Leaderboard

Popular Content

Showing content with the highest reputation on 11/09/15 in all areas

-

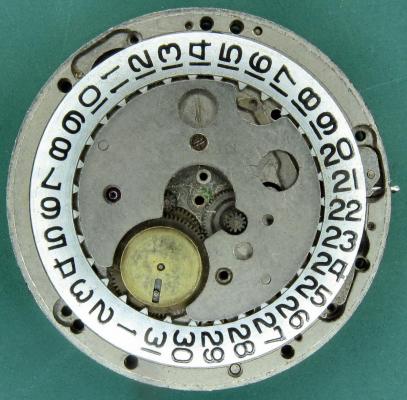

I have forgotten about these two. I bought them years ago when I started collecting automatic watches. The one on the top works for a few minutes when shaken, which is a good sign. The one on the bottom must have a keyless issue because the hands move when the stem is in the first position (winding). Found them today as I was looking through a box full of watch parts and odds and ends. I think these will be my next project. I have the feeling what prevents the top one from working properly is a dirty movement and lack/old oil.2 points

-

2 points

-

Final update on this watch repair. You guys were correct the cannon pinion was the fault. A simple job!!!!! WELL When I tried to remove the CP it would not budge yet it was clearly too loose. Eventually I removed the CP by levering it off using small hand levers. When I inspected the CP all was revelled. A good guess being a previous repairer had tried to tighten the CP by putting 3 or 4 extra friction divots on it,s shaft & had just distorted the CP hence why it would not come off but still had no friction. Also the centre wheel pinion was very badly scratched. The normal way around this (so I have read) is to broach out the old divots & start again but this watch had no centre seconds & the CP,s top was closed so broaching was not possible & a replacement CP & centre wheel was required. NEXT problem the fhf 189 was manufactured with different size CP,s & the first replacements were the wrong size (To big) but a big thanks to Rogart 63 (member) I finally got the correct size CP & fitted it after giving the divot a bit of a squeeze,. I also got the correct centre wheel from another supplier. The watch now works fine but really needs a service & possibly a replacement mainspring but the main fault has been fixed. Sorry no pics just got involved with the repair & forgot.2 points

-

2 points

-

I meant to post this a while ago. FOR SCREW DOWN CROWNS. A) Screw down the crown tightly onto the case without the stem and measure the distance between the bottom of the crown and the case. B ) Screw the new stem tightly into the crown, then insert into the watch until it engages and locks into the movement. C) Press the crown down firmly as far as it will go and hold it there. D) Using the vernier callipers, measure the distance between the bottom of the crown and the case. E) Subtract the size determined in (D) from the size measured in (A) then subtract a further 0.15mm from this size. This is the amount to shorten the stem by. This should allow the crown to screw full home without compressing the stem too tightly between the movement and the inside of the crown. F) Cut the stem leaving it slightly longer than the size determined in (E), and dress down to size using the diamond lap and vernier callipers as described in the original post. G) Screw the crown onto the shortened stem and check fit and function, before using a tiny spot of Loctite to secure.2 points

