Leaderboard

Popular Content

Showing content with the highest reputation on 04/10/24 in all areas

-

Hi everyone, I've been here two years now almost to the day and have loved every minute of it. During this time I've connected with folk that have suddenly disappeared leaving me sad and wondering why they left and what happened to them, its now my time to leave for a while. But first i want to thank everyone for all the help, advice and banter over the last two years I've met some incredibly kind and amazing guys. My time has become limited and precious, so watchrepair and visiting the forum is taking a backseat for the moment, although i may pop in occasionally when i have time. This is due to a personal life change regarding my 87 yr old mum who had a stroke on Sunday. My learning here is on hold while i do some teaching of my own, helping my mum to talk and communicate again . Thanks again for making my time here so enjoyable and i hope to join you all again soon. Take care and look after yourselves, make every minute of the day count, time is so precious x.7 points

-

Okay, What you may be experiencing is recoil, when the spring fully unwinds inertia from the train wheels causes the mainspring to it to overrun and then in runs backwards momentarily. I'm led to belive this is a good indication of a well cleaned and serviced movement. Others may have a better explanation. Regards CJ4 points

-

I've got about 20 ml of Fixodrop epilame in a smoked glass pipette bottle and squirt a few ml into a small aluminium storage pot (32 mm wide X 18 mm tall) which is tilted on a staking block, so the epilame is just in a corner of the pot. I put my escape wheel in the pot so it is just covered and dip my pallet fork jewels into the liquid one at a time, which takes one minute in total. I draw the Fixodrop back up with the pipette and back into the bottle. I haven't noticed any real loss of liquid due to evaporation over the course of five years I have had this. Obviously there has been some evaporation, but it isn't to the degree that some make out. It has about the same evaporation rate as something like IPA, so I may have lost a millilitre or two. 10 ml in a bottle with a mesh in the neck will last you hundreds of watch parts over several years. The mesh is big enough for whatever you are going to epilame, including keyless work if you so choose. Personally I don't use a mesh arrangement because I don't dip the whole pallet fork into the epilame, because I don't want it getting in the notch and creating a dust when the impulse jewels hits. In my experience, it is definitely worth buying and using, especially with the escape wheel and pallet fork jewels. Lubricating the pallet fork becomes child's play once treated with Fixodrop.3 points

-

yes there is always a chance. or have enough friends and send the image and get the answer back I have below. then if you are in the Seattle area the person who gave me that occasionally gives lectures on these watches yes I remember the watch with the rubber clutch just didn't remember what it look like. This is a Pierce 130. Good luck with it. It has an internal rubber clutch that must be replaced when it is serviced. then now that we know what it is we can search for it. a little information is found at the link below https://mb.nawcc.org/threads/pierce-130-and-134.178909/2 points

-

This thread just saved me $. I was just about to buy one of those oilers. Thank you guys. I’ve been using a very fine beading needle honed to a fine point and it works pretty well. I guess I’ll just stick with that.2 points

-

Hi @Neverenoughwatches, I will keep you and your Mum in my prayers. A caregiver's job is a tough one. I have known nice little old ladies to undergo drastic changes in their demeanor after suffering a stroke. Patience and understanding is essential in all circumstances. Never lose your cool or be condescending. Try and enroll in a caregivers training course. It really helps. You cannot take on the role of a caregiver 24/7. You need to get a relief caregiver. You need to take care of yourself before you can take care of others. Do not be afraid to ask for help. Hope to hear from you soon.2 points

-

I do similarly to Jon; I buy the 100ml bottles, put about 10ml in a 30ml brown lab bottle with wide neck to use. I tilt it and dip the escape wheel in, and for the fork I use #5 tweezers, closed, to such up a little, then apply to the stones. It does evaporate a bit, but I toss it as soon as I suspect it may have dust or whatever in it-- long before it gets very depleted. The 10ml lasts ages. I think they reformulated it at some point; 20 years ago it evaporated much, much faster.2 points

