Leaderboard

Popular Content

Showing content with the highest reputation on 05/29/18 in all areas

-

I can assure you these shims are indeed part of the movement. Back in the 70’s and 80’s all the Russian movements of that period had them. They were machined to size and shape to fit under the balance cock.2 points

-

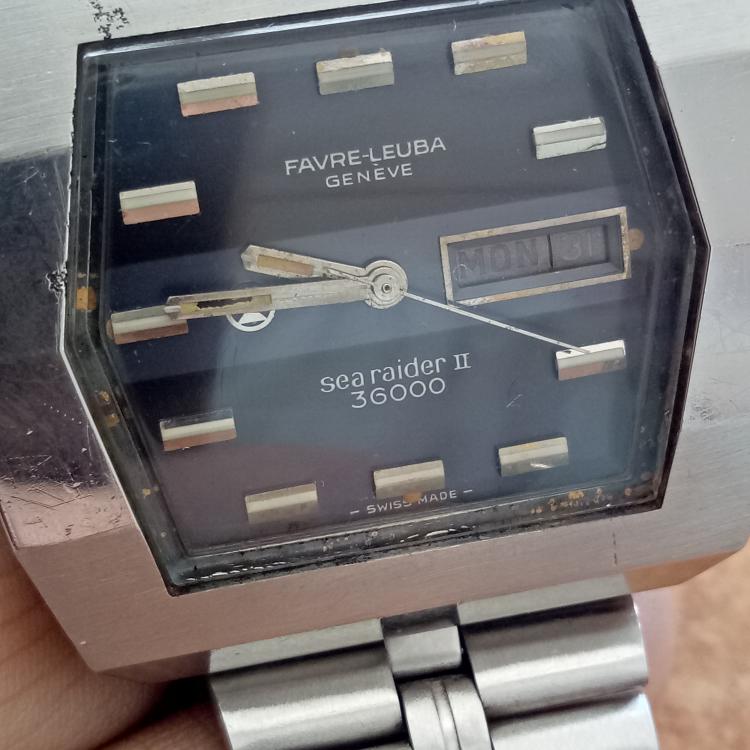

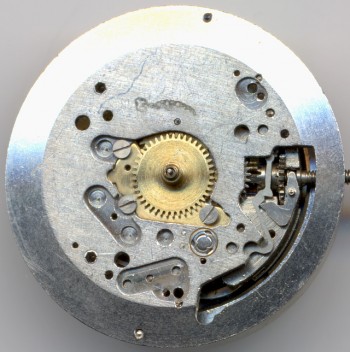

Just bought a Favre-Leuba Sea Raider 2 from a local seller (in Malaysia), cost was approx USD100 incl shipping. I've been a fan of Favre-Leuba for a long time and I've been looking out for a Sea Raider but they usually fetch a high price (for me). This one was advertised on a local facebook group and I didn't waste time grabbing it. It's a very chunky design that screams 70s... The dial is in good condition, there is some marks along the edge... this could be some lume material from the hands or wear caused by the dial rubbing against the case/crystal revealing the brass dial material. If it's wear it can be masked by colouring the visible brass with some black paint or even a sharpie. The day and date wheels have faded to the point that they're barely legible. Case is really big.. Look at how low the crown is! Case back is pretty low-relief. I imagine having a deeply embossed case back would probably give you a mark on your wrist! Did I mention the case was big? It won't fit comfortably under your sleeve. The case originally had contrasting polished and brushed finish.. Someone has tries to re-do it but it's still not perfect, if you look at the dial closeup above, you can see some pitting around the 11 and 9-10 markers. It's powered by a FL 1164 hi beat calibre.. Which is based on the AS1167/1168. Well that's one more ticked off my list. Anilv2 points

-

1 point

-

The dial says ”Mowy” but there’s no id visible anywhere on the movement so I presume it’s a ”generic” of some kind. What intrigued me was the rather elaborate casing design with all its bits an pieces... phota attached. Sent from my iPad using Tapatalk1 point

-

1 point

-

Not sure if I'm understanding your question? Then you don't quite have things correct in the picture. The detent the protruding pin goes into the slot of the stem not where it is now. The setting lever goes into the notch of the clutch wheel as opposed to where it is now and then everything should be fine. Sometimes on really cheap watches they minimalize the components.1 point

-

1 point

-

Finally got it all together and running and setting well. Runs to within 5 s/day and fairly even in all positions. The beat error is a bit high (0.7 - 0.9) but with my experience of ruining hairsprings I am leaving this alone as the overall timekeeping is good !!!!! Checked all my dis-assembly pics and cannot see anything out of place or broken before taking apart. So I may never know why it was jammed up, maybe a bit of dirt or a previous repairer had had the same problem with me when fitting the train bridge and let it go. I got the watch (a Rotary which dates back to 1970'-80's) from my local charity shop (I try and repair/renovate their non-runners on an FOC basis as my hobby in retirement) so have no history.1 point

