Leaderboard

Popular Content

Showing content with the highest reputation on 10/16/19 in all areas

-

3 points

-

This subject has been previously covered, I posted a question regarding the very same, search the title " How are stainless steel watch cases polished ". Best3 points

-

Thank you. This repair forum is fantastic on many levels the people on here are honest and reliable and makes the whole experience pleasurable.2 points

-

Well, this being a (mainly) hobbyist repair forum -as opposed to a collector's- the idea is to share and and teach how things are done. And polishing is a good example of something easy and rewarding.2 points

-

Good advice from @watchweasol. Most likely a servicing issue rather than a breakage. Imagine your watch as a little engine and where the pivots for the various 'engine' parts run in lubricated (jewel) holes. Over time that important lubrication deteriorates and the engine parts cannot spin freely and the watch does not run. When you tap the watch you give enough energy for the watch to run again and overcome the deficient lubrication but the effect is of course only temporary. What a watch service does is to dismantle the watch, thoroughly clean all the parts, re-lubricate the necessary parts and perhaps replace a worn item like the mainspring. Much like a car service you could do this yourself but you'll need the tools and expertise to do it. Otherwise you have to take it to someone who can service it ... but as a skilled and time consuming job it's not a budget thing. So for most people how they proceed boils down to the value of the watch ... not only in cold monetary terms but also their connection to the watch. Unfortunately with perfectly lovely watches that are not of high value a lot of people decide the service cost is not worth it. A shame as there must be gazillions of watches languishing in drawers out there!2 points

-

Cleaning has nothing to do with that, you have a too thigh endshake, or other balance / escapement fault.2 points

-

Yeah, I have allways been that ”engineer” kinda guy these things are truly amazing machines and any kind of learning related to watches intrique me on so many levels! Hope you will get the appreciation that you earn at least from these comunities if not from your family and friends ps. The pun was nice1 point

-

There is still a cost implication especially pardon the pun starting from scratch. Sometimes it is cheaper just to replace given time constraints and materials even as a hobby, we only have a certain amount of time and money to play with. But I have to agree the satisfaction in acheiving a task like this is amazing, just wish my family and friends would realise this.1 point

-

Yeah I came here just for that tips for taking care of things in more sustainable way in long run! Thank you very much for your toughts and opinions btw! Such a nice community you have here!1 point

-

Isn't difficult to polish a glass when using the proper tools, material and technique. To be on the safe side practice on something other watch first. If you give a Seiko watch to a local repairer expect them to complain they can't get parts for it, as Seiko USA sells only to the dealers and centers having an account. But mov't parts are easy to get.1 point

-

Well, as mentioned above that is a special shape glass, the original could be in excess of USD 50, if you can find it. Fortunately when using the proper techniques crystals can be polished to perfection.1 point

-

1 point

-

Take a good picture in the current conditions, apply the miraculous product, then picture again. We'll talk then.1 point

-

was it silocon oxide that came before diamond paper? in any event, you should look up various methods. vin1 point

-

Polishing cloth may be good for what collectors call "hairlines" but will do nothing to scratches. As Nucejoe correctly indicated above, use the search function to learn how that type of repair is done. You can't replace your watch high dome crystal with a sapphire because these are not manufactured in that particular shape. That is also the reason why Seiko didn't originally fit one on the Cocktail Time, unlike the other SARB line models.1 point

-

No. For scratches on glass you need first wet paper on a rotary tool, then finish with diamond paste. Many thread on the subject here.1 point

-

No I would try to do just a tiny coverup job, scartches are very light and it could be done without taking anything apart1 point

-

i have never tryed to replace a Hardlex with an acrylic . would you have to re machine the bezel. i'd like to do that. vin1 point

-

How much bevel? If it is not functional you can get a generic crystal for $1 or a sapphire for $10, and that would be my advice. Otherwise you can always polish the existing to perfection without even removing it.1 point

-

Cousins lists the part number for a Seiko 7019-7060 crystal as 310W13GN00 Just did a quick look on ebay and found 2 NOS ones for sale, but how deep is your pocket?1 point

