Leaderboard

Popular Content

Showing content with the highest reputation on 02/07/20 in all areas

-

Hi all ,an old watchmaker friend of mine he is 76 and still goes to work as a watchmaker everyday . Imagine his knowledge .Anyway on with the topic . As you all know sometimes when you service a watch it doesn't matter what you do the amplitude would be nice another 5 or 10 degrees higher .Peter (that's his name ) told me to get an old piece of ladies watch mainspring and cut it about 2 inches long and wire it to a piece of pegwood leaving an inch hanging past the end .Get a hold of the pallet fork with a holder of some sort ,tweezers will do if your steady enough and burnish inside of the folk where the impulse jewel makes contact . This works amazingly as it polishes the inside and gives an uninterrupted smooth passing of the impulse jewel .Takes a bit of time but it works . I wanted to make videos of him doing some great stuff and upload but he won't let me Anyway give it a shot .4 points

-

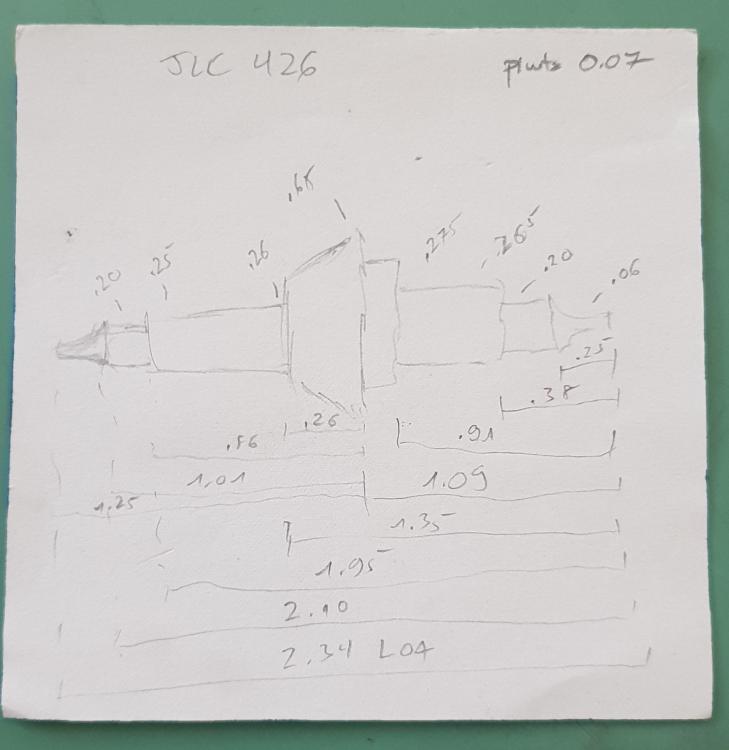

I do about a staff per week and have honed things a bit in a couple of decades. One thing I'd modify on the drawing above is how the measurements are referenced for the lengths. I find it's good to have a start point, and work from there as much as possible. In the little sketch below the tip of the pivot is "zero" and all the lengths are referenced from there. This helps avoid stacking up errors, where if you were individually measuring the length of the balance seat, hairspring collet diameter, pivot etc. even if being very careful you can end up surprisingly far off on the total. In my case I rough them out with a cross slide so while I have lengths referenced from right to left for everything, there is a second set of lengths starting from the hub for the lower half. If I was flipping the staff to work the bottom I'd do new lengths referenced from the lower pivot.2 points

-

I would be careful using anything acidic, you really run the risk of removing more of the writing on the dial, esp since some of is already coming off. there are two things you can use that are safe. Calcium Lime Rust (CLR) and WD-40. I like to do a cleaning with CLR first then finish off with the WD-40. It’s safe on writing and varnish, u have to do some wiping, i suggest using a make up remover pad to gently wipe off the lime. Use the WD-40 to remove any CLR residue2 points

