Leaderboard

Popular Content

Showing content with the highest reputation on 04/14/24 in all areas

-

I'm pretty sure the impulse pin is held in place by friction on this caliber, not shellac, so luckily that shouldn't be a problem. Of course, it doesn't hurt to take a look. BTW, I've been using Horosolv degreaser for my balance springs for several years now and I'm super happy with it. Yes, likely costs a fortune compared to KleanStrip but as an enthusiast, I use very small volumes.4 points

-

Hi guys, I wrote a set of five lessons regarding the Landeron 248 chronograph, which I'm presently taking my second year students through. The lesson I'm posting here is the second of the five. It looks at disassembly of the chronograph mechanism focussing on the chronograph tension spring setting and understanding its importance. The first lesson explained how to set all the seven eccentric studs correctly, so the chronograph operates to its optimum. If someone can service a vintage chronograph such as this and set the eccentric studs properly, especially the minute register mechanism, then an ETA/Valjoux 7750 is child's play. I have posted this lesson as a PDF, but unfortunately the videos in the lessons don't play, as it was written in PowerPoint Here's a link to my cloud where you'll find the PowerPoint lesson. You'll need quite a new version of Microsoft Office to get the videos to play, otherwise they won't. https://docs.google.com/presentation/d/12gb3BRu0smAGK634YC1ZtZZ5XH-OtzlU/edit?usp=sharing&ouid=107902587627140904870&rtpof=true&sd=true Enjoy Lesson 23. Landeron 248 Chronograph.pdf3 points

-

You may find with the hammer end being that profile is naturally pushing the chronograph wheel down and getting into a gap between the top of the chrono runner and the bottom of the bridge because it is like a knife edge. You may want to correct the shape of the end of the hammer and check the tension of the chronograph runner tension spring pushing the runner up towards the chrono bridge. Ideally the hammer should be flat on the end, but a slight rounded shape won't hurt. I've seen some right rounded ends and they work fine. Focus on stoning the end down so it hasn't got that gap/angle when put against a flat surface like you've shown. Here's a lesson I just posted regarding the chrono work on the Landeron 248, especially looking at the chrono tension spring and its setting and amplitude difference from the chrono running to not running. Unfortunately it's a PDF so won't show the vids, but there is a link to the PowerPoint that will2 points

-

Success! Installed into case with spacer ring and all is well! Thank you again.2 points

-

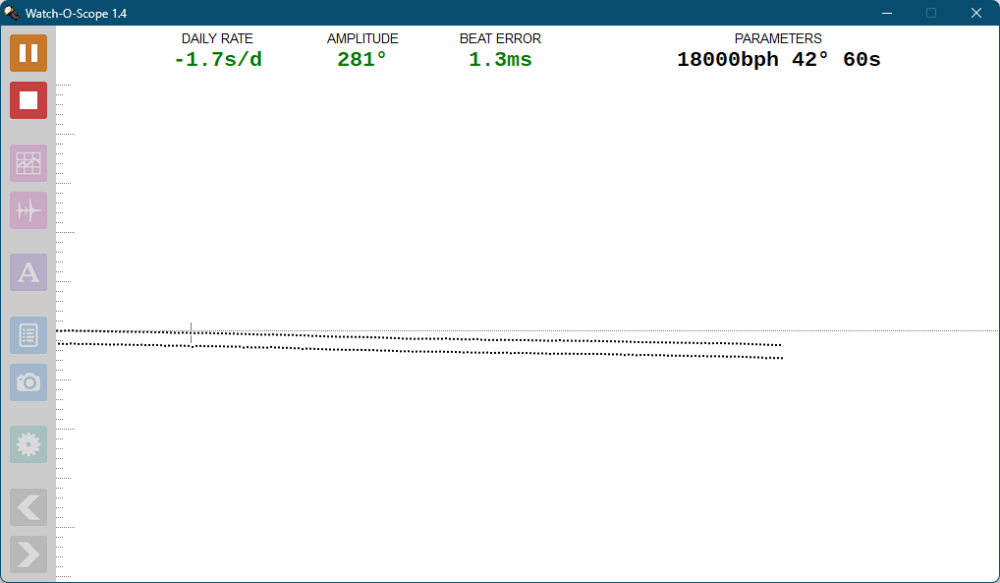

Well, there aren't enough frames to count, but it oscillates for a good 30 seconds or so with a puff of air. I have to say, for my first balance staff replacement, I'm pretty pleased with these results. I know, show me other positions. Maybe after dinner \ Edit: well I was right about needing to see other positions. The hairspring is definitely hitting something in positions other than dial down--you can hear it when you put it to your ear. The overcoil probably needs more tweaking. Which I'm not going to do right now. Maybe some time in the future when I'm ready for more hairspring practice I did close up the minute hand, since it was freewheeling, and get it cased back up.2 points

