Leaderboard

Popular Content

Showing content with the highest reputation on 01/18/16 in all areas

-

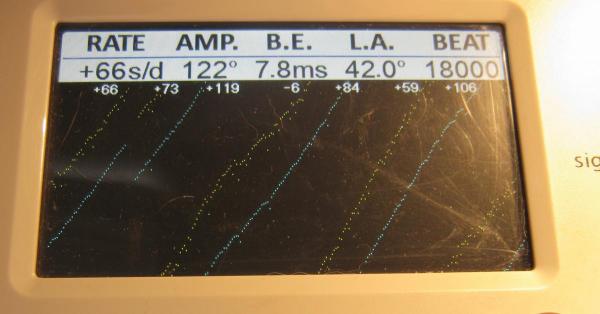

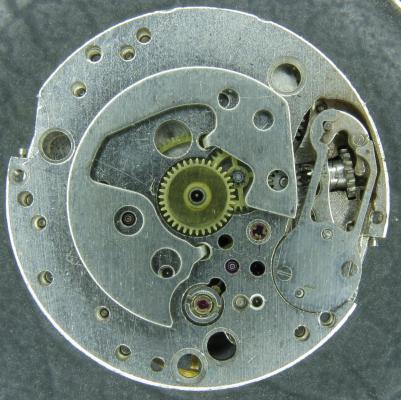

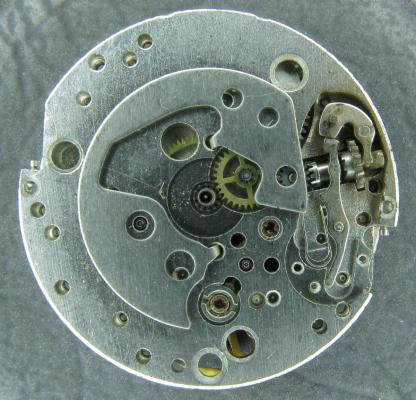

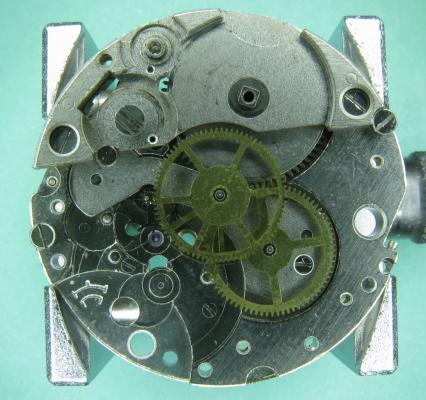

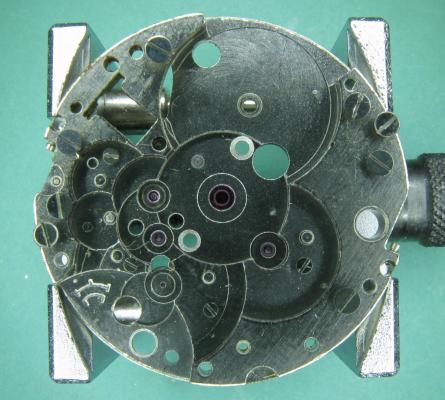

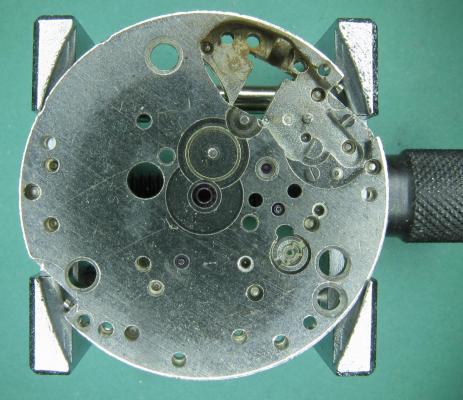

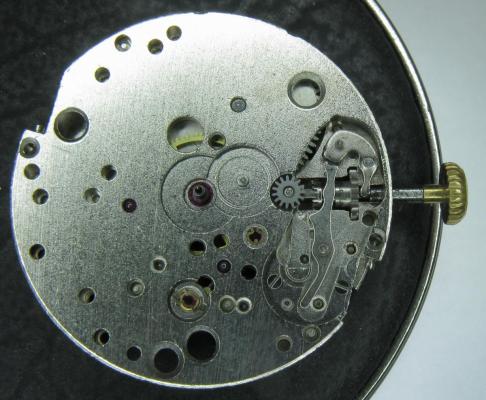

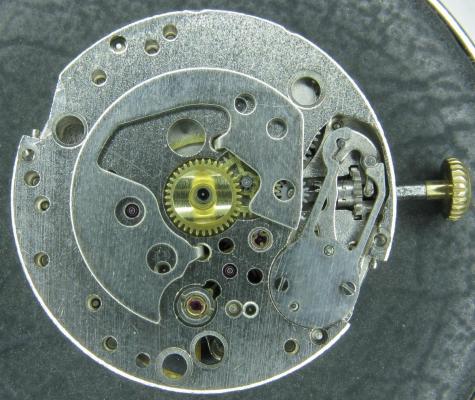

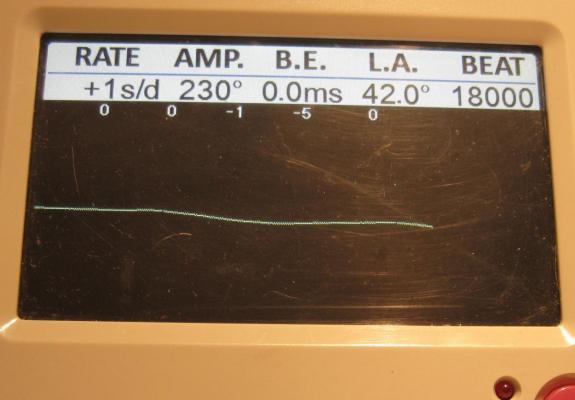

Just before Christmas I sold (through the good offices of eBay) an absolutely immaculate example of a 19 jewel Sekonda hand winder. I was a little sad to see it go as I don't think I am likely to see another in as good order for some time, and having just serviced it it was running like a champ but I couldn't justify holding on to it. Well, shortly after it had arrived with its new owner I received a message through eBay from the buyer. Huw had contacted me to say how pleased he was with his new acquisition, and did I service watches? as he had another example of one of these that was a little stiff in the winder and gained about a minute per day, and he felt that it maybe could benefit from a bit of a spruce up. I have done quite a few of these so am reasonably comfortable with them so I quoted a price and accepted the commission. A couple of weeks ago Huw's watch arrived so I thought I'd do this as a walk through. Looking well used but not abused, Huw had explained that he bought this not too long ago as a stop gap whilst his other watch (a Sekonda quartz chrono) was out of action with battery issues. First impressions are of a watch that has seen a lot of wrist time in its (probably) 40 years. The Timegrapher trace confirms the rate at roughly +60s/day, and confirms that a service is long over due. With the crystal out of the way the condition of the dial is actually rather good. The shadow to the right of the 7 is a lens fault on my camera, not the dial. With the back removed there is plenty of dirt speckled around the whole movement and everything is bone dry. The good news though is that it doesn't look like anyone has messed anything up inside. You can see the spring clip retainer on the escape wheel end stone (a bit like Seiko Diafix but not quite as clever). You can also see corrosion to the back of the bezel, this watch spent a lot of time on some ones wrist. With the movement out of the case the reason for the stiff winder and all of the dusty crud in the movement is brutally apparent. The outer end of the stem has started to rust causing it to bind in the case, and the resulting rust powder is thick on the inside of the case. These cases