-

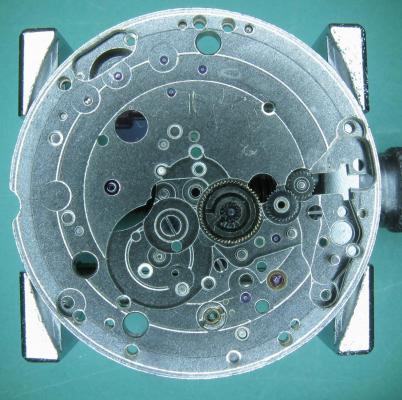

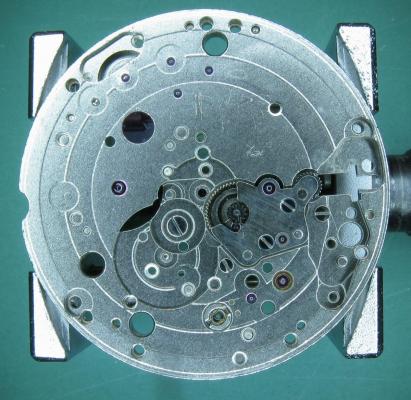

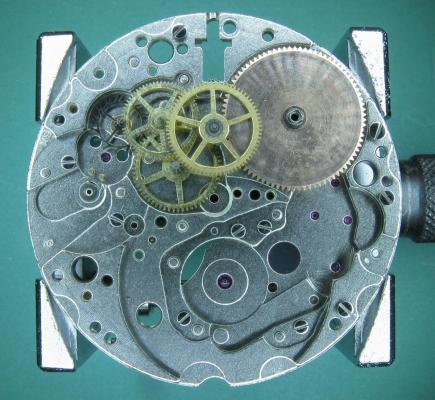

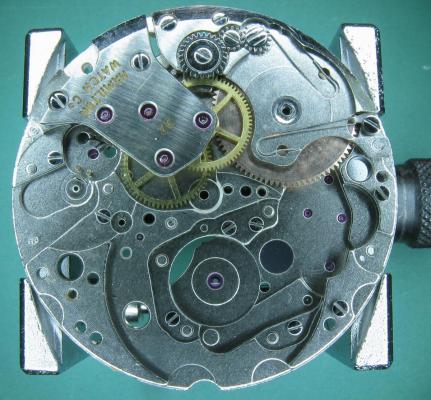

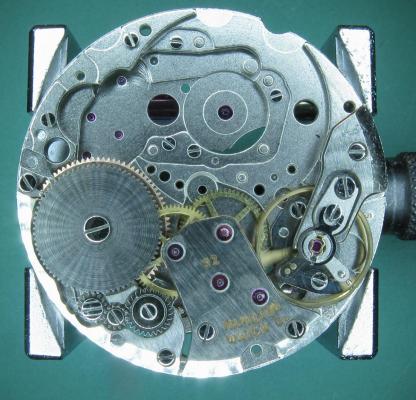

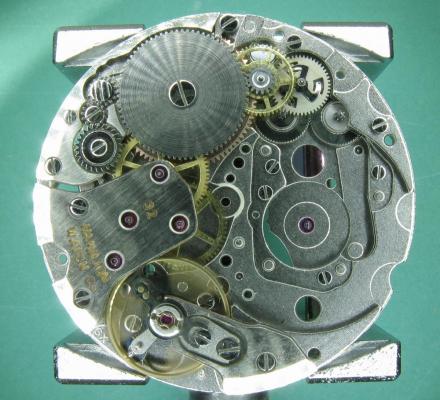

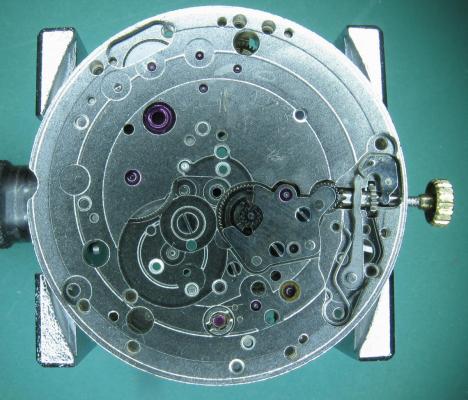

This is what I got up to over the Easter break. It was a project that I bought as a box of bits for a few quid about 4 years ago because although I had no idea what it was (the listing didn't say), it looked interesting and I fancied the challenge. It turned out to be a Hamilton Intra-Matic Westminster which the previous owner had tried to "fix", got as far as dismantling, and given up on. Cosmetically it was in good order but mechanically was not good. The rotor pinion had lost its bottom pivot, as had the second wheel (centre wheel in a more conventional wheel train). And because it had spent some time rattling around loose in the box of bits the hair spring was in a poor state, and what had me really stumped when it came to working out how it all went back together was a large and rather complicated looking wheel and pinion assembly for which I simply couldn't find a home. Any way, it was put to one side until I could track down a donor for the parts and to hopefully show me where the "spare wheel" went. The movement is a 30 jewel Hamilton 92 micro-rotor, which is a re-badged Buren 1281. Unfortunately (for me) this has been used in a number of higher end autos and also as the base movement in some big name modular chronographs because of its thinness, which means that they tend to hold 3 figure values even as spare parts donors so it took a while for me to track down a suitable candidate at the right price. However, I did manage in the end to nab one for just over £30 and it arrived at the beginning of April, so the fun could begin. No strip down on this one as the Hammy came to me fully dismantled, here is the donor as I got it. It's a Buren 1281, a bit grubby with some missing screws, and the minute hand pinion has seized onto the centre post. I later discover that the canon pinion (which is actually on the second wheel pinion) is loose and I reckon that someone had diagnosed the loose canon pinion, had tried to correct it by tightening what they thought was the canon pinion, which was in fact the minute hand pinion, onto the centre post, over did it, and caused the whole thing to seize, hence spare parts movement on eBay!!! I stripped out the second wheel (complete with canon pinion which I tightened), rotor pinion, balance and hair spring, and the main spring (which was in better shape than the Hammy one), and then put the parts through the cleaner; the Hamilton 92 parts had already been cleaned. And here we go with the good bit. The Hamilton 92 main plate; cleaned and ready for reassembly. I usually start with the wheel train when I build a movement back up but that's not possible here because the motion works bridge also carries the lower pivot jewel for the second wheel, so the motion works have to go in first. With the bridge in place you can see the pivot jewel in between the minute wheel and the intermediate wheel. The movement is flipped and the wheel train and barrel (cleaned and greased main spring, and braking grease on the barrel walls) are positioned. Train bridge and barrel bridge installed complete with crown wheel and intermediate winding wheels. At this point the end shake on all of the wheels was checked and the general free running of the