-

1 point

-

Jon, as you know, this has appeared at exactly the right time for me, so thank you! It never ceases to amaze me how generous the members of this forum are with their time and energy, especially the pros.1 point

-

1 point

-

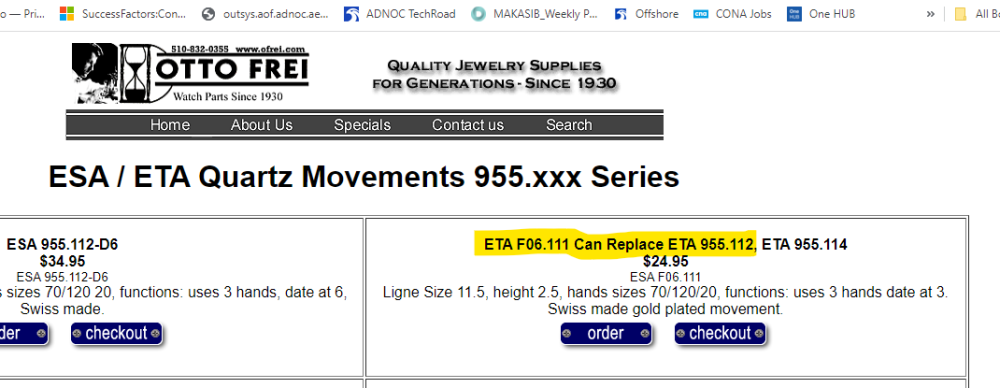

Looking for some help, my friend had an issue with his watch having water enter the movement. It has stopped working and I fear the movement could be fried. Just in case this worst case scenario plays out I was looking at new movements. The movement is an ETA (Tag) 955.112. I looked on CousinsUK and they say it is a discontinued movement. They only have the version without the seconds hand for sale. Does anyone know the correct movement to replace the ETA 955.112 with? I did see one site state that the ETA F06.111 was the replacement, but I'm not sure I trust the source enough to order one without checking here first. Also it looks like the crystal gasket may be to blame, can anyone point me in the right direction for a replacement? It is a Tag Kirium, but the part numbers have been worn off that case back. I guess this would also imply that the 955.114 could also replace the 955.112??1 point

-

That's another (nice) way of bluing. All the equipment I used, I either had already or made it made it myself; "el-cheapo". Since this article was written, I blued quite a few hands successfully. It's also a matter of learning the equipment you are using and by doing it more often, you gain experience. For me the "el-cheapo" way works. But your "system" is nice too1 point

-

it's not the movement. It's the case for a watch for diving it has to withstand being in water and typically the watch companies like to brag about how deep the watch can go. So basically they will make watches that go so deep that the diver could not possibly where the watch because they can't go that deep.1 point

-

This is an old thread, but there is a much easier way to consistently, repeatably and controllably blue watch hands, screws and other steelwork compared to the traditional pan of brass shavings over a flame. A small metal container of brass shavings, heated over an electric laboratory hotplate is very effective. You have fine control of the hotplate temperature, and can achieve repeatable and consistent results by keeping records of what temperature was required to reach the desired colour for a certain type of steel. Beginners will achieve quality results, consistently, a lot quicker using a hotplate. The hotplate has other uses too, such as heating an escapement meter for adjusting pallet stones, and more, but that is beyond the scope of the dial restoration forum. Best Regards, Mark1 point

-

1 point

-

Can you tell us which one specifically? Maybe just some adjustment to the way you work is required? Does your desk tilt? I have a hard time imagining how parts can slide.1 point

-

I know for a while it wasn't working at all as I pointed up up above. Then it may be working again I'm just not 100% sure? Your question did come through as a email and the comment below by @RichardHarris123 hat also is come through as an email like it's supposed to.1 point

-

One more thing I’d add to the excellent list by nevenbekriev, check that you haven’t accidentally switched the top and bottom endstones of the balance wheel. The endstones are sometimes of different thicknesses, and switching them can cause end shake problems that can result in a watch that won’t run dial down. Hope that helps, Mark1 point

