Leaderboard

Popular Content

Showing content with the highest reputation on 05/01/18 in all areas

-

Well when I said old tool, here's a internet copy of a 1899 watchmakers suppliers catalogue similar tools appear on page 102 of the catalogue they may have at the time forgot to add your name to there mailing list . https://archive.org/details/20thcenturycatal00purd It does make interesting reading as a catalogue thats over 100 years old there are some very familiar old tools listed.2 points

-

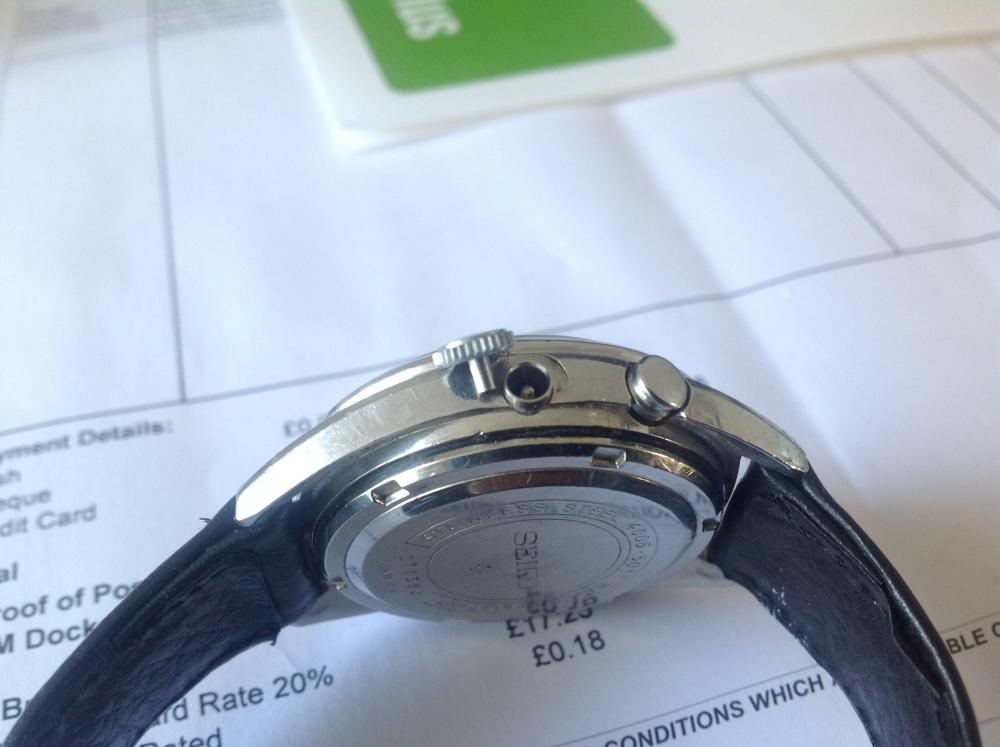

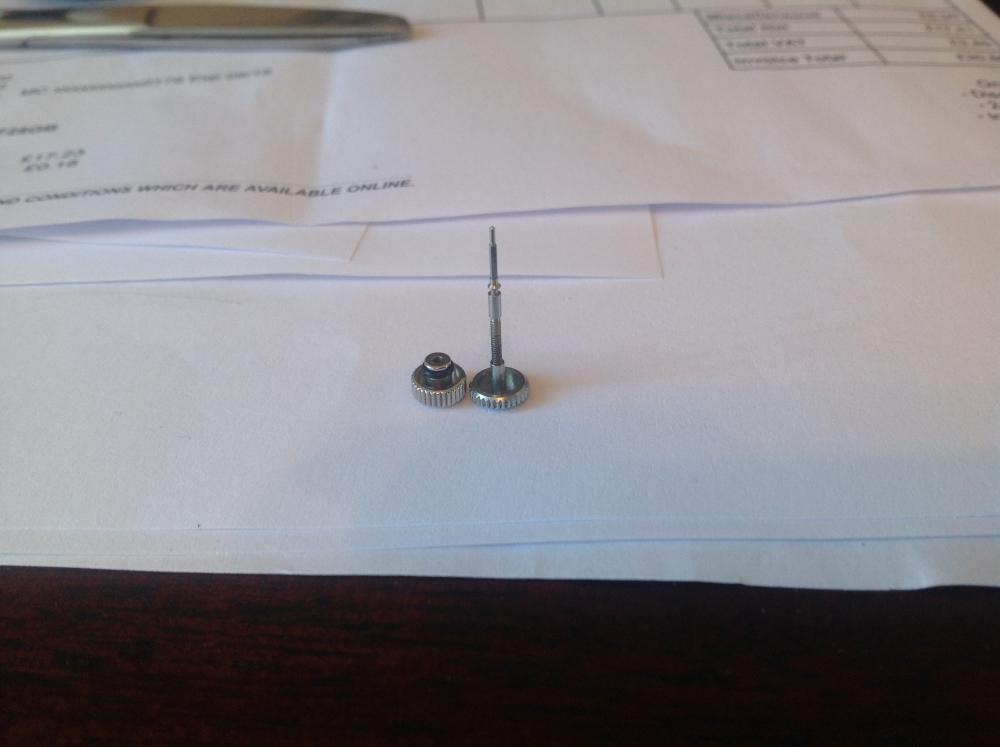

Well after some consideration I finally shelled out for a beaten up old Bell-matic. It is probably the most complicated watch I have, up to now, that I willl have worked on. It is not too bad I suppose but after bidding on about five of these watches i was surprised by the price they command even in poor condition. This is the pic from the bay Now that I have it I find the dial is not in bad condition at all, I accepted that the plexiglass was bust and it would need a new one (from Cousins) and the case has some need for buffing. However, despite being described as being in working condition there are quite a few faults. I found the crown was decidedly non standard and when wound backwards simply wound off and it transpires that it is in need of replacement. I thought I was in luck when I found one for £2.88 in Cousins but my hopes were dashed when the crown supplied proved to be the wrong tap size being 10 or 11 and not Tap 9 (10/100 mm) which is needed to fit the 354805 stem. Here is a pic of the crown that came with the watch - it is patently wrong. Here is a pic of the crown from Cousins alongside the other crown and it is obviously a better match to the tube and the gasket comes with it. Unfortunately the tap size was wrong but to give Cousins their due they contacted Seiko who confirmed I needed a 55M22NS1 crown (now obsolete) and they had supplied the wrong part and Cousins gave an immediate refund but did not ask for return of the Crown which I consider to be good service though I have now got my fingers crossed for the Plexiglass and gaskets I bought. Well thats my latest project. I am minded to drill out and re-tap the crown as in every other aspect it seems a perfectly acceptable crown. I may have to get some different taps though as the ones I have are a bit problematic on their lead in for the depth of metal to the dead