Leaderboard

Popular Content

Showing content with the highest reputation on 05/08/21 in all areas

-

Dear all, Can somebody with a better understanding of the various steel sorts explain what steel designation is the right one for daily watchmaking lathe use. What I mean is when de Carle writes something like: "...turn on lathe, harden in oil and temper to blue". What modern steel type would be suitable? I know I can buy blue steel rods from Cousins but I would really like to know what's behind it. Cheers and all the best from Hamburg, Alex1 point

-

1 point

-

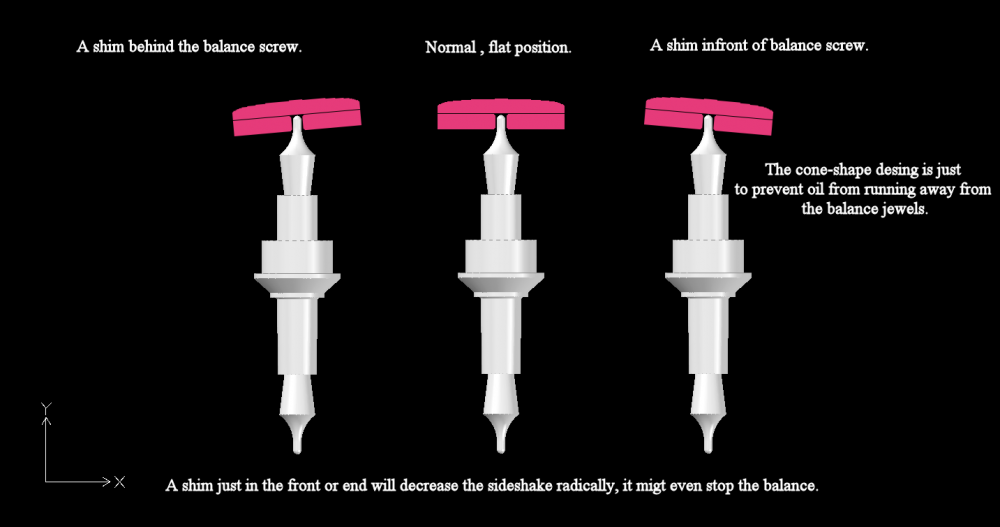

Personally, I'm no fan of the shim theory, it might introduce more problems than it solves. Most pivots are fitted so they will work with the balance jewel lying flat, and the cap jewel too. If you tilt the balance cock forward or backwards the space for the side shake will be noticeable less even too small maybe. The end shake will also be affected and the pivot will for sure not rotate correctly against the cap jewel. A shim which lifts the balance cock straight up is okay if the end shake is to small, even seen people make small notches under the balance. I rather fix the root of the problem without these shims. But this is just my opinion. I made a quick drawing of my thoughts.1 point

-

Below a very good research article about Havila, as revealed by Google search. https://watch-movements.eu/blog/en/2020/03/05/havila-a-nearly-unknown-movement-manufacturer/ About parts you should diagnose first what exactly is broken or missing?1 point

-

1 point

-

I find this watch very interesting beside being super nice. Maybe one of the first examples of partnership between an America apparel brand (founded 1892) and a Swiss maker (founded 1881) ? The 'unadjusted' marking tells how affordable and unassuming the quality and practicality of an automatic watch can be. The large lumed elements will brighten the darkest night, and any good quality, durable strap will be worth on this one.1 point