-

There are textured bench mats, with small grooves or ripples across their surface, and some find them very helpful in preventing watch parts from sliding or rolling away. Having a raised edge along the sides and back edge of the bench you work on is a feature present on most purpose built watchmaker’s benches and is easily added to most tabletops. To avoid parts rolling off the bench towards you, some watchmakers wear an apron, the end of which is tacked to the front edge of the bench to catch stray parts. Quality tweezers, well dressed and a gentle touch when handling parts will with practice keep parts from pinging off into space. If you’re removing a spring or other parts that are prone to fly away, hold one end down with pegwood or a probe, cover it with a sheet of clear plastic or work inside a ziplock bag whilst gaining confidence with controlled handling of parts and the disassembly of movements. Having a work surface at the right height makes a big difference too, both in terms of parts handling and ergonomics. Hope that helps, Mark1 point

-

What is the actual solvent in Kleenstrip? I checked the web and found that there are a lot of products called "Kleenstrip", ranging ftom acetone to paint strippers.1 point

-

1 point

-

I can't give a personal recommendation as I didn't do such a job so far. But Christian from watchguy uk has an advice (answer to first question below this article): https://watchguy.co.uk/service-omega-speedmaster-145-022-76st-calibre-861/1 point

-

Thanks chaps. To be honest I'm probably not going to pull it apart to get the dial side of the movement, so I'll base further research on the Landeron 39 as a starting point.1 point

-

This might come under the Hamilton name. Here is some info on your watch. https://pocketwatchdatabase.com/search/result/ball/1B74011 point

-

the easiest way to tell what staff you need is to remove the staff you already have. Then if it's like a 992B staff it should be a friction staff so be careful and don't knock out the blue hub it frictions into.1 point

-

Well that moved along quickly. So its a Pierce cal.130, with a broken spring at least. Between my original post and now I was wondering how the movement accommodated driving the hands round and allowing the reset. I had come to the conclusion that friction must be involved and was going to look closer at all the leaf springs dotted around the main plate, seems there might also be a rubber or fibre component involved. I've attached photos of the dial side - plenty of wear there. Thanks for the links, time to start learning more. That's why we do this, isn't it?1 point

-

No need for a new bezel, it just needs removing and a good clean, clean the case under the bezel too.1 point

-

I turned away a job last week for a ETA 2892-A2 chronograph because it has a bolt on chrono module. As others have already said, parts aren't available for the module, so if it is disassembled and a part is needed, a lot of time has gone into something that is now unserviceable and then you have to then explain to the customer why you can't do the work and why you have wasted their time. If the module needs no parts, that's great, but it isn't worth taking the risk in my experience1 point

-

I have a different view to the DD module world. I began watchmaking for one main reason: To understand and enjoy complicated mechanisms. So when I already had some years of experience with several ETAs, PUWs, Rolex I entered the chronograph business step by step. Landeron 248, Valjoux 7734, Valjoux 72, Buren 12. And while working on the last one I came across a picture of the DD2020 without cover plate and had only one thought: Wow! Freaky! How the hell does this thing work? So I bought a Omega Speedmaster Reduced just for the sake of disassembling, reassembling and understand that thing. I wrote a little article on the r-l-x-forum about this (not a service-walkthrough as this is not a watchmaker-forum, but just a description how it works): https://www.r-l-x.de/forum/showthread.php/197912-Konstrukteure-auf-Speed-–-das-Omega-1140-mit-Dubois-Depraz-Chrono-Modul There is a lot of information on the internet which guided me, especially Marks videos about his Breitling for Bentley service and the Omega 1140 tech sheet availiable on watchguy UK: https://watchguy.co.uk/cgi-bin/files?showfile=Omega/Omega 1140.pdf&filename=Omega 1140.pdf&dir=Technical Manuals&action=documents I am not familiar with the DD4500 but after a look at this article https://www.thenakedwatchmaker.com/decon-dubois-depraz-chrono-big-date I am quite sure that in the area of the chronograph there are a lot of levers and wheels which are identical to the DD2020. Of course this doesn't change anything on the situation that parts are not availiable (when I worked on the DD2020 I was lucky that no module parts where worn). I like the DDs as they are freaky mechanical stuff, interesting challenge for advanced amateurs with lots of time. If I was a pro and had to do a service in a short time at reasonable costs maybe I would get to a less positive judgement.1 point

