Leaderboard

Popular Content

Showing content with the highest reputation on 11/20/22 in all areas

-

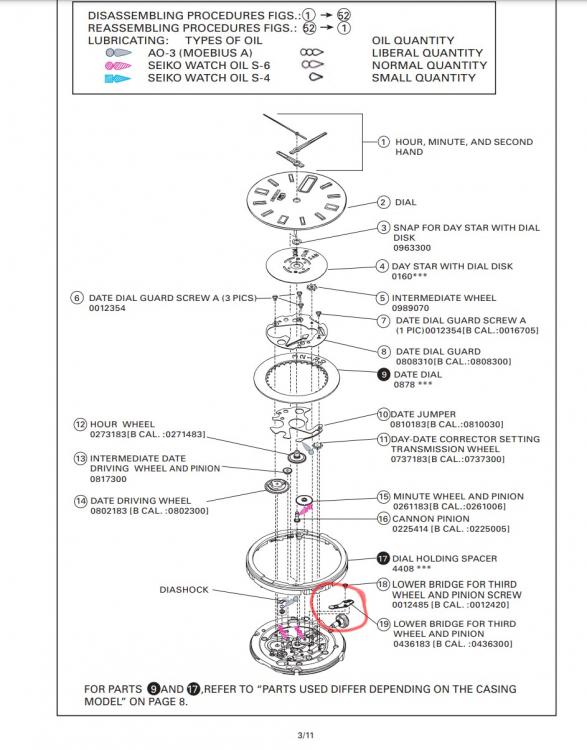

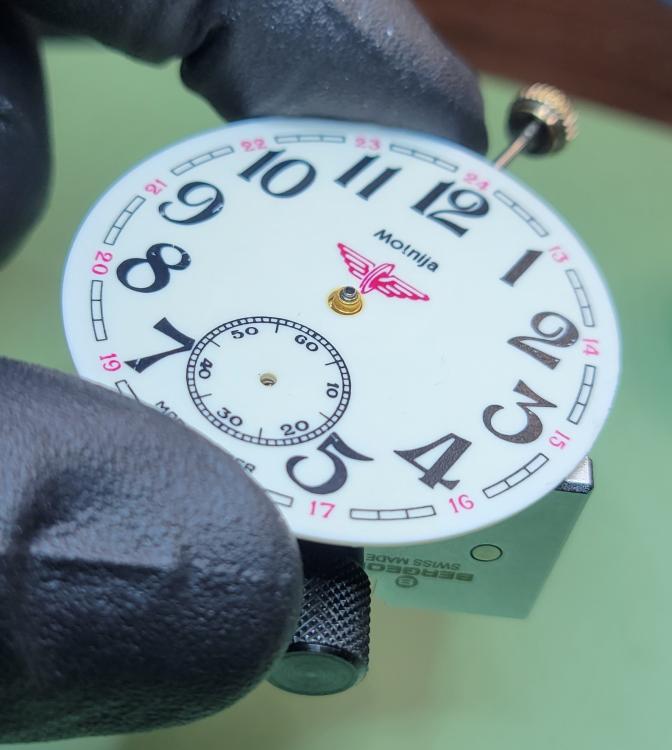

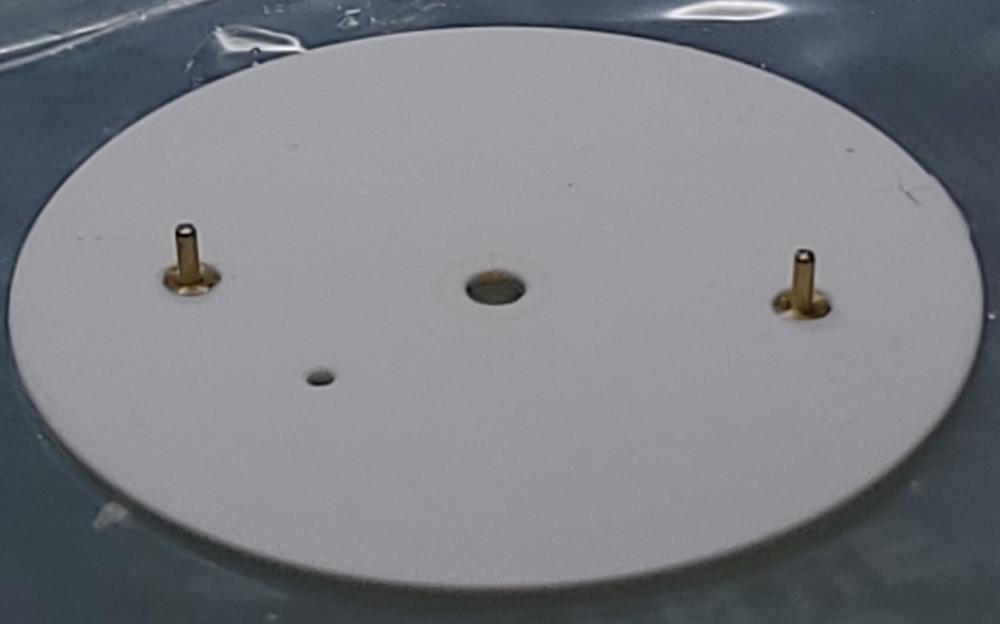

I FIGURED IT OUT! So for archival purposes this is what was goin on. The reason the movement was stopping is because the escapement lockup was failing. The reason the lockup was failing is because there was too much endshake in the escape wheel. The reason there was too much endshake in the escape wheel is because this is one of those weird 7s36 movements with the two extra useless jewels. In the service manual AND the only tutorial on the internet of a service of specifically a 7s36b, it tells you to put on this plate with the two useless jewels in this pic, 3rd wheel and pinion plate after you put in the pallet fork and balance etc. This is fine and i'm not sure why the movement works for the guy doing the tutorial before putting that plate on but putting this plate in drastically cuts down on the endshake of the escapement wheel and everything appears to be working as normal only after it's on. Before it was on the pallet fork would sometimes be on top of the escapewheel which would cause those tooth skips. Very pleased i can move forward again.6 points