-

1 point

-

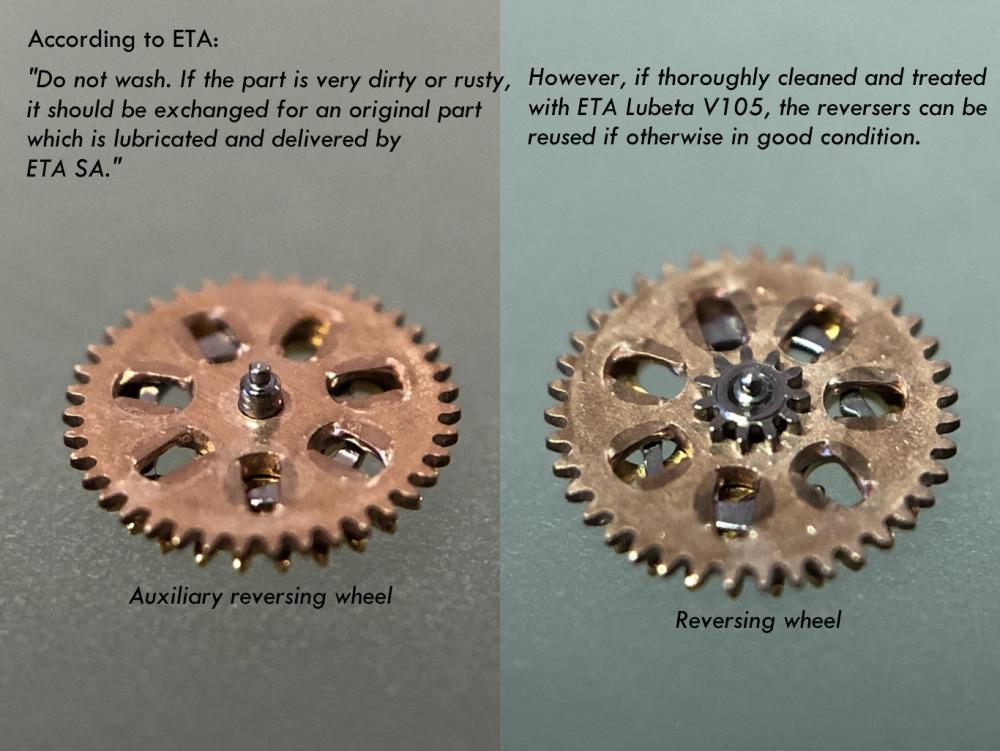

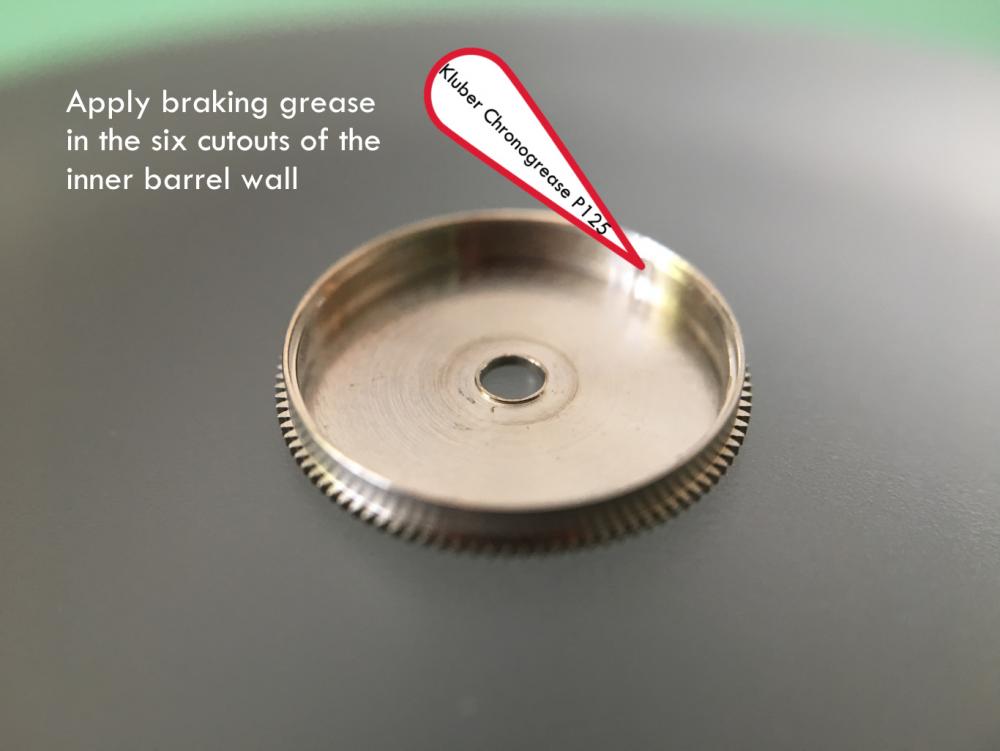

@VWatchie That's really great work! Simply presented with plenty of pictures that speak a thousand words. You've got a talent for teaching!1 point

-

Depends on where you place the shim, if you shim ONLY the outer side of the cock's locating pins, cock will tilt downward so will lower the jewel setting. Regs Joe1 point

-

Hi Tom, If it's a runner and has a seconds hand check that. If the seconds hands jumps from second to second it's a quartz watch. If it is sweeping from second to second with barely noticible interuptions it's mechanical. In the unlikely event that it's electrical and has yet a sweep second: buy it. It's most likely a pre-quartz tuning fork watch and a collectors item. Cheers and all the best from Hamburg Alex1 point

-

https://www.steminc.com/PZT/en/piezo-ceramic-bimorph-15x15x06mm-4-khz-wire-lead1 point

-

it appears to be that we have a broken link. Try this link instead https://www.watchfix.com/1 point

-

Thanks guys for all the help so far, I am overwhelmed by the generosity of the advice given. I have found a company who will take a look for me and go from there. I will keep you updated with the information I receive.1 point

-

Who ever is handling the auction would know, just ask or look at the catalogue.1 point

-

Hi there apparently the release is on the plate below the looped lever and gets pressed down and towards the outside of the case to release the stem, try that.1 point

-

the bestfit book works fine for more common watches or basically newer watches and there are some older books for the older ones that might give us a clue. Of course it would be nice to have the diameter so I don't have to look through huge sections of the book. they would be a lot easier if we knew the movements. In the absence of the movements somebody could measure watch and then we can look in places like the bestfit book. Because a lot of times it's a lot easier to modify an existing stem that it is to make an entirely new stem. But we would need measurements to work with1 point