end I will be tapping. I am in no doubt that there will be a lot of work here, the pointers look grubby and I suspect the spring for the alarm is faulted, though I heard the alarm work for a brief couple of seconds - it will need a full service but there are a few teardowns on the net - Christian has done one I could follow and I have found some more - luckily it seems to be a popular watch. Spares are available some easier to get than others but i will have to open it up and find out as I go along. That leather strap is revolting but it is the least of my jobs, date does change with pusher and the alarm ring does move and finally it does tick. Buffing the case should make a difference. Here are a final two pics - that is the best pic of the face I could manage through the bust plexi. I joined a Bell-Matic forum in another place (SCWF) and have accessed a shedload of info and spec sheets (grateful thanks to JohnWN) that will be handy. Just as an after thought heres a pic of some of my current favourites. The little Gradus needs some work and has seen some knocks but I will get round to it one day. I have a couple of cases with other stuff in ranging from the sublime to the ridiculous that I may get round to posting "some day". Bye for now - Cheers, Vic1 point

-

I think these come with a sealed barrel which might explain any duff information about a mainspring. In an ideal world it's a 'barrel complete' part. I've had a quick look around and there's a good Zodiac article here which also discusses mainspring sizes should you opt to tackle the dastardly sealed barrel: http://www.vintagezodiacs.com/zforums/index.php?topic=2134.01 point

-

I use a case holder like this one because it allows room for the balance to swing freely. Most times I just set the hands with a pair of tweezers. If a pusher is needed I than have one favorite one which is double ended with fiber board tips. each tip has been bored out to fit either the hour or minute hand respectively. Feel free to reach out if you need any vintage Timex parts. I do have a few laying around....1 point

-

I have one as well and it’s good for most movements. I have a few dedicated holders for Rolex movements and I recommend and prefer the dedicated ones. Id like to get a 2824 and 2892 one as well (at least). But for occasional use on various movements that’s a good choice. Just mind thebalance wheel before you crank it down... ask me how I know.1 point