whole train tested, then the pivots oiled. The ratchet wheel in place, the pallet fork installed and the escape wheel teeth / pallet jewels lubricated. The balance dropped in and off it goes. Then the auto winding reversers and reduction wheels go in. The three armed spring on the first reduction wheel is a ratchet which prevents the rotor from helicoptering during manual winding. Unfortunately it also gives the crown a very gritty feeling when you hand wind which takes a bit of getting used too but it is normal. Bi-directional flip-flop (for want of a better term) gear and auto wind ratchet in place. Cover plate on and the micro-rotor assembly installed. Turning things over again the keyless works go in. Then the calendar works, date wheel, and cover plate. Before the dial and hands go back on. Confirmation on the Timegrapher that all is well. The obligatory wrist shot. And something more formal for the album :-) This is now an absolute favourite of mine and has a permanent home in my collection. It took a lot of waiting to get the donor but it was well worth it. The watch has been running continuously since 11 April kept wound from wearing it when I get home from work in the evenings and at the weekend, and has remained within a few seconds of reference time. And the "spare wheel"..... was precisely that, it didn't belong with the box of parts that this project started out as. I do hope the seller didn't miss it :-)1 point

-

Hi guys, just thought I'd share details of the watch I'd just finished for a friend. The movement is an eb8420-73, the watch was sent to me as a non runner. After teardown, clean & initial inspection, I found the friction spring for chronograph runner was missing a finger & the chronograph second hand had stuck to the glass. after the rebuild I had a problem with the balance & end shake. Dial side down it ran ok'ish, but dial side up it completely stopped. First I tried a new complete balance, it did help but I still had issues. Then I managed to source a new balance bridge complete with balance etc.. & this resolved the issue. I then stripped the second hand & chronograph min counter & resprayed with Matt neon paint relumed & replaced the glass with a high dome crystal. http://images.tapatalk-cdn.com/15/11/09/5b655d63baa2e184e4a045a79ef98fd9.jpghttp://images.tapatalk-cdn.com/15/11/09/5169eec975882638ce2d19dc01856f3e.jpghttp://images.tapatalk-cdn.com/15/11/09/0091d0415802976c328fd91619efdc1f.jpghope you guys approve of the finished article. http://images.tapatalk-cdn.com/15/11/09/11d81c884f1e5e4dce413f0a83214ac9.jpghttp://images.tapatalk-cdn.com/15/11/09/4db29cc8272a76c3ef95a982bbfd8171.jpg1 point

-

The top tool in picture 2 is a screw plate used for tapping out screws on a lathe and its use is explained on page 217 of Donald de Carle practical watch repairing book1 point

-

Don't use a pointy thing, use a 1.20mm flat watchmakers screwdriver, this ensures you don't push the button too far down, and screw things up. Do you know the history of the watch? I have experienced similar on some movements, and turned out that a previous owner, or watch repair guy replaced the Swiss parts for Asian and they didn't mate right, thus coming out of position. How old is the movement? Again, I have had similar issues you are experiencing, where in some cases, the harbour that the sliding pinion rests with the stop lever (Hack lever) this harbour was worn due to incorrect/over lubrication, and the whole area was scorned/scratched/worn.1 point

