Leaderboard

Popular Content

Showing content with the highest reputation on 01/29/18 in all areas

-

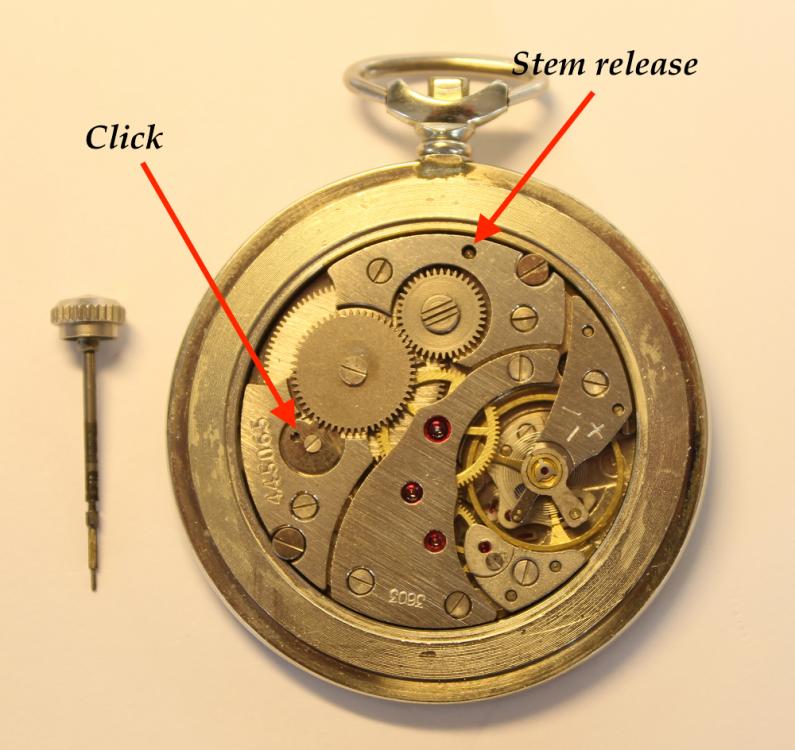

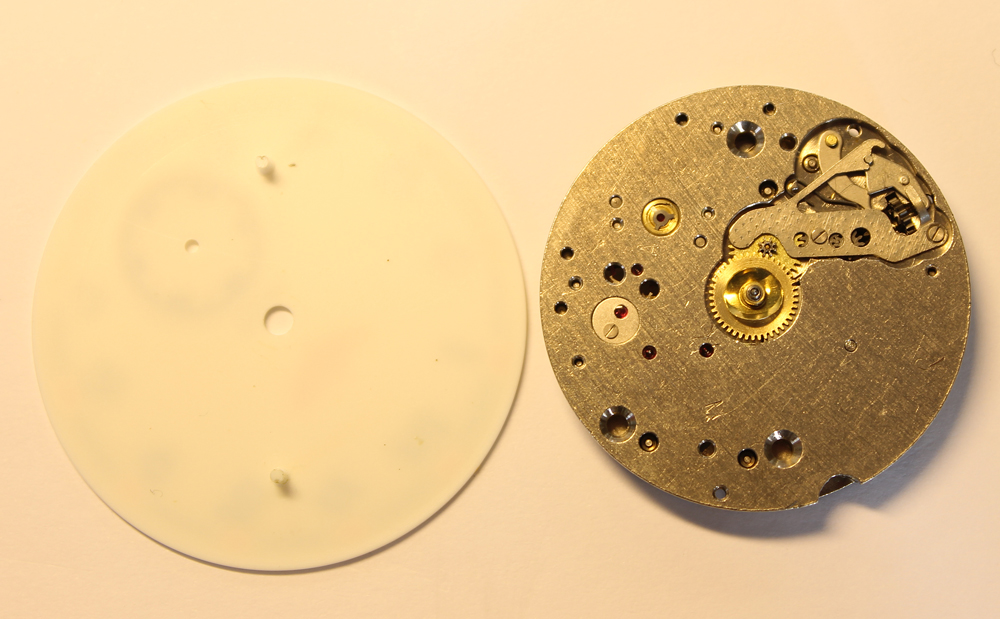

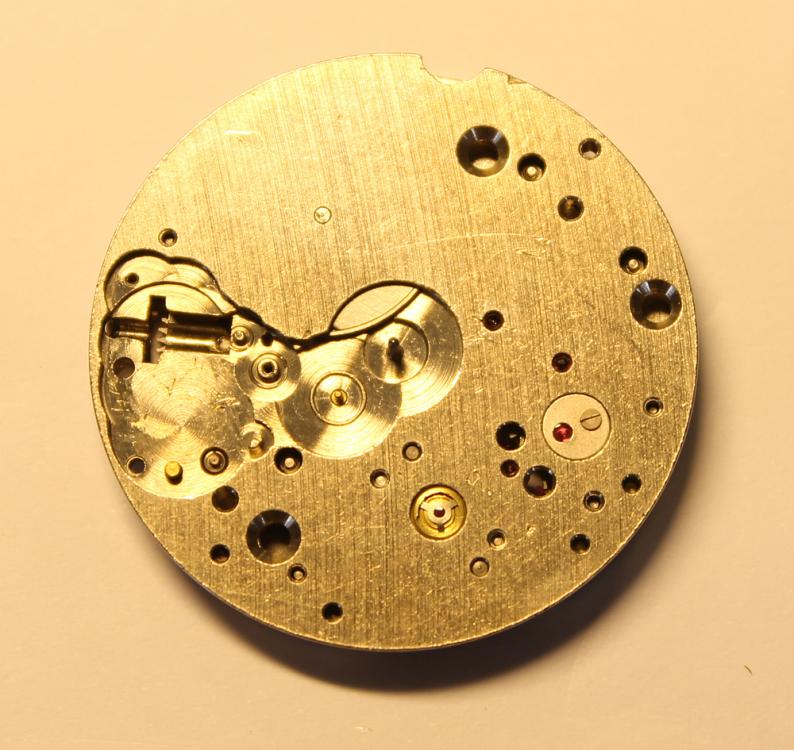

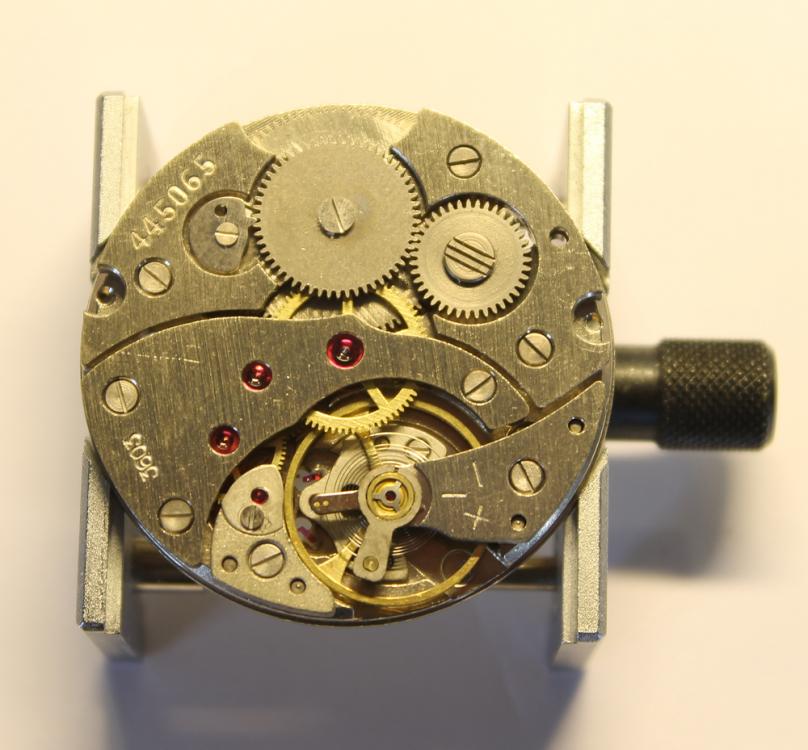

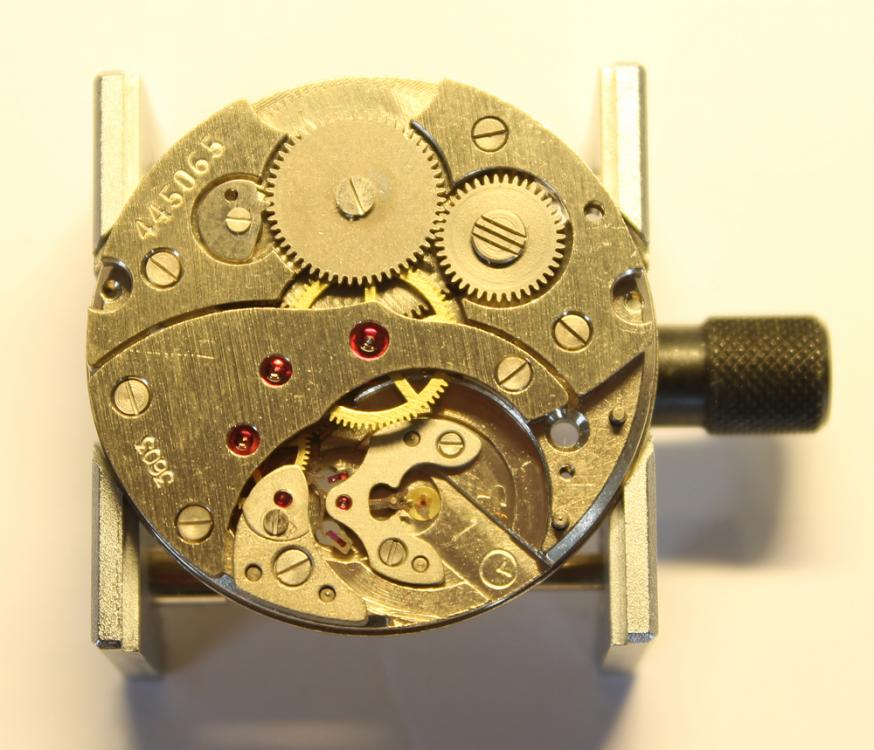

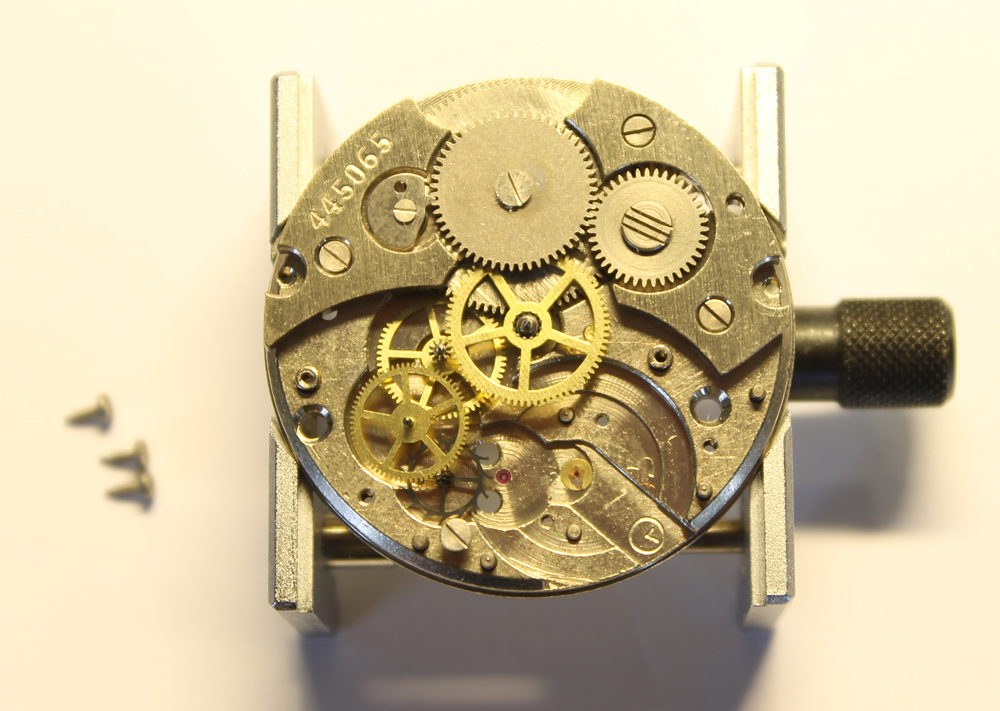

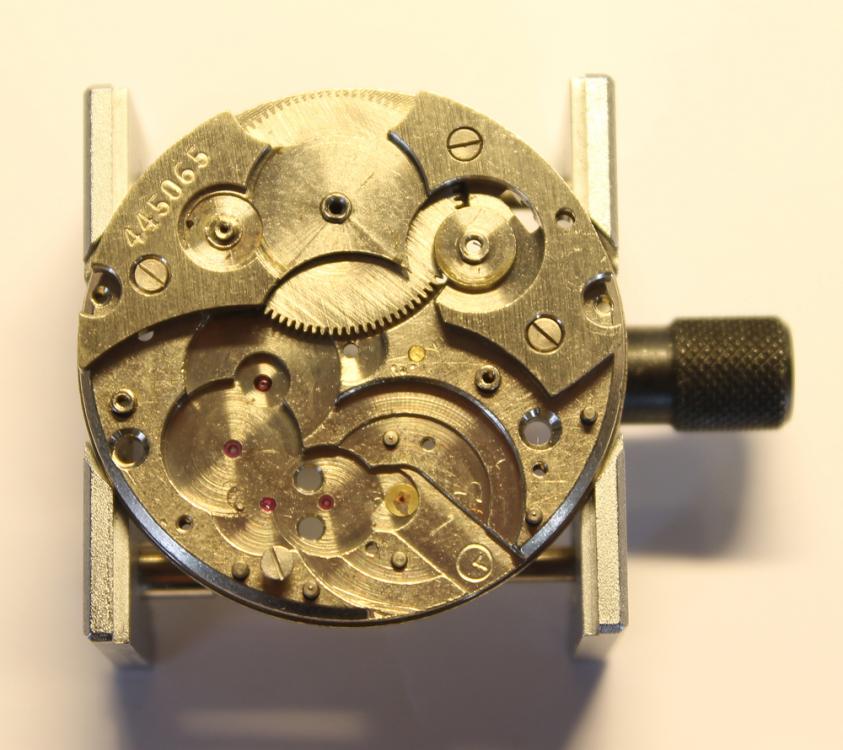

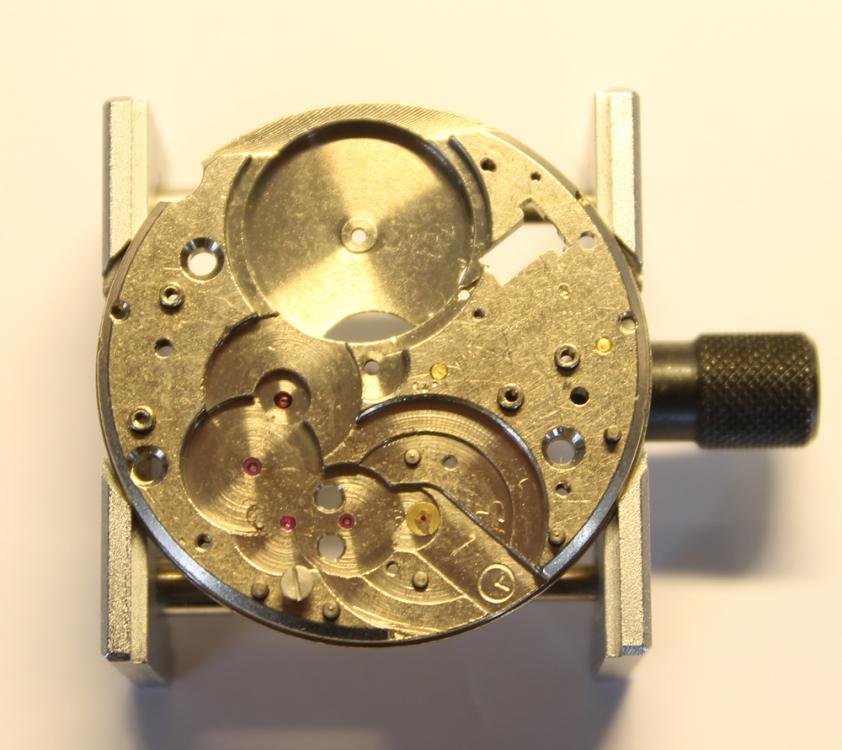

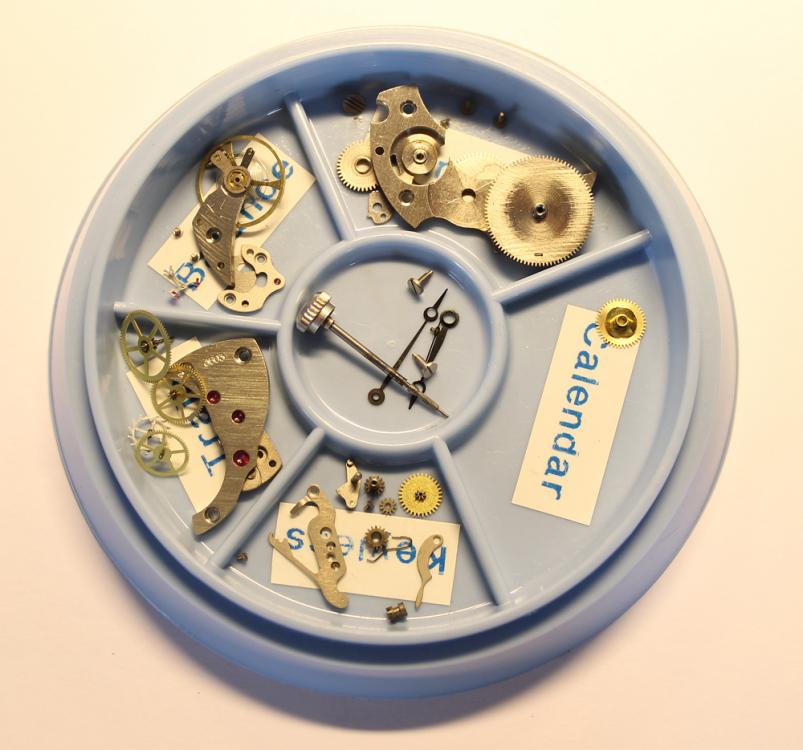

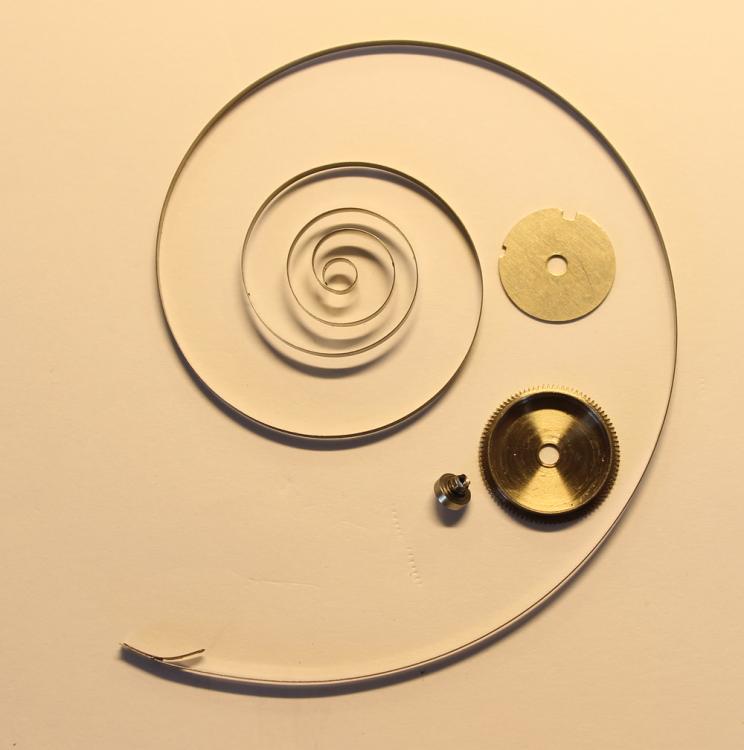

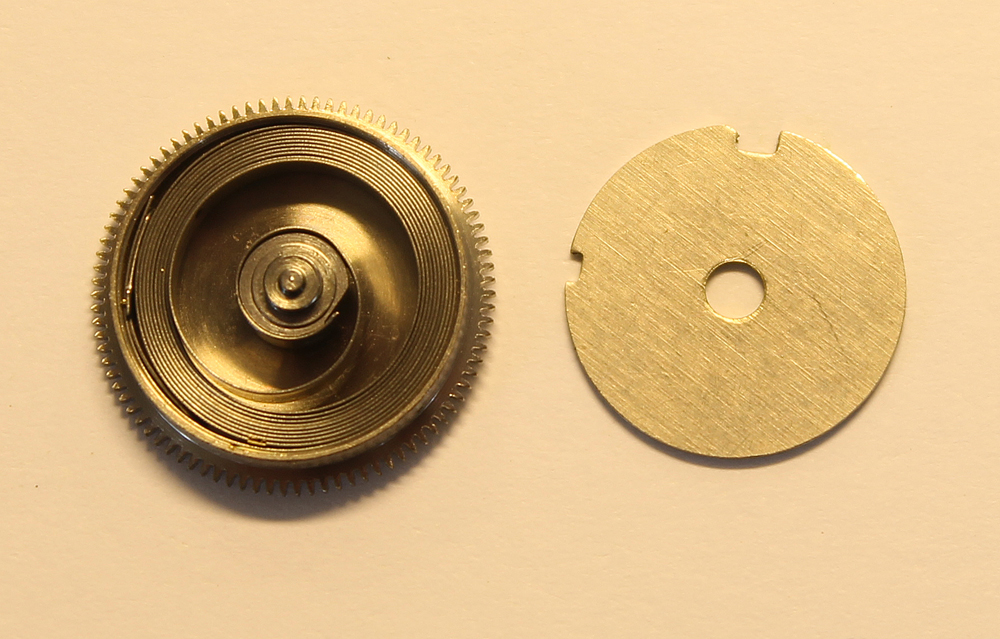

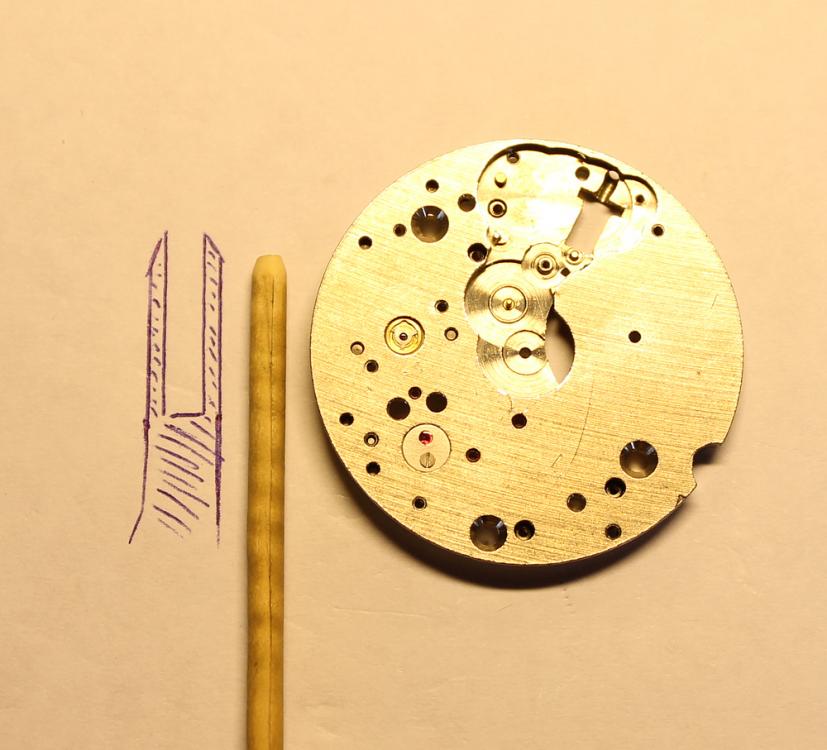

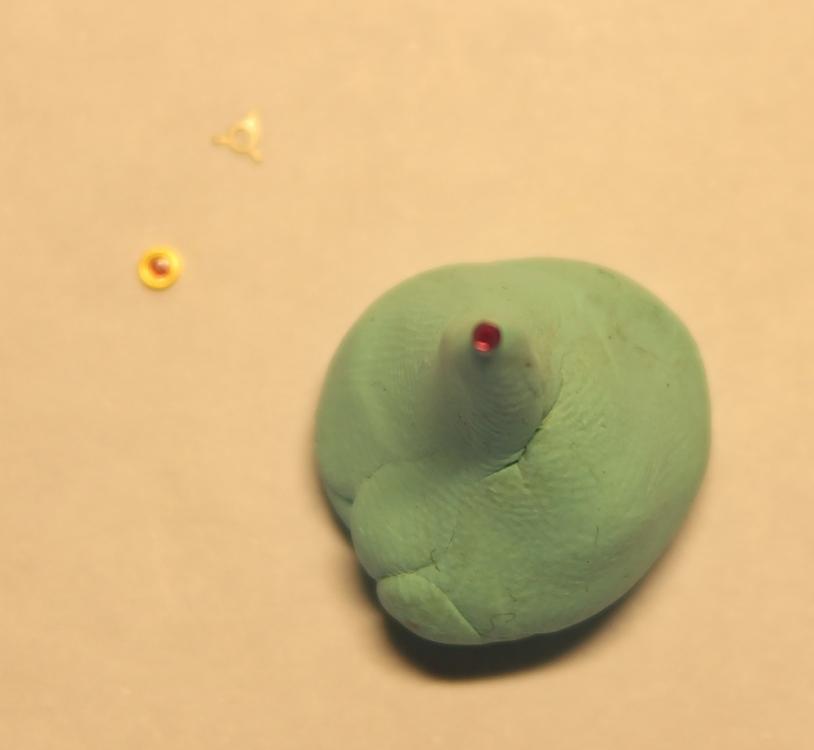

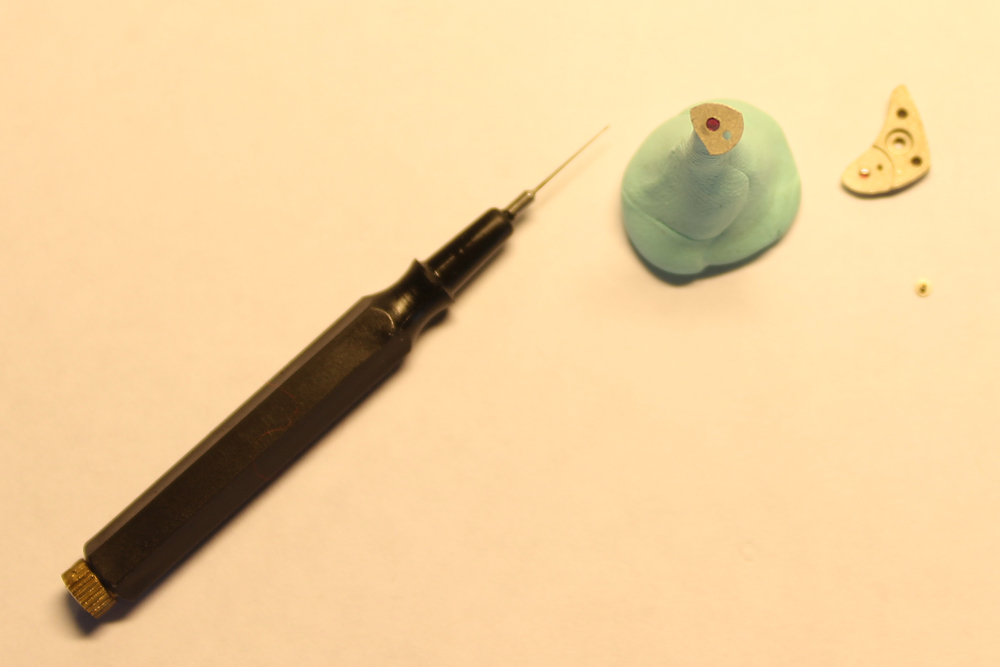

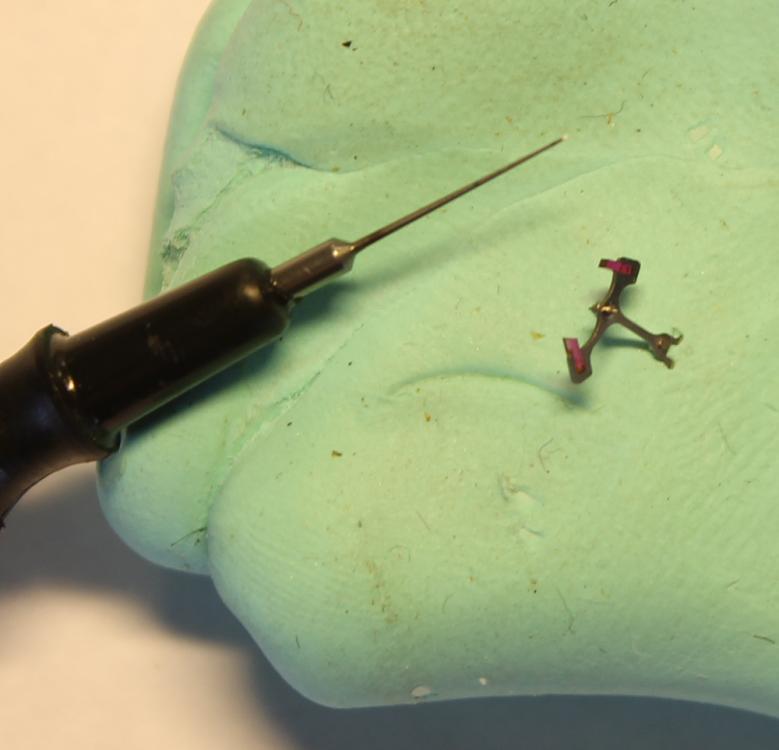

Hello All; I managed to get a NOS Molnija Pocket watch from a collector who passed away. Before I do this relative simple walkthrough, I read up on this iconic Russian pocket-watch and like to share some of its history I gathered; The Molnija movement is basically a copy of a Swiss cal.616 movement designed by Cortébert. This design was very popular and turned out to be a blueprint for many other movement designs such as in Rolex watches from around 1940's: The Molnija (Молния) pocket watches were made from November 1947 to October 2007. The main factory was located in the Ural town of Chelyabinsk with a second factory outside of Moscow. The Russian word Молния means "lightning". The Russians improved accuracy of the movement quite a bit when they upgraded it to their 18 jewels version of the movement but the basic design remained the same until the closure of