Leaderboard

Popular Content

Showing content with the highest reputation on 08/15/24 in all areas

-

5 points

-

The price gives it away it's a fake. Just look at that bracelet as someone has already pointed out it's as rough as a badgers ass.4 points

-

Most schools won't teach how to cut gears, or if they do, just the basics. You do learn how to saw and file to a high level, and how to make turned parts on a lathe, like winding stems and balance staffs. To cut gears you need some special machinery; lathes can be adapted to do it, but small watchmaker lathes are far from ideal. You also need the profile cutters to form the teeth. Once the hairspring was invented, two big issues became the focus. Isochronism- the stability of rate over high and low amplitudes, and the effects of temperature. Up to the 1930 or so, the best option for compensating the effects of temperature (gaining rate in colder temp, losing rate in hotter) was a bimetallic balance of roughly 2/3 brass and 1/3 steel, in various configurations but usually with the rim cut at the cross arm on both sides. As the balance heats, the sections of rim contract, as it cools, they expand, thus correcting for the change in elasticity of the hairspring (which was made from steel). Charles Guillaume invented Invar in the early 1900s, which is an alloy that doesn't change length with temperature change, then Elinvar, which doesn't change elasticity with temperature change. It was a pretty big deal, netting him the Nobel Prize. Now a watch could be made to rival the best bimetallic balances using a monometallic uncut balance coupled with an Elinvar hairspring. Over the years further developments were made, in particular making the hairspring alloy virtually non-magnetic (another big deal). You can make a balance from a number of materials and get good results using a "compensated" hairspring, but most high quality balances are made from beryllium copper. If you want to make a balance that uses a regulator into a freesprung, you will need to add some sort of adjustable masses to the balance rim. This will cause the balance to be too heavy for its hairspring- but you can also remove material from the rim to compensate for the added mass. It's pretty high-level watchmaking work, not something to start with.4 points

-

If we're being honest with ourselves, "modern" watchmaking has become quite precious.3 points

-

Hi. Guys thought this night be usefull to some of you who don’t have the Bestfit Books to look at. dictionary_ebauches_sa.pdf3 points

-

I don't see this video in the topic's past history to my surprise. Watching George Daniels work and listening to him philosophize is completely fascinating. Watching Daniels handle a fine handmade tourbillon and silver engine-turned dial without any finger coverings and quickly mash the minute hand onto his masterpiece with the back of his tweezers makes me dizzy. (Hoping to prove the timekeeping superiority of a mechanical watch over an electronic one was a lofty goal)2 points

-

That whole operation winding half the mainspring, putting in the arbor, and snapping on the lid was one shot and took about 15sec in total (which is 1/4 the time I spend thinking about which way my spring goes into the barrel)2 points

-

Nah mate , Frank is telling you about the gash in the safety roller, i marked it up for you in purple. At least thats how it appears2 points

-

Slight bends like this I find on almost every chronograph that comes for service (I test every arbor and pivot of chrono and minute runner - not tested most would seem ok ). I would clamp the tip in a collet (bend outside). The pinion will wobble severely, compared to the tailstock runner tip. Then tap the arbor with a tweezers back until any wobbling disappears. The bend must be much more for breaking. Frank2 points

-

Funny how one can make it sound like a simple affair and then someone else can.............kind of not. Lol After reading joe's and geotex's comments, it makes more financial and reputable sense to just save those for date watches and buy the appropriate non-date version movements required. Makes no sense to cause yourself a headache now and a potentially bigger one further in the future. It may actually be a recognised and acceptable modification but why take chances. My trade is different but the same principles apply, make it right first time and you only make it once. Happy customer means happy business I'm not a watchmaker and never will be in the true sense of the word. I think I'd make a good apprentice and with luck one day be a good amateur maybe even part-time professional with the odd qualification. At 57 i am a pro in my trade with 40 years of experience of it and a businessman with 37 years experience with past success but winding down now, trademen with physical jobs can only last so long. To build a reputable business you need principles and methodology that you stand by while working. It takes time and a lot of effort to build a reputation, stick to good principles that you set for yourself af the start and your reputation will grow. There's a saying here in Yorkshire " you're only as good as your last job " and its absolutely true. People risk their own character when recommending , for some it can be like recommending themselves. I rarely do it for others. So that follows that good reputations take time to grow. Those same people that are slow to recommend only need to blink to generate critism, that follows that criticism can dent and destroy a reputation. Get it right , get it right and keep getting it right. Rich.2 points