-

2 points

-

1 point

-

1 point

-

how was it behaving before you dis-assembled it? if it was the same then it could be any number of things, wrong jewels replaced, wrong escape wheel, jewels inserted wrong, bent bridge etc. if it started after you touched it then it may be something you did, but just to understand it runs fine without cap jewels installed? Dig you peg the jewel hole and maybe accidentally push the stone too far in? you can try using penetrating oil and gently pushing the cap jewel out a bit, just make sure you re-clean them afterwards. also do you have a pic of the entire movement?1 point

-

What you removed is called bezel. Now you need to pull straight out the the stem, which is designed for that, either made of one or tow pieces. A nails clipper with a filed center notch can be useful. The center on the back is not not removable and even if it was it would not allow to reach the stem release. BTW we have a section where it's considered polite for new members to introduce themselves.1 point

-

Yes but its organic acids lactic and gluconic and its heavily diluted with water, using straight up vinegar will most likely instantly remove the lettering. You can dilute these acids but i dont trust my mix of water to acid ratios and I wouldn’t recommend it to the OP. For $6 a pint its already pre-mixed ready to go and hasn’t failed me yet. I have also used these products on radium lumed dials without any issues with the lume afterwards. I attached an example. I wish i had a before pic with dial out the yellow crystal hides all the lime that was on the surface. With all that being said, this is a varnished dial and since there is ink on it so there isn’t many alternatives here without having to reprint. But with the CLR and W&D 40 the OP can make it look much better than it looks now.1 point

-

You can't, because it's not dirt, is either oxidation or chemical turning of the paint. As soon you get to touch you can only make it worse, not to say that is any good now. BTW, we have a section of the forum where it's considered polite for new members to introduce themselves.1 point

-

1 point

-

If you can identify the movement then you can probably just buy a new one. Post some good clear close-up pics of the movement and make a note of any numbers or symbols on the movement plates, particularly on the main plate underneath the balance wheel and someone will likely be able to ID the movement and caliber.1 point

-

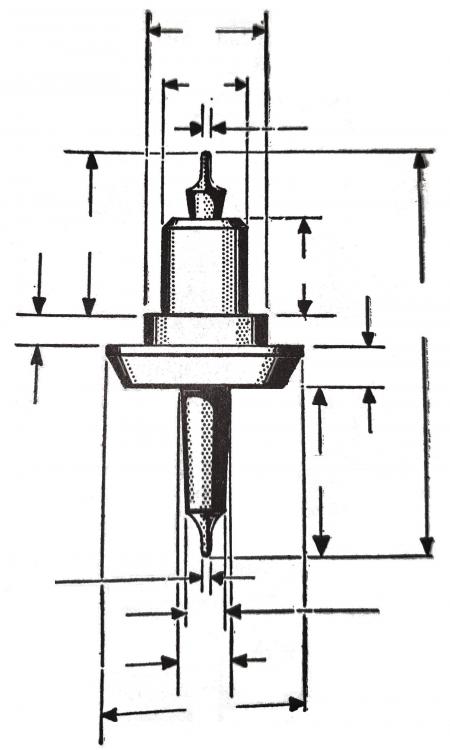

I've got a 1920s Jaeger car clock with platform escapement that I need to make a new balance staff for and tonight I will measure the broken balance staff to get all the critical measurements. Previously I have just made a rough hand drawn sketch of a balance staff but decided it would be nicer if I had a good diagram I could use to write the measurements on and then keep it filed away should I ever have to make another ABEC balance staff. I was thinking of making one up in CAD from scratch but in flicking through Henry Fried's book 'The Watch Makers Manual' I found a perfect diagram. Took a photo of it, did some clean up of it in GIMP and then turned it into a PDF file for easy printing. I have set the PDF to be A4 size. I have attached the PDF and a JPG of the image too as I thought this may be of use to other people. If you haven't already got a copy of Henry's book I do recommend it, as in my opinion it gives the best walk though on making a balance staff using only the equipment an average watchmaker would have in their workshop. Balance Staff.pdf1 point

