Leaderboard

Popular Content

Showing content with the highest reputation on 01/08/21 in Posts

-

5 points

-

While digging through my dad's boxes of watches that customers never picked up, I ran across this Jubilee diver. I wound it up and monitored it for many days--it was keeping great time. Then I noticed that the date was not changing. Long story short--the date cam is made of plastic and had broken. I found another movement on Ebay (BTC 7422)--got it, and I replaced the cam, polished the crystal and now it is as good as new (almost).2 points

-

I have the Bergeon extractor, an old one so "old school quality", I don't think it's ever actually worked for me. Also, the standard tips are too big for most modern stuff. I agree with Marc, try backing it out. Very often the remaining bit is actually loose once the head comes off. If it's tight, I've had better luck than the Bergeon tool using a jeweling tool, using a pusher and stump that effectively do the same thing, clamp the screw by its ends, then swing the plate/ part around. Often have to make up pusher and or stump to fit, but it's a few minutes work. In the really bad cases the part goes on the jig boring machine and gets milled out. Yuck.2 points

-

I believe that there have been some comments on here in the past regarding the Chinese offering which suggested that the two bore axes didn't line up very well. However, before you part with your cash, have you tried using a fine pointed needle to rotate the broken part of the screw out? If you have access to both ends of the screw (which you must have in order to use the extractors anyway) then the screw shaft isn't tight against anything once the head has sheared off, which means that there is a good chance that threaded part will just unscrew, and a fine needle point should be able to get enough purchase in the broken top of the shaft to turn it.2 points

-

Once I was searching for a similar shock spring for at least half an hour. I was using my i-Phone flashlight as i find it very suitable for such "search & rescue" situations. Then I decided enough is enough! I turned off my i-phone flashlight and placed it on the desk near microscope.. And what did I see?... Correct! That "lost" spring was peacefully resting on i-phone's screen...2 points

-

I can't tell you how many times my ol beer gut has been the resting spot of a pinged part.2 points

-

Vostok 2409 Service Walkthrough Disassembly Pictures (Please sort by name in ascending order) Vostok 2409 Service Walkthrough Assembly Pictures (Please sort by name in ascending order) Being able to service the ETA calibre 2824-2 was a long-term goal and a dream when I started servicing and repairing watches some years ago. However, my first “calibre love” was the Vostok 2409; a reliable Soviet/Russian 17 jewels manual workhorse without any complications which has been around since 1970. It is still in production and found in Vostok’s Komandirskie series of watches, by some called the AK-47s of the watch world, together with its bigger brother the Vostok Amphibian dive watch. Modern-day Vostok Amphibians use the automatic Vostok 2415 (w/o date complication) and 2416 (with date complication) calibres, but the Amphibian that I’m servicing in this walkthrough, an Albatross Radio Room, popular among collectors, is from the 1980s and in those days the manual 2409, as well as its predecessor 2209, was commonly used in the Amphibians as well as the Komandirskies. While I was servicing this watch, I noticed that the crystal didn’t fit perfectly in the watch case. Being a serious dive watch originally designed for the Soviet navy this was, of course, unacceptable, so I replaced the crystal and video recorded the event in my “Bergeon No 5500 Crystal Press Review”. For me, the 2409 was a great movement to get started with as it probably is the most affordable movement on the planet, and spare parts are readily available and cost next to nothing. A lost or damaged part never spells financial disaster. Also, eBay offers an abundance of used Vostok watches in decent condition housing this movement for as little as $20 and sometimes less. A brand new Vostok 2409 (www.meranom.com) can be had for as little as $27. Be aware that, almost without exception, the eBay listings always state that these Vostok watches have been serviced, but in my experience they never are. Well, maybe dipped in a can of naphtha, left to dry and then injected with a bit of oil here and there. I’ve seen horrible examples! A somewhat tricky bit about the 2409 is to remove and replace the anti-shock springs. For this, I use a self-made tool made from peg wood. It’s shown in one of the assembly pictures together with a description of how I made it. A very similar tool is demonstrated in this video. Later, as I was working myself through Mark Lovick’s watchrepairlessons.com courses, I trained with the Unitas 6498 pocket watch movement which is the selected movement for the courses. In all honesty, from a learning point, the Unitas 6498 would have been an easier movement to get started with (especially the anti-shock springs), but the tinkering with the Vostok 2409 was a low-cost and fun way to get started and made me better prepared for the courses which answered a bunch of questions and was amazingly instructive. Eventually, I plan to publish a “Vostok 2414 Service Walkthrough”. The 2414 is identical to the 2409 but adds a very uncomplicated date complication. So, if you want a whole lot of fun for next to nothing when it comes to money, there is no other movement I would recommend before the Vostok 24XX movements, and the 2409 is a great starting point if you have a desire to begin tinkering with watches. Be warned though; tinkering may take over a substantial chunk of your life!1 point