-

probably wishful thinking for that one in that did you look at the inscription on the back? The 1935 is a bit of a problem I think any of the books that I have that use the fingerprint system the earliest one I have I think is 1950 and I don't know how far back the system goes with typically on vintage stuff we have issues. On the other hand taking the dial off might reveal a name often times there on the dial side on the vintage watches unfortunately I suspect wishful thinking on this one it looks like at least one spring is broken. I've circled the component it looks like it probably went farther and now it does not.2 points

-

2 points

-

My name is Ali (alisha) I live in Indiana, USA with my husband and our 3 dogs. I'm not so much here for a hobby but to learn about the late 1800 clock that has been passed to us from my husband's grandparents. I don't have a picture of it right now but it is very similar to this photo I got off Google.1 point

-

If this has been discussed elsewhere feel free to delete. So for things like the train bridge shock settings in 7XXX series seiko movements it's impossible to set them wet and have a good oil bubble. You gotta set them dry and oil from the other side. When i started out i was told you basically have to have an auto oiler for this. I got one, i hate it, it works, sometimes, but it does a terrible job at metering the oil flow and there's about a 20% chance it will overfill it instantly causing me to have to reclean the jewel and try again. On top of that, for things like the 3rd wheel in the 7s26 it according to most SHOULD be oiled with hp1300 even though the tech sheets for the various versions of the 7s26 are all over the place on this. Some iirc recommend 9010 in the shock setting and 1300 in the lower jewel. One says 9010 on both. One wants you to use grease on the bottom jewel, it's strange.. So unless you want to get two auto oilers for the two shock settings and fill one with hp1300, what do you do? Well just save yourself 100 bucks on a pretty crappy tool imo there's a much simpler way to do it. Just take your dip oiler, put a bead of oil on the back of the setting once the shock setting has been set already, then take your wheel and poke the pivot through the jewel hole and capillary action will draw in the oil and do it slowly and precise enough you get that perfect bubble every time. I don't know if this insanely easy technique is used a lot here but nobody suggested it to me when i was starting out and i blew about 120 bucks on a tool i now realize i just don't need. Just a little psa for people that aren't aware of this insanely simple technique that requires no tools.1 point

-

I always remove capstones for visual check, how else can one be sure. In case of rub- in jewels, relevent pivot is roughly indicative of the capstone's condition.1 point

-

@Neverenoughwatches Rich I am so saddened to hear this bad news. Mum comes first and I hope to see you back here sometime. I am around if you ever need someone to talk to, I’ll DM my number mate. Tom1 point

-

That's very sad news and the forum will be poorer without you. We will keep your seat warm and look forward to welcoming you back when time allows. As others have said, look after yourself and get help sooner rather than later.1 point

-

Take care of both of you mate. May good fortune be with you wherever you go and whatever you do.1 point

-

I just had a look in BestFit. I picked a random 18''' size movement, Longines 18.25, which according to Ranfft was launched in 1908. So there is a chance.1 point

-

Thanks will try and see if a pack from cousin fit it is. The round plate that sits on top date wheel and the day ring sits in that plate and the screws fit in that plate under day ring1 point

-

So sorry to hear it. Take care of Youself and You fammily, this the most important. Good luck and hope to hear from You soon with good news. I have this expirrience and I can say that recovering from stroke depends not only by the severity of the stroke and age, but very much on the care that is thaken for the person.1 point

-

That's really sad news. Wishing you strength and peace as you navigate through this difficult time.1 point

-

A document I picked up on the net explaining the different types of escapement and their operation EscMechanics.pdf1 point

-

Hi @Neverenoughwatches sorry to hear about your Mum, only 7 older than me. Enjoyed the chats and look forward to your return when things get better. I might give you a blast now an then so keep the channel open.1 point