-

It's not a bad idea to clean it up but bear in mind you have something like 200 pieces there. As said above you don't want to affect the original functional surfaces, so a gentle method like steel wool and oil to remove rust. Any pitting will be left but that's better than digging deeper. At 2 minutes per part you're looking at 7 hours of work and fairly well beaten up fingers, so ask yourself if it's worth it for 50-75 bucks more when it sells, if it even makes a difference. Personally I prefer buying equipment grungy but original rather than shiny but less functional.1 point

-

With an amplitude that high, you're not far from hitting the banking (knocking). Hopefully your screenshot is from when the watch was fully wound, and at maximum amplitude1 point

-

Nice, these type of sheets are very useful when replacing an obsolete staff. I've added mine here too, in case someone can use them. I can't remember where I got them; I may have stripped dimensions from an existing image or something like that. balance-staff.svg balance-staff.pdf1 point

-

Ok. The longer you leave it in, the more risk that the lacquer will come off, so keep an eye on it. Gently rinse with water when the corrosion dissolves. It may be an idea to re-lacquer too....1 point

-

You may be able to dissolve it by soaking in weak acid. The green looks like verdigris, presumably because the brass dial blank has corroded through the varnish. This is always a risk, but doesn't look like you have much to lose.1 point

-

1 point

-

Hi Jeff, Welcome . Yes this is where to greet and welcome our new friends. Looking forward to making friends with you, that should'nt take much of your time since I can tell you all I know in twenty five words or less.1 point

-

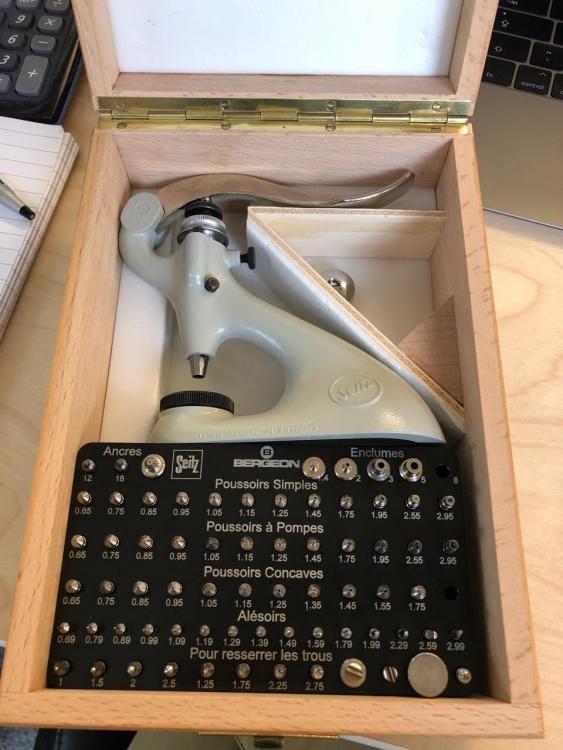

Thank you for the idea to clamp the pallet fork with the jeweling tool - it worked brilliantly! Straightened right out. Used the jeweling tool to incrementally set the height for the shock bloc then micro adjusted the end shake to have just a hair. And the balance springs to life with 0.1 beat error and 290 amplitude. It’s still losing 60 seconds per day so I will likely adjust the Stella screws to capture a better beat rate. And I’ll add, for all the stress of doing this I’ve realized what a dream it is to have a jeweling tool! I really must get one!1 point

-

1 point

-

1 point

-

1 point

-

Yes, as mentioned above. And even if you could magically remove the clear coat, that would not make any easier to restore the oxidation or whatever chemical decaying. Regarding reprinting unfortunately there are very few shops worldwide to do that. For a modest piece it can cost many times its. value. That assuming they have ready suitable cliche or templates, othwrwise is even more costly.0 points