-

Simplistic of above is hairspring anything that changes the hairspring characteristics. In other words they hairspring is attached to the balance wheel at the collet and the watch at the stud. There is the regulator pins and that's it. They hairspring can't be stuck together with magnetism or oil sticking the coils together. Or touching anything else like the balance arm sets a really popular place it likes to go touching. Sometimes that's really hard to see. Touching the balance bridge. Anything that makes that hairspring appear to be shorter it will run superfast. The problem with restaffing is the balance wheel comes apart and has to go back together perfectly and it's really easy with the hairspring to have bad things happen. Plus when you put things back together they have to be in the right place in other words watch has to be in beat that will cause an issue. Things that change the balance wheel like restaffing if you're not careful. If it's a bimetallic balance wheel it's really easy to squeeze it the arms get bent in and it runs insanely fast normally when you restaffing you're supposed to make sure the balance wheel is running flat and true so this shouldn't occur usually occurs later on when people are doing something with the balance wheel will squeeze the arms. The problem with watch repair is it's a lifetime learning experience. It's hard to have simple quick rules that explain everything. Troubleshooting issues with the balance wheel doesn't matter who you are can be quite a challenge. Earlier in the week I had a 18 size Elgin pocket watch behaving strange for timekeeping couldn't quite figure out the problem. Then I noticed that when I put the hairspring back on it was up just a hair and that was enough to cause an issue. But it took me quite a bit of time to figure out what that problem was I Leaning towards the pivot problem because that's what it appeared to be. This is where there can be so many issues when you Replace the balance staff.1 point

-

1 point

-

Must say, this is a perfect example of accelerated learning by modern tools! These photos even made me buy a dozen or two of these Russian watches. You and Endeavor are a true inspiration sources even for a hard-core Swiss watch enthusiast like me. Thank you….1 point

-

watch running fast..... 1. What is the amplitude? 2. demagnetize movement and tools 3. Are hairspring coils sticking? If so how did you clean the balance assembly? 4. Mainspring replacement? If so what strength did you use. There air about 4-6 different strengths for each caliber waltham movement which will vary based on jewel count. 5. Oiling the escapement, what oil did you use and how did you apply it. Did you get any on the hairspring, or on the top of the pallet jewels?1 point

-

The pin trick worked a treat, a bit fiddly but once it was out a tad I could get purchase with the pliers to twist it the rest of the way out. Thanks all.1 point

-

Wow! I thought I was NUTS taking lots of photos during disassembly & assembly ? Excellent quality photos and very interesting review / thoughts about Vostok movements.1 point

-

The o The post heading suggests that it is a Seiko 4R36 (NH36). I'm wondering if the issue is because the attempted manual day change is too close to the midnight position of the movement? Try winding the movement forward a few (5 or 6) hours then trying the day change again.....1 point

-

1 point

-

1 point

-

1 point

-

The OP has requested to be removed from the forum, I have no idea why as he did not state a reason - but it seems he got the help he wanted. But the thread will remain active as the information here may still help others in the future.1 point