-

1 point

-

Happen to be working on a PUW1261 with similar rusting of the stem into the clutch wheel and winding wheel. I cleaned off the worst of the rust with a fibreglass pen (well away from my other watch work as the small fibres get everywhere!) but could not budge it even after soaking in deodorised kerosine (BBQ lighter fuel) for a few hours. I then left them overnight in Plus-Gaz and they came apart with a good tug. I cleaned off the worst of the rust again with a fibreglass pen . I then soaked overnight in Kurust (which I used to use on rusty car panels!) which converts all the rust (Ferric Oxide) into Ferrous Phosphate which is like a protective layer. The Kurust contains phosphoric acid which converts the rust, (I gather well known brands of cola also contain phosphoric acid and will convert the rust but not tried!), the parts should be thoroughly washed in water and dried after treating. The reason for doing this treatment is to prevent the rust reforming as it surely will if microparts of Ferric Oxide are left in the material without being converted (of interest is that most greases contain some water and so can restart the process on their own if not serviced regularly!). The phosphate left after treating will prevent further rust formation. The phosphate layer is mid/dark grey and can be cleaned off using the fibreglass pen again and/or 1200/2500 wet and dry to get back to a bright finish with the ingrained phoshate still left. I finished off the square hole in the clutch wheel by applying a paste mix of diamantine and oil to the stem and working it until it was nice and free and the stem part polished up a bit, then cleaned off with a wash. All parts where then put through a normal clean cycle.1 point

-

spring looks ok, and the stem came with the movement - i'm actually wondering now if it's the alignment of the case - I might be forcing the stem in slightly diagonally. Have to look tonight.1 point

-

Hello Mike, That's a very fine watch and as said above most likely needs a service, this needs to be done by a very skilled technician, a great deal of damage can easily be done in the wrong hands. The obvious solution would be an authorised Omega repair shop but that will not be cheap, with such a fine watch any DIY attempt could end in disaster, not worth the risk.1 point

-

As above it really should have a service. You also need to know if the watch is in beat,how the watch is performing or is it just a case of adjusting the regulator, You will need a timographer to perform these tasks. If you have not repaired or serviced watches before I recommend to have a watch repairer look at the watch.1 point

-

Just come across these when looking through a local supplier. Go to the link and put in the search - plastic box watch movement https://www.hswalsh.com1 point

-

Right, here it is! This Zodiac is, aside from some cosmetic details, identical. www.ranfft.de/cgi-bin/bidfun-db.cgi?10&ranfft&0&2uswk&Zodiac_76 The Cyma is certainly a 21,600 bph 21 jewel movement and the engine turning is very like that on another Zodiac movement I saw online but can't now find!1 point

-

1 point

-

Looks like this fits the bill https://pocketwatchdatabase.com/parts/catalog/elgin/861/291 It's a tricky job and special tools and knowledge is required. I suggest that you send it to a high quality watchmaker if you haven't done one before.1 point