the factory in 2007. In other words the Molnija movement was originally a Swiss Cortébert movement. A high quality movement. The movement is mainly made out of a nickel copper alloy. The smaller and more delicate cog wheels are made of brass and the bigger wheels which are directly connected to the main spring are made out of carbon steel. Molnija technical specifications Movement diameter: 36 mm Movement types: early movements are called "ЧК-6" (ChK-6) and they have a nice striped pattern finish (Geneva stripes). Around 1964 a new movement called 3602 was introduced. The 3602 is almost identical to the "ЧК-6" but it has no finishing pattern and some of the internal dimensions are different such that you can not exchange parts between the two types. The 3603 movement is a 3602 movement with shock protection (the balance wheel jewels are different). Jewels (gemstone bearings): normally 15 on the "ЧК-6" and 18 on the 3602/3603 movements Rate: 2.5Hz, 5 beats per second, 18000 bph (beats per hour), Lifting angle 52 degrees. Main-spring reserve: The watch runs about 40 hours when fully wound. Balance staff: riveted, note "ЧК-6" (ChK-6) and 3602/3603 movements require different staffs. Balance wheel: The balance wheel alloy was changed and improved over the years. At least 3 different kinds of alloys with different colors in Molnija watches. Hairspring material: Elinvar, hairspring form: Breguet overcoil for 3602/3603 and flat hairspring for ЧК-6 The Chelyabinsk Watch Factory used in the 60's and later sometimes this symbol of a watch showing 9 o'clock. Shock protection for a mechanical