-

I avoid these at all cost! They really aren't pleasant to work on, and the absolute unavailability of parts or tech info just makes it a gut wrenching nightmare. You can have friends in the biz with parts accounts all over the map, there are no parts available from DD. A friend of mine even lives about a block from their main building, and is their local fireman, and a trained watchmaker, and I'm 1000% sure he could show up with brownies and croissants for the whole workshop and no parts.1 point

-

Here it is (Kristall 2000S Glass Grinder), was around £200 as I remember: I assume the S stands for the red 'sports - stripe' on the box Thinking that maybe the best way to do it would be to 3D print a dummy plastic crystal, and tweak until it is the perfect shape then superglue this dummy onto the rough cut crystal and then finish the shaping on the grinder - if you start grinding plastic you have gone too far. Once ground to the correct size you could dissolve off the plastic/superglue dummy with acetone leaving you with a pretty good crystal?1 point

-

A guy i worked wih years ago his wife made stained glass lead tarariums . To shape the glass she used a bench glass grinder, which is like a spindle moulder that i use for shaping timber, basically a drum sander fed through a hole in a table. You could make a miniature version of something similar using a dremel tool, if you could add a water feed that will reduce airborne glass particles, or just keep wetting down with a sprayer. Or work in a pan that holds a little water using a cordless dremmel.1 point

-

I found these guys in the UK, I haven't used them, so don't know if they can cut a new crystal without a blank, or what their prices are like, but they have an email address so may be worth asking - would be interested to know: https://www.crystalfit.co.uk/ I also found this web site which gives some basic instructions on hand making a crystal: https://german242.com/en/rectangular-bale-shape-watch-crystal-cutting/1 point

-

. The good old days when watchmakers could be authorized to be service providers are centers. Citizen was interesting because one time to time care packages would come with all these nifty packages of citizen parts. So that means we would've had all the books but I also have a universal book with a whole bunch of stuff then as far as cutting crystals goes I also worked in a material house cutting glass crystals so yes it can be done but maybe we could find an original so in my universal book of a whole bunch a watch companies the way it's explained for citizen numbers is there's a four digit number that we could care less about and then there's the rest of the number that we care about no idea of the letters are important or not. 54 – 18714 that is the crystal number and minor confusion at least for me in the book is that in this particular section of cases for the crown in the stem well for the crown there's variations as it appears to be three different crowns with two different stems then the case number reference from the book doesn't translate to the website we needed this number. Unfortunately the number it yields does not translate to the main website as to an item? http://cgi.julesborel.com/cgi-bin/matcgi2?ref=CIT_CS^37-1017 looks like your little late but we get a picture and it looks like the right crystal so that means no show up again https://www.ebay.com/itm/134939666624 found another one that hasn't in stock apparently but I bet should be pricey to just order one Crystal. http://www.stsupply.com/watch-parts/parts-by-brand/citizen-parts/crystals/54-18174h-citizen-crystal.html1 point

-

Several companies sell crystals cut to size, cousins sell blanks.1 point

-

The right decision depends on the condition of your watch and what your plans are, if its worth spending $300 plus on, then JohnR advice is best, also, however small there is a chance of finding a ruined Omega balance to scavange the spring off of, so we would start with spring of the right CGS No. Your balance left Omega adjusted , then if some watch destroyer fitted a staff in the wheel, theres a good chance he throw the wheel out of adjustment and handed it back to the owner perhaps even unpoised. Secondly, Balance spring come in different grades, and meet metalurgical and physical specifictions. This all means your balance wheel can be completed with a spring to oscilate at the rate your watch needs to show accurate time, but is unlikely to meet the original standards embeded at Omega. A spring out of Cheap , Russian or Chinese watch would do , IF its spiral is the same or close to your Omega spring. So, in case you are determined to attack , enough knowledge and experience is available at WRT to work with you in building a balance complete out of your balance wheel. Just shout. Rgds1 point