-

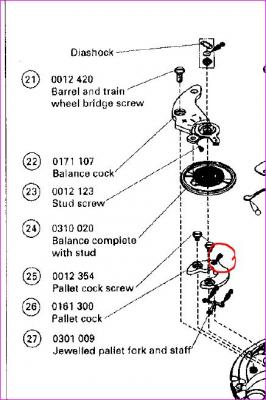

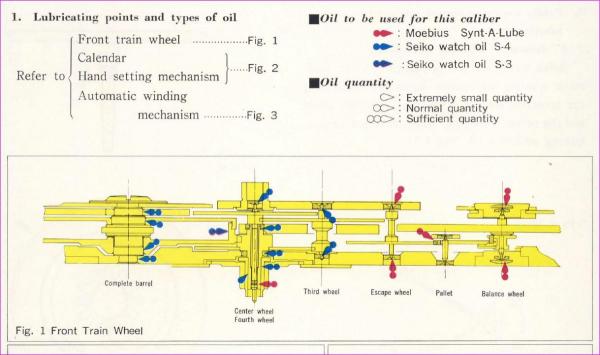

It be really nice if we could have a close-up picture of the watch specifically centered over the balance wheel. I'd like to see the position of where you put the regulator and the floating stud. If you don't understand what you're doing you can move these in really bizarre positions and the watch is never going to keep time. Then if you had access to a timing machine/timegrapher It really can help speed up diagnosing things like this. There are some things that only the timing machine will show you there is no other way to find out. Then an alternative to a self-contained timing machine can be found at the link below. http://www.watchrepairtalk.com/topic/3002-d-i-y-watch-timing-machine/ Then lubrication one of my favorite subjects especially in horological groups. So most of us know that the end of the world will come if we oil pallet fork pivots. For anyone with access to a timing machine put some oil on the pivots especially if its heavy oil the results could be quite dramatic. Except this is a Seiko watch and Seiko sometimes does things differently. In another group somewhere we were discussing the forbidden subject of lubrication I was probably pointing out the evils of oiling the pallet fork pivots and somebody pointed out that Seiko oils all of theirs. The reality when I went to the tech sheets is not all of them but most of them. So I've attached some images the black-and-white comes out of service manual for the watch in question. Then at one time Seiko produced nice colorful lubrication charts two separate ones attached 7005 and the 6206. Notice one is oil and the other is not. Then even though I pointed out Seiko does something different for someone learning watch repair your timing problem is not the lubrication of the pallet fork pivots it's probably something basic and simple it's not the obscure things that get the beginners it's the simple things that you don't understand yet.1 point

-

Here's my setup . I was doing some work in a residential area one day and some people in a nearby house were moving out of state and getting rid of things . They gave me their daughters craft table . Laminated wood , adjustable leg height , wheels on the back legs , and a tilt table top if used for drawing . Also a crome storage rack with colored plastic drawers that I pulled out of the trash bin ........Waste not , want not ,..... That's my stereo Microscope under the plastic cover...telescoping double boom....it's big1 point

-

As already stated it's a balance truing tool for removing kinks in the balance rim a description of it use is given on pages 206, 207, 208 of Practical watch repairing by Donald de Carle1 point

-

1 point

-

Interesting interview with the great man, can you believe the interviewer was actually wearing an Apple Watch in front of him tho?!1 point

-

I don't think a survey will help matters with the supply of parts, but I have filled in the survey it took all of 10 minutes. The only thing that would change the mind of the Swiss watch industry would be if revenues are affected by such decisions. The prices of Swiss watches has been outstripping inflation for the past ten years now, Rolex, Omega and many other manufactures have increased prices beyond the reach of many does this make sense? Rolex manufacture around 600,000 watches a year my guess is they are trying to produce less with out losing revenue if they sell 600,00 watches at a average of £3,000 a watch it makes more sense to sell 300,000 at an average of £6,000 a watch and limit supply and increase the image of exclusivity and maintain the brand image. The industry also seems to want to push independent jewellers out of the supply chain and more brands are moving toward boutique stores and forcing independent stores into expensive refits, if they cant afford it then they lose there franchise. I have had many bad experiences with manufacturer service centres, Omega and Jaeger Lecoultre have both been appalling in the past, they offer poor value extremely long turn around times and are generally expensive. Simple jobs will become expensive. In the past year I have been told by one manufacturer when enquiring about a simple crystal replacement that it could only be done as part of a full service going from what should have cost £50.00 pounds at the most to £400.00 including compulsory service in the end a independent fitted one for £35.00. I have also been told that a steel bracelet I had on my Omega Speedmaster could not be repaired and would need to be replaced at a cost of over £400.00 pounds, The same strap was repaired by a independent repairer for £20.00. I hope that things like this will make the general public think twice before purchasing a Swiss watch from the big manufacturers, because practises like this will be the norm in the future and hopefully the big manufacturers will suffer from there own sharp practice there are plenty of good watches to be had from smaller manufactures and the gap would hopefully be filled by these. At the end of the day it is simply a revenue increasing exercise these manufactures are more interested in selling new watches than ensuring your inherited watch your father wore continues to run.1 point

-

A bit more progress. Just the crown to make, put on some dial markings, and a clean up and tidy. Hands made out of a broken main spring. Hour wheel extended Fourth wheel ground down to remove sub seconds Crown will be made out of an old brass bolt and fitted to an extended stem Dial markings to be added Watch is keeping good time1 point