-

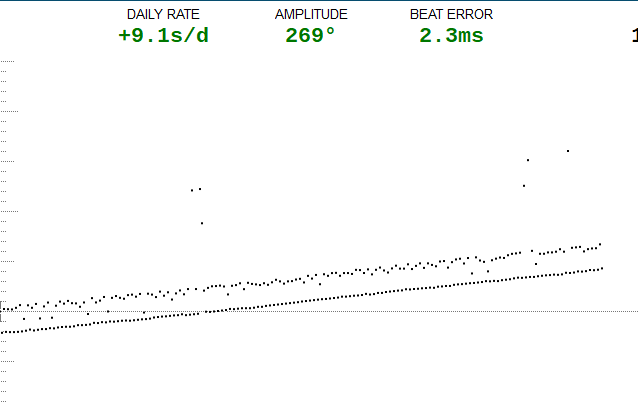

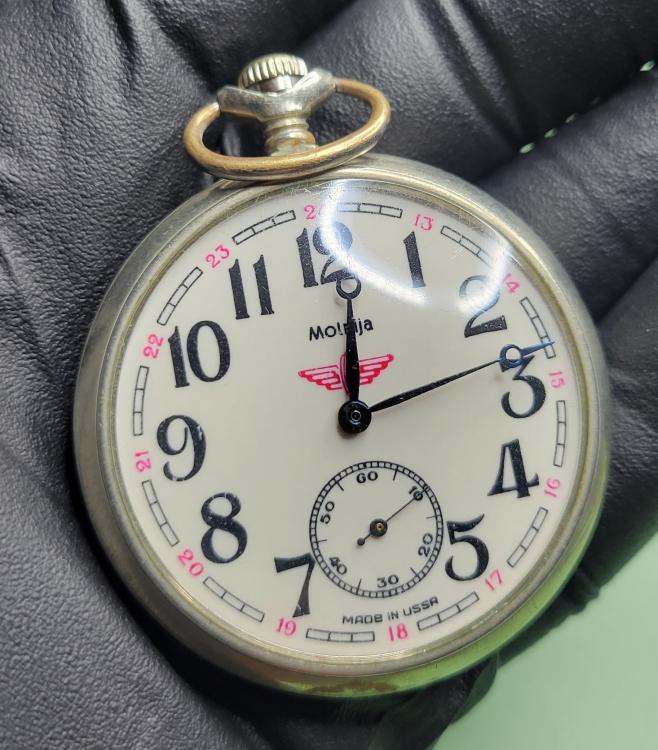

@JohnR725and @grsnovi: good points too ! My plan was give the donor movement a proper service and see what it does. If I decide to swap parts, it will initially only be the balance assembly (balance wheel & hairspring). If my GGF's watch runs happy on that, that's already one option. However, if one gets to the point were the pallet fork, and most likely the escapewheel also needs to be changed, and perhaps when that combination isn't happy even more, yes then it become perhaps a "necessity" to swap the whole movement. For sure, I'll keep track as to which part belongs to which movement. I ordered a box full of junk-parts. Among those parts are quite a few balance-wheels and I do hope to find some more appropriate timing-screws. The original balance wheel had two timing screws missing. Without these two, the movement runs +600 / +700 sec/day with the regulator at full "slow". When I install two of my (too heavy) timing-screws in either slot, the movement runs -600 / -700 sec/day with the regulator at full "fast". If I install only one of those too heavy timing screw, the movement runs DD, with the regulator in the middle (the lift-angle empirical established and for now ignoring the beat-error); What I need to find are two timing screws, combined weight slightly heavier than one of my current timing screws (I don't have under-cutters etc). Then comes the poising part. As for the arbitrate, but best guess, vibration point, perhaps we have to live with that "as-is". So I haven't given up yet on the old balance assembly. It does need more work and as @dadisticsays, a project which requires time. Next to that, the mainspring barrel has wear, so has the center wheel, causing both to be slightly tilted. I'm hoping that by reducing all the relevant hole sizes to straighten those two and that the amplitude will increase..... Regardless, the good news is that most likely I'll get a running watch, be it with the original movement, the donor-movement or a combination thereof Yes it is! There was a late family member who made sure that not all was lost, and there is even one more picture of my GGF. Standing proudly on (clearly) his steam locomotive, wearing perhaps the pocket-watch (you can see the chain) which is now in my possession ..... sadly the watch I received didn't come with a chain, but I guess, if the watch stopped working, these chains were either used for something else or sold. I do assume that my GGF knew these living & breathing machines, knew all sounds and the locomotives quirks. These drivers were thoroughly skilled people and therefor, to restore his watch, I like to pull all my skills (known and yet to be learned) out of the cupboard......5 points

-

There was just enough space - about the same on both sides. The shellac looks like the jewel - I've marked it in the pic. Now the lock looks closer to 1/3 width of the jewel. It was over 1/2 With too much lock, it's interesting to put some power on the mainspring, and move the fork with some pegwood. It becomes clear why you lose so much power: The fork has to be moved a long way before the stone unlocks, all the time the stone is pushing back against the escape wheel ("recoil"), trying to drive it back against the gear train. Hence loss of energy. There's a good explanation of energy losses in the escapement in Lesson 21 of "The Chicago School of Watchmaking"3 points

-

Just serviced the donor movement. I had to put a new spring in (meant for GGF's watch) since the spring in the donor was a clumsy repaired spring. Apart from that, cleaned, pegged and oiled. Lots of recoil. It is for sure a newer movement. GGF's watch banking-post were adjustable and the main-spring barrel had a hook. The donor has fixed banking-post and just a dimple inside the main-spring barrel. There is wear & play, but mainly in the spring-barrel. While taking pictures the amplitude was improving, but for just hot out the oven, not too bad; Next up swapping the balance assembly ...... Swapped balance assembly & cock to GGF's movement; Clearly less happy So it seems that either I get GGF's balance to work or it's going to be a whole movement swap to the donor movement. Looking at the current facts, that brings me to @LittleWatchShop idea; "I think I would swap the movement and continue to work on the original". I may just do that3 points