-

Can the crown be pulled out from winding position to hand setting position? Or is that stuck in one position only? If it is stuck in one position, the sliding pinion is probably rusted stuck to the winding stem. You can try putting some penetrating oil around the area and leave it for a day or so. Be careful no to get the penetrating oil onto the dial.1 point

-

Get something like this guitar mic pickup. You can find it even cheaper than Walmart offers: https://www.walmart.ca/en/ip/Cergrey-3m-6-35mm-Audio-Jack-Clip-on-Microphone-Piezo-Violin-Acoustic-Guitar-Pickup-Clip-on-Mic-Pickup-Piezo-Pickup/PRD18DFNMN9XGMP1 point

-

Judging by the looks, I am not sure if this is strongest magnet you can find, I took mine out of a big junked loud speaker, big and strong magnet, I have no trouble hunting shock springs with it or other parts for that matter. I have attached the magnet to a shoe string and just hold it a few centermeter above the ground so as to be no need to bend or get on my knees to search the floor. Bag trick is useful too, I think I invented it. Regs Joe1 point

-

1 point

-

I am sure you did not expect Russians to rely on Moebius oil supply, thus they had, and still have, an excellent watch oils selection: МЦ-Н replaced МЦ-3 МН-30 replaced МЗП-6 МН-45 replaced МБП-12 I also have МН-60 for use in -60C to +50C (in case you are visiting North Pole and then Global Warming hits you hard ... unexpectedly) I will definitely read your service walkthroughs for 24xx calibers. Thanks! Those in Bold are mineral oils, no longer produced (i believe).1 point

-

I knew you would ask! ? Here is choice of oils for Poljot, Vostok and similar watches: 8200, 8141 and МН-45 (Russian letters М & H (H is N) ? "Масло часовое МН-45" http://www.zarechie.ru/catalogue/oils/instrument/mn-45.html I could not get replacement for 8200 and 8141 to be Moebius-Free / Independent, but 9010 has been successfully replaced by MH-45. No complains at all.1 point

-

Letter from Joe Collins, Thanks for inquiring about my mainspring winder. I do not make the Winder any longer. Here are the Plans I do not supply the sleeves for capturing barreled springs. These can be bought at Merritts Antiques for about $40 US. (9 piece, Ollie Baker type) They can also be found at TimeSavers and other materials outlets. A video of the winder in use can be found here: http://www.youtube.com/watch?v=6uOsZ_ZIvLc Thanks again for the inquiry, Joe Collins Email: [email protected] @@@@@@@@@ Update from Al, Here is a gentleman that built a winder that explains what he chose to do. I do not like his copper clamps for the barrel, they may scratch the barrel. But if lined with leather or made of wood is another way to accomplish the task. Use a Tap handle which has a 4 jaw chuck to grip the four sided mainspring arbor. https://www.youtube.com/watch?v=S5XxM5PwSNM&t=149s And another variation on a theme using mechanics tools. https://www.youtube.com/watch?v=Qczmx8I1zzI He also shows the purchased components from stores. There are many other YouTube video's in case you want to browse other clockmakers solution to a problem. Clock repair supply houses: Merritts.com Timesavers.com1 point

-

One of the interesting thing is that occurs on this discussion group is that people continuously re-ask the same questions over and over again because? For the newbies they fail to grasp in their excitement that conceivably we all went through whatever they're doing and more than likely the question has been asked before on the group. The problem with the resources out there is people have to remember that they exist otherwise they're not going to look they're going to make use the resources the message board like I need this tech sheet and it will appear. So why bother to remember were all these resources are or care what all you have to do is ask. Or even my amusement because it happened with a couple of questions lately I do a search to find an answer for someone's problem and I find the answer on this message board somebody's already had a similar problem With the same watch. Such an interesting problem with typically the easiest solution for everybody is to just ask here and it will materialize. The problem is for those of us that make things materialize it would be nice to have a central database somewhere of all the PDFs but you're looking at several gigabytes of data. Although looking at the properties of one of my main folders of data but not all the Datuk is it scattered across the computer 21 GB. That doesn't include any of the new stuff that I've downloaded within the last couple years. Then conceivably there's some duplicates because of various sources I we just copy the DVD and put it in the computer so I know there's some duplicates but it gives you a clue of how big the database could be if you start accumulating all the PDFs.1 point