-

You carefully lever it off, minding not to damage the hairspring. They are not particularly tight. Levers like for removing watch hands. I have used stanley knife blades before, just go under the hairspring and gently prise it off. Remember to mark where the end of the hairspring sits for alignment refitting it, or it will be out of beat.1 point

-

That is surprising, as that product is specified for plastic / acrylic crystals, but your watch is has an Hardlex (hardened glass) crystal.1 point

-

1 point

-

It's a base metal, no screw-down crown. Nothing fancy. I would say that's a watch which looks good enough with all the scratches and usage marks to wear it daily, and cheap enough to not worry about it at all . Yes, the name means that (that's in Swedish).1 point

-

Here's the new one I was waiting for, I have received it today for $33. Why am writing all this, I have ran into a $20 quartz which was surprising difficult to open, so I've ordered the tool and my initial review here. There are various other similar pivoting ones available, form $15 all-plastic one, to the "King of the Orient", $100+ Seiko S-261. Sturdy construction. The reversible blade has two widths, 12 and 16mm, but the prying slot (where present) of some snap-back watches is like 5mm wide. That will be easy to correct, even if a replacement blade is relatively expensive for about $10. I think that in theory it could be improved. As it comes, the blade pries down, meaning that case hast to be put dial up and maybe one finger on top of it. Now, I'm sure that it will easily open 99.9% of snap-backs, and even remove stubborn bezels or similar feats, but I had liked it more if there was a way to hold down the case opposite side from the screw, and prying up. However the Chinese (or whatever Swiss maker it was copied from) may be right after all. Because in theory, theory and practice are the same thing, but in practice, they aren't.1 point

-

I also go for placing the gears, then lightly placing the top bridge, putting in a couple of screws, but do not under any circumstances tighten them more then maybe 1 to 1 1/2 turns or so, just enough to catch the threads and no more. This allows you to rock things about till those annoying pinions all pop back in place. Gravity should bring down the top plate, not finger pressure. If you are pressing down in frustration, then something is going to give, and that almost certainly is going to be one of the pinions that isn't lined up. Your fingers should be pressing just lightly enough to stop the bridge from lifting, but gently enough so that you can maneuver the gears in to place. This requires a very light touch. The use of soft needles and sewing pins to guide things around is good advice. Again, you are moving things gently, not jamming them into the holes. Initially it feels like you are trying to balance half a dozen marbles on a plate, but with practice, it gets easier. Once you are certain all of the pinions are in place, lightly tighten the screws down, and check to see if the bridge rocks at all, if so, check again, as something is almost certainly no aligned correctly. As you screw down the screws, keep checking that the bridge is going down evenly, and that things haven't jammed up. Only once you are certain that the train is moving and the bridge is flat, would you snug them down completely. I also agree with getting hold of an HMT or two. They are cheap as chips. You can often pick up some of those hideous Chinese skeleton automatic watches for a couple of quid too, but their build quality is pretty variable. I like the HMTs better, as they are actually fairly well constructed, since they are licensed copies of Citizen movements, produced to similar quality standards or at least they were when they left the factory. Some of the people servicing them over the years may have added a few "apprentice marks", and one or two I have picked up were barely able to limp along, despite the seller claiming they were "recently serviced". They almost invariably respond well to cleaning, servicing, and adjusting, and since they have a more traditional multiple bridge construction with jeweled bearings, they are easier to tear down and put back together than some of the all eggs in the same basket, single bridge pin lever mechanisms. Finally, since you can pick them up for a few quid, it is less painful when some pico-scopic part, pings into a parallel universe, or over exuberance breaks something. We have all done both of these things. I have launched small parts, and accidentally mangled hairsprings, more often than I care to mention.1 point

