Leaderboard

Popular Content

Showing content with the highest reputation on 06/05/19 in all areas

-

Like most of us, I look for perfection and oiling cap jewels with a regular oiler take a lot of practice and patience. I found myself having to reclean and re-oil over and over before I could approve my work. So, I decided to invest in an automatic oiler for this purpose and although very expensive I think it was worth every penny, and I was so happy about it that I decided to make a video about it. Please bear with me though as this was my very first attempt at video editing.2 points

-

The replacement movement was that purchased new from the material house or somewhere else? Then for the 947 series there appears to be zero technical literature but it looks vaguely similar to the 944 series which came out in 1981. So no matter where you purchase this watch it's going to be need to be serviced. Quartz watches with gears are just like any other mechanical watch at some point in time they need servicing and keep the circuit or the plastic plate out of the cleaning fluid it looks like the watch has a lot of plastic at least for the mainframe.2 points

-

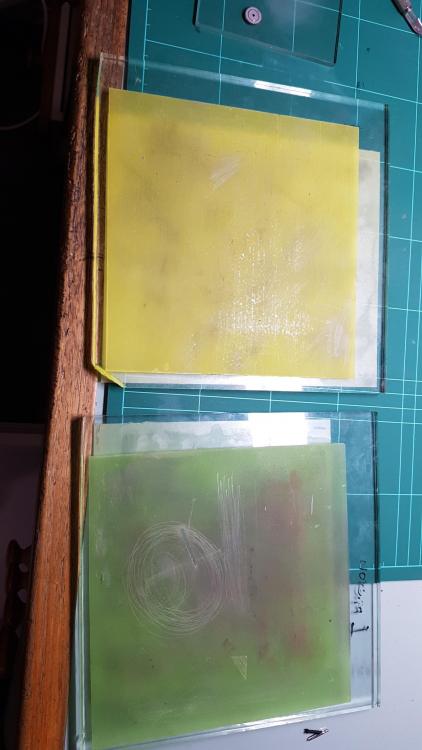

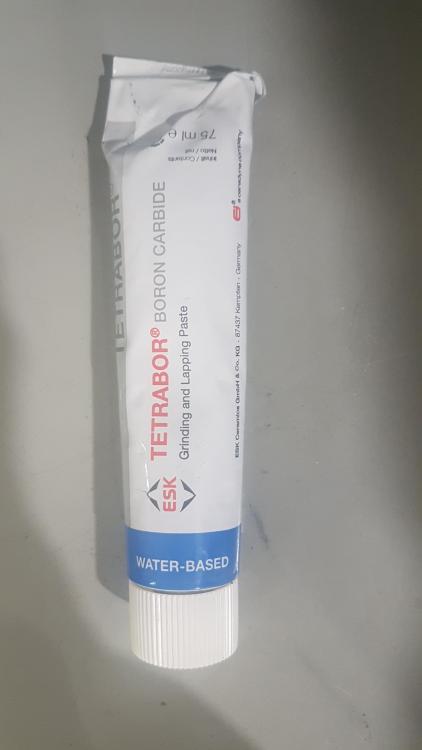

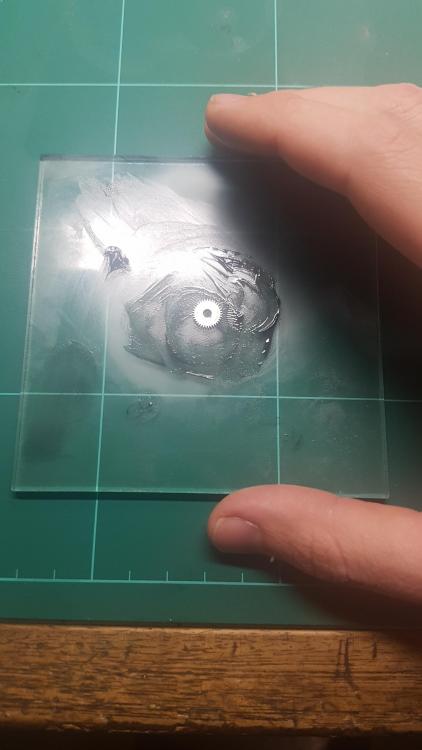

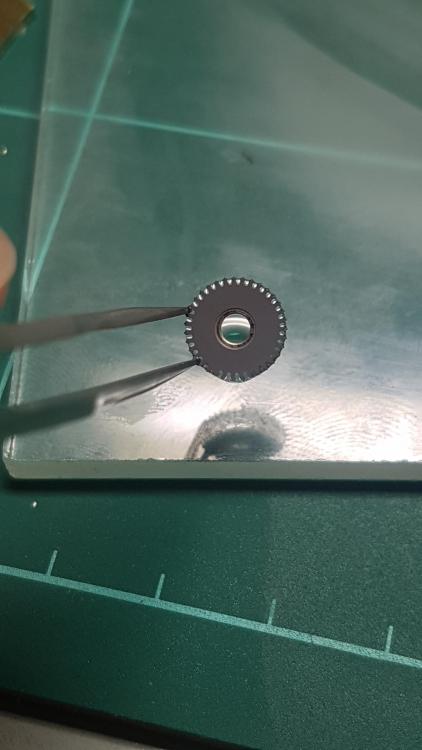

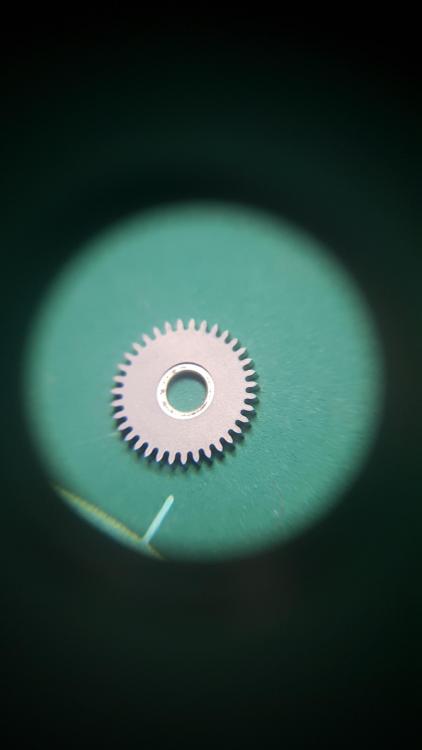

Hello All, This is my first post so I thought I would show a little finishing technique I learnt a while back. It basically turns the ratchet or crown wheel into a matte/ frosted finish. It was popular back in the day with some high end companies and still looks good in my opinion. I'll run through how it's done and try answer your questions as best as possible. What you need: 1. glass plate 2. Micron paper in various grits. 