-

1 point

-

One other caveat...beware of the JESUS spring..small little springs in the works that fly off to only God knows where..when working on or around them I like to put the watch inside a gallon sized plastic bag..I work on top of a sheet of copier paper.. the springs get contained and you can spot them easily against the white paper.1 point

-

Welcome Bradhead and congrats on your choice of movement. I started out with Vostoks myself and had an absolutely amazing time with them taking my first steps at tinkering, servicing, and repairing. When new, the Ratfaced git's Vostok videos were very useful and inspiring to me. Anyway, when and if you want to get serious I do recommend www.watchrepairlessons.com. The Ratfaced git (Dan) is a self-taught retired car mechanic, and he doesn't always do things by best practice. Nevertheless useful and inspiring! You don't have to guess about the calibre if you know it's a Vostok 24XX something. If it is a mechanical (wind-up) Vostok without a date complication it is a 2409, otherwise a 2414. If it is an automatic watch without a date complication it is a 2415, otherwise a 2416. Either way all of these movements are very similar, with the added date complication being the only difference, and most parts (with a few exceptions) are interchangable. Now, about your watch; Well, it's always difficult to speculate but my guess is that you didn't get the stem pressed in all the way. This is a somewhat common problem with the Vostoks. I suggest you grab the stem on the inside of the case with tweezers (or very pointed pliers) and try to press the stem into the movement the last bit as far as you can. You need to use a bit of force, but be careful. Sometimes you hear a click when the stem seats itself properly. For spares you can pick up a lot of movements on eBay for next to nothing and then scavenge them for parts which is good and fun practice. For example: https://www.ebay.com/itm/2409A-B-caliber-VOSTOK-Watch-Movements-Altered-Art-6-pcs-415/153773928815 Good luck and please keep us updated on your progress!1 point