-

Hi over the years I have done many BFG866 watch movements, They were a work horse unit years back, Yes the are a P.I.A. when re assembling the top plate and getting the pivots to line up. My method was to fit every thing in place put on the plate and hold with two screws tightened sufficient to hold every thing but still allow you to manipulate the wheels, I also made some tools, poor quailty sewing needles bent into various shapes to allow you to push or pull the wheels into line, similar to the ones we use when rebuilding clocks they were to me easier than tweezers. They can be made from wire and then hardened fitted to a dowel handle. poor quailty needles bend easy good quality one are hard an snap un less you soften them up. As M1KS says cover it up and walk away if frustration creeps in. We all make a balls up now and then perseverance and paitence are the key words here, Just keep trying, The BFG 866 although simple construction is probably not the easiest one to start on, Tame M!KS's advice or pick up some cheap Russian jobs and crack on.1 point

-

If the escape wheel pivot is snapped or not correctly seated it can give the appearance of jamming the train looking like it won't release power as the wheel is tilted. The only suggestion I can make is patience and if you feel like you're beginning to get frustrated. Cover it and walk away for a bit then return later, I've broken pivots more times through frustration and a desire to hurry up than carelessness or otherwise. Pin pallet movements are both good for practise in that they're plentiful and cheap but bad in that they're incredibly fiddly to get the barrel and train plate aligned. For good cheap practice movements I heartily recommend a couple of cheap HMT watches from eBay Indian sellers, you can get them for less than a tenner in auction and 10 to 15 on bin listings, they're based on a citizen, (miyota) and are quite nice to work on for practise.1 point

