Leaderboard

Popular Content

Showing content with the highest reputation on 10/24/17 in all areas

-

Always been fascinated by these but could never justify the cost. One day maybe.2 points

-

Why? if it is just scratched you can also polish it. It will take more time but it can be done without removing it and you will have tools to do it on any other watch in the future. Search this forum for details.2 points

-

I don't think that there is an absolute "best" speed as such as it comes down to individual preference. There are factors to consider though. Essentially, the faster the work rotates the faster you can cut, and the faster you can totally screw things up. If the lathe is spinning fast and you choose to progress slowly by taking finer cuts you can end up work hardening the piece, you can also get a build up of heat. Work at to high a feed rate and the graver will dull too quickly. Fail to notice in time that it needs touching up and you end up burnishing the surface of the work. If the graver should dig in, the faster the work is turning, the greater the damage. However, get it right and higher RPM means that you can turn out wore work in a given time. The flip side though is that if you have the luxury of being able to take your time, slower RPM affords you much more control, it's much easier to take finer cuts and to get a better finish. Don't forget that a lot of the very best work is done on a turns powered by a bow, which, as it's working between centres, has the added advantage of allowing the work to be taken off for measuring or fitting and then be returned without any loss of concentricity.2 points

-

Ok guys managed to get myself a nice 6mm Lorch lathe at the weekend with a selection of collets ( not a complete set though ) and some step collets and a heap of other bits that to be honest I need so help with, what do they all do and how do you actually use them. ive used a big ol Colchester lathe before for basic turning/milling etc etc, but all these bits with my Lorch I’m a little stuck. I’ve searched the net to see what comes up and to be honest there’s not a lot about the actual bits, so I’m asking the members here for some advice. Dont mind the angle of the bed ok, it was just placed and not fixed for the photo.1 point

-

I’d say that may be the culprit. When you washed it, it probably wasn’t cleaned there. The force needed to spin may not be much to your finders but it’s insurmountable to the movement. I suggest you work on removing CO and wheels associated, wash them well and try again. Cheers Sent from my iPhone using Tapatalk1 point

-

It is for a bespoke case I am designing and making. Trying to figure it out how the movement holder will be fixed to the case and some dimensions I need. Will search further on the links you posted. Thanks DanP1 point

-

Are they for any special watch. Otherwise i have seen ETA screws with tabs on Ebay . There must be on cousinsuk. This will have you covered for all sizes. https://www.ebay.com/itm/Watch-Movement-Repair-Adapter-Securing-Screws-Washers-For-ETA-2836-2834-2846-/302391791756?hash=item4667f4908c:g:es4AAOSwMedZdD5q If i remember correct 955.112 have the same size screws as 2824 -21 point

-

I don't think that this watch has an acrylic crystal with a tension ring if that's what you're referring to...1 point

-

1 point

-

Hey guys, my name is Massimo, italian but living in Japan at the moment! And right here I started collecting watches, mainly from the '70. Of course most of them need care and I found this great forum from which I already learned a lot, but I definitely want to learn more... At the moment I own already around 50 pieces but most of them needs some works, so I hope you can help me out! Talk soon and thanks to everybody in advance!1 point

-

1 point

-

1 point

-

1 point

-

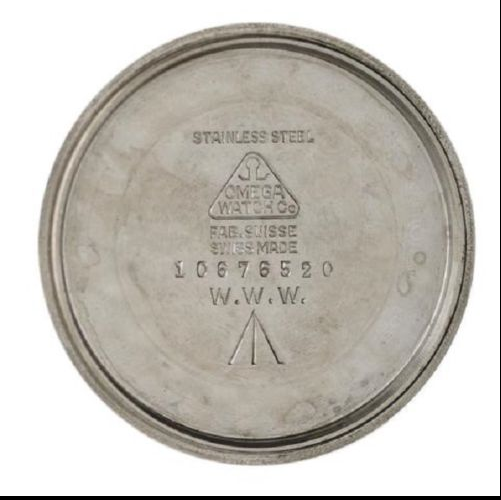

I was finally able to acquire this vintage WWll Omega Dirty Dozen 1940's caliber 30T2 watch . I had been looking at this model for quite a while ,….wiping the drool away every once in a while . This watch was issued to British soldiers during WWll . The dial is the original one supplied by Omega . I had seen others with a refinished dial , but it didn't "do it " for me . The hands are a replacement which is a MOD [Ministry of Defense ] approved alteration and neither the dial or case have ever been refurbished according to the seller who is listed as a Trading company in New York . The watch has a 30T2 movement which is a robust and reliable performer used by Omega in other models as well . It also has fixed lugs to hold it securely to the strap even in combat . W.W.W. stands for Watch , Wristlet , and Waterproof which was a spec given by the MOD in the 1940's . It has a 35mm case Diameter W/O crown . In total 12 different manufactures produced watches to this specification for the MOD . These watches were also referred to as the Dirty Dozen . Hodinkee has an article on these 12 watches which are in the following link…. https://www.hodinkee.com/articles/dirty-dozen-twelve-military-watches And here is my Omega ' Dirty Dozen ' watch... I hope you enjoy looking at it as much as I do …….Aloha , Louis1 point

-

1 point

-

1 point

-

Practical watch repairing Donald de carle. All of his books are wonderful.1 point

-

If the balance is not swinging freely, you can investigate if there is a balance stop which is supposed to engage when the crown is pulled out is incorrectly configured. If the balance is swinging freely then you need to remove it and see if the pallets are moving as expected. If they are then the problem possibly with the balance or jewel holes (check the shock system). If not then you have a blockage in the train of wheels. Its a case of process of elimination until you get down to the actual problem. Start with the escapement and work back through the train to the power source. Warning: These movements are quite tricky to locate all the wheels and auto works when re-assembling so make sure you take plenty of pictures and be patient. Go slowly.1 point