-

Update: this worked like a charm. I will post photos once the project is finished2 points

-

I don't have very many tools now. I sold most of them which included thousand of watch parts and clock parts, so many watch tools I couldn't count them. I still have one lathe with milling, clock mainspring winder loads of files clock Broaches brass rod, screwdrivers watch and clock, eyeglasses and loads of dumont tweezers, probably other stuff packed away in boxes.2 points

-

Hi Is this the technological dictionary you are looking for. The Eubauches dictionary of Swiss parts. dictionary_ebauches_sa.pdf2 points

-

2 points

-

You could try to fill it with silver solder, but not sure how well this would work, and is dependent on your skill level and experience, not something I would go at as I don't have that skill in my bag of tricks. Is it gold or brass, I think it is plated brass as I can see some plating wear (?) maybe a jeweller could fix it for you as they do this all the time when re-sizing rings etc, so shouldn't break the bank. I can't tell what kind of watch it is so may not be worth the expense of having a jeweller fix it?2 points

-

I am self thought watch destroyer. Though any watch balance wheel can be matched with hairsprings of any strength, and I have built a few balance completes, for Movements of unknown calib. With balance wheels of unknown calibs Hairsprings of unknown strength. The finished product can be regulated to exact beat needed to show right time with the train at hand, as long as in static position, thats on bench, but runs inaccurate in dynamic ,on wrist, in pocket. Always a pain to get an acceptable avg rate of all positions in dynamic state. Several prametres get in the picture in balance rim design and alloys are the main in hairspring technology ,whilst one can't care less what material or alloy the pendulum of wall clocks is made of. Rgds2 points

-

Thanks for the reply. That’s very interesting information. I don’t work in watch repair. I’ve just slowly become increasingly interested in the details of how watches work and started wondering how far one can go into tinkering with them. So I’m not in the watch business. I’m just someone who has a modest watch collection and am at the point where instead of going the route of saving up for increasingly expensive watches, I’d rather start tinkering with cheaper watches on my own and make my own unique probably fairly quirky watches. I’m a mechanical engineer for my day job so I do like thinking about how things work, how to take them apart, and put them back together (always the hard part). I just figured that it’s possible to buy a 2824 for $150-300 or a Chinese copy for $50 and started wondering how hard it’d be to make different modified movements with different types of balance assemblies. Rolex and omega seem to use free spring balances so I wondered if it’d be possible to somehow take a balance/hairspring from one watch and put it in a different one and make it work. Maybe it’s an impractical plan but I may give it a try since it seems fun even if it doesn’t work. It could be cool to make a fancy engraved/ skeletonized 6897, but the engineer in me wants to also mess with the mechanical part of the gear train and balance assembly too. when you say watch schools used to teach people how to make things, do you mean that it’s possible to fabricate your own gears and balance wheels and things like that out of brass just using jewelers saws and drills? If so that sounds like it’d be really fun to attempt.2 points

-

To me it looks like what you think is the spacer is actually just part of the case. As @RichardHarris123 said, the clamps, and also the 2 screws at 3 & 9 suggest a front loader.1 point

-

The case clamps suggest the movement comes out of the front.1 point

-

To identify your ladies watch, the dial needs to be removed, measure the mainplate's diameter and show us the parts of the keyless works.1 point

-

You will love it . 9Stayed there 12 years ago, food was awful in hotel but the view was incredible, one night a raging lightening storm over the lake , never saw or seen anything like it since.1 point

-

1 point

-

1 point

-

Manufacturers are equiped with batch gears cutters, I guess its all programmed on CNC machines. Considering your interests we ought to put you in contact with @nevenbekriev, he can make the tools and parts he needs, just recently I asked him if he can make escapewheels, I be darn, he posted a vid showing how he does make them two days later with some rather basic machines he got, he did saw and filing manually. You can find vids of such industrial production machines on youtube or machine makers adverts.1 point

-

Pleased to hear you are having a good time, enjoy it matey . Last time i sewn anything was a hole in a sock when i was nipper1 point

-

We need to see the roller from aside, not from above. If the cylindrical surface of the guard roller is smooth where the guard pin can touch the surface, then everything is OK. There is a video somewhere in the beginning of the thread and there no defect on the surface is seen Well in the video the roller rotates fast so not much can be seen, but I don't imagine how such deep cut can be done, so may be it is actually not deep but just a mark and more like photo doesn't show correctly1 point

