 point

-

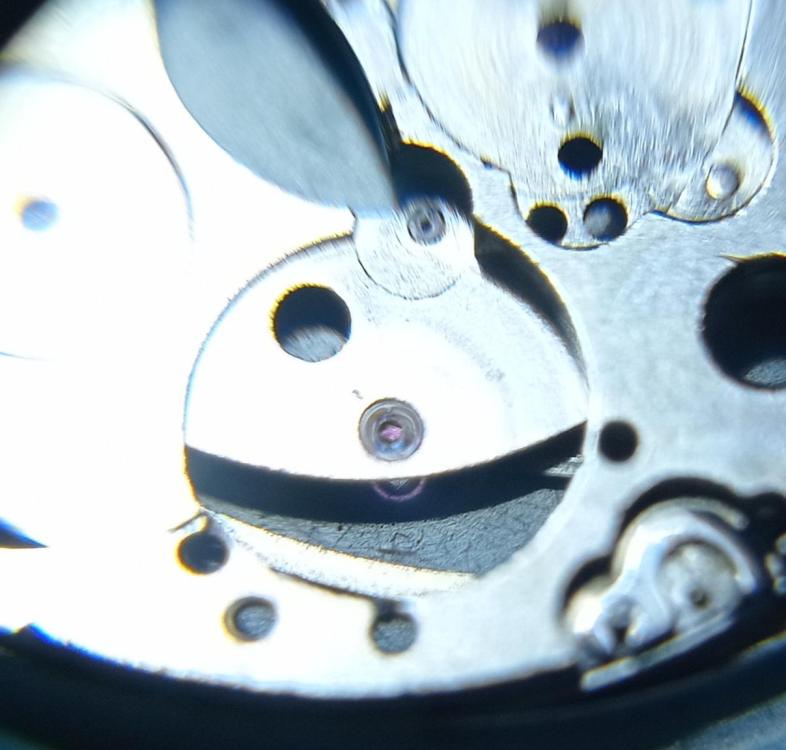

With a few exceptions, most watches use movements inside which are made by someone else, for example I am currently working on an older Accurist watch, which has a movement inside made by ETA. You should take the back off the watch and look for a makers stamp on the movement, this is quite often located under the balance wheel (see example below), usually a little shield with some letters inside to identify the manufacturer and then some numbers/letters under this for the model number (Cal.). You may have better luck looking up the movement than the watch manufacturer. Post some pictures and I'm sure someone here can identify it if you are having problems1 point

-

1 point

-

1 point

-

1 point

-

That is the mark for the First Moscow Watch Factory used between 1945 and 1963. According to Ranfft production was shared between 1st Moscow watch factory and the Watch Factory Maslenikov for a while. Check out the link here. It suggests that there are variants from Pobjeda, Raketa, Slava, Wostok, and ZIM. I would be surprised if you can find a new part for it which means that you will need to look out for a donor movement. Looks like there should be plenty of choice.1 point

-

The way that case is tarnished, it certainly does look like silver. A quick wipe with a silver polish cloth and I bet it shines. (Not saying how pure the silver will be..)1 point

-

1 point

-

On these clocks the pallets are mounted on their arbor with a friction fit, and beat error is adjusted by carefully rotating the pallets around the arbor against the friction. To do this place the clock on a level surface and set it running. Observe the pendulum and listen to the ticking. If it's out of beat then the tick on one side of the swing will be longer than the tick on the other, this is because the pallet is engaging too deeply with the escape wheel on that side. Once you have determined which side of the swing has the longer tick, gently push the pendulum across to that side until you feel a stop. This is when the pallet is fully engaged in the escape wheel and can't go any deeper. Now gently but firmly push a little more. This causes the pallet arbor to rotate slightly in the anchor so that when the pendulum is released it will have slightly less engagement on that side than before. Test the pendulum again and you should find that the ticking is less uneven. You may need to do this several times, pushing the pendulum against the stop on the longer tick side of its swing until you get it right and the ticks are even. It's very easy to go slightly too far so you may have to adjust in the other direction as well. If the clock is intended to live on a surface that isn't level then all you need to do is set the beat up on a test surface that has the same slope as the intended location for the clock. That way even though the clock isn't level it will still be in beat. Obviously the severity of the slope that you can accommodate with this procedure is limited by how much free swing the pendulum has. I first got this procedure from instructions on a factory printed label stuck on the inside of the door of a Smiths clock, so at one time it was part of the set up instructions Smiths provided for their clocks, and I have used it on many Smiths clocks since. I can't comment on how it applies to other makes. Also I would say that, as with most things horology, if it requires anything more that gentle force there is probably something else amiss and further investigation is needed to prevent inadvertent damage.1 point