watch indicates that the delicate pivots that hold the balance wheel are mounted in a spring suspension system. A shock resistant watch is supposed to survive falling from a height of 1 meter onto a horizontal hardwood surface without any damage to the balance wheel staffs. Most of the Molnija pocket watches are caliber 3602, without shock protection. Shock protection is highly recommended for wrist watches but rarely used for pocket watches especially older models. Pocket watches are more protected against shock if they are properly secured with a chain or some kind of string and carried in a pocket. A few pocket watch models in the late 80's and early 90's were caliber 3603. The 1980's models had a triangular metal piece holding the balance jewel and the later 1990's models had a star shaped metal piece with a round center hole. The 3603 Molnija movement (shock protection) is not seen very often but it can be easily identified because the regulator has two arms that can be moved and the jewel on the balance cock is held in place by a small metal piece sitting on top of the jewel. The watch I received had the more rare 3603 movement, and the solid Silverine case was, apart from some "drawer-wear, in a superb cosmetic condition. It has a Steam locomotive theme and is also called a "Railroad" watch. The finish on the stamped locomotive is done with a grey paint, which wears off in time. The paint on this watch had no wear to speak of. Here a close up of the 3603 movement with a "star" shaped anti-shock spring, suggesting that this movement is from the early 1990's. Clearly, nobody has