-

We are enjoying Italy, been out all day, chilling under the air conditioning now. Just because you can't sow!!1 point

-

1 point

-

Any flexible glue works well, locktite flexible gel for example. Better still get your sowing kit out.1 point

-

Clocks definitely open up all sorts of possibilities and solve a lot of problems. Like you don't need a balance wheel anymore you can have a pendulum. Many years ago in the national Association and watch and clock collectors magazine I saw an article of somebody who made a clock. Now making a clock for them is not that unusual Each year they have a craft contest and usually somebody each year makes a clock or two or three. But that particular magazine somebody filed all the gears. Personally I think that's insane but the person made his entire clock and it was truly a thing of beauty. Although he did have a bad choice for the plates use some sort of Super tough bronze that cut his pivots off. So add the disassemble o'clock and put bushings in that were more friendly If you're still interested in watches why don't you get the book watchmaking by George Daniel's he tells how to make a watch and all of the components so you can see how to do that. Then here is a YouTube channel that will help you get started with your watch and or clockmaking https://www.youtube.com/@Clickspring1 point

-

1 point

-

If the gaurd pin ( frank tells it as safety dart) if it's decided to come into play , will it catch the safety roller damage ? Forewarned makes forearmed, fix things before they fix you.1 point

-

No. I mean the cut in the circumference of the smaller (safety-)roller - and no, not the recess at the impulse jewel position.1 point

-

Getting the second hand to sit and track level wont be easy. I've straightened parts like this better by rolling them on a good flat steel block and tweezers Tweezer handle.1 point

-

I don't have pocket watch sized winders and the vintage prices keep going up so I have only ever wound them by hand. There is something really amazing seeing Daniels work with his hands in that way; very direct craftsmanship and the beauty is in the engineering and design rather than cleanroom perfection.1 point

-

I'd think the free balance mod could be quite easy on a movement that already has adjusting screws on the balance wheel? If you remove the regulator arm, the hairspring will have a slightly longer effective length, all the way to the anchor stud, so the watch will run slow. That can be compensated for by filing or grinding small amounts from an opposite pair of weights (or removing shims), then the fine adjustment made using the existing screws. eg. from a quick look on ebay - a pocket watch movement and a wristwatch movement. The pocket watch has clearly visible adjusting screws; I think the other has those also, though the image is not so detailed. There are many others, if you look as mechanical watch movements on ebay, including some ETA ones.1 point

-

1 point

-

Hi unless you can get to see the movement. I should leave it alone, what’s tha asking price.1 point

-

Looks fake to me. Also looks like the complete pendant tube has been pulled out with the crown instead of unscrewing it.1 point

-

Easiest thing to do is to remove the canon pinion, it keeps ticking, problem is on the dial side, stops then its on the movement side1 point