-

Glad I'm not the only one who's confused. It hardly seems conclusive, but I think there are enough pointers to suggest that the setting lever spring is one of the interchangeable parts. I have the ETA part in hand, and need to replace the movement. The two-position movements are more difficult to find generally. I'd like to switch to the Sellita, which means I'd need to remove the date wheel, etc. and swap the setting lever spring. It's a pretty simple part, and we know the macro parts and the relationships involved are almost certainly unchanged between manufacturers (if you can even say that, since Sellita was often the manufacturer for ETA). It's a flat plate with holes otherwise, and it's not like they can swap studs and holes around like they do with the plates... If I'm wrong about the $8 part, I have to hunt down a new one. I don't know how easy it is to find Sellita parts, but they're supposedly not spending millions to keep us from buying them. I haven't had any Sellita movements come across my bench needing parts so far... I could also see if I can find a dateless movement for a similar price to the dateful movements, and just save myself the whole affair, but last time I tried they were harder to find and considerably more expensive. Worst case scenario, I can't find a dateless SW-200 (whatever the exact movement number is), and the part doesn't interchange cleanly. Then I'm stuck with a ghost position... I can take out everything but the spring, and it'll at least not be an issue setting the watch during changeover (if that's even a thing for this movement).1 point

-

1 point

-

So sorry to hear about your mum, but glad she has you ready to step up and help her recover. All the best, and we'll see you when you're back.1 point

-

How very sorry Neverenoughwatches to hear about your mum. I have always enjoyed your posts and knowledge and I will miss you. Please keep in touch and let us know how your Mum is recovering. Take very good care and I wish you both good luck.1 point

-

1 point

-

1 point

-

Curare, Nucejoe, Nevenbekriev, Delgetti and to you JohnR275. Thank you to all for your replies. Relief is the name. Wow! I have read these replies 3 times now, just to make sure I understand. Good to know I am getting to move in the correct way. Forward. Brilliant hobby this. Thank you so much. Ross1 point

-

1 point

-

oh dear end of the world how sad oh wait? I was taught it was called backspin. backspin of the escape wheel is considered a very good thing as it indicates your gear train is nice and free. Unfortunately it doesn't occur in all watches but it is a test to verify the gear train is nice and free. then the wording is a bit complicated hopefully it makes sense. No balance wheel and pallet fork and you attempt to wind your watch. .You can either slowly turn the crown very slowly or you can turn it fast and you get a couple of clicks on the ratchet wheel because the gear train doesn't let the energy off instantaneously it has to spin. Now your gear train is spinning and you stop winding there is energy in the gear train and possibly still some energy in the mainspring so the gear train will spin until it runs out of the mainspring energy and it still also dissipate its spinning energy it doesn't just instantly stop. This spinning energy of the gear train is what were looking for. How this is the hard part to see. The gear train a spinning runs out a mainspring energy continues past that point and winds the mainspring a little bit in the opposite direction. The next part can be extremely hard to see which is when it runs out of energy going forward. This is because it will stop fast and the backwards winding of the mainspring will pull it backwards. See may not actually see that stopping but if you're looking at the escape wheel and paying attention you will now see the escape wheel when it finally runs out of all the energy come to a stop going backwards. so yes it really is spinning backwards and slowly comes to a stop as it runs out of all of the energy. Then sometimes even this is hard to see because it may just stop you have to be looking at it carefully to see the backspin so this was something that I was taught in school look for the backspin and you know your gear train is nice and free. But as I said it does not occur in all watches and you do have to be paying attention to look for it. yes dyslexia I know it well I torture everybody with my dictation software. So we could call this a dyslexia moment of the perception of something that evil and bad is actually the opposite it's an extremely good thing. So I strongly advise you not to fix something that's good as it really is a good thing. think about it this way of free gear train easy to spin is good versus the gear train that has problems and too much friction.1 point

-

Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement.1 point

-

Finally solved after another inspection yesterday. I found the fork pinguard was slightly shorter. Several gently taps extend that pin enough. Actually the watch is under testing and everything looks good. Thank you watchweasol!1 point

-

Agree. In one of his books Jendritzki even says that this "turning back of the escape wheel caused by the click spring" is a criteria that the escape wheel runs absolutely free and you have done good work.1 point

-

Ross, I believe that when You start to wind the mainspring, actuallly the escape wheel turns in correct direction and it changes the direction only when the spring unwinding comes to the end. If so, this is something normal.1 point