serviced this watch since it left the factory. It ran, but stopped. The movement is held in place by two case-screws and is removed via the front, so the front bezel and the glass have to be removed first. Removing the hands; I used some 0.2mm thick plastic to protect, in this case the plastic dial. Remove any residual tension in the mainspring by holding the crown, lifting the click and let the spring tension slowly escape via the crown. Once the tension is off, the winding-stem can be pulled by depressing in the stem-release button. Undo the two case screws and take the movement out via the front. The plastic dial has two dial feet, hold in place by two dial-screws on either side of the movement. Note the anti-shock for the balance wheel and the separate cap-stone for the escape-wheel. Started disassembling the keyless works; With the keyless works and cannon-pinion removed; Flipped the movement over; Removed the balance assembly. Clearly to see the dried and solidified oil on the inside of the top anti-shock. Also the "nine-o-clock" stamp of the Chelyabinsk Watch Factory, normally "hiding" under the balance wheel. The escape wheel cock and wheel-bridge removed; Next is the ratchet wheel, the click, crown-wheel (left hand screw!) and thereafter the whole train can be removed; Next is the barrel bridge and barrel The movement has now been fully stripped and ready for some thorough cleaning. Also the main-spring has to be cleaned & checked; I normally take it out by hand and wind it by hand. After some practice it's not hard to do; however never loose concentration while uncoiling