are a bit prone to this kind of problem as there is absolutely no attempt to seal them even against dust, let alone water, so even sweat on a hot day can seed the beginnings of a corrosion problem. With the dial off the press fit retaining plate for the motion works is exposed along with the keyless works. There's that little end stone retaining clip again, and the Raketa version of Incabloc on the balance. The rust doesn't seem to have got this far. With the set bridge out of the way though there is a hint of rust in the keyless works. Ouch!!! Just in time me thinks!! Balance and cock removed and the hairspring looks to be in good shape apart from the terminal curve which is off concentric. That will need to be sorted or the regulator will distort the hair spring as it is moved. Here also is the shim that Raketa are fond of using under the balance cock to adjust the balance end shake. A bit further in and plenty of gunge under the ratchet and crown wheels. Train bridge removed to reveal the train layout and a sub-bridge for the 2nd wheel. The main plate stripped with the screws put back in their respective holes. I do this so that screws don't go missing in the cleaning machine and I always know which screw goes where. The stripped main plate dial side. And then with the balance reinstalled (minus jewels) ready for the Elma. After a thorough clean everything is ready for inspection and reassembly..... ....starting with the balance jewels. This is when I check and adjust the hair spring for flatness and concentricity, eyeball the beat, check the end and side shake on the balance, and that everything swings freely. If you leave it until later there is too much other stuff in the way. Once I'm happy with it the balance/cock assembly comes back off until later. There is still a little work to do in this pic as the coils are still not quite concentric. The main spring re-lubricated and back in the barrel. This maybe could have been replaced but it wasn't too bad so went back in to help keep the cost down. Barrel, barrel bridge, 2nd wheel sub-bridge, and train back in place. Pallet fork and bridge installed. You can see the exit pallet poised ready to receive a drop of 941 on its impulse face. Walking the pallet too and fro then distributes the oil to the escape wheel teeth. Drop in the balance and away she goes. The cleaned up and de-rusted keyless works go back in.... ...and then the motion works and cover plate. Dial and hands back on, and ready to re-case. Again, to help keep the cost down I didn't replace the crystal with a new one, however, the original was just a little too deeply scored to easily polish out and there was