-

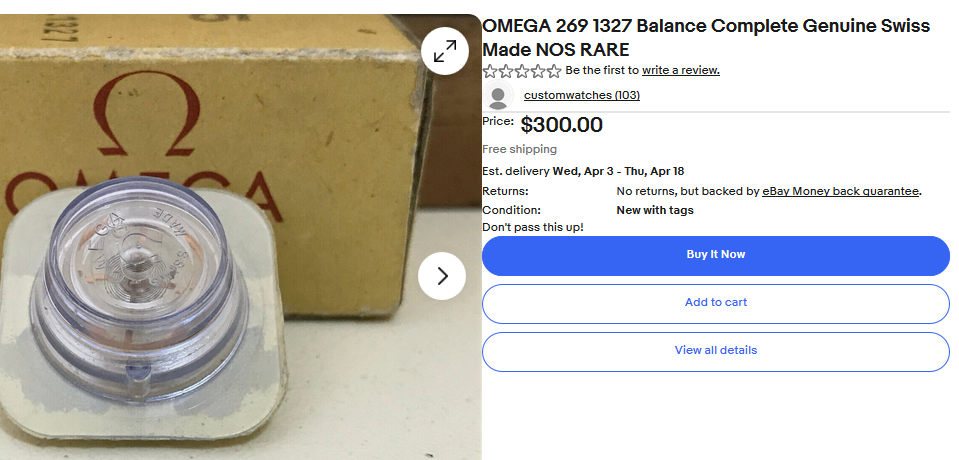

usually on modern watches you cannot purchase a separate hairspring. the part number you have is for the balance complete which is the only way you're going to get the hairspring is with the balance wheel as they are matched very very closely. then unfortunately the problem with Omega watches are there expensive and the components replace them are expensive but eBay is a good source here's one brand-new. https://www.ebay.com/p/240120481221 point

-

Have had a good look around but did not want to have to buy a whole movement cal 286 or 269. Thanks1 point

-

possibly at one time the hubs were available separately. I have seen hubs in a bottle of replacement staffs but don't remember which watch company or which staff that was. So know that at least one company had an upgrade upgrade from regular balance staffs to friction staff's. So perhaps at one time they were available. If you could find a really broken watch you perhaps could steal the hub from that for yours. I know they can go back in if they accidentally come out because I've done that at least one time.1 point

-

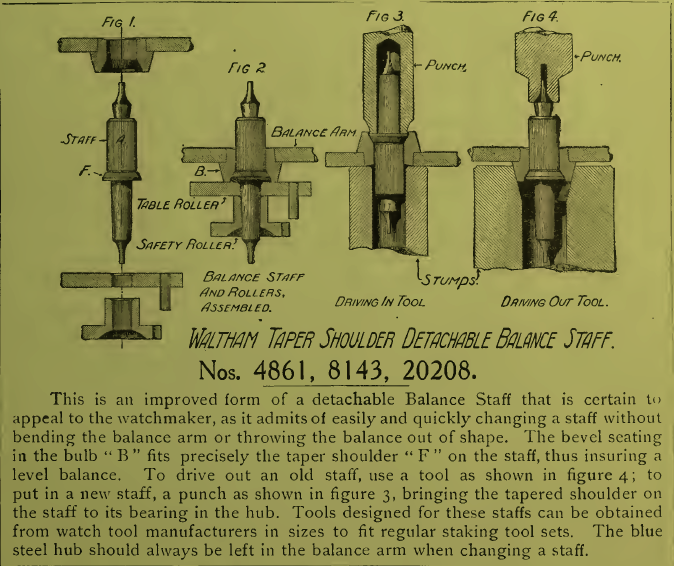

I found a nice picture to show the problem. When you replacing balance staffs you want to be very careful to pay attention to blue steel parts which are used to indicate that it's not a regular staff and that it's a friction staff. Several American watch companies have used friction staff as it makes it really nice to change them providing you don't accidentally drive out the blued steel part then it becomes a pain to get this back together again. So if you're lucky can put the blued steel part back into the balance and you still need to get the staff out. Might be easier to do it now that the whole thing is out of the balance wheel but the blued steel parts still has to go back in. Then because you probably don't have the nice punches that the show is none of us do if you're really careful you can find something in the staking set to get the staff in and out you just have to be super super careful.1 point

-

Maybe the message board software thinks were spending too much time here and that we should acquire a new or different hobby? In the past that had issues with email addresses which is why change to something entirely different. Then I went into the settings and played with those and I was getting some messages but not what I used to get. So yes the message board does seem to have issues.0 points

-

I'm having issues too. When I post a new thread or follow someone else's thread I always select the "A notification when new content is posted" option. Lately though I am not getting notifications (I checked my spam folder too).0 points