or winding the spring though ! These springs LOVE their freedom !! Cleaned and checked the spring, re-wound and oiled it. Make sure the springs "side-wings" engage in a special hole inside the barrel and place the lid correctly. It is also a good idea to demagnetize each part before assembling. Magnetism can cause strange and "un-explainable" running behavior later on. Best is to "nip it in the butt" right from the beginning. Since we are dealing with dried and solidified oil, each and every jewel has to be cleaned thoroughly with peg-wood. Even down to the smallest jewel hole has to be cleaned manually. Every pivot has to be checked and manually cleaned it required. Failure to do so, chances are that the watch doesn't run fine. For removing the anti-shock star form spring, I'm using this drilled out and edge-shaped peg-wood. It works very well for me; After cleaning the anti-shock cap stones, I'm using Rodeco to support it for oiling. Once the oil is on, you pick the Rodeco up, turn it upside down and place the cap-stone in the waiting Chaton. Hold with your tweezers the top of the stone and pull the Rodeco off. When using a 5x magnification, this works as a treat for me. Same methode for the escape wheel cap stones; Also Redoco for holding the pallet-fork while oiling the stone-tips; (hmm ...... it's about time for some new Rodeco !) Assembling the watch is the reverse of the above. After some adjustment the timegrapher produced the following picture; I'll settle for that ! Hope you enjoyed this reading and that this walkthrough will benefit somebody, some day Roland.2 points