-

1 point

-

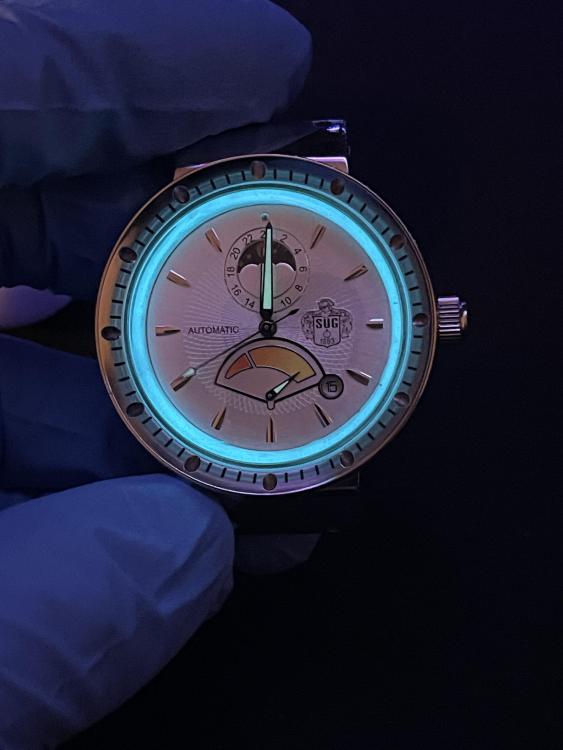

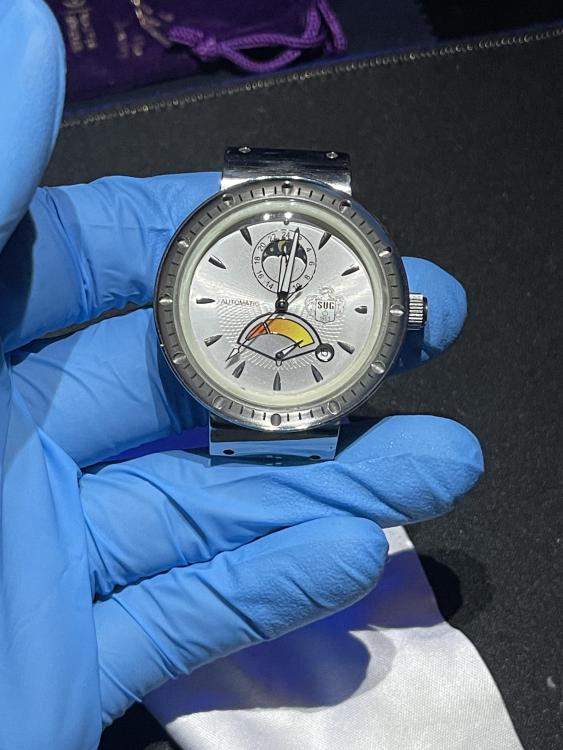

Hey all, I’ve been messing around with this S.U.G automatic that I got a few weeks ago. when I first got it, it had some yellowing between 40 and 55 minutes on the outer dial ring, so I attempted to remove it with no luck. On top of that I realized there was tiny little lume dots that I had ruined one of in the process. after seeing this I decided to sand it down and try to polish it. I liked how it looked but it needed something more… so I decided to make my own lume epoxy and see if I could make this ring glow. Here’s the results. It reminds me of a neon clock you’d see in an old American diner. Next is to make a strap attachment method that should last, and try to find a crystal to replace this plastic lens!1 point

-

1 point

-

thats just not how we learn matey. There are watches that i have been forwards and backwards with for a couple of years, i avoid where i can swapping non basic parts out. Take a break and come back to it later1 point

-

1 point

-

Oh dear this won't do it all? We're going to have to find you a different discussion group to be on because this is the group that 300° or death is the only acceptable answer. Yes of course this is always my amusement the watch companies if they published specifications they don't care about amplitude either they only care about timekeeping what a weird concept. Then if they even publish their amplitude specifications it depends upon the company for instance Seiko does not although they now publish a lift angle maybe someday they'll give us an amplitude. But the other companies only care about amplitude at 24 hours and of course the watch still has to keep time. Typically it's 200° thoughts some of the watches will go West I've seen some ETA watches at 190° and Omega it depends on the caliber will go down to 160°. So yes until customers have timing machines the watch companies only care about timekeeping because that's all the consumer cares about. Unless a course Huron discussion group and anything less than 300 considered yourself a failure and maybe should take up another hobby.1 point

-

1 point

-

1 point

-

Today's blue dial is being sported by a SII Cal. VD57B based "Prime Time" chronometer. It looks good, but could easily look much better. It is obviously engineered to a price, but the designer missed a few tricks that might have made this watch a little more interesting. It has lume, on the hands only. It could do with at least one lume pip on the dial for orientation, but better still would be lume at each hour. All of the hands are silver. It wouldn't cost more than a few cents to have fitted coloured chrono hands, and/or a coloured sweep seconds. Red or orange would probably look pretty good, maybe both, red chrono and an orange or yellow sweep. There were a few other issues. The seller had fitted it to a pretty awful "rolled sheet metal" band, which was held in by two broken spring bars. The crown and stem had not been fitted correctly and promptly pulled out when I went to set it. The chrono had not been correctly reset when the battery was changed, but fortunately the manual for the module is available online, so these little annoyances were all easily addressed except the strap, as I only had a 19mm NATO in the stash. Something more interesting in the correct 20mm size is on its way from the depths of China, which I may show when it appears. I may also have a crack at jazzing up the hands too, I'll see how I am placed for time. Having said all that, this is a 404 club watch, one of only two chronographs in the collection. The other, a Swatch is by far the superior of the two in terms of quality.1 point

-

1 point

.thumb.jpg.47b1d9b4f01aa320df20cae4cd1eaa81.jpg)

.thumb.jpg.855ec4d2c6a843b0981b824425517bf8.jpg)