-

1 point

-

1 point

-

I use a pencil roll like this for many of my tools. Easy to roll up and put away when done. During use it lays out at the top of my worktable, makes grabbing a screwdriver, hand levers, pin vise etc. very easy. Best of all, not expensive. This one is Derwent.1 point

-

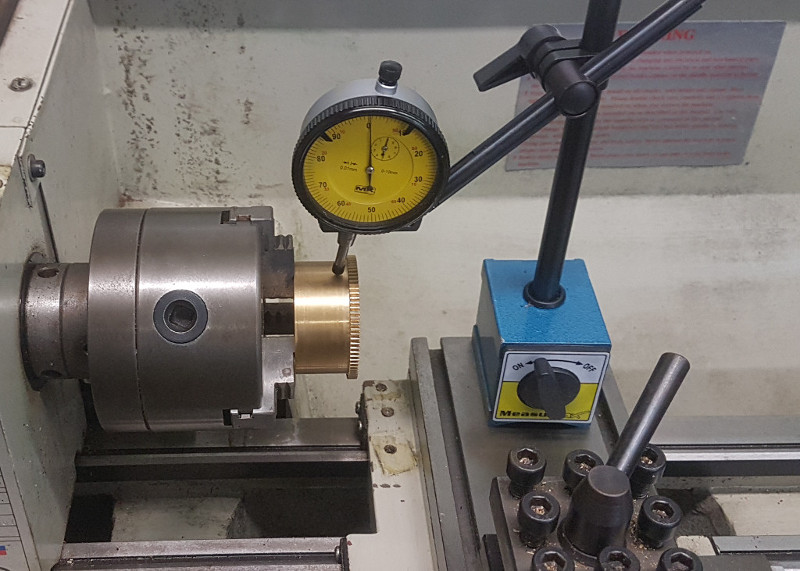

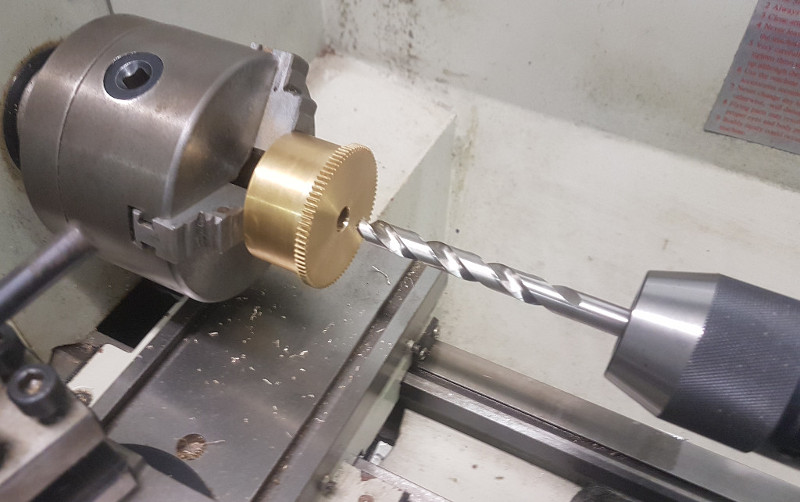

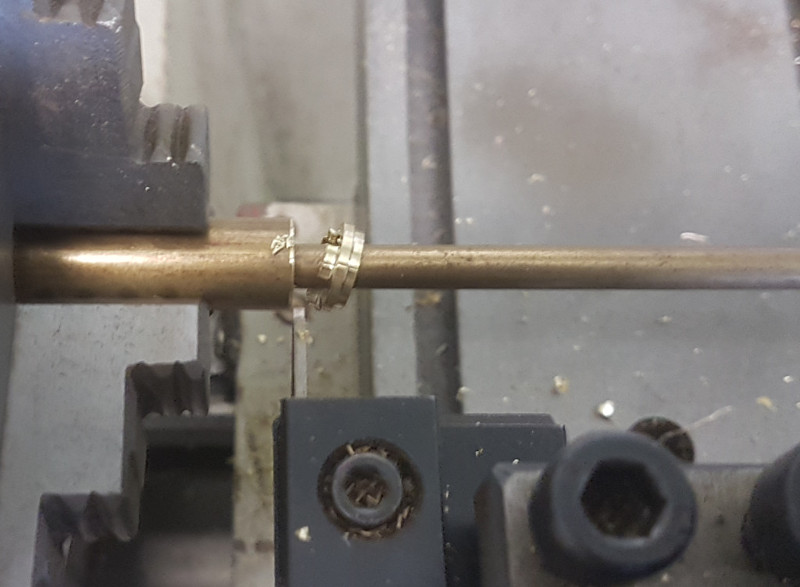

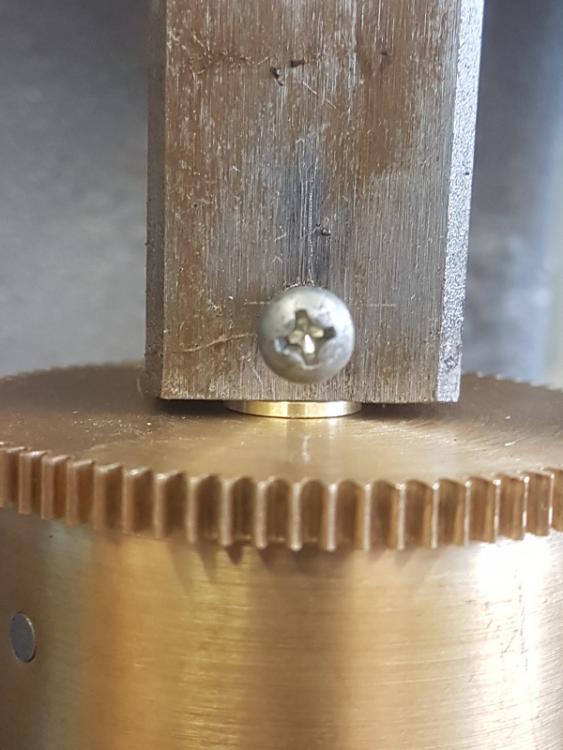

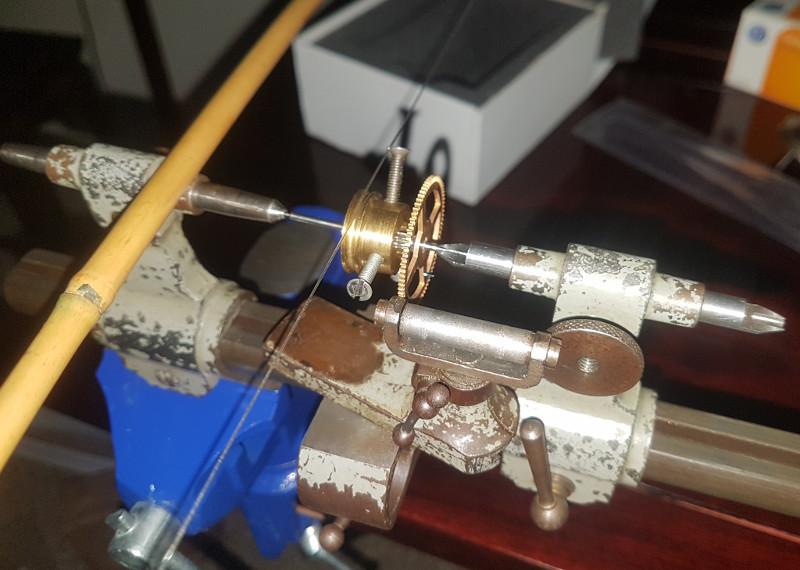

The clock is now ticking and chiming, just need to finish regulating it. I won't go through everything I did, but just show what I think are the more interesting things. Firstly the Chiming barrel arbor hole had worn oval and need bushing. First the barrel was set up on my large lathe and centered using a dial test indicator It was then drilled out to 10mm and the hole was measured to ensure it was exact A brass clock bush tube was selected that was 11.4mm outside diameter and 8mm inside diameter. The thickness of the base of the barrel was measured and the height of the lip of the bush was machined 0.2mm taller than the thickness of the base of the barrel and the diameter was machined down to 10.05 to be a friction fit inside the barrel. A 1mm lip was left to sit on the outside of the barrel as this would not impact end shake and gave added strength. The bush was then transferred to the watchmakers lathe to clean up and add a leading edge chamfer to make it easier to fit. Finally it was pressed into the barrel using an arbour press. Once the mainspring arbor had been polished the bush was then broached to size using clockmakers broaches. I needed to polish a number of pivots that were all 0.8mm in diameter. I know some people can just hold the wheel in a pin vice and using a pivot file and a block of wood polish the pivot, but I'm not that good. I got some bar stock that fitted the tailstock on my watchmakers lathe and drilled it 0.8mm. I then turned a taper to the end and transferred it to my mill and milled just over half way through the bar so just slightly less than half of the 0.8mm hole was left. I then set up my watchmakers lathe as a turns and using a pulley that I had made previously which has 3 screws 120 degrees apart screwed it onto the arbor and using a bamboo rod and finishing line made my bow so I could use my lathe as an oversized jacot tool. The pivot was filed with a pivot file, finished with a triangle Arkansas stone and burnished with a pivot bunisher. Hope this is of interest to some people.1 point