-

@JohnR725 note that I said: "...and hope..." ...as I have learned first hand that you can't take 110 year-old parts from one watch and just drop them into another.3 points

-

2 points

-

Not so much getting your hands on one is robbing the bank to pay for one. I was kinda hoping some creative soul would design and then 3-D print and escapement model. Because it be so much easier to explain things if you had a visual aid like an escapement model.2 points

-

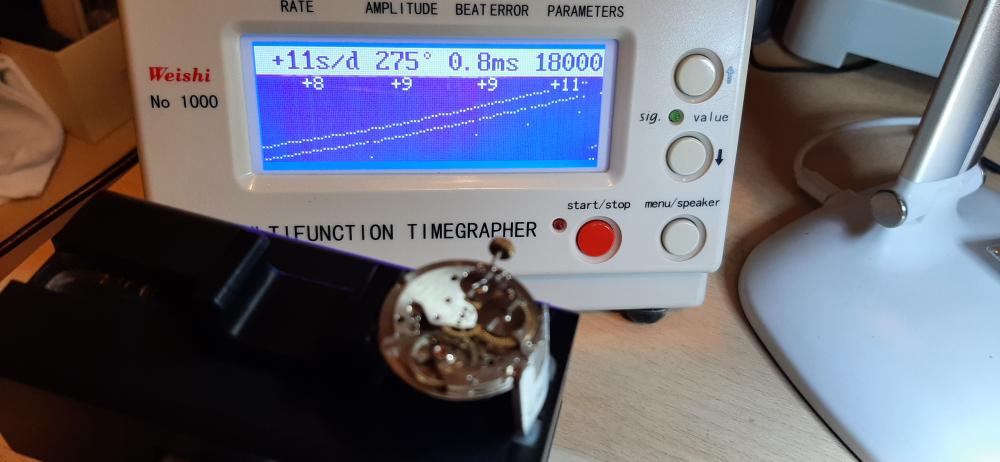

WOW @nickelsilver you have opened my eyes. I didn't realise such a small tweak to the pallet stones could make such a difference. And I can't understand why they are wrongly positioned when the pallet looks original. After reading your explanation, and Fried's, I had a play around under the microscope to get a better understanding. Then I just pushed both stones in a touch, and gained about 40° : 275° DU/DD. CU/CD are both about 225° and clean plots. I need to clean and lube the pallet (looks like something on one of the escape wheel teeth), so it may get better. I think it would be safe to move them in a tiny bit more, but I'm happy with what it's showing.2 points

-

You realize that all of this is based on a assumption? The assumption is that because they look the same that they must actually be the same. In other words that you can swap the parts. Often times with vintage and howl vintage is this watch? Do we establish a timeframe of its birth? Often times with vintage watches the parts are hand fit this means swapping the donor into the original may require modifications. It's always a conceivability of that they may not swap at all. You should come and work in a modern watch shop they do movement swapping all of the time. Any time a watch doesn't work especially a quartz but some mechanicals now that you swap the movement and no one gives it a second thought is just a component of really big component with lots of subcomponents. This is an interesting idea because it would give you a running watch to carry and show Often nobody's I care whether it's the original movement or not you will. Then you can restore the original movement and put it back in again and nobody's going to know either way annual have a spare movement just in case.2 points

-

I think that we slowly can distill an answer out of the above replies. My initial intention was to keep working on the original movement. Reduce the non-jeweled hole sizes (arbor / barrel, arbor / main-plate & bridge and center-wheel) and try to find the correct timing screws. Poise the balance wheel and get the watch ticking again. Now with the new nice donor movement, I don't feel that, if it has to be, changing out the balance assembly (wheel & hair-spring, excluding the bridge) would be a crime but see it more as a necessity. The donor movement is to be kept as spare-parts back-up in case something more / else goes wrong with the original movement. I think my aim is now to keep the movement as original as possible until parts replacement becomes a necessity. It's of course already quite nice and a luxery to have an identical movement for parts. That's already a positive contribution to my GGF's watch story It's going to be an exciting & educative project Thanks all for your contribution and hopefully, in the not to far future, I can show you my GGF's watch in its full working glory again Thanks2 points