-

Actually quite a handy little gadget for around 25 quid. The best use of it as WW mentions is the pulse test, an audible click that can be heard from it as the chip emits its signal to send an electrical impulse to the coils. The cmos can be tested independently , the one i have can also test for a dead or working quartz crystal.1 point

-

I have this weird little Chinese number that kinda does the same job. Link to a similar ebay item -> here <- and AliExpress -> here <- Ebay/AliExpress keyword search "Professional Mechanical Watch Demagnetizer Demagnetizing Tool for Watchmaker" I bought it out of curiosity as I assumed it had some clever circuitry with coils and transistors to produce an alternating magnetic field, as it is not mains powered. I was completely wrong. It has a small DC motor attached to a disk with some magnets glued to the disk with their poles N,S,N,S. The disk spins, the magnets spin, and it demagnetises things. It also spins the mechanisms of quartz watches very nicely. The build quality is of course terrible and for this reason I can't say it is better than more expensive devices, all I can say is that it does actually, surprisingly, work. EDIT: A proper line tester will generally be able to pulse the quartz mechanism at 1 pulse per second (and probably at other rates), the above device pulses it at a much higher rate than that and sends the hands whizzing round. This is great for unsticking quarts mechanisms, but not for actually testing their accuracy.1 point

-

I know I'm getting on a bit in life. I have never heard of ChatGPT.1 point

-

Here it is. Photograph taken outside on the front step as light too poor inside. It has taken me a while, and I have learned so much. Still so much to learn. Special thanks to YouTube videos. Adam (Weekend Watch Repair), and our leader Mark Lovick (WatchFix - Watch Repair channel).Their presentations on the Bellmatic 4006a have been my bible.1 point

-

1 point

-

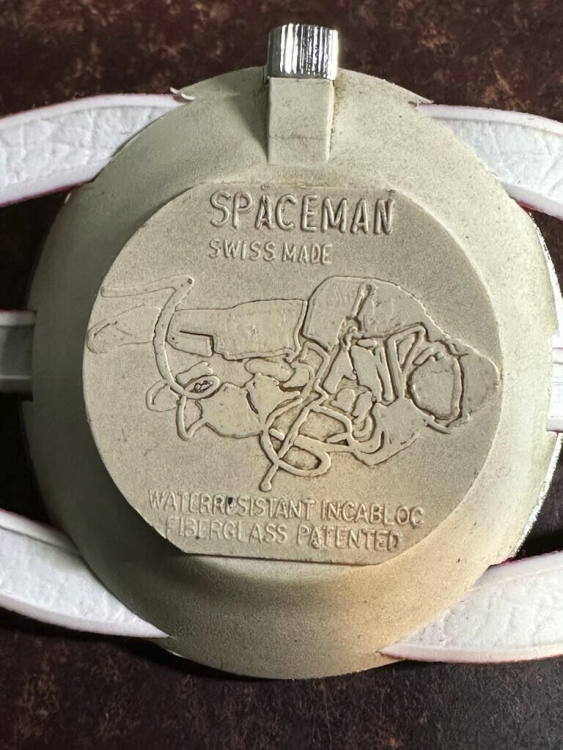

This is one I've been chasing around eBay for a while. It's so perfectly 70s weird. Bidding didn't go as high as I expected, so here's hoping it's not a scam! As far as I can tell it looks correct. No pictures of the movement, but the seller seems reputable so I took a chance. Winging its way across the pond from the UK, so we'll know in a couple weeks.1 point