-

1 point

-

Also an auto mechanic... Once I tried to get my screwdrivers organized by handle color to tip: i.e. the Phillips tips were green and straight tips were red. That didn't last long, as some specialized tips were only available with certain handles (usually black) etc. Seemed like a good idea. Now I have every color in the catalogue mixed in the drawer... For wood working I organize my drill bits and router bits on wood blocks. No reason that wouldn't work with precision screwdrivers too...1 point

-

1 point

-

Well ... it was just a joke. Though I both love Mickey Mouse's watches and Rolex watches I consider the two sorts being contradictory. I really don't think , though I can't be 100% affirmative, that Rolex ever produced a Mickey Mouse watch nor that they did let a firm officially modify their production. Nevertheless the watch seems to be, as far as I know, a real 1601 Rolex, so that dial could be both what some people call a "refinished dial" or a fake dial. I suppose Rolex would probably consider all the watch as a fake, even if only the dial is fake, but this is definitely a nice MM watch.1 point

-

1 point

-

1 point

-

We too lost a cat, Isabella Catallini, that had been with us for 20 years. I tried to tell myself that she had a long, good life, but it seems that when a friend has been with you so long it makes it even harder when she passes.1 point

-

Not dreamed up at all, that is exactly how they should be fitted. Do NOT try to press it in, it will just break, particularly if it is a bevelled edge crystal. You could use a smaller crystal and cement it in but this is a compromise for an under-cut bezel; the degree of the compromise depending on whether the crystal has a bevelled or 90 degree edge. The correct approach is to use a bevelled edge crystal that is slightly too big to drop in, heat the bezel so that it expands, drop the crystal in place and when the bezel cools down and contracts it should be a nice snug fit so that the crystal doesn't rotate in the bezel. crystal fit.pdf1 point

-

Hi, with the balance removed the lever should run to each banking position when delicately moved with a pin and the escape wheel should rotate. If the escape wheel does not revolve one tooth at a time as the lever is moved across then there is likely no power getting to it from the gear train. Especially inspect the gear train for cleanliness and free operation the most likely being say dirt on the 3rd. and 4th. wheels. Check the pallet is free to operate freely. Check that there is a touch of end clearance (shake) so that the balance is free to rotate when the balance cock retaining screw is tight and that the hair spring is clear to operate. I hope this is of help.1 point

-

1 point

-

1. Watch was working before you starting messing with it right? 2. When you started to regulate it, I believe you would have moved the pointer either to the (+) or (-). 3. It is possible that while doing this, the stud holder may have moved a bit when you moved rate adjuster. This will affect the beat or the 'tick' will not balance the 'tock'. These two parts revolve around a common axis and it happens. 4. Unless that you are really sure that you have not damaged the balance or hairspring, I believe your balance is out of beat. ways to damage your balance wheel.. -Inadvertantly applying pressure on the rim of the balance while manhandling the complete movement while its out of the case. -Pressing on the balance cock too hard thereby damaging the pivots. -Physical contact with the hairspring.. such as poking a screwdriver thru the hairspring? -removing the balance wheel and getting the hairspring caught in the regulating pins. Like Roberto said, get a second opinion. Anil1 point

.jpg.6225a64433578a11e0218b27c20b13f5.thumb.jpg.d82b0cd1e370f3a3a59a06afa957d184.jpg)

.jpeg.5ce1ab90a52cf4a2194e9f7b41ef2759.jpeg)

.thumb.jpg.6f3f182c797ed6c7cc62fd39cce8e528.jpg)