-

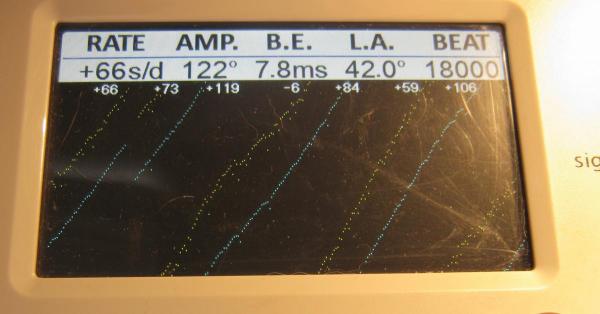

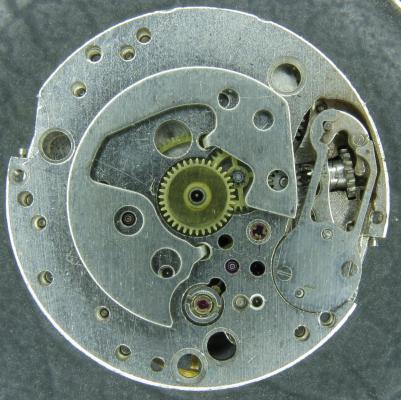

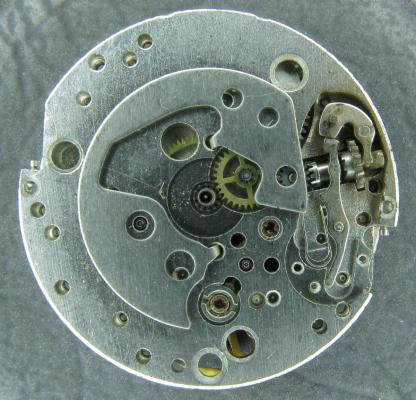

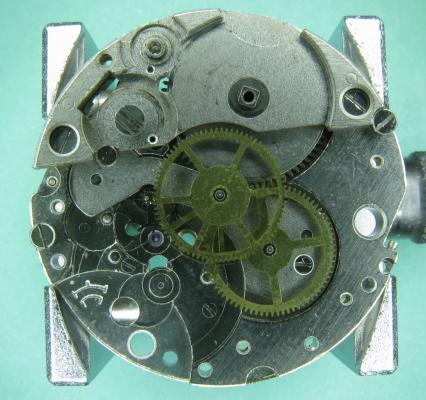

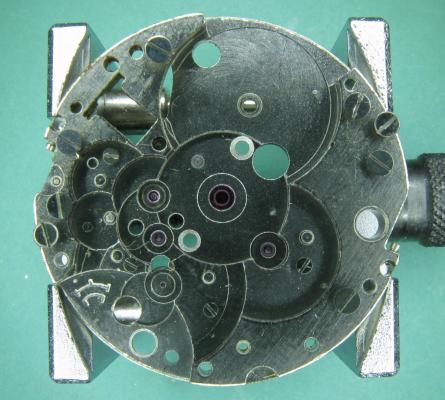

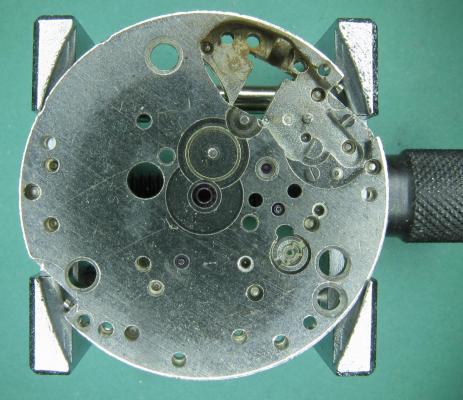

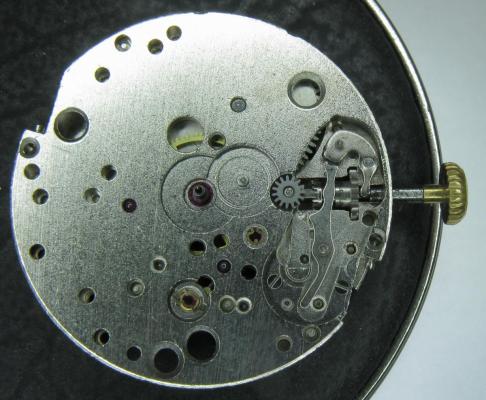

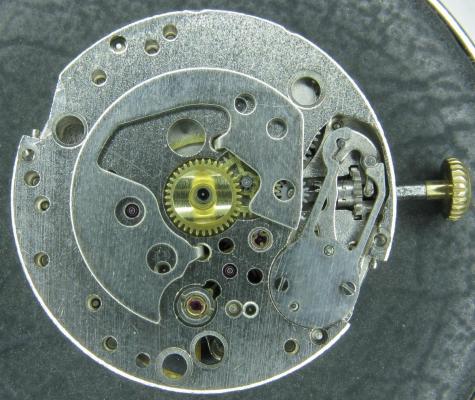

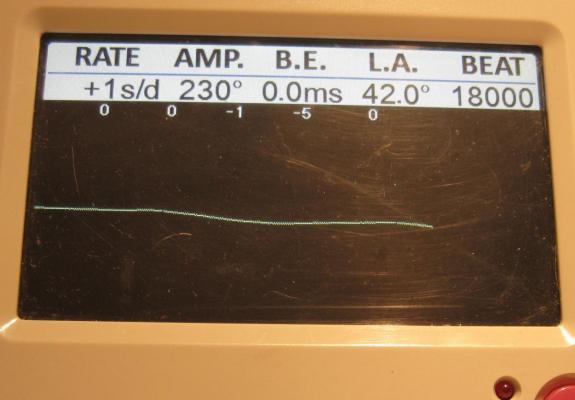

Just before Christmas I sold (through the good offices of eBay) an absolutely immaculate example of a 19 jewel Sekonda hand winder. I was a little sad to see it go as I don't think I am likely to see another in as good order for some time, and having just serviced it it was running like a champ but I couldn't justify holding on to it. Well, shortly after it had arrived with its new owner I received a message through eBay from the buyer. Huw had contacted me to say how pleased he was with his new acquisition, and did I service watches? as he had another example of one of these that was a little stiff in the winder and gained about a minute per day, and he felt that it maybe could benefit from a bit of a spruce up. I have done quite a few of these so am reasonably comfortable with them so I quoted a price and accepted the commission. A couple of weeks ago Huw's watch arrived so I thought I'd do this as a walk through. Looking well used but not abused, Huw had explained that he bought this not too long ago as a stop gap whilst his other watch (a Sekonda quartz chrono) was out of action with battery issues. First impressions are of a watch that has seen a lot of wrist time in its (probably) 40 years. The Timegrapher trace confirms the rate at roughly +60s/day, and confirms that a service is long over due. With the crystal out of the way the condition of the dial is actually rather good. The shadow to the right of the 7 is a lens fault on my camera, not the dial. With the back removed there is plenty of dirt speckled around the whole movement and everything is bone dry. The good news though is that it doesn't look like anyone has messed anything up inside. You can see the spring clip retainer on the escape wheel end stone (a bit like Seiko Diafix but not quite as clever). You can also see corrosion to the back of the bezel, this watch spent a lot of time on some ones wrist. With the movement out of the case the reason for the stiff winder and all of the dusty crud in the movement is brutally apparent. The outer end of the stem has started to rust causing it to bind in the case, and the resulting rust powder is thick on the inside of the case. These cases are a bit prone to this kind of problem as there is absolutely no attempt to seal them even against dust, let alone water, so even sweat on a hot day can seed the beginnings of a corrosion problem. With the dial off the press fit retaining plate for the motion works is exposed along with the keyless works. There's that little end stone retaining clip again, and the Raketa version of Incabloc on the balance. The rust doesn't seem to have got this far. With the set bridge out of the way though there is a hint of rust in the keyless works. Ouch!!! Just in time me thinks!! Balance and cock removed and the hairspring looks to be in good shape apart from the terminal curve which is off concentric. That will need to be sorted or the regulator will distort the hair spring as it is moved. Here also is the shim that Raketa are fond of using under the balance cock to