-

Hi all I am trying to repair a Seiko 7009A movement, what is the correct size Mainspring winder needed for this size watch movement. I have one of the Chinese Winding kits bot nothing fits this spring, so was going to get the proper size Bergeon winder as I have quite a few of this movement to work on in the coming months. Thanks for any input on this Paul1 point

-

Gentlemen and ladies, I'm embarrassed to say that the reason for the sudden drop in amplitude was not the fault of my WeiShi 1900, but my fault. The tip of the seconds hand was ever so slightly touching the inside of the crystal at certain points, making the amplitude fluctuate. Once rectified and the gain setting set to its default value, the TM gave the same results with the movement cased.1 point

-

Thank you oldhippy. I will set up a saved search on eBay to be notified every day. Thanks Tom. I did see a few assortments but most of them seemed to gravitate towards pocket watches, case screws and the like. Thanks Neverehoughwatches. I was looking at one collection today but very few screws. I'll be on the daily hunt on eBay.1 point

-

Ebay is the best place look each day as its always changing. It's a very good place to look for old stock1 point

-

Timex did not sell replacement mainsprings. Your best bet is to find a donor movement. M107, M108, M109 should all be the same.1 point

-

I have bought cousinsuk screw assortment and there are some very small screws there. If you’re looking for a specific type of screw there are possibly more.specific screw selections available. Tom1 point

-

Almost half the diameter of the arbor. Have you anything to lose attempting to extend the ms slot.1 point

-

Occasionally old swiss or American joblots crop up on ebay. The bridge and cock screws tend to be the larger ones in a watch movement with the crown and rachet having the largest heads. A general assortment from most suppliers should include some of those sizes.1 point

-

I have looked as well. Very recently I bought a collection off ebay. Disappointed. I was gunning for American watch screws. For Swiss screws that I have needed, I made them because my screw plates can cut those threads.1 point

-

Hi khan, Its due to excessive side shake on barrel arbour, which in turn is caused due to worn bushings in the mainplate or barrel bridge or the arbour itself is worn thin. I remove just the ratchet wheel and check the barrel arbour's side shake, you should feel almost zero side shake. Good luck pal.1 point