-

Balance wheel running backwards is an ungodly new invention . escapewheel back spin lets us hope that laying eggs is still a job for chickens. I like my previous post deleted. My your escapewheels always spin right, and not confuse me to lay eggs.1 point

-

Hello to everyone! The one that I have photos of at the moment is the NH35 build that I made a month or so ago and took a couple of pics for a review of the parts I wrote. The rest (not that a couple of older Seikos, one whose brand I don't even remember, and an old Gruen (sp?) pocket watch are any great shakes) will have to wait for their close-ups. I've been sort of planning to try working on the pocket watch when I feel that my proficiency is high enough. It's not an heirloom or anything, I just don't want to cause more problems than I solve, and it already has a stem that comes out if pulled (what I know so far suggests that this might just be a loose setting lever, but I haven't opened it and am trying to resist guessing as I suspect there are other issues with it as well.) I did consider putting up a shot of my half re-assembled 6497, in the movement holder, but figured that the new guy shouldn't be snarky so I just stuck to the pics of the custom build (two on the leather strap and one on a bracelet)1 point

-

What calib is this? Could you have installed mainspring in wrong direction? I heard in some calibs a wheel can be fitted up side down, have never had such a case, though. The click shiws you which direction the barrel is to turn. What happens if you rotate the barrel in other direction. Perhaps you have invented a new improved watch.1 point

-

I don't know where you can get a scanned copy. You could always buy the book. I know its expensive but older copies come up a lot on ebay, but if you are going to repair these clocks the newest version is the one to get. You will also need a clock mainspring winder. The 400 day beat setting tool is must. They all run on very little oil.1 point

-

one of things helpful to do with screws is to arrange them in groups of identical screws. Usually once you have them all together ill become apparent what at least most of them are for. A lot of the components like the pallet fork bridge will either have one or two screws and those screws will be different etc. so you usually have the bigger category the plates screws and it makes it a lot easier if things are in categories.1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

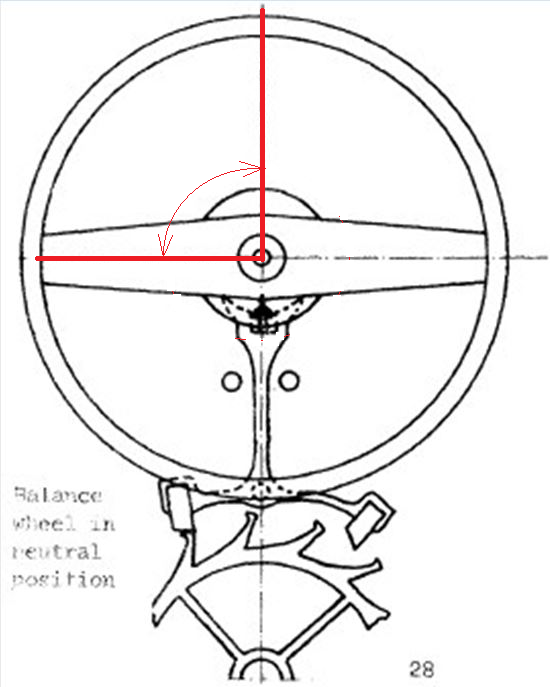

Something to add: The angle marked on the drawing should be always 90 degr. It is not important for the movement, as it will work regardless what the angle is, but it is important for the watcmakers that will service the watch. The balance arm forms certain figures when the balance rotates. This figures are symmetrical and in case the angle is exactly 90 degr. and the movement is 'in beat', then the axe of symmetry coincides with the line of bearings balance-lever (the vertical axe on the drawing). So, a watcmaker will be able to say if the watch is exactly in beat just by a look at the oscillating balance, and no timegrapher or other device will be needed.1 point

-

This is why I like this forum. Members have different views and offer them freely without rancour. There are many variations on a theme. If it works , then it's correct for that person. Another may adapt partially or not at all. Professional or hobbyist, all give recommendations. We watch, listen, use, pass on observations. Guidance is offered from experience and not to deride. I look at many things in a totally different light than one, two years ago. I do things in a totally different way. Great place to learn this.1 point

-

1 point

-

1 point