-

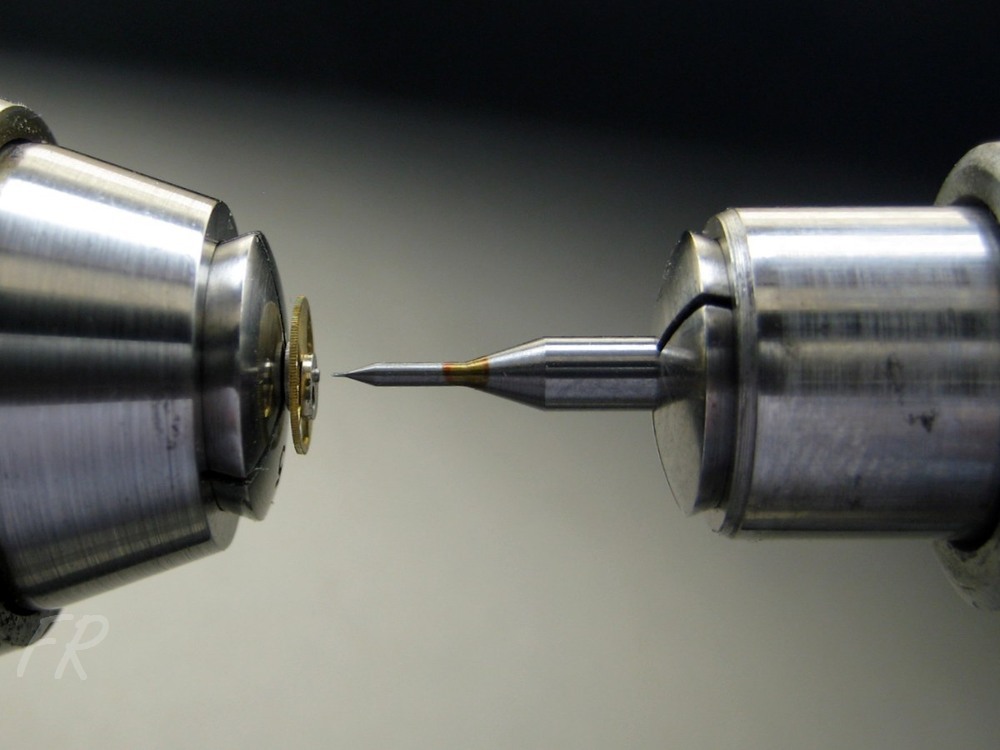

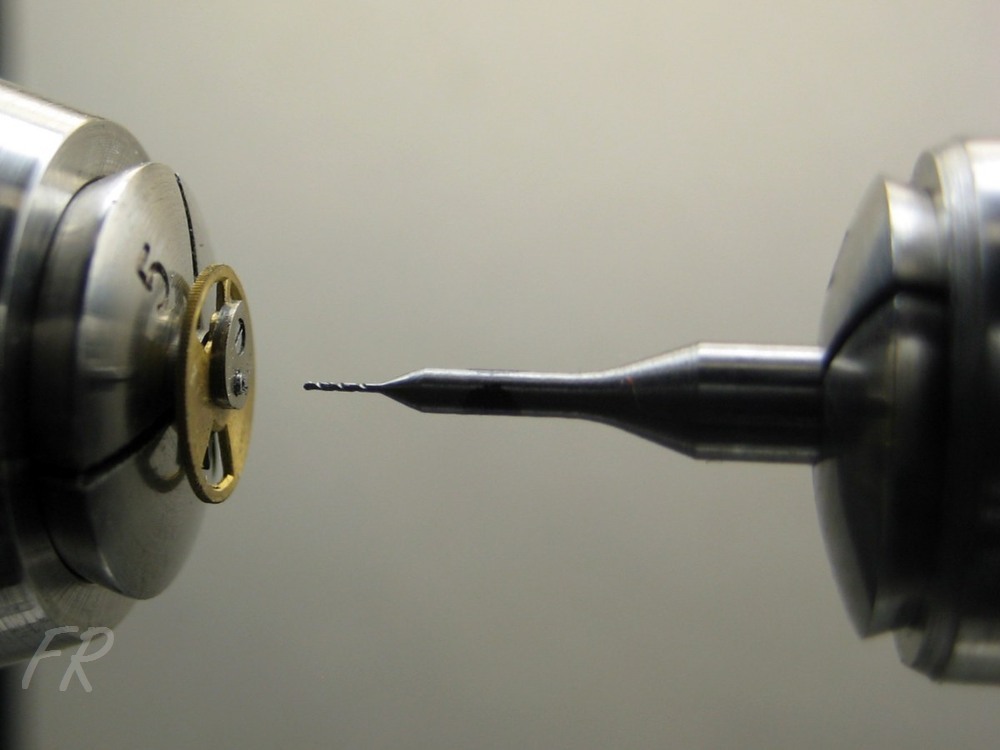

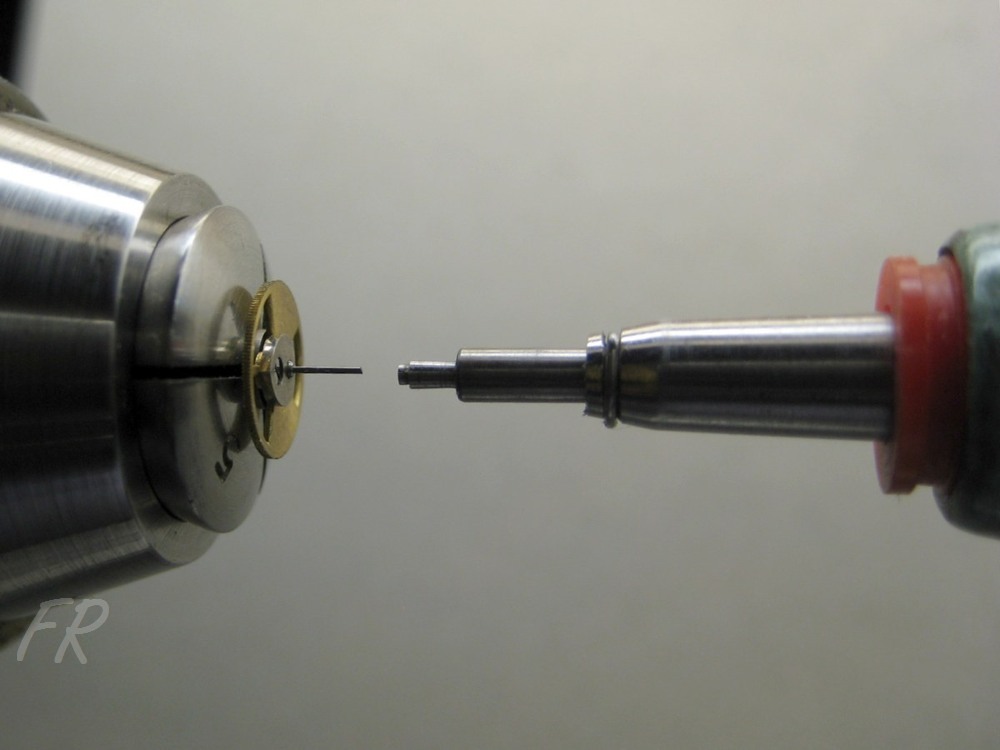

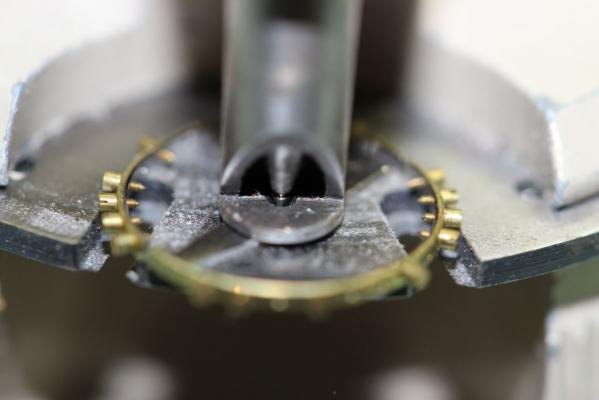

Drilling and replacing the pivot should be the preferred method IMHO if parts are rare. Rather than changing the whole wheel, this will save scarce resources. Chronograph runners are the first parts that get unavailable, guess why? For skilled and well equipped workers this repair is fast and not very difficult to do. Last year I got a WW2 chronograph in my workshop for repair. Both chronograph runner and minute register wheel had their pivots broken and sapphire jewels cracked. Tools used: Lathe, center drill 0.20mm, drill 0.25mm (both tungsten), Pivofix or Jacot tool: Frank2 points

-

For fixing objects in an engraving block. https://www.amazon.com/ENGRAVING-ATTACHMENTS-Setting-Jewelry-Rubber/dp/B00BLTG0PS1 point

-

Brilliant thanks. How did you match the model number to the glass number? Sent from my iPhone using Tapatalk1 point

-

Agree. I didn't had the time and will to locate a spare transducer or better diagnose the fault. Now I'm back to shaking a cup, to be honest it seems to produce the very same results.1 point

-

for the small parts, such as hands, crowns, screws etc. I use this basket (I've gotten one at the local Dollar Store), which I removed the chain off, and it works really well. My basket is a bit bigger than the hight of the machine and I kind of squeeze it with the cover which is no problem at all. As for the bigger parts, I just put them on the bottom and let the machine do its works. I do not have any experience with any professional machine nor really have a need for