what looked like a very small fracture. So a quick scout through my spares box and I found a second hand replacement which has cleaned up nicely. And the proof of the pudding ... as they say!! At 230 degrees the amplitude isn't anything to write home about but it is a significant improvement on the starting point. A new mainspring would almost certainly help this up into the high 200's (on the watch Huw bought from me I seem to remember it was 300+), but 230 is certainly usable. It is otherwise a nice clean trace with minimal beat error. It has been running for a week now in which it has gained just under a minute, so after a final tweak to the regulator it will be ready to return to Huw. I like these movements a lot. They are well designed and well executed, and capable of excellent results if looked after. They also seem to turn up quite frequently at the boot fairs. Unfortunately though, the lack of any attempt to keep moisture out of the case does mean that they quite often suffer from corrosion issues, and the relatively low cost (both when they were new, and when they turn up second hand) means that they are often used as a beginner watch smiths practice or learning watch, with the resultant butchery that many of us have dealt out as part of our learning curve. It's a shame in many respects, but then we all have to learn somehow. When you do find one that has survived unmolested though they are very well worth looking after. My thanks to Huw firstly for buying my watch, secondly for asking me to help this one to keep going for a few more years, and finally for allowing me to post his watch on here.4 points

-

2 points

-

I would turn the watch over, front and back - in front of them - while photographing it, also in front of them, with a compact camera. If they can't be bothered to spare the time for that, hand it straight back and walk away. If they ask why it's so important, explain the situation. It may even be advisable to open the case in front of them and do the same, but that may not always be convenient. A signed disclaimer is also useful - but then it's starting to become a business...2 points

-

If anyone can hunt down an obscure brand Roberto can. I know that from personal experience. :)1 point

-

You have been dealing with somebody that was unstable and unable to deal with negative news, no matter for how many years you have know him/her.. I wouldn't be worried for a next time, the operative word once accused of crime.. mention slander and the penalties associated. People in their right mind back off immediately, others are served with justice. And all the other comments are right on the spot.1 point