-

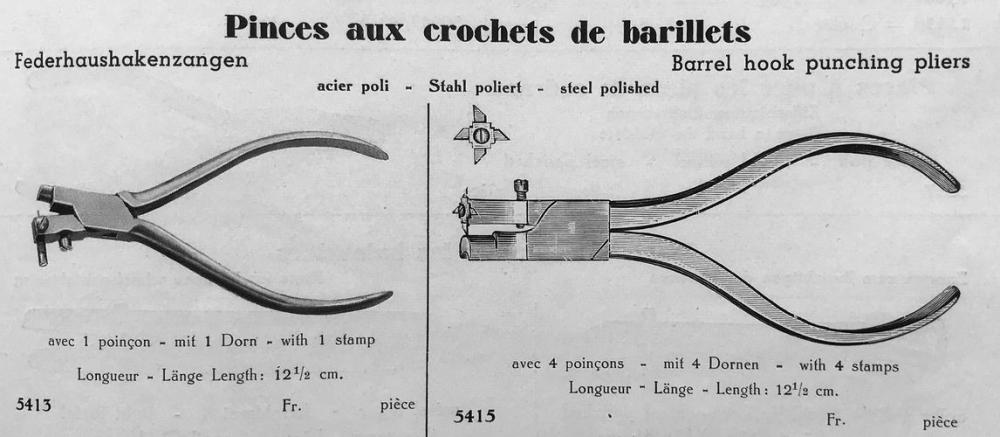

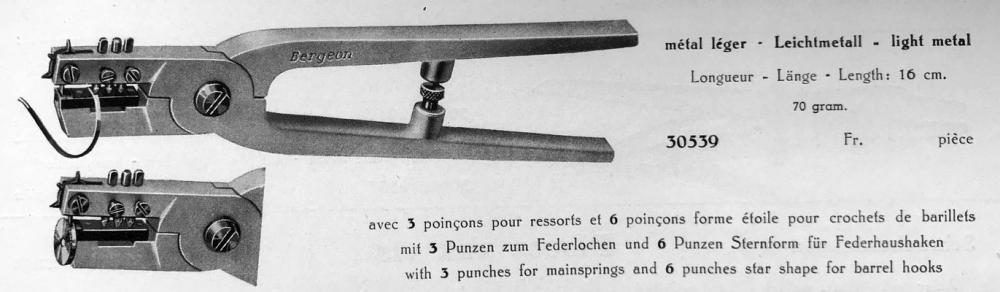

Frank, having put an appeal out to my local BHI members I had a look on eBay just now, and would you believe it, I found a set, hopefully here midweek I will do a couple of test holes in a spare barrel before the customers barrel gets the good news. i will probably only use these once but they are worth their weight in gold . thanks for the picture of the tool that you posted1 point

-

1 point

-

How’s the surface finish on these 3d printed parts like? Looks like there may be small plastic fibres which if stuck in watch parts would cause problems.1 point

-

Rub in, in the case of the escape wheel bridge, the other one is a cap jewel, held in by a small plate, so far as I can tell. I didn't fiddle with either of them. They currently work, but should be replaced. The snakes tongue works as a counter weight to preserve the energy from the impulse so far as I understand. BTW You might like this Breguet related article. https://watchesbysjx.com/2019/08/breguet-natural-escapement-evolution.html1 point

-

The best I've ever seen was on the BHI website. Very nice drawings nice simple write up and unfortunately it's no longer there. That would present a copyright issue if somebody like that so much they swiped it and made a PDF it probably wouldn't be ethical to distribute it because it would probably violate a copyright perhaps. Although I did find it already made PDF once on the college website actually the local college. Made up of handouts they've had in the past and they hand out that was given at and AWCI seminar given at Seattle a very long time ago. Then off I just figure out where the heck that went all attached the but is not as nice the BHI was very clear on the exacting procedure adjust this then go the next step next step next step versus just playing with things like people typically do in leaving things a big mess. Very common on anything vintage. This is a perfect example of why when diagnosing problems you should look at more than one position. Dial-up and dial down should be identical it will rule out pivot and jewel issues. Then going to the vertical positions also helpful for diagnostic purposes. I ask you like to do six positions but I get spoiled at work the machine just does that all by itself. But still even at home I used to do all my watches and six positions just because the microphone does rotate makes it easy to do. Then your interesting waveform is not just the pallet. It's basically one side of your escapement appears to be having a problem. So it can be the pallet stone it could also be the roller jewel a could be also the fork slot even though it seems like it should show up other places. So basically one side of the escapement. When it's doing this interesting waveform what does the amplitude look like? In other words visually does the amplitude look like what you perceive the timing machine