at this time (something that same me money and space). the machine comes with two power 30w and 50w and I use the 50w for the longest time possible (30 minutes) and sometimes for watches that I tend to buy at the flea market or get from friends, I double the time and give it two rounds. Do not waste your money with Esslinger unless for items that you can't find any other place. A ) Ultrasonic Machine from AE B ) Basket1 point

-

With pendulum clocks always remove the pendulum and when moving always tilt the clock towards yourself, this will prevent the pendulum from swing about and will preserve the suspension spring. Place paper between the crutch to stop the crutch from tripping. With some French striking clocks, you have to remove the bell to get to the crutch. With chiming clocks most have, hammer locks so lock them, if not place paper so hammers don’t make noise (it will drive you nuts) if you’re driving and the vibration can cause the clock to strike or chime. Place paper to prevent movement from vibration, which can trigging the strike or chime. Longcase clocks make sure the dial and hands are away from being scratched or bending of the hands, a blanket is best place movement face down on that. Don’t forget to let the lines out and keep the strike and time lines away from each other so they don’t tangle, I used to wrap them around the seat board. Anniversary clocks or 400-day clocks always lock the pendulum and place in a box with lots of packing. The very old disk pendulum and the ones that do not come with locks be careful of the suspension spring but always pack them well. DON’T FORGET CLOCKS THAT CAME WITH KEYS REMEMBER TO TAKE THEM WITH YOU.1 point