-

1 point

-

1 point

-

Następny projekt to "Brygantyna": Srebro, średnica 36 mm. . Podkład i klejenie drutów . Wypał podkładu i przymiarka do koperty . Nakładanie emalii . po kilku wypałach znowu należy dopasować do koperty Gotowa tarcza . Ostatnio ta tarcza w konkursie jubilerskim zdobyła 3 miejsce :-). link : **Kindly see rules regarding linking to your blog** Mam nadzieje że się spodoba. :D Zapraszam Leszek.1 point

-

Hi Dan, Like Lots of folk I only do stuff for relatives and close friends and have been lucky not to get any grief. Sometimes I do wonder if I am nuts, I just got a Quartz from a friend and he apparently got it in Aldi at Christmas for a fiver as a gift for his girlfriend but it keeps stopping. Sometimes I am lost for words and the first three things I was going to say had to be cancelled before they got out of my mouth the fourth thing was why not just take it back and get a refund ! I ended up bringing it home and I will try to sort it out - I believe the idea is you get good Karma for helping folks out. However, if any of them try it on they know the watch will need surgical removal - but that's to be expected from us Geordies ( and probably Scots as well eh George ) Cheers Vic1 point

-

Hey Usually fix friends watches for people I know and do not know. The best thing 2 do is take a picture of the watch front and back. The cell phone will automatically date and give a location of where and when the photo was taken. Take the photo in the present of the person. This comes in handy......1 point

-

This is why i more and more like the the old Seiko movements. There aren't any small click springs and small screws. The smallest bit is the pallet fork. Even the date corrector lever has a built in spring.1 point

-

Dear bobm12 This has to be a good thing. I have a fear of owning a watch with an "In House" movement when it comes to the cost of repair, if the stories I hear are true. Mainly that manufacturers won't sell spare parts and they have to go back to them. I fear this could be a licence to "Print Money" Sent from my SM-G900F using Tapatalk1 point

-

Seiko's 7S26 do not have high amplitudes. The 225 was perfect......sorry m8. But might be some licht on the end of the tunnel. Stud is not glued so you should be able to put it back.1 point

-

I only help out friends and acquaintances, but I still point out any blemishes and explain that there is always the slightest chance of marking the case when it is opened. I haven't marked a case yet, but saying there is the slightest possibility allows them to change there mind easily, and God forbid that I caused a slight mark, they wouldn't be surprised. The most annoying thing that has happened, was when one of my wife's friends insinuated that I had swapped watch boxes. She said that the box was in pristine condition and also had spare links in it. Needless to say I was less than chuffed and told her in no uncertain terms that it was her box, and that there were no links when I received it. I told her to send it to Tag the next time!1 point

-

How dishonest can people be. I must say in all the time I had in fixing watches and clocks I never came across anything like this. All I did was point out to customers the poor condition that the item might have and mark it down on there ticket receipt along with the est of the repair.1 point

-

i've never thought about the downsides of this hobby. those stories are horrifying, dan. i wonder if it would make sense to open the watch in front of the customer to make sure it's a legit watch. photos might be a good idea also. i remember years ago in the sixties, my mom and grandmother were talking about the local small town jeweler. at the time they thought he stole the jewels out of my grandmother's watch. i can see now that it wouldn't make sense for a jeweler to do such a thing. they obviously thought that they were real, mountable jewels.1 point

-

Very good point, Dan, I usually fix other people's watches but since they are all friends and I examine what they bring me in front of them -- I make a point to tell them it is not a business but a hobby -- I have not run into such problems...and my fees are probably too modest. If I was doing it as a business, I would say, I'd start with a disclaimer they will be subject to sign first and then I would go with the checklist. Since I don't get a lot of volume or expensive watches, I can't really tell by experience so I'll be curious to know what an actual business -- or an established watchmaker's -- standard procedure would be. Cheers, Bob1 point

-

1 point

-

1 point

-

1 point