-

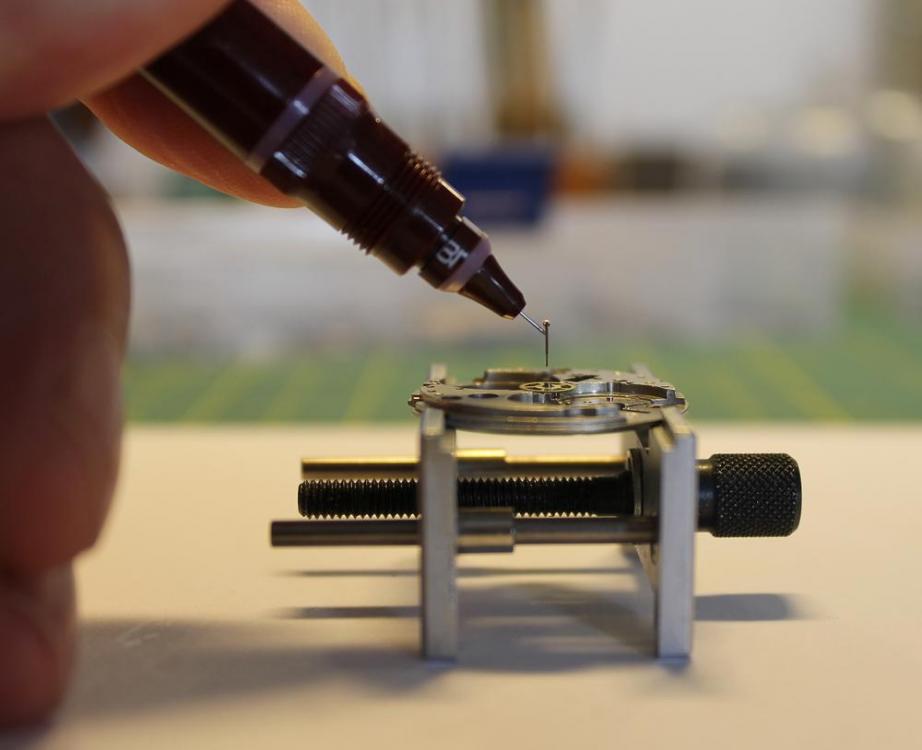

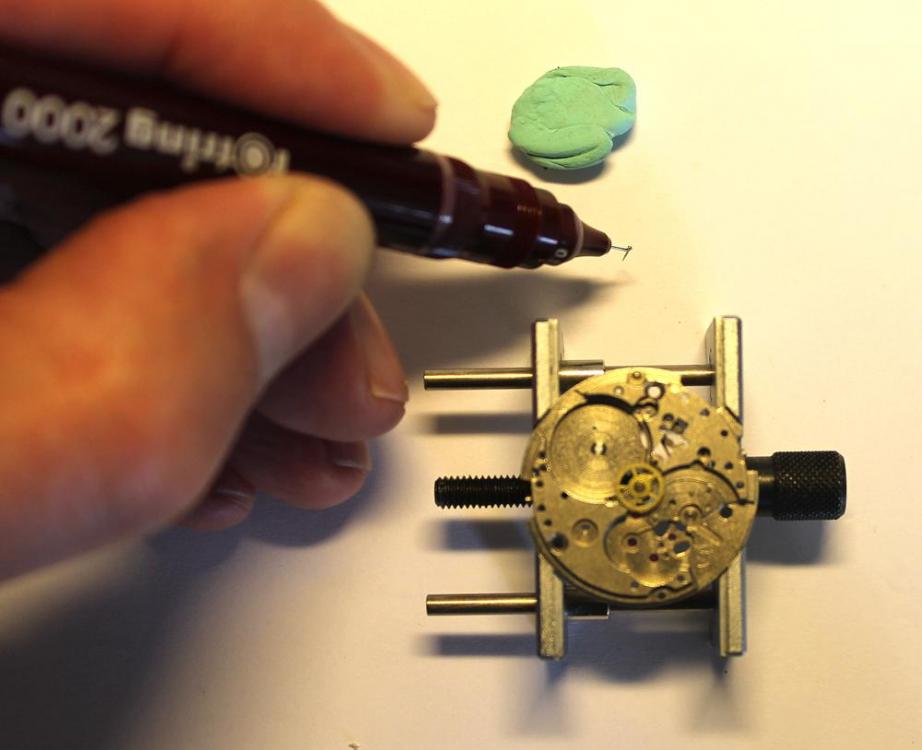

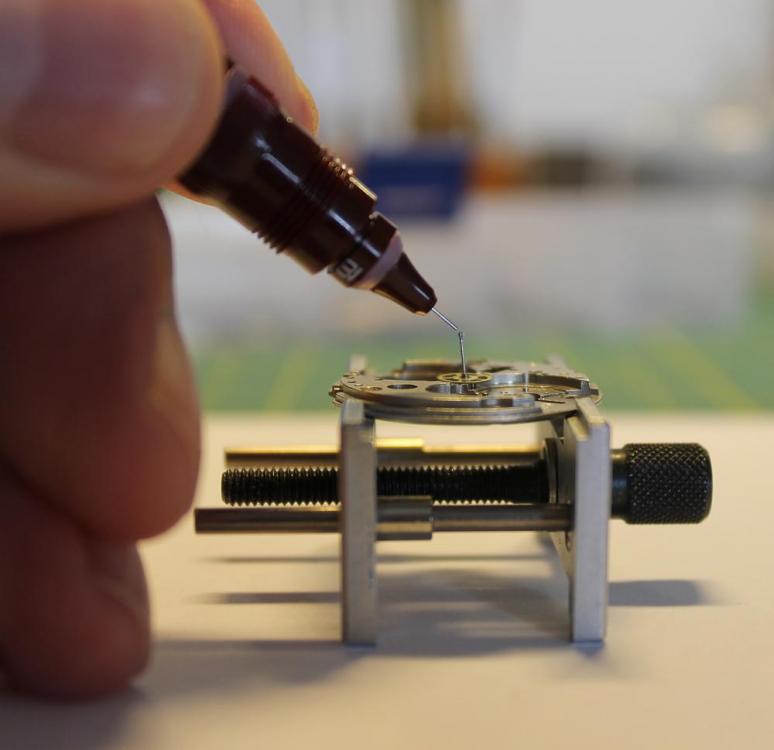

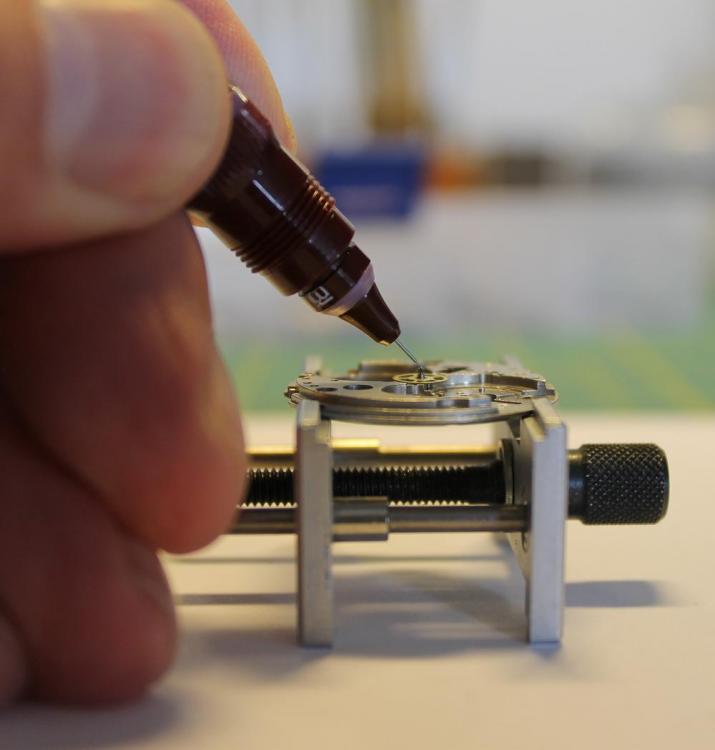

There are many ways leading to Rome and whether to lubricate or not can be up for debate I normally do lubricate the seconds pinion and indirectly the dog-leg leaf-spring. For this job I'm using a 0.13mm new, but old-fashion Rotring pen with some light oil in the reservoir. I'm not using Moebius, but Dr.Tillwich 1-3 oil. Just for the purpose of demonstration I took an empty 2409 main plate with the center-wheel inserted. Normally the small tip of the Rotring pen is wet enough, due to the capillary working of the oil, to pick up the seconds pinion; You can run the pen past the pinion and this will lubricate the pinion, if ever so slightly. I than insert the pinion and push it carefully down the shaft of the center-wheel. The gently push on top of the seconds-pinion will lubricate the top of the pinion ..... and therefor indirectly the tip of dog-leg leaf spring. The dog-leg leaf-spring can cause a variety of problems such as irregular amplitude, low amplitude, "dropping" second-hand when tilting the watch or a jittering second-hand. It needs therefore to be adjusted such that it just touches the top of the seconds-hand pinion, easy to be lift up but enough "push" to provide just enough friction to let the seconds-hand to run smoothly. Anyway, it's up to the watch repairer to decide how & what .... Just my two cents1 point