20 and 12 will do. 3. Tetrabor 800 grit/ mesh 4. Ultrasonic or cleaning machine 5. rodico First thing first, you have to flatten your ratchet wheel. To do this I use some lapping paper on glass. I start on a 20 micron and rub the ratchet wheel with my finger in a figure 8 pattern or circular or however I feel. (we arent trying to achieve black polishing flatness) If you are worried you can set up a jig to hold the ratchet wheel. but I often find using your finger will suffice. Once happy, move onto a 12 or 9 micron and do the same. At this point it is imperative to clean the wheel so that you remove all the grit from the paper that may be stuck between the teeth. So chuck it in an ultrasonic or your cleaning machine. Next place some tetrabor onto your plate, no need to add oil or water. place wheel onto plate and start rubbing it in. Generally it doesn't take to long no longer than a min or so. Doesn't hurt to check the piece to see how the finish is developing. if you want to check you can dab it with rodico, very carefully to remove the tetrabor. Do NOT wipe with a tissue or anything, this finish scratches so easy its crazy!! you can always chuck it through the ultrasonic (carefully) to see how the pattern is going. Its the checking and chasing that one last scratch which takes up the most time. The slightest bit of dust or dirt on the glass plate will scratch the wheel. You can always blue the wheel after, it comes out with an interesting tone when blued with this finish. This technique is fairly hard and does take some time to get good at, because it's just so easy to scratch and because of this scratches stand out against the matte surface. I'll try answer questions as best as possible. I try and post interesting stuff on Instagram regularly at least 3 to 4 times a week. obr_horology is my account on insta. its just time consuming to post (slow at typing) I plan on doing a youtube video in the coming weeks to better explain it. I learnt this from Henrick Korpela. Check him out if you haven't heard of him. He also writes in the AWCI and gives away a lot of info. Thanks O1 point