says. Often times of the amplitude is way too low you'll start to see all sorts of interesting things which may be an amplitude issue. But I'm still bothered by the waveform kind of well basically is not Street is weaving around a little bit that's an interesting issue caused by what? Unfortunately DIY is actually the best approach except it's still DIY. While the problems with plugging in the PC in that comes up on the timing machine software is typically you cannot plug a piezo microphone into the computer because it's the wrong type. It's expecting a capacitive microphone. There is a Chinese one that you can buy out there but the other approach is you already have a nice microphone. Basically you can just tap into the existing microphone and put in audio. I'm pretty sure we covered that some more in the discussion group. Because the audio is something that's really nice almost all the witschi machines have it it's basically standard operating procedure when you start getting anything weird is you listen because it's amazing what you can hear and so much of it that you can hear that doesn't sound good doesn't look good on the timing machine either but it does help to narrow down problems. okay did find the handouts that I found online once all sorts of interesting information. It would be really nice though with one of these in the future of somebody would document like this the timing machine shows this this was the cause. Because as I said it's not always just the entry or exit stone I once had a roller jewel that would wobble so in one position it looked or one side looked bad the other side looked fine it was just the roller jewel. Or as you note all sorts of other issues can occur thing is not quite where there supposed to be things that are rubbing in some positions not others. Oh thinking about positional stuff, little eight reading I have a link to a PDF Yes a manual for an old obsolete timing machine but written at a time where watchmakers were new to timing Machines. What makes this nice then is it explains how the timing machine works talks about the waveforms for instance page 17 announce PDF page notice it talks about escapement things that can affect the display. An example basically of why you need to look at the watch in more than one position because you're missing out on the beautiful diagnostic effects of a graphical display. Then in case you think I'm joking about the effect of the graphical display in a variety of positions somebody with the last year or so I was Omega watch is perfect on the machine but it sucked on the wrist because they never time did another position and when they put another position it sucked and I don't remember what the outcome was but unless you hold your watch in one position you really do need to check it in several positions to see what it's doing. http://www.historictimekeepers.com/documents/Micromat.pdf Escapement handout wostep nscc.pdf1 point