-

If it has a pendulum remove it and as a precaution pack the inside with newspaper.1 point

-

Hi, looking forward to participating. I started my journey into tinkering with watches a few years ago, slowly acquiring parts and learning. I like mechanical things and I enjoy fixing things, whether my Jeep, things around the house, electronics (stereos, oscilloscopes, ... ). Little did I realize watch repair exists on a much higher plane. I have managed to successfully disassemble, clean, oil some Timex watches, a few 6S Elgin movements, and perform a few other basic tasks like fixing the shape of a couple of hairsprings, ... but not without many hard lessons along the way. If it weren't a challenge it wouldn't be worth doing. Anyway, looking forward to learning more! Sent from my Pixel 2 XL using Tapatalk1 point

-

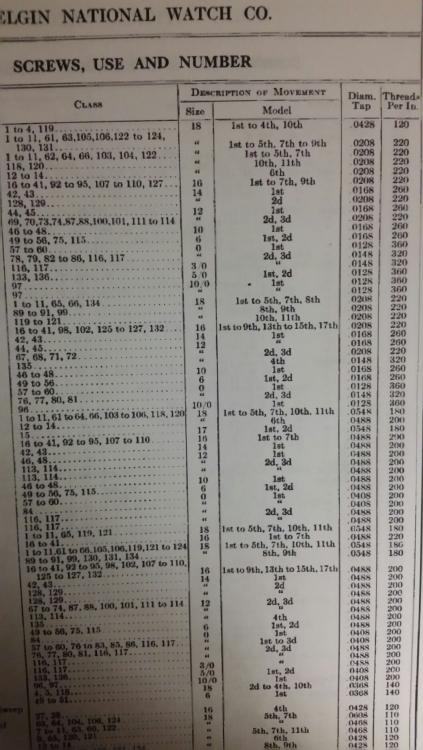

Elgin and Watham made their own thread sizes for their pocket watches so you cant buy new taps and dies to fit their old watches. You need to find an old set off ebay when they turn up that are hotly contested. Guessing the newer wristwatches made by the Swiss branded as Waltham and Elgin used metric threads1 point

-

If it's the metric set that I found in searching it would be of no use for American pocket watches, here's an image of page 1 of 8 of screws just for Elgins, and they are all in inches. Some jewel setting screws are 480 tpi, and some on this page are above 300. My guess is old time screws were rolled, as modern mass produced screws are, then cut to length and then the head and slot were formed last. I see no other way to mass produce such small pieces individually. Occasionally I have seen Elgin tap sets on ebay, and they sell for a mint when they appear.1 point

-

edit window closed and I miss a bit....I'm giving the way to anneal carbon steel. A shorter, simpler cycle might anneal it enough, but the point is if its not working its because you are either not getting it to the critical temperature, or more likely its not being cooled slowly enough. A BIG advantage to to doing a full normalizing (think slow and full anneal) is that the stresses are removed. Without that, there is an increased chance of cracking at the stress riser (ie bottom of the V thread) when you do the quench to heat treat after machining1 point

-

I haven't seen a Pocket Ben in person but... On the 1800's and early 1900's pocket watches with plain circular or oval shaped bows (Pocket Ben styles 1 - 2a), one uses bow pliers to bend and adjust tension on the bow. I am assuming the material used in the Pocket Ben is similar to that used in the various cases I have and They have little nubs on the end that fit into a sort of socket on the stem tube and are held in by tension. If it is style 3 and up, then I defer to others. I would think a parts watch would be the way to go if there is a way to replace that newer style bow. Old style bow assortments come up for auction often. I have some larger spares if you need. Ref: https://clockhistory.com/0/westclox/series/series-17-1.html Sent from my Pixel 2 XL using Tapatalk1 point

-

Well, she's cleaned, oiled, reassembled, and running pretty strongly. I don't have a timing machine so I have to just see how it keeps time while it's on my wrist. I had a beautiful Watchmaster G47 timing machine, but it was impossible to get the necessary paper rolls for it so I got rid of it. Someday soon I'll get one of those new electronic ones that a lot of guys are using. Anyway, the biggest tip that I'd give on this Wittnauer 7LT is to be extra careful when replacing the balance in the watch. It comes in from the side and has to get under the center-wheel and the fourth-wheel. It's very easy to get the hairspring hung up on top of the center-wheel, so beware of that. Wittnauer was kind enough to provide a channel in the pillar-plate that lets the lower balance pivot, roller-table, etc., drop a bit lower to make it doable. Still, it's a bit of a challenge. The arrow in the image points to the channel in the pillar-plate. As I said above, it's a very nicely finished movement. It does seem that all of the 7LT movements were not finished the same. The Revue model, along with others I've seen don't have the polished winding wheels. I guess that was about different years of production. Cheers.1 point

-

1 point

-

I thought I would post this vid. It is a vid promoting Seiko but it is also excellent in showing how a mechanical watch works. Well worth watching.1 point

-

1 point

-

Yes that would certainly be enough to cause the safety pinion to do its job, you should inspect the barrel arbor for wear, and replace the mainspring.1 point

-

What you are describing is a Elgin safety pinion you dont need to tighten the pinion very much because its supposed to unscrew its self if the mainspring snaps. The wheel should have a d shaped hole to the center place it on the arbor so the d shape lines up with the flat on the arbor then put the washer on and then put the pinion on and screw it down it does not have to be tightly screwed down at all because when you reassemble the watch, when you wind it up the pinion will tighten its self with the torque from the mainspring. Pictures paint a thousand words and you should endeavor to provide them in order to get an answer, not all Elgin center wheels are the same. I am only assuming from your description it is a safety pinion pictures would help to confirm my assumption or may help someone else to answer your question.1 point

-

1 point

-

Don't worry I've got a few clocks in the post and a few more waiting for me to start on. Over the coming months I plan to ask questions about early 20th century French carriage clocks, Kundo anniversary clocks, US Navy Seth Thomas deck clocks, National time recorder clocks and if I get to them Russian military clocks too. Yes I do have far more clocks waiting for me to get to than is healthy. I would like to say to other members feeling disheartened about not getting replys from original posters take heart in the fact that many other people read your posts too and your post probably ends up helping several other people too that may not even be members of the forum, you may never know it, but your post has helped spread knowledge1 point

-

Just uploaded a new video. This one is one of my favourites, an Omega Military watch from the mid to late 40s. It had a broken balance staff, impulse jewel and the pivot on the centre wheel had a groove worn into it. I didn't film the lathe work but managed to get quite a bit under the camera. I hope it's useful to someone. Some pics:1 point