-

Using hammer straighten on anvil or any hard flat metal surface, then Grab a piece of sand papar with it, pull the sand paper out, repeat till you get the flat surface and the grab you want, next lay the sand paper on flat glass, as if holding something close the tweezers and reshape the outside and the tip. Avoid finer than original tip. A good tip is one that dose not foul as you exert little excess force while holding a round object like a jewel.1 point

-

You are spoiling us... :-) Let me check the details a bit when I have taken the thing apart. Then I will get in touch over PM. Sent from my iPad using Tapatalk1 point

-

Thanks, I think you’re spot on ! Nothing on Ranfft for that either but found some pic’s on the web that definitely points in that direction. And Jeambrun sounds french enough... Next step is to pick it apart and asses the damages. The balstaff is gone to start and the top cap jewel as well. Maybe there is more lurking ”in there”...? If I’m really lucky, Rogart has some stuff in his drawers... :-) Sent from my iPad using Tapatalk1 point

-

Another little thing as well as the above mentioned is make sure the caseback die is big enough , a to small a die tends to just exert pressure on the middle of the caseback therefore flexing the caseback edges out a little thus making the back bigger and harder to get on . You want the die to be as big as the caseback really and as also mentioned , some can put up a good fight1 point

-

I can't say about that one as I'm unfamiliar with it but I'd suggest Mark's course would be good. His videos on YouTube are excellent and a good indicator of quality teaching. https://www.watchrepairtalk.com/watch_repair_videos.html/1 point

-

That looks like a very well engineered movement (for its time). I'm intrigued by the purple conformal coating. Usually the stuff is clear, or perhaps green or white. There must have been a good gentian harvest that year.1 point

-

Plastic gives me the creeps.I hate to put a tool to it.you could try flushing the movement out with plastic safe electronic cleaner spray.I have had mixed success doing this...but in my case better success than actually taking ,or more accurately breaking a plastic quartz movement apart.1 point

-

1 point

-

From what I've been reading, it looks to be all have this. http://www.ranfft.de/cgi-bin/bidfun-db.cgi?10&ranfft&0&2uswk&Baumgartner_8661 point

-

Is it only the digital 866 that has this gear on the barrel or does all 866 have them?1 point

-

1 point

-

1 point

-

Sound advice given, If you can lay your hands on a line release tool and give it a short spin and re run the movment , it may just be sticky lubrication not knowing how long it was on the shelf but as mentioned a good clean and lubrication required all the best1 point

-

Water damage to the EB or bad electric connection are two main causes. There is a chance to combine good parts out of the two.1 point

-

I'm not sure about your caliber movement, but many quartz watches are serviceable/cleanable. Of course, some are not. I suspect that yours is just dirty and needs a cleaning and oiling. In some ways they're easier than mechanical, but in others, like handling the highly magnetic stepping motor, can be a challenge. You will need some brass, or good non-magnetic, tweezers to do so. Good luck.1 point

-

From the best of times to the würst of times. I am not making this up, but the thing didn't actually work until I added a little oil(*). It seems that in order to get the sausages movement moving, you need to add some grease. {Insert double entendre laden sausage joke of your choice here}. (*) Actually I needed to free it up with a little lighter fluid, then oil the pivots,.1 point

-

Thanks for the good advice, JerseyMo. I checked everything out as you suggested, and also went ahead and swapped in another Model 25 date wheel just in case. So far, so good! Attached are some pics of the watch on both a vintage expansion bracelet and a sporty plastic/resin watchband. The date still rides a little high in the window, but I can live with that. Cheers and many thanks for the assist.1 point