Leaderboard

Popular Content

Showing content with the highest reputation on 12/17/19 in all areas

-

2 points

-

Maybe someone was happy to have found his lost Tissot watch. And Tissot likes to place their name on things2 points

-

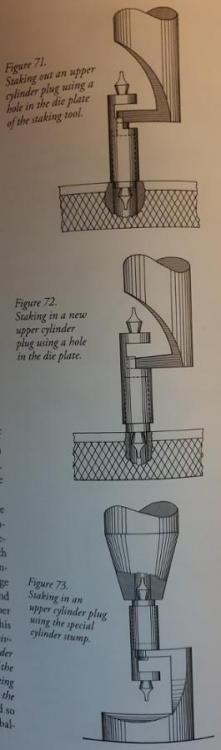

Hopefully these 3 pictures will explain the use to you on how they are used to remove and insatll the cylinder plugs show in John's post This is from Archie B Perkins book Antique Watch Restoration Volume 1 which is just 1 of 4 great books from Archie if you have the money spare as they are not cheap.2 points

-

I would put it in my lathe on a three jaw chuck and make it round, and of course smaller. Then I would make a ring the can be placed over the new circle, and make it the same size as the old bridge circle, then place the crown wheel in place. Sent from my iPhone using Tapatalk Pro2 points

-

A related question in the US would be why are Swiss watches sometimes marked unadjusted or limited number adjustments versus American pocket watches for instance? That was because of the early days to protect the American watch industry there were tariffs and things like adjustments the number jewels marked on the plates push the cost up. So the watches were all adjusted or regulated they just weren't marked that. The terminology is kind of misleading? The simple answer is they verified that the watch would keep time in various positions and temperatures. Then the other thing that happens with watches that are marked multiposition temperature etc. the quality the watch improves. I'm attaching a PDF it explains what they expect just not how they did it. So regulated of course means you can move the regulator watch keeps time. Ideally on a railroad watch the regulator is in the middle timing screws were adjusted to get the watch to keep time. Adjusted to position means they took time to poise the balance wheel. The more adjustments the more time they spent to get that right. Adjusted the temperature is usually a bimetallic balance wheel that they moved the screws around to find the proper position where the movement of the bimetallic balance wheel would cancel out the effect of temperatures. Hamilton 992b 950 timing.PDF1 point

-

No, the impulse jewel on the roller table should definitely be part of what you bought1 point

-

Or you can, for starters, go the manual way and use lighter fluid/naptha (which is what most people recommend, especially for beginner work). Could also use some water and diswashing soap I guess. Perhaps some isopropyl for final rinsing.... ? Careful what you clean and how. The palet fork needs a different approach. Ultrasonic can make the rubis come off.1 point

-

It’s entirely your choice and what makes you feel happy. I’m not a fan of bracelets and like leather straps, the black strap matches the dial and if you add a deployment clasp I think it would be perfect.....but that’s only me.1 point

-

I believe temperature has to do with the watch being able to maintain time accuracy in more extreme temperatures. (has something to do with the materials used, I guess, but also to design) 4-5 positions means, again, that the watch is able to maintain time accuracy regardless of the angle. Normally time keeping is influenced by the angle of the watch (because of gravity, inertia, weight of parts, etc.). But it depends on what type of movement (quality, design, vintage or modern, etc.). Someone might explain this better, this is just a quick answer.1 point

-

1 point

-

The movement seems to be similar to the EB 687/AS 698 -> http://www.ranfft.de/cgi-bin/bidfun-db.cgi?10&ranfft&&2uswk&EB_698 There seem to be several variants of this movement all with caliber numbers that don't show upon either ranfft or 17jewels.info For example this AS 867 "Beaver" -> Take care with the balance, as I have been unable to find a replacement balance staff for mine.1 point

-

You could be correct that Tampon may be the French terminology for the part. I'll go through my books and find a picture showing those tools in use1 point

-

What Jon has said is the best option and the only way to clean it correctly. If its not too gummed up with dirt there is a less scary way to atleast oil it which is better than nothing whilst you are still learning. Place the balance upside down and carefully lift the balance slightly, not too much or you will damage the hairspring. Now with your finest oiler place a drop of oil directly on the pivot hole without putting oil on the hairspring else you will need to clean it all again and start again. Next using a very fine wire, or a tool like this https://www.cousinsuk.com/product/oilers-3-in-1-incabloc-specialist Poke the fine wire into the pivot hole so it touches the end stone. Capillary action will draw the oil into the pivot hole oiling the pivot. This is not the preferred way to do it as you haven't cleaned out the old oil, but consider it a stepping stone until you feel confident doing what Jon said above which is the best way to do it.1 point

-

I didn't read your post correctly and then scrolled down to the photos and spent several seconds trying to figure out how you photoshopped it in and tweaked it to give that grainy effect till I went back and read your post again. That's a pretty cool statue.1 point

-

You may do better asking here https://forums.calibre11.com/ There is also a lot of general information about their watches on the site. John -1 point

-

I went with b in the end, after getting terrible amplitude which I mentioned in another post. As you say, not too difficult, because you can work one side in first, hold it steady about halfway engaged, the push the opposite side down and across into the slot. Then rotate the whole thing to the centre. I used a x10 lupe. One of the jewel holes was dirty, so well worth the effort.1 point

-

1 point

-

1 point

-

This is a fiddly job if you have never done this before, so it might be an idea to practice on a scrap movement. The cap jewel is a non shockproof type and will need to be unscrewed from underneath the balance cock. You can see the end of those screws in the picture you posted. First you will need to take off the balance cock from the movement and carefully turn it upside down, making sure the balance staff pivot is sitting safely in the jewel hole, Then turn the 'boot' which I have marked with a red arrow 90 degrees, so the hairspring can be released from between the boot and the curb pin. Do this with a very fine screwdriver, as there is an indentation in the boot to do this. The friction fit stud that the end of the hairspring is pinned to with a tiny brass tapered pin. I have marked this with a red circle. This stud is held in place by friction, by the looks of your picture, rather than a small screw coming out from that arm and will release with downward pressure on the top of the stud in the picture. The arm that the stud fits into will need to be supported in some way to do this, usually using a staking set to do this if it is a really tight fit. I use an adapted tool that pushes the stud and holds the underside of the arm at the same time. Once the stud is free and the boot moved 90 degrees the hairspring and balance wheel are free. You can then undo both the screws on the underside of the balance cock to remove the cap jewel to be able to clean and oil it1 point

-

I suppose a picture would help. Before the lever escapement there were other escapement's one of them that was very popular was the cylinder escapement. It is an interesting feature where if you break a pivot off it can be replaced. Then a note regarding proper horological terminology? A lot of this will depend upon when and where you are. There are quite a few parts that will have multiple of names for the exact same part. This leads to irritation and confusion by the material house people when people insist on using names different than what they're used to. So for instance grabbing a copy of Britain's watch and clock makers handbook dictionary and guide refers to the things that go in the cylinder as plugs. Continuing with my amusement on terminology I would agree with Tmuir that his terminology is correct because I've seen references to that. But grabbing a another reference that I would consider more reliable or at least better or perhaps is the book The Illustrated Professional Dictionary of Horology by G A Berner a rather interesting book because It has lots of horological terms and it's in three languages. So in its definition or talking about the cylinder it refers to the things on the end as plugs made of steel. There is an electronic version of the book available at the link below which totally sucks for the definition of what a cylinder escapement is as it's lacking quite a few words missing from the book itself. But apparently the book is available for purchase and yes it's always been expensive if you could find it. https://www.fhs.swiss/eng/dictionary.html1 point

-

Since it's regularly happening every 8 seconds I'm thinking a gearing problem; the 4th wheel has 8 teeth in its pinion, which will equate to 7.5 seconds per tooth "in action"- but it would be odd that all the teeth on that pinion or the 3rd wheel that drives it would be damaged and damaged equally. Though if for example the train bridge was removed with power on the watch the 3rd wheel teeth may have zipped accross another component raising burrs or something. Is the train nice and free with the balance and fork out?1 point

-

The pile of Slava automatic parts arrived, and I had a quick rummage through them last night. I started with that green pile of snot on the right, and after a lot of cleaning and a small amount of brute force, I extracted the mechanism from the case. It was held in by a stem that was rusted solidly in place. Once extracted, it got torn down. I discarded the dial into my scrap pile for the time being, it is a complete mess. I then cleaned and partially re-assembled the mechanism, to the point where it is all ticking away nicely, but still dialless. The only part other than the dial and stem that needed replacing was the day disk, but there were a couple of clean examples in with the rest of the spares. It is now running on the bench, as is the mechanism with the red hands next to the cardboard box in the picture above. That case needed a 322 crystal (which I had) and a stem (which I do not have). So, I'll need to source couple of stems, and do a little more work, and I should have two complete working dual barreled automatics. With a little more part swapping, I may even be able to get one or perhaps at a pinch two more going, using the remaining stuff and parts from another donor in my spares pile, but I may be short of some keyless work bits. I'll keep you all posted with my progress. I did some damage though. While attempting to remove the dial, I had the "green gunker" movement in a movement holder and it kept popping out. I then grabbed it between my thumb and forefinger to get a better grip. Thinking to myself "I had better be really careful here, or I'll stab myself in the thumb with this screwdriver", I then proceeded to stab myself violently in the thumb with the screwdriver. Much profanity and not a little blood later I passed my wife with my thumb in my mouth. "What are you doing" I was asked. I refrained from replying "Nothing dear, just bleeding to death", as I headed off to grab the Dettol and the Elastoplast. So today I have a throbbing left thumb with an interesting blue tattoo mark. Sometimes I wonder if this game is too dangerous and perhaps I should take up something safer. Base jumping perhaps.1 point

-

1 point

-

I have this Certina watch, and I wanted to ask you guys what's your opinion on combining the watch with this Hirsch Osiris strap: I am waiting for your opinions, and if you don't find it suitable, I'm waiting for suggestions from reputable brands, priced around the 40 EUR mark. Thanks, Alex0 points