adjust the balance end shake. A bit further in and plenty of gunge under the ratchet and crown wheels. Train bridge removed to reveal the train layout and a sub-bridge for the 2nd wheel. The main plate stripped with the screws put back in their respective holes. I do this so that screws don't go missing in the cleaning machine and I always know which screw goes where. The stripped main plate dial side. And then with the balance reinstalled (minus jewels) ready for the Elma. After a thorough clean everything is ready for inspection and reassembly..... ....starting with the balance jewels. This is when I check and adjust the hair spring for flatness and concentricity, eyeball the beat, check the end and side shake on the balance, and that everything swings freely. If you leave it until later there is too much other stuff in the way. Once I'm happy with it the balance/cock assembly comes back off until later. There is still a little work to do in this pic as the coils are still not quite concentric. The main spring re-lubricated and back in the barrel. This maybe could have been replaced but it wasn't too bad so went back in to help keep the cost down. Barrel, barrel bridge, 2nd wheel sub-bridge, and train back in place. Pallet fork and bridge installed. You can see the exit pallet poised ready to receive a drop of 941 on its impulse face. Walking the pallet too and fro then distributes the oil to the escape wheel teeth. Drop in the balance and away she goes. The cleaned up and de-rusted keyless works go back in.... ...and then the motion works and cover plate. Dial and hands back on, and ready to re-case. Again, to help keep the cost down I didn't replace the crystal with a new one, however, the original was just a little too deeply scored to easily polish out and there was what looked like a very small fracture. So a quick scout through my spares box and I found a second hand replacement which has cleaned up nicely. And the proof of the pudding ... as they say!! At 230 degrees the amplitude isn't anything to write home about but it is a significant improvement on the starting point. A new mainspring would almost certainly help this up into the high 200's (on the watch Huw bought from me I seem to remember it was 300+), but 230 is certainly usable. It is otherwise a nice clean trace with minimal beat error. It has been running for a week now in which it has gained just under a minute, so after a final tweak to the regulator it will be ready to return to Huw. I like these movements a lot. They are well designed and well executed, and capable of excellent results if looked after. They also seem to turn up quite frequently at the boot fairs. Unfortunately though, the lack of any attempt to keep moisture out of the case does mean that they quite often suffer from corrosion issues, and the relatively low cost (both when they were new, and when they turn up second hand) means that they are often used as a beginner watch smiths practice or learning watch, with the resultant butchery that many of us have dealt out as part of our learning curve. It's a shame in many respects, but then we all have to learn somehow. When you do find one that has survived unmolested though they are very well worth looking after. My thanks to Huw firstly for buying my watch, secondly for asking me to help this one to keep going for a few more years, and finally for allowing me to post his watch on here.1 point