-

This watch has been a great learning experience. First, the results. This is after a day of running in. I know the beat error is still a tad high, but I haven't messed with it since pressing the hairspring back onto the balance staff. It turns out not only was the hairspring twisted up in a few directions, but the balance wheel itself was dished such that one edge was hitting the center wheel! A little work with my staking set was able to fix most of it. It's still slightly wobbly, but it clears the center wheel. I've been wanting truing calipers for a while--I have another of the same watch that needs a balance staff replaced, so maybe I'll use that as an excuse to buy a new tool. I also got to use my dial foot tool, since both feet were broken on the plastic dial. It was very easy to use. The hardest part was getting the old foot out of the movement plate! Only thing left is to case it up. It's got a handsome little dust cover under the snap-off back.1 point

-

Ah ok i guess different countries have different access to buying platforms. Sorry about that but think positively, keep your eyes and ears open and good things will come your way.1 point

-

That's a ton of lock on the entry pallet. Like more than double necessary; that alone will eat 30+ degrees of amplitude. I did write a condensed but pretty thorough explanation of escapement checking here: If I ever get my hands on a demonstration escapement I'll try to redo it with photos.1 point

-

https://en.m.wikipedia.org/wiki/Ship_of_Theseus I have faced this dilemma and it is tough. GGF rarely saw the movement, but always saw the case, dial, and hands. I think I would swap the movement and continue to work on the original.1 point

-

If you look at the file types it's not an acceptable file type. Then even if it was an acceptable file type one of the things I really should do with this message board is a limit file sizes because some of the PDFs get really really big and big files on the message board isn't really what a message board likes to have an of video would be very big usually okay looking at the timing machine if everything seems to be perfect the waveform is kind of moving around a little bit don't you find that strange for everything being perfect? If you stare at the timing machine when it's running does the amplitude seems to go up and down or does it really stay close to what it is. I know it's a sin for me to say this but did you know if you service this watch for customer they wouldn't care about the amplitude they would only care about timekeeping. 24 hours from now what is the timekeeping is that keeping time? I know it's a silly concept worrying about time versus the most important thing in the universe is amplitude but we don't have an amplitude meter on the dial we just have a hand to tell time does the watch keep time for 24 hours? Because that's all they cared about in the old days before these newfangled timing machines came out.1 point

-

Can you post some photos of the case and movement it might also help with identification.1 point

-

1 point

-

Me either. At this point in life I'd be happy to never have another watch with either a day or date. They're a pain to deal with at the end of each month (worse in February).1 point

-

Thanks for the quick reply, will keep an eye out for a Number 6 On a good note and down to luck more than anything else I managed to get the Chinese 8200 one to wind the spring and successfully load it into the barrel, more luck than judgment I am sure, but at least its all back together and working. Paul1 point