-

Hi Clockboy and Karl, if you look at my picture above (red arrows), you will see that a secure support simply is not possible: part of the arm (over the hub) stays without any support when pressure comes from top. No Platax, K&D or Unruhmax can avoid this. A link to this topic. Unfortunately in German, but many pictures. It also shows a tool for removing the hub without lathe. Observe the distorted staff near the end of the thread. For me the most convincing reason to avoid punching out. Frank1 point

-

Welcome to WRT and congrats on your fine pocket watches! You will find much valuable information and help here. That sounds great! Anyway, if by any chance you happen discover that you're missing that single required tool in your collection, stay away from the toolbox and the kitchen drawer. The "watch tools" found in those places aren't well suited for watch repair. Trust me! ?1 point

-

1 point

-

1 point

-

1 point

-

It’s interesting to see how the human mind sees no or little complexity in the fields it has no knowledge. Perhaps a good thing or we would be too intimidated to start any new endeavors.1 point

-

There are several ways to learn watch repair. There is studying getting a practice movements practicing until you feel confident or more confident and then starting to work on things. Or there is the painful way which is all too common. That is you assume watch repair is easy and by the way you're not the first there's lots of people on this group that start this way. So the good of this exercise is that you regretted doing this. You've learned something starting on a little tiny watch that you value wasn't the best approach. Now that you're grasping the problems with watch repair you have two approaches to the current problem. The fastest way would be to fall your own suggestion give the watch to somebody else. The other would be to set it aside. You need time to get up to speed if you look at the top of the website under resources there is a watch repair class you can take. Then continue your lessons on learning watch repair at some point in time you come back to this watch. Or you could do both get your watch fixed so it's out of the way and not bothering you and continue your lessons on becoming better at watch repair both acceptable.1 point

-

A lot of questions up there? I'll list your questions out and answer them if I can Why rochelle salt was used in the past? The simple answer is it's what they had available at the time. The Piezoelectric A fact makes for a really good microphone for watches it small compact. Then since are asking so many questions. As a reminder the word microphone may not actually be technically correct. We're attempting to pick up the vibration that the watch generates which happens to be in a audio frequency range. The microphone itself preferably picks up zero audio because otherwise there's all sorts of background noise typically in a room. Or even the old days with the paper tape machines they were making a clicking printing sound you definitely did not what the microphone picking up its own printer. So were attempting to sense a vibration in an audio range. I think in one of the really early machines they attempted the use of carbon microphone. But there physically bigger and don't work as well. One of the nice things with piezo They can be relatively small and not entirely picky on how their mounted sort of and they seem to work quite nicely. Plus I'm sure the original ones were adopted from something else there are available relatively cheap. I'm guessing the original square pick up his exact same one found in audio microphones so they didn't have to make something new and different. why the green bimorph? Because someone was attempting to make a easy to make pickup and they were trying to squeeze it in a physical space. Not that you can't squeeze the disc into a small space but the green sensor is much smaller. Also the original person who made the microphone was in the UK for all the green sensors appear to be and the relatively cheap if you buy him in very huge quantities. They just hard to get for the rest of us. Does it matter how you glue it? Yes according to the technical sheet it does. Which is why if you look at the original pickup that we have it does appear to be glued at one end to have a cantilever of effect like it's supposed to. And everywhere else we see a similar type mounting at least if you want it to work correctly. Why Mark and Jamez reported with the green bimorph that they have not used pre-amp? Some more I thought I snipped out the images but I can't find him because conveniently I don't name them correctly. this just means I don't have any images for us right now. If you look Marks video carefully when you get the green sensor and pay attention to where the wires go they disappear off and there's a whitish object in the bottom corner of the microphone housing. Mark doesn't see it because he's not looking for it. As to the other person I don't know maybe you should try it be easy enough to just wire one up and plug it into the computer and see if it works. One of the ways to answer questions is to do experiments to try things to see what works and doesn't work. Then they'll your questions he didn't ask about optical microphones? Supposedly they work better than capacitive microphones. Here's just an example would probably have to design something special in other words steal the optical part and bounce it off the pickup but the watch pushes against as a wild guess. https://www.sintef.no/en/projects/2010/micro-optical-microphones/1 point

-

1 point

-

290. It’s healthy. I think there was some sticky on the pallets or hairspring. Good soak in one dip seems to have fixed it. I did think the end shake on the pallet fork seemed a bit extreme... was thinking of lowering the upper jewel slightly. The jewel in the pallet fork cock looks as if it can come down a bit. I wonder if it’s been moved during a previous service. This chrono has been hard work. 3 times I’ve been ready to close the patient I’ve realised something isn’t right and had to go back in. But I’m learning the movement!1 point