-

1 point

-

The customer is always right, so they say. If the watch were worth a good price, it would be best to keep it as original as possible. I do not know if it is worth anything. Someone on here might be able to help. My own thoughts, I like it just the way it is, certainly the dial and its condition, it adds character. I am a sucker for old things.1 point

-

No winner with this quiz. The correct answer is 2 C1695 3 C1730 1 C1840 Early good longcase clocks will most certainly have a glass in the door (sometimes they are called a bullseye). This was so you could see the pendulum. If you come across such a clock and you are not sure if the movement is correct, if you cannot see the pendulum it sure is a different movement. Early Longcase clocks always had narrow long doors. The latter the clock the shorter the door and it will be wide. Thank you for taking part. Even if it were only two. Members do not be shy next time have a go.1 point

-

Making bridges is above my pay grade but if I was doing it, I’d probably want to use a boring head, rather than a lathe. Location and perpendicularly seem critical to me, as a novice. You can drill, team, and then tap without moving the location of the hole center. My experience with larger tapped holes I use the Bridgeport (knee mill) and lock the cross slide once I have my location. Spot drill, drill, tap without changing location. If it’s critical I’ll run my drill but in a collet rather than a chuck. I can also under-drill and ream it to size prior to tapping. This is also good for counter-boring where an endmill might be used for the counter and you end up with uniform space all around the screw head.1 point

-

You ideally need three oils/greases as a minimum, but you could potentially get away with just two of you substitute the grease for a thicker oil. Further down the road you will buy more. Grease for the mainspring (braking type of for autos). Can often be used on keyless and calendar works if non-braking. Thick oil for slower part of the train (centre (2nd), 3rd wheel pivots), barrel arbor, canon pinion, keyless works, sometimes automatic works. Fine oil for faster part of the train (4th, escape (5th)) balance pivots, and pallet faces. For the fine oil where the train will be moving at a much faster rate with lower torque, there is an argument for getting something which will last a long time and maintain its performance. Some would suggest something fully synthetic like Moebius 9010. It’s best if you research yourself and make your own decisions. Watchmakers can be very stubborn and self-assured when it comes to discussing lubrication. Read about the difference between natural, mineral, and synthetic oils and how they vary in qualities. Some creep, some turn acidic, some dry out easily, some thicken, etc, etc. Just watch out for the snake oil!1 point

-

well gents, it's been awhile but work has been quite involving as of late,I managed to do a lot of research on cleaning alabaster stone, I stared with just brushing the dust of, then went to town with a damp cotton wool ball covered in baking powder, then I managed to get hold of some borax and stared to use abit of that. Many years of nicotine and obvious soot from a fire place or two it started to come up reasonably light in colour. It's still not as good as it could be but I think without professional restoration it's not going to get any better. For super shiny brass plates I discovered the use of French chalk, I used brasso on all the parts then without polishing them off I washed them off in lighter fluid, once dry I got my clock brush (found in a box of bits from an auction ) gave it a good rub on the French chalk and then gave it a vigorous brush over each part, if you've never used it before the please do try it, it brings the brass up really nice. As for the running of the movement, I found it had had a repair on then pendulum, not to bad I thought, but after Ihad cleaned and lubed the movement and refitted it to the case it kept running slow, so I kept winding the bob up the pendulum, then it got the repair and I unfortunately wound the bob onto the join at the repair and twisted the repair and in the process cocked up the thread!!!!!!, I was kinda stuck then as the bob was just not staying where it should in the pendulum, a quick think and I pooped into work to the metalsmith and got him to cut a few pieces of my brass plate so I could attach one of them to the pendulum, that ideas was good but you cant thread a flat bit of brass can you! Another moment of thought and I pulled my lathe out and grabbed some 3mm brass rod, turned it down to 2.5mm, I really would like to get a cross slide for my lathe as turning down 6cm of rod by hand is quite a feat. I didn't have but now do have a lovely tap and die set of super small proportions, biggest size is 2.5mm, I got from the shop toolstore for £35, its a lovely set and I can see it being put to use quite often, anyway I threaded the rod and tapped the bob I then had to file off a good section of the rod to make it flat so I could solder it to the remaining part of the pendulum. Movement refitted and it started staright away, but it kept losing time, every morning I would turn the bob one turn for every minute it was slow to speed it up, I even wound it quite a few more turns than was required but still the next morning it wold be slow again, then I noticed it, the bob due to the nice new threads was working its way by itself back down the pendulum. So out came my brass sheet and drill and a small hole was drilled and tapped and then cut out and filed into a rather fetching nut shape. I done this to use it as lock nut under the bob, so far today it seems to be slightly fast, I'm not worried at the moment just keeping an eye on it to make sure its a constant gain meaning that when the bob is lowered and locked I should have a very nice mantel clock.1 point

-

Thank you Anilv. I took your advice and started with the orient. It is funny how monstrous the eta 6497 look in comparison. Having a lot of fun. Nothing lost or broken yet.1 point