Leaderboard

Popular Content

Showing content with the highest reputation on 11/06/19 in all areas

-

If End curve is not properly shaped, adjust arm pins may push the coils to the side. At the end of the end curve, passed the bend, the HS should be manipulated which can bring the coils to center. Someone savy with Ipad can draw arrows showing where to streigten. Balance runs good in the vid. So at this point, priority is with the regulation. End shake if due to pivot wear, standard repair is to replace the staff or complete balance. I flip the end stone over to face dome side with the pivot, on which some frown. If pivot length is good, some times moving the jewel- chaton housing would work. We got to find the cause for the proper fixing. Is the other balnve just a wheel or has got HS on it?1 point

-

1 point

-

Hi Should be the Abbey clock clinic it an American site and look under the sub heading clock repair.1 point

-

1 point

-

Easier said than done, which is why I do the saying lol. Lots of watches run most of working life twanging or similar noise. I got six NOS movements, each makes a noise of its own. If handy letting us hear the noise may help. Best Regards1 point

-

1 point

-

Keep an eye on escape wheel as you turn the balance, the instance entery pallet is about to drop, impulse pin is to be at the right position to receive energy from the fork horn. If impulse jewel has passed the said position, the horn hits on impulse jewel from behind, that is an impact not an impulse. Such impact imparted to the impulse jewel will be scattered through out the body of balance complete, causing the HS to vibrate as strings do in musical instruments, you hear it as the twang twang that Nicklesilver mentioned. Hairspring is crying,, get rid of the impact please,,. Impulse is not a hit rather a push on the impulse jewel.1 point

-

1 point

-

1 point

-

1 point

-

Go to Dave’s watch parts and you should find a replacement Sent from my iPhone using Tapatalk Pro1 point

-

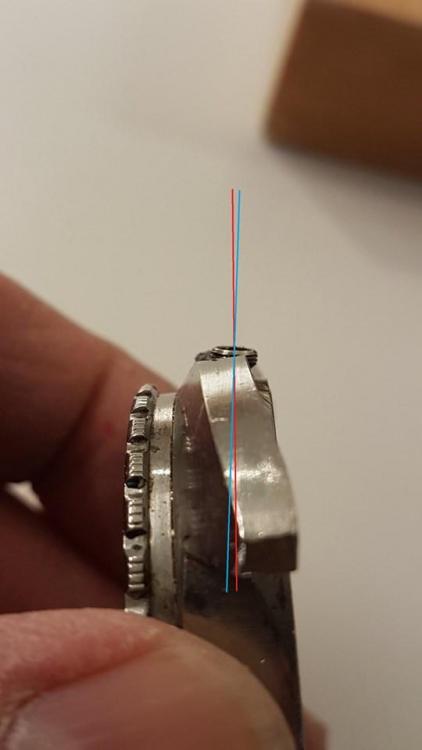

Hello to you all folks, thought I should share this story with you ,,,, Then I finally completed my big project "Doxa Searambler 300T from 1968" which I have been working on from March 11 to June 27 this year, for about 14 weeks. And I have to say very happy, although I have not yet managed to find a good solution on the BoR link. Have been in contact with the Doxa factory via an acquaintance who is AD in Sweden, so let's see what gets there. But anyway, here's the story: Bought this on March 11 in miserable condition, see photo 1. It was pretty messed up after been worn after 50 years of use as a professional dive watch, so all of the marks were gone on the bezel ring, the glass was scratched, really needed a service, see photo 2 and 3. Some had also tried to change the casetube and crown without knowing how to do this. And should rather been doing things they fully master insted. The casetube was inserted with an wrong angel into the case, so the result was that the crown did not enter the movment right. See photo 4. To fix this, the old casetube had to be drilled out / pulled out. This one was not fastend good enought, so I could just pulled it out. If this is done right, they is stuck like hell. .. See photo 4. you can see the red line that shows the correct angle into the case, while the casetube that was mounted befor was incorrectly angeled into the case, see the blue line. A incorrect crown was also inserted, the original crown is 6.92 mm in diameter and 4.60 mm high, stem thread is 0.9 mm. The one sitting here was far too small and is completely wrong compared to the original. The dial was very spotty and had lots of marks after many dives. And that the lume had got the greyish color. See photo 5. So full dismantling was needed, stripping everything, movment out, glass out, bezel ring dismantled from the case, cleaning of all parts. So when everything was cleaned up, the build-up could begin. First the old case tube had to be drilled and pulled out, so it was dismantled, and the new casetube was inserted with a crown. See photo 6. Found a crown that is quite similar in appearance and about the same size. Doxa is known to have very little parts to these olde watch available unfortunately. So finding original casetube with crown seems like a pretty impossible task. See photo 6. Did service work on the movment, ETA 2783, no parts had to be replaced, just a little tightening of canon pinion, because it was a little loose in motion. Painted bezel ring by original colors. See photo 7. When it comes to the dial, I wanted a crisp and fresh dial, so I chose to use an friend of mine who is an specialist in restoring dials, and who is the real magician when it comes to repaint of dials. See for yourself....See photo 8. Lumes on the hands and indexes was put on by me, had to mix ut a certain light cream color lume to match ut the right patina. Also managed to source a glass made according to original spec. which was fitted. Then after about 3 months, all parts were mounted in place, the work was installed, the test round was done with brilliant results. And I could finally take this piece of jewelry on my arm ... See photo 9. Beautiful!!! Go...Go....Switzerland !!!1 point

-

Welcome to WRT,...looks like an 7750 base?....Why replacing the mainspring if the chrono pusher are stuck when the watch is keeping perfect time?1 point

-

Hi Jody welcome to the forum. Sounds like you have had a bad experience. Pushers seize up due to ingress of water swat dirt, The fix the problem the movement has to be removed and then the pushers which contain small clips and springs. If you van supply photos of the movement and the caliber number we may be able to find the tech sheet for your watch. It will give you a better understanding of what it comprises of before taking it apart.1 point

-

It can open anything...over engineered. ..and I'm an engineer:) Sent from my GT-N5110 using Tapatalk1 point

-

1 point

-

I feel like a bit of a barbarian, when I superglue an M10 nut (other sizes will also work) to the back of some particularly gunked up, cross threaded, corroded or mauled case back, but it does work, and if you take care when removing the nut/glue with acetone, the case will be none the worse for the experience. I do have a couple of case back removal tools, but sometimes you are up against damaged notches or so much corrosion that you fear the tool may slip, or something will break. Don't try the superglue and nut trick on soft precious metals or some forms of plating, as it may not end well. Stick to stainless backs. One other obvious advantage is that you get a helluva lot of M10 nuts for £2,0001 point

-

Best opening tool I ever bought. Expensive but worth every penny Sent from my iPhone using Tapatalk1 point

-

When it comes to buying cheap tools,I am like a dog chasing a skunk..I never learn.1 point

-

Hi Nice jobs one can get over enthusiastic with the (restoration) I like to leave them with the marks they gained in life That IS the story. Restored to as new condition, well thats like triggers broom iTS HAD SIX NEW HEADS AND 4 NEW SHAFTS still the same old broom !!1 point

-

Here's an entire catalog filled with absolutely essential goodies. I tried to order the 18 Volt Cordless Hammer, but their customer service is crap... http://www.meyette